Premium Aluminum Forging Services: Precision Engineering for Global Industries

In the competitive world of metal manufacturing, aluminum forging stands as a cornerstone process for creating high-performance, lightweight components with exceptional structural integrity. At MAIKONG, we combine advanced production capabilities with superior Chinese supply chain advantages to deliver premium aluminum forge solutions that meet the most demanding specifications across aerospace, automotive, medical, and industrial applications.

Our state-of-the-art facilities in Shenzhen, China, specialize in both standard and custom aluminum forgings, including high-performance alloys like 7050 aluminum forgings and 7075 T6 aluminum forging components. With decades of expertise and a commitment to excellence, we’ve established ourselves as one of the leading aluminum forging companies serving the global B2B market.

Understanding the Aluminum Forging Process

The aluminum forge process represents a sophisticated metal forming technique that delivers superior mechanical properties compared to casting or machining alone. During forging, aluminum is heated to specific temperatures and then precisely shaped under controlled pressure, creating a refined grain structure that significantly enhances strength, durability, and fatigue resistance.

Key Advantages of Aluminum Forging

- Superior strength-to-weight ratio

- Enhanced structural integrity

- Improved fatigue resistance

- Excellent corrosion resistance

- Consistent material properties

- Refined grain structure

- Greater dimensional accuracy

- Reduced material waste

- Extended component lifespan

- Better performance under stress

Forging Methods at MAIKONG

Our facility employs multiple aluminum forging techniques to accommodate diverse project requirements:

Closed-Die Forging

Precision-engineered dies create complex geometries with tight tolerances, ideal for high-performance components in aerospace and automotive applications.

Open-Die Forging

Versatile process for larger components where material flow is less restricted, allowing for custom shapes while maintaining excellent mechanical properties.

Impression-Die Forging

Creates precise, complex geometries with superior surface finishes, perfect for components requiring both aesthetic appeal and structural integrity.

Premium Aluminum Alloys for Superior Forgings

At MAIKONG, we work with a comprehensive range of aluminum alloys, each offering specific performance characteristics to meet diverse industry requirements. Our metallurgical expertise ensures optimal material selection for your specific application.

High-Performance Aluminum Alloys

| Alloy Series |

Key Properties |

Common Applications |

Industry Usage |

| 2000 Series (Al-Cu) |

High strength, excellent fatigue resistance |

Aircraft structures, aerospace components |

Aerospace, defense |

| 6000 Series (Al-Mg-Si) |

Good formability, corrosion resistance, medium strength |

Automotive parts, architectural components |

Automotive, construction |

| 7050 Aluminum |

Superior strength, excellent stress corrosion resistance |

Aircraft wing components, critical aerospace structures |

Aerospace, defense, high-performance applications |

| 7075 T6 Aluminum |

Exceptional strength, good fatigue resistance |

Aircraft structures, military equipment, high-stress components |

Aerospace, defense, precision equipment |

Specialized Expertise in High-Performance Alloys

MAIKONG has developed particular expertise in working with premium aerospace-grade alloys, including 7050 aluminum forgings and 7075 T6 aluminum forging components. These high-strength alloys require precise temperature control and specialized forging techniques to achieve optimal mechanical properties.

Need Expert Guidance on Alloy Selection?

Our metallurgical specialists can help you select the optimal aluminum alloy for your specific application requirements.

Contact Our Materials Team

Advanced Manufacturing Capabilities

MAIKONG’s state-of-the-art aluminum forge facility combines traditional craftsmanship with cutting-edge technology to deliver exceptional quality and precision. Our comprehensive manufacturing capabilities ensure we can meet the most demanding specifications for both standard and custom aluminum forgings.

Equipment Specifications

| Equipment Type |

Capacity |

Precision Capability |

Production Volume |

| Hydraulic Presses |

300-2,500 tons |

±0.2mm |

High volume capability |

| Mechanical Presses |

500-3,000 tons |

±0.15mm |

Medium to high volume |

| CNC Machining Centers |

5-axis capability |

±0.01mm |

Custom and precision work |

| Heat Treatment Furnaces |

Temperature range: 150-550°C |

±5°C temperature control |

Batch processing capability |

Production Capabilities

Size Range

- Minimum: 50mm diameter

- Maximum: 1,500mm diameter

- Weight range: 0.1kg to 200kg

Volume Capacity

- Prototype: 1-10 pieces

- Small batch: 10-500 pieces

- Production: 500+ pieces

Quality Assurance

Every aluminum forging produced at MAIKONG undergoes rigorous quality control procedures to ensure compliance with international standards and customer specifications:

Material Verification

- Chemical composition analysis

- Mechanical property testing

- Grain structure examination

Dimensional Inspection

- Coordinate measuring machines

- Laser scanning technology

- Optical comparators

Non-Destructive Testing

- Ultrasonic inspection

- Magnetic particle testing

- Dye penetrant inspection

Industry Applications for Aluminum Forgings

The exceptional properties of forged aluminum make it ideal for a wide range of demanding applications across multiple industries. At MAIKONG, we specialize in producing high-performance aluminum forgings tailored to specific industry requirements.

Aerospace and Defense

The aerospace industry demands the highest standards of performance, reliability, and safety. Our 7050 aluminum forgings and 7075 T6 aluminum forging components deliver the exceptional strength-to-weight ratio and fatigue resistance critical for aerospace applications:

- Aircraft structural components

- Landing gear components

- Engine mounts and brackets

- Wing components and fittings

- Missile and defense system components

Aerospace-Grade Aluminum Forgings

MAIKONG specializes in high-performance aerospace aluminum forgings with full material traceability and certification.

Request Aerospace Capabilities

Automotive and Transportation

The automotive industry benefits from aluminum forge components that reduce weight while maintaining structural integrity, improving fuel efficiency and performance:

- Suspension components

- Steering knuckles

- Engine components

- Transmission parts

- Chassis components

Medical and Healthcare

The medical industry relies on the precision and biocompatibility of aluminum forgings for various applications:

- Surgical instrument components

- Medical device housings

- Imaging equipment components

- Laboratory equipment parts

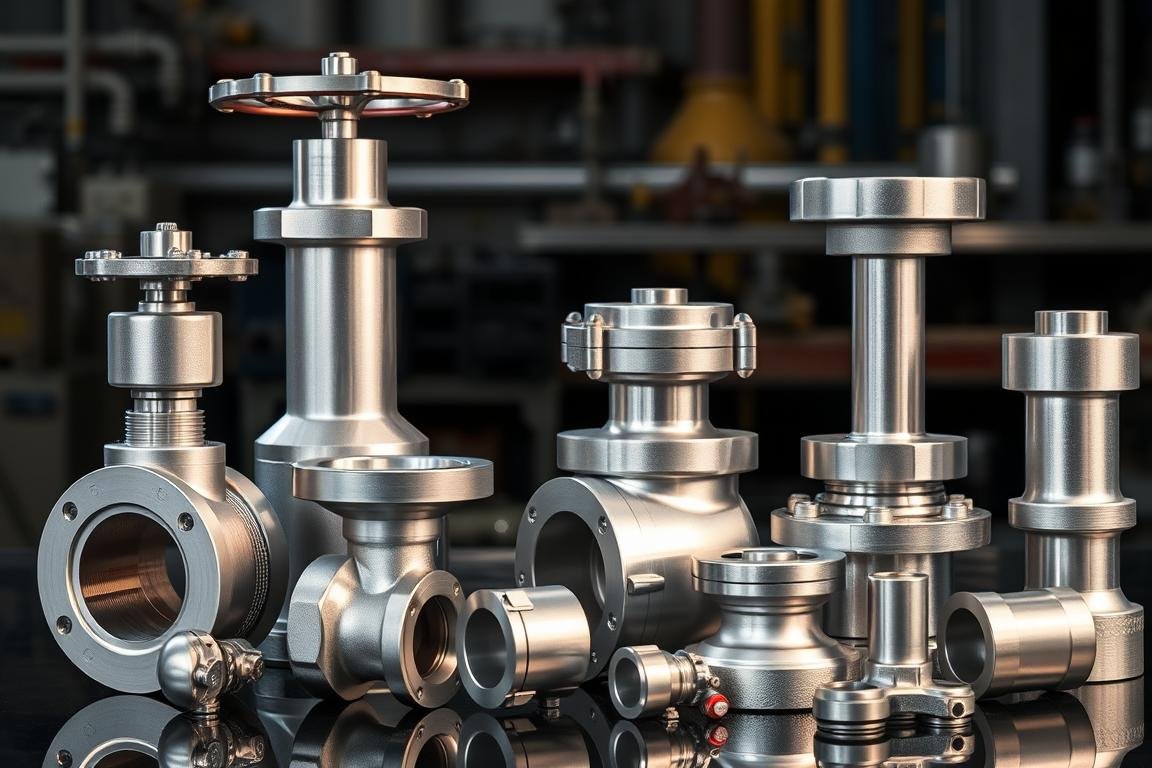

Industrial and Energy

Industrial applications benefit from the durability and corrosion resistance of quality aluminum forge components:

- Valve bodies and components

- Pump housings and impellers

- Oil and gas equipment components

- Renewable energy system parts

- Heavy machinery components

Custom Aluminum Forging Solutions

At MAIKONG, we specialize in developing custom aluminum forgings tailored to your specific requirements. Our comprehensive design and engineering support ensures optimal results for even the most challenging applications.

Our Custom Forging Process

1. Design Consultation

Our engineering team works closely with you to understand your requirements, providing design optimization recommendations for improved performance and manufacturability.

2. Prototype Development

We create precise prototypes for validation, allowing you to test form, fit, and function before committing to full production.

3. Production Scaling

From small batches to high-volume production, we scale manufacturing to meet your specific quantity requirements while maintaining consistent quality.

Value-Added Services

MAIKONG offers comprehensive secondary operations to deliver complete, ready-to-use components:

- CNC machining

- Heat treatment

- Surface finishing

- Anodizing

- Assembly services

- Non-destructive testing

- Packaging and logistics

- Documentation and certification

Ready to Discuss Your Custom Project?

Our engineering team is available to review your specifications and provide expert guidance on optimizing your aluminum forged components.

Start Your Custom Project

Why Choose MAIKONG for Aluminum Forging

As one of the leading aluminum forging companies in China, MAIKONG offers a unique combination of technical expertise, manufacturing capabilities, and customer service that sets us apart in the global market.

Our Competitive Advantages

Technical Expertise

- Specialized knowledge in aerospace-grade alloys

- Advanced metallurgical capabilities

- Design optimization expertise

- Comprehensive testing facilities

Manufacturing Excellence

- State-of-the-art equipment

- Strict quality control processes

- Efficient production workflows

- Comprehensive secondary operations

Customer Service

- Dedicated project management

- Real-time WhatsApp technical support

- Transparent communication

- Flexible production scheduling

Supply Chain Advantages

MAIKONG leverages China’s robust manufacturing ecosystem to deliver exceptional value:

- Access to premium raw materials at competitive prices

- Efficient logistics and supply chain management

- Comprehensive in-house capabilities reducing outsourcing costs

- Economies of scale through optimized production processes

Quality Certifications

Our commitment to quality is reflected in our comprehensive certifications and compliance with international standards:

- ISO 9001:2015 Quality Management System

- ISO 14001 Environmental Management

- IATF 16949 Automotive Quality Management

- AS9100D Aerospace Quality Management (in process)

Excellence in Aluminum Forging

MAIKONG combines advanced manufacturing capabilities, technical expertise, and superior customer service to deliver exceptional aluminum forging solutions for global industries. From aerospace-grade 7050 aluminum forgings to automotive 7075 T6 aluminum forging components, we provide the quality, precision, and reliability that demanding applications require.

With our comprehensive capabilities in brass aluminum forging and other metal fabrication services, we offer a one-stop solution for your complex manufacturing needs. Experience the MAIKONG difference – where Chinese manufacturing excellence meets global quality standards.

Partner with MAIKONG for Your Manufacturing Success

Join the growing number of global companies that trust MAIKONG for their critical aluminum forging requirements.

Contact Us Today