Premium Aluminum Forging Companies in USA: MAIKONG’s Industry-Leading Services

December 17, 2025

Need Custom Aluminum Forgings?

Our engineering team is ready to review your specifications and provide a competitive quote within 48 hours.

Why Choose Aluminum Forging Companies in USA for Your Manufacturing Needs

Aluminum forging delivers exceptional performance characteristics that make it the material of choice for critical applications. The forging process aligns the grain structure of aluminum, significantly enhancing its mechanical properties and creating components that outperform those manufactured through alternative methods.

MAIKONG’s precision forging process aligns aluminum grain structure for optimal strength

Superior Strength-to-Weight Ratio of Aluminum Forgings

The strength-to-weight ratio is a fundamental engineering principle that addresses the balance between material strength and weight—an essential consideration in industries prioritizing performance, efficiency, and safety. Aluminum, recognized for its lightweight properties and robust mechanical characteristics, is enhanced through forging, refining its internal grain structure for enhanced resilience and strength. This makes aluminum forgings from top aluminum forging companies in USA like MAIKONG the optimal choice for withstanding static and dynamic loads.

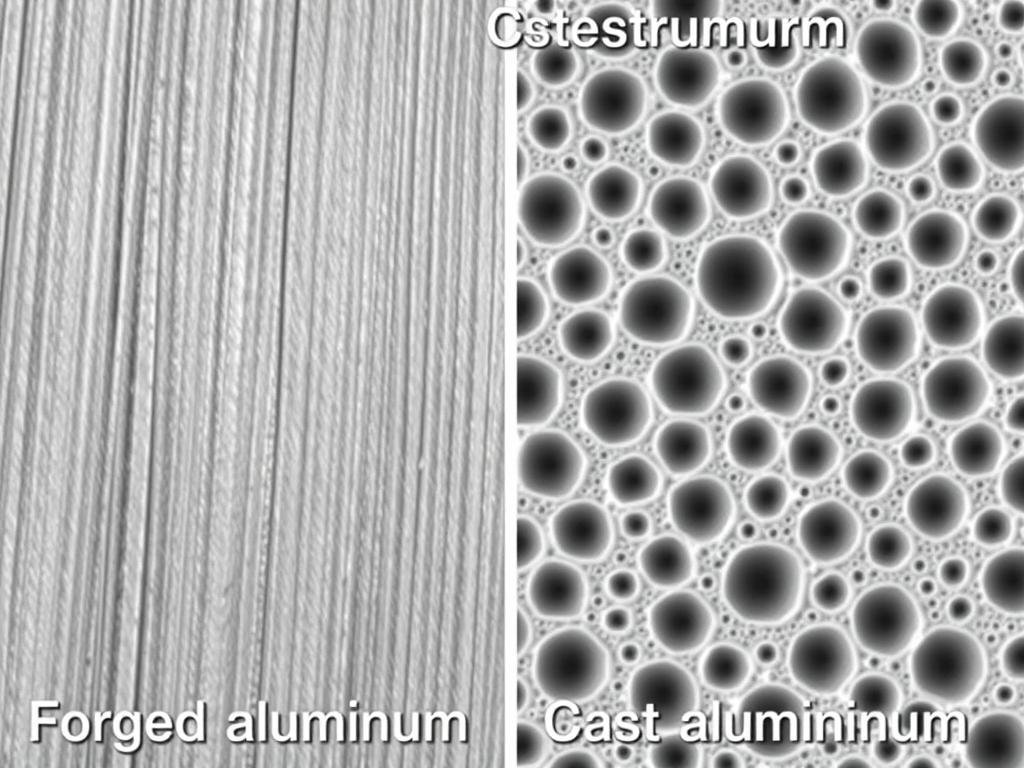

Aluminum Forging vs. Casting: Why Leading Aluminum Forging Companies in USA Prefer Forging

Understanding the differences between forging and casting is crucial when selecting the right manufacturing process for your aluminum components. The table below highlights why MAIKONG and other premier aluminum forging companies in USA recommend forging for critical applications:

| Comparison Categories | Aluminum Forging | Casting Aluminum |

| Strength and Durability | ✅ Higher due to dense, uniform grain structure | Potentially lower due to air pockets and inclusions |

| Tensile Properties | ✅ Superior tensile strength and resistance | Lower tensile strength |

| Fatigue Resistance | ✅ Better resistance against fatigue failure | Potentially lower fatigue resistance |

| Dimensional Accuracy | ✅ Better accuracy and tighter tolerances | Potential inconsistencies |

| Weight-to-Strength Ratio | ✅ High strength-to-weight ratio | Bulkier parts may be needed |

| Critical Applications | ✅ Ideal for structural members and load-bearing components | Limited suitability for critical applications |

Microscopic comparison: Forged aluminum (left) shows aligned grain structure while cast aluminum (right) shows porosity

MAIKONG’s Comprehensive Capabilities Among Aluminum Forging Companies in USA

MAIKONG offers end-to-end manufacturing solutions that set us apart from other aluminum forging companies in USA. Our integrated approach ensures quality control at every stage of production.

CAD/CAM Integration

Our engineering team utilizes advanced analysis software to identify and mitigate potential issues early in the design process, optimizing your aluminum forgings before production begins.

Material Selection Expertise

We thoroughly evaluate mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness of aluminum alloys to select the optimal material for your application.

Precision Tooling Design

Our tooling design ensures initial quality, while regular maintenance preserves consistency—both critical for producing high-quality aluminum forgings that meet exacting specifications.

Advanced Forging Processes

Our forging workshop is equipped to accommodate diverse aluminum forging specifications, with presses ranging from 800 to 3,000 tons to handle components of various sizes and complexities.

Heat Treatment Services

We conduct comprehensive statistical analysis and documentation for our in-house heat treatment processes, ensuring consistent mechanical properties across all aluminum forgings.

Precision CNC Machining

With over 60 CNC machines providing 100+ tons of metal processing capacity monthly, our machining workshop handles precise and intricate forging machining operations to tight tolerances.

Explore Our Full Range of Capabilities

Discover how MAIKONG’s comprehensive manufacturing capabilities can benefit your next project.

Quality Assurance That Sets MAIKONG Apart From Other Aluminum Forging Companies in USA

Quality control procedures are essential to ensure that forged components meet stringent standards. At MAIKONG, we implement rigorous testing and inspection protocols throughout the manufacturing process.

MAIKONG’s quality control specialists perform dimensional verification using precision CMM equipment

Our Quality Certifications

- ISO 9001:2015 certified quality management system

- AS9100D aerospace quality standard compliance

- IATF 16949 automotive industry certification

- Comprehensive material testing and verification laboratory

- Statistical process control implementation

Inspection Capabilities

- Coordinate Measuring Machines (CMM) for dimensional verification

- Non-destructive testing including ultrasonic and magnetic particle inspection

- Metallurgical analysis and hardness testing

- Chemical composition verification

- Full documentation and traceability

Industries Served by MAIKONG – Leading Among Aluminum Forging Companies in USA

As one of the premier aluminum forging companies in USA, MAIKONG serves diverse industries with specialized aluminum forging solutions tailored to each sector’s unique requirements.

Aerospace

Lightweight, high-strength components for aircraft structures, landing gear components, and engine parts that meet rigorous aerospace standards.

Automotive

Performance-critical components including suspension parts, steering knuckles, and engine components that reduce weight while maintaining strength.

Defense

Durable, reliable components for military vehicles, weapons systems, and tactical equipment that perform under extreme conditions.

Medical

Precision components for medical devices, surgical instruments, and diagnostic equipment requiring exceptional cleanliness and reliability.

Energy

Robust components for power generation, oil and gas, and renewable energy applications that withstand harsh operating environments.

Sports & Recreation

Lightweight, high-performance components for bicycles, motorcycles, and sporting equipment that enhance performance and durability.

Comprehensive Services from One of the Leading Aluminum Forging Companies in USA

MAIKONG offers a complete range of manufacturing services beyond aluminum forging, providing integrated solutions for all your metal component needs.

CNC Machining Services

With 60+ CNC machines and 100+ tons of monthly metal processing capacity, our precision fabrication services include turning, milling, Swiss machining, multi-axis machining, surface grinding, and laser engraving for both metal and plastic parts in any volume.

Aluminum Forging Services

Our aluminum forging expertise delivers components with superior strength-to-weight ratios, enhanced grain structure, and exceptional mechanical properties for the most demanding applications across multiple industries.

Steel Forging Services

From carbon and alloy steels to stainless varieties, our steel forging capabilities produce components with exceptional strength, durability, and performance characteristics for heavy-duty applications.

Brass Extrusion Services

Our brass extrusion services deliver precision components with excellent electrical conductivity, corrosion resistance, and aesthetic appeal for electrical, plumbing, and decorative applications.

Partner with MAIKONG – Your Premier Choice Among Aluminum Forging Companies in USA

MAIKONG is actively recruiting distribution partners and agents across the United States to expand our presence in the American market. Our competitive pricing, superior quality, and comprehensive capabilities make us an ideal partner for distributors, representatives, and agents serving manufacturing clients.

Join MAIKONG’s growing network of US distribution partners and representatives

Why Partner with MAIKONG

- Competitive pricing structure with excellent margins

- Comprehensive manufacturing capabilities

- ISO-certified quality management system

- Technical support and engineering assistance

- Reliable delivery schedules

- Exclusive territorial arrangements available

Partnership Requirements

- Established presence in manufacturing markets

- Technical understanding of metal forging applications

- Commitment to customer service excellence

- Proactive sales approach

- Regular communication and reporting

- Minimum annual sales targets

Become a MAIKONG Distribution Partner

Contact us today to discuss partnership opportunities in your region.

Contact MAIKONG – One of the Leading Aluminum Forging Companies in USA

Ready to discuss your aluminum forging needs? Our team of experts is standing by to provide technical assistance, quote your project, or answer any questions about our capabilities and services.

Get in Touch

WhatsApp: +86 13-51090-74-01

Email: Lucy@maikongforge.us

Website: https://maikongforge.us

Request a Quote

Submit your specifications for a competitive quote within 48 hours. Our engineering team will review your requirements and provide detailed pricing and production timelines.

Why MAIKONG Stands Out Among Aluminum Forging Companies in USA

As you search for reliable aluminum forging companies in USA, MAIKONG offers the perfect combination of quality, capability, and value. Our comprehensive manufacturing solutions, technical expertise, and commitment to customer satisfaction make us the ideal partner for your aluminum forging needs.

Ready to Experience the MAIKONG Difference?

Contact us today to discuss your project requirements and discover how we can deliver superior aluminum forgings for your applications.

Contact us online by Whatsapp: