In industries where performance cannot be compromised, machined aluminum forgings 7075 t6 stand as the gold standard for high-stress applications. These precision-engineered components combine exceptional strength-to-weight ratio with outstanding corrosion resistance, making them indispensable in aerospace, defense, and high-performance mechanical systems. MAIKONG specializes in delivering premium quality machined aluminum forgings 7075 t6 that meet the most demanding specifications while offering competitive pricing and comprehensive manufacturing solutions.

Technical Properties of Machined Aluminum Forgings 7075 T6

The 7075 aluminum alloy in T6 temper represents one of the strongest aluminum alloys available, with mechanical properties rivaling some steels while maintaining the lightweight advantages of aluminum. Understanding these properties is essential for engineers and procurement specialists seeking optimal materials for critical applications.

7075 T6 aluminum forging with optimized grain structure for maximum strength

Chemical Composition of 7075 Aluminum Alloy

| Element |

Composition (wt.%) |

| Aluminum (Al) |

87.1-91.4 |

| Zinc (Zn) |

5.1-6.1 |

| Magnesium (Mg) |

2.1-2.9 |

| Copper (Cu) |

1.2-2.0 |

| Chromium (Cr) |

0.18-0.28 |

| Iron (Fe) |

≤0.50 |

| Silicon (Si) |

≤0.40 |

| Manganese (Mn) |

≤0.30 |

| Titanium (Ti) |

≤0.20 |

| Other (each) |

≤0.05 |

| Other (total) |

≤0.15 |

Mechanical Properties of Machined Aluminum Forgings 7075 T6

| Property |

Value |

| Tensile Strength |

83 ksi (572 MPa) minimum |

| Yield Strength |

73 ksi (503 MPa) minimum |

| Elongation |

11% minimum |

| Hardness (Brinell) |

150 HB typical |

| Fatigue Strength |

23 ksi (159 MPa) at 5×10^8 cycles |

| Shear Strength |

48 ksi (331 MPa) |

| Density |

2.81 g/cm³ |

| Modulus of Elasticity |

10.4×10^6 psi (71.7 GPa) |

Key Advantages of 7075-T6 Aluminum Forgings

- Exceptional strength-to-weight ratio

- Superior fatigue resistance

- Excellent machinability

- Good corrosion resistance (with proper treatment)

- Dimensional stability

- High tensile and yield strength

- Excellent stress resistance

- Good thermal conductivity

- Suitable for precision machining

- Reliable performance in extreme conditions

Need Technical Specifications for Your Project?

Our engineering team can provide detailed material data sheets and help you determine if 7075-T6 aluminum is the optimal choice for your application.

Get Technical Support

The MAIKONG Forging Process for 7075 Aluminum

At MAIKONG, we’ve perfected the art and science of producing premium machined aluminum forgings 7075 t6. Our comprehensive process ensures optimal grain flow, enhanced mechanical properties, and superior structural integrity in every component we manufacture.

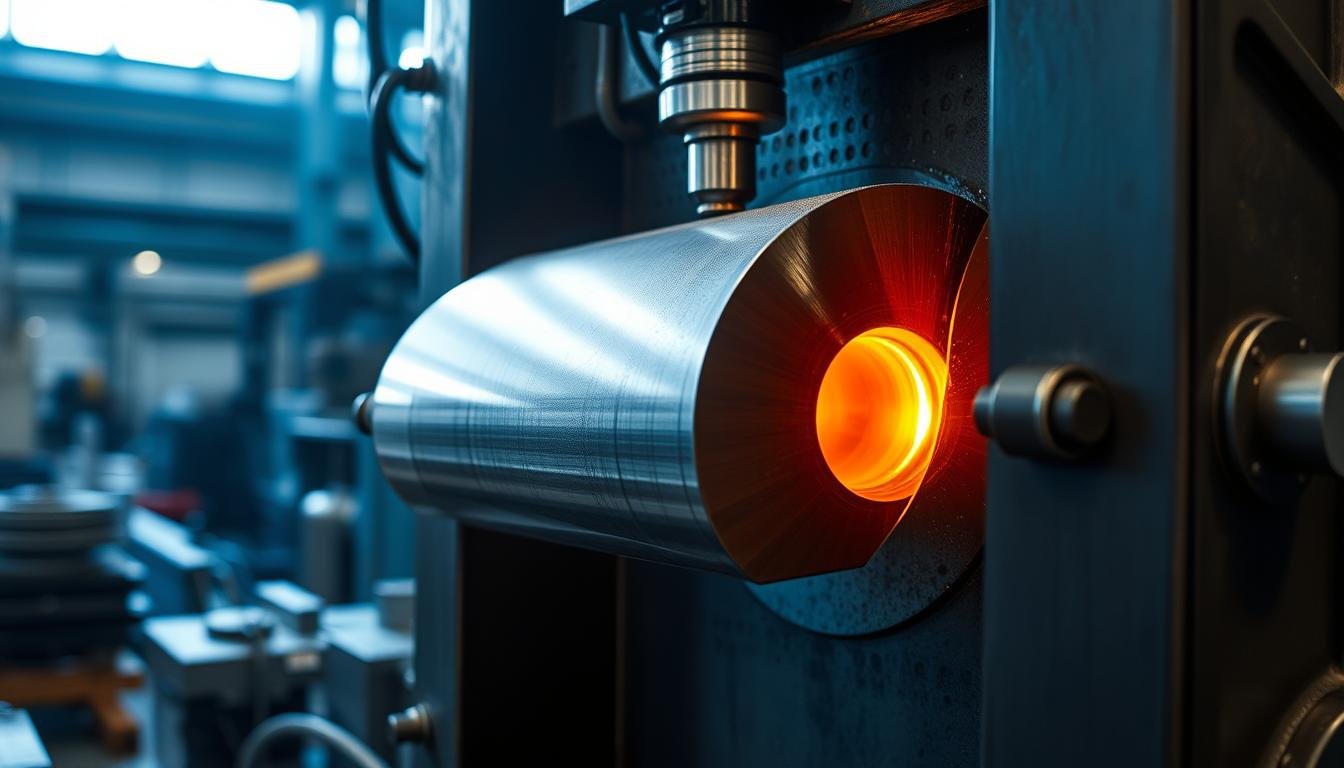

MAIKONG’s precision forging process for 7075 aluminum components

Our Advanced Forging Methodology

Material Preparation

We begin with premium-grade 7075 aluminum billets, which undergo rigorous quality testing to ensure material integrity before entering our forging process.

Precision Heating

Our computer-controlled furnaces heat the aluminum to precise temperatures (typically 780-900°F) to achieve optimal plasticity for the forging process.

Controlled Deformation

Using hydraulic presses ranging from 800 to 3,000 tons, we apply carefully calculated pressure to form the aluminum into the desired shape while optimizing grain structure.

Heat Treatment

Our in-house heat treatment facilities perform the precise T6 tempering process, including solution heat treatment followed by artificial aging to achieve maximum strength.

Precision Machining

Our advanced CNC machining centers transform forgings into finished components with tolerances as tight as ±0.0005 inches, ensuring perfect fit and function.

Quality Assurance

Every component undergoes comprehensive inspection including dimensional verification, material testing, and non-destructive evaluation to ensure compliance with specifications.

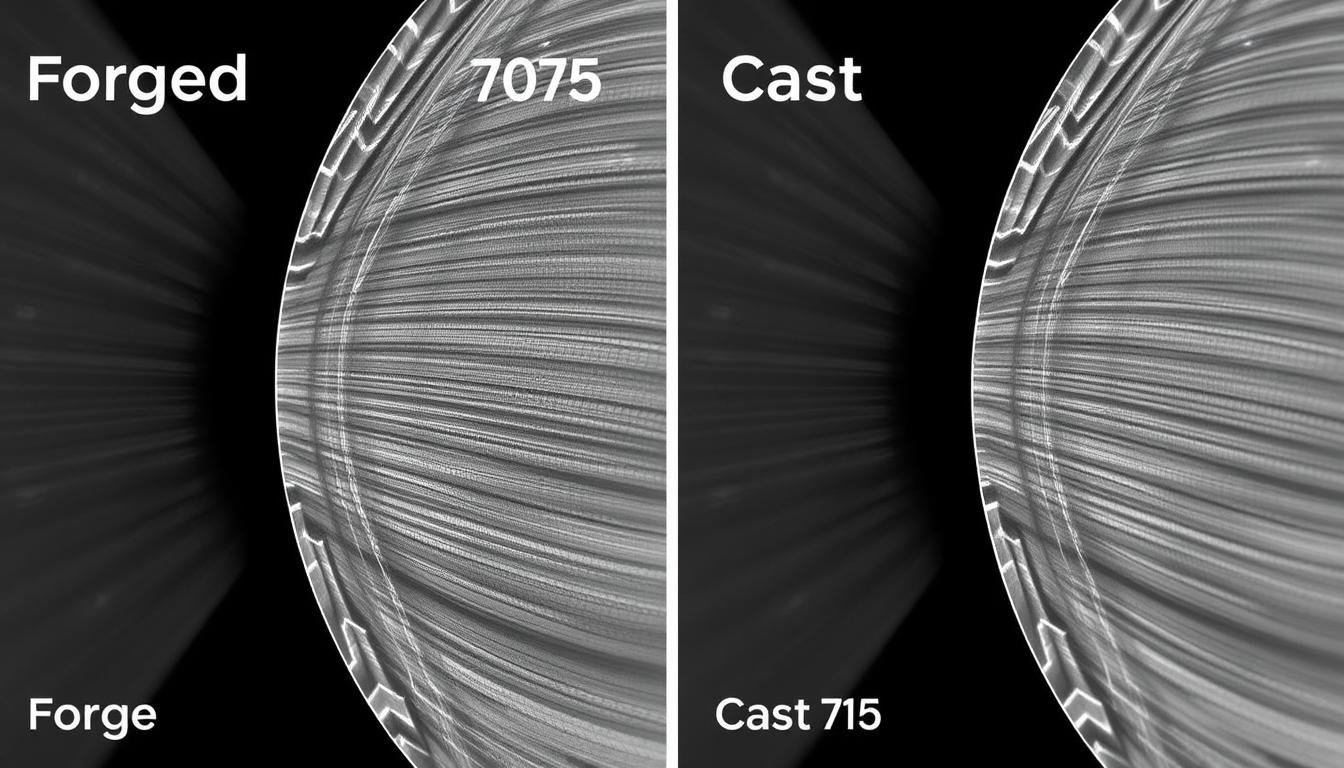

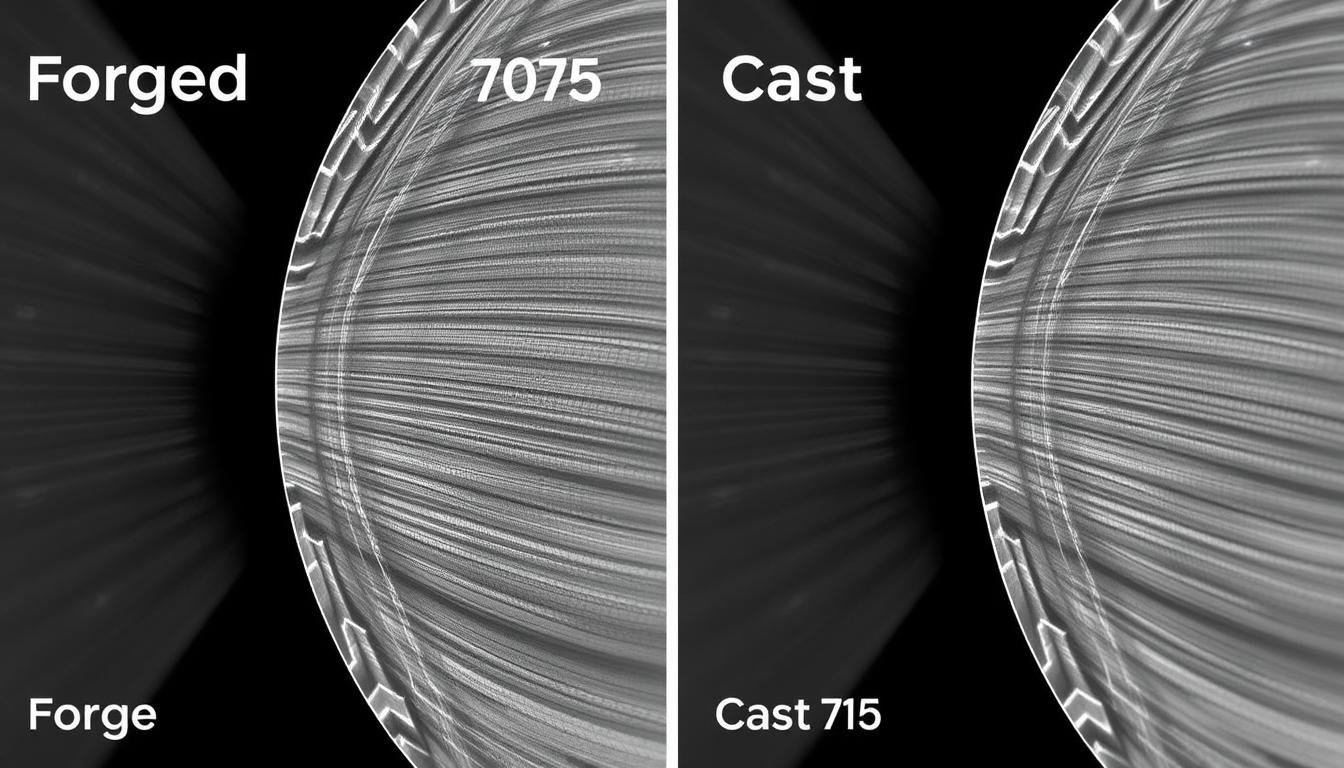

Grain Flow Optimization in Machined Aluminum Forgings 7075 T6

The forging process aligns the grain structure of aluminum along the contours of the part, significantly enhancing mechanical properties compared to cast or machined-from-plate alternatives. This directional strengthening is particularly valuable in high-stress applications where component failure is not an option.

Optimized grain flow in forged 7075-T6 (left) vs. random grain structure in cast aluminum (right)

Ready to Discuss Your Forging Requirements?

Our engineering team is available to review your specifications and provide expert guidance on optimizing your components.

Contact via WhatsApp

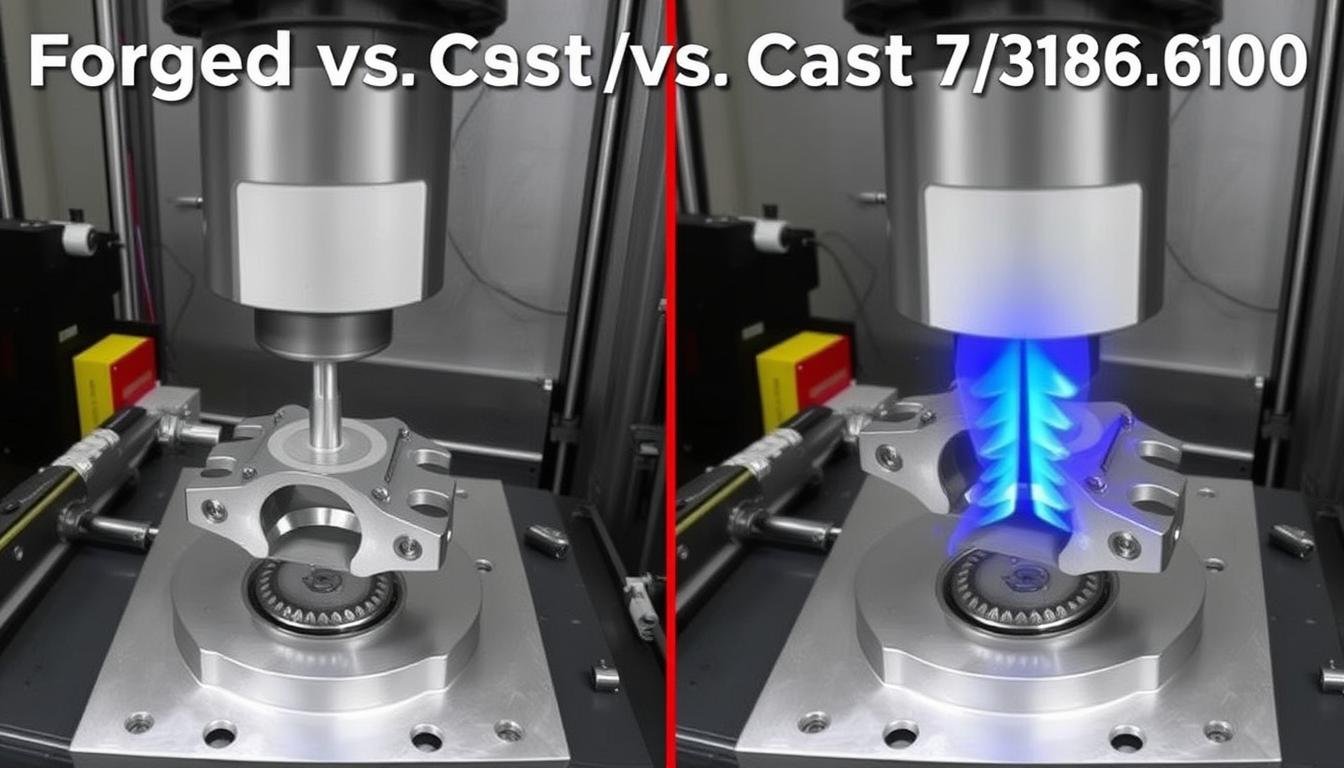

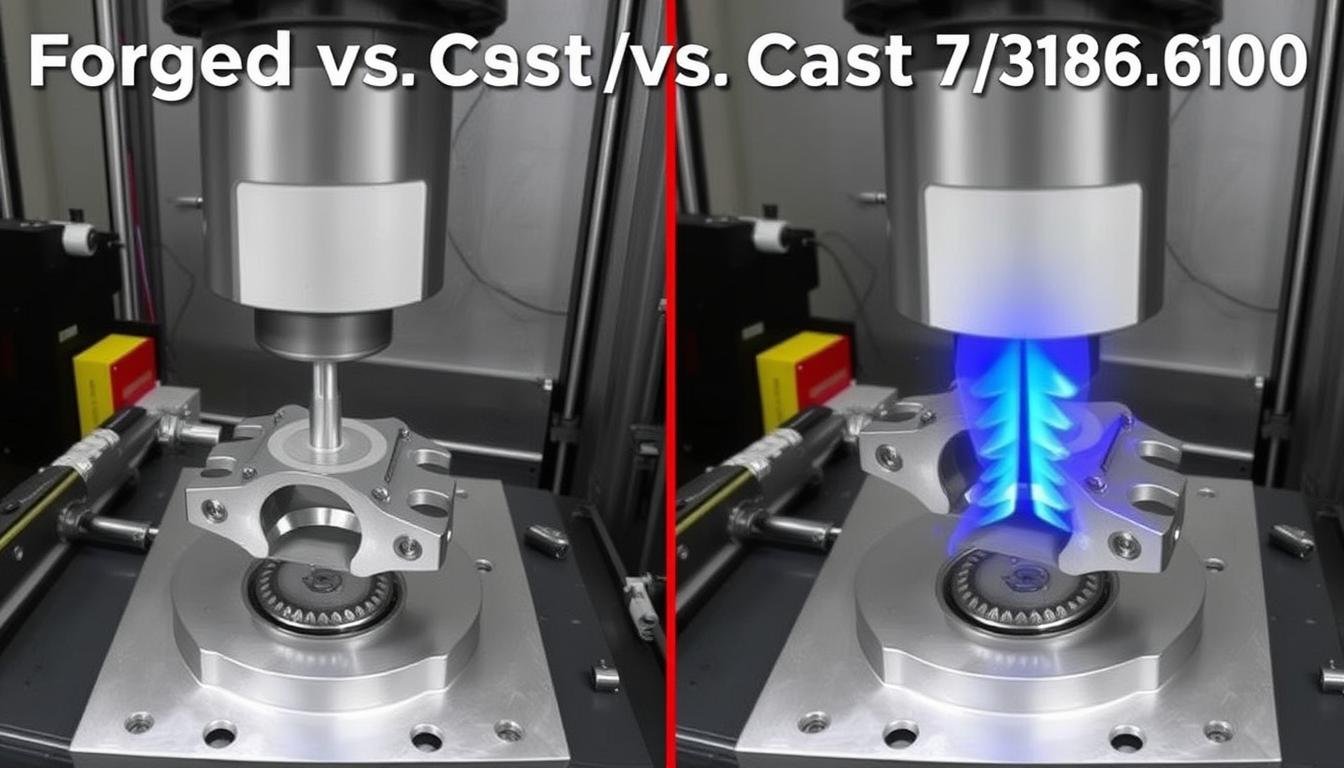

Forged vs. Cast Aluminum: Why Choose Machined Aluminum Forgings 7075 T6

When selecting manufacturing methods for critical aluminum components, understanding the fundamental differences between forging and casting is essential. For applications demanding maximum performance, machined aluminum forgings 7075 t6 offer significant advantages over cast alternatives.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Heat Treatment Response |

✅ Responsive for controlled material properties |

Less predictable response |

| Grain Structure |

✅ Directional grain flow for improved properties |

No directional grain structure |

| Weight-to-Strength Ratio |

✅ High strength-to-weight ratio |

Bulkier parts may be needed |

| Resistance to Corrosion |

✅ Improved due to denser structure |

Naturally forming oxide layer for resistance |

| Engineering Consistency |

✅ Controlled material characteristics |

Variability in material properties |

| Critical Applications |

✅ Structural members and load-bearing capabilities |

Limited suitability for critical applications |

Performance comparison: Forged 7075-T6 components maintain structural integrity under higher stress loads

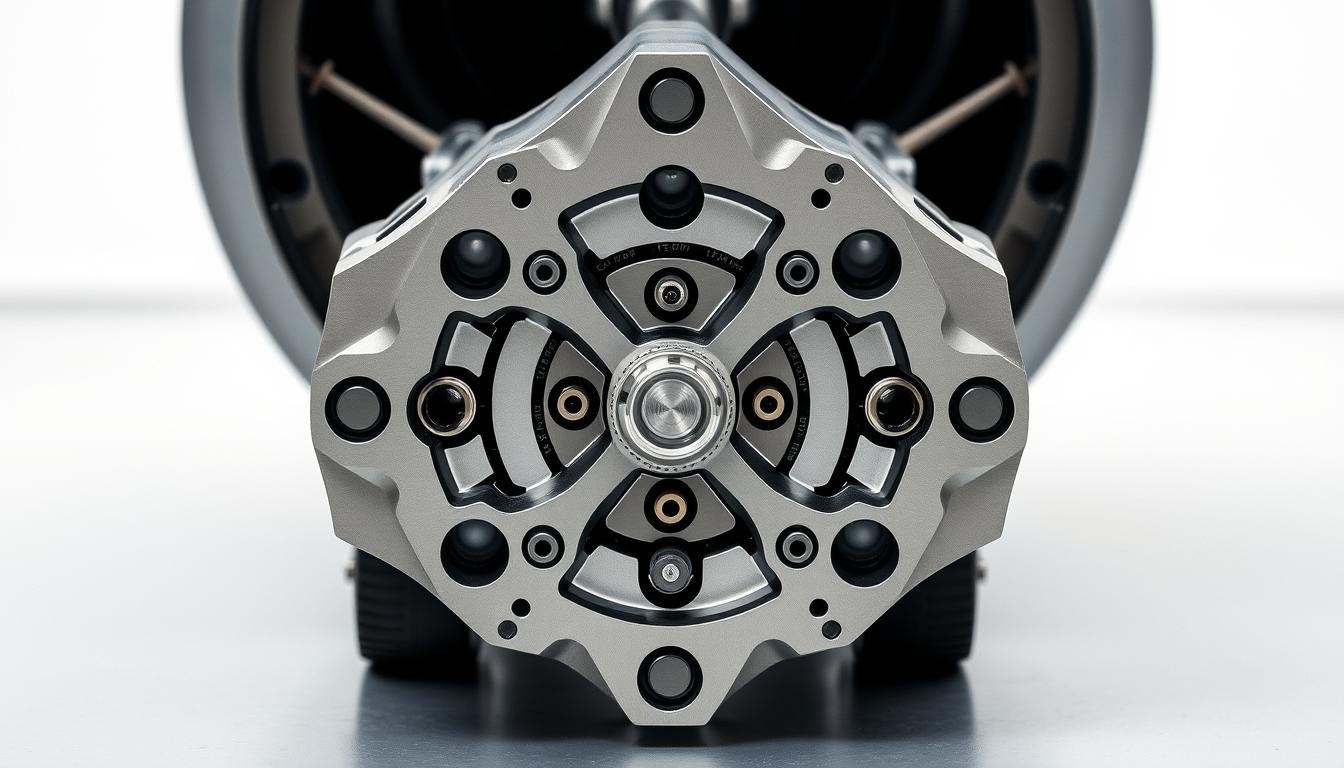

Applications of Machined Aluminum Forgings 7075 T6

The exceptional strength, fatigue resistance, and machinability of 7075-T6 aluminum forgings make them ideal for applications where failure is not an option. These high-performance components are widely used across multiple industries where reliability under extreme conditions is paramount.

MAIKONG’s precision machined 7075-T6 aluminum components for critical applications

Aerospace Applications

The aerospace industry demands materials that offer maximum strength with minimum weight. Machined aluminum forgings 7075 t6 excel in this environment, providing reliable performance in critical aircraft components:

- Aircraft structural components

- Wing spars and ribs

- Landing gear components

- Bulkheads and frames

- Engine mounts and supports

7075-T6 forgings provide critical strength in aircraft landing gear systems

Defense and Military Applications

Precision-machined 7075-T6 components for defense applications

Military applications require materials that perform reliably under extreme conditions. The high strength and excellent corrosion resistance of machined aluminum forgings 7075 t6 make them ideal for:

- Weapons mounting systems

- Armored vehicle components

- Missile guidance systems

- Military aircraft structures

- Naval equipment housings

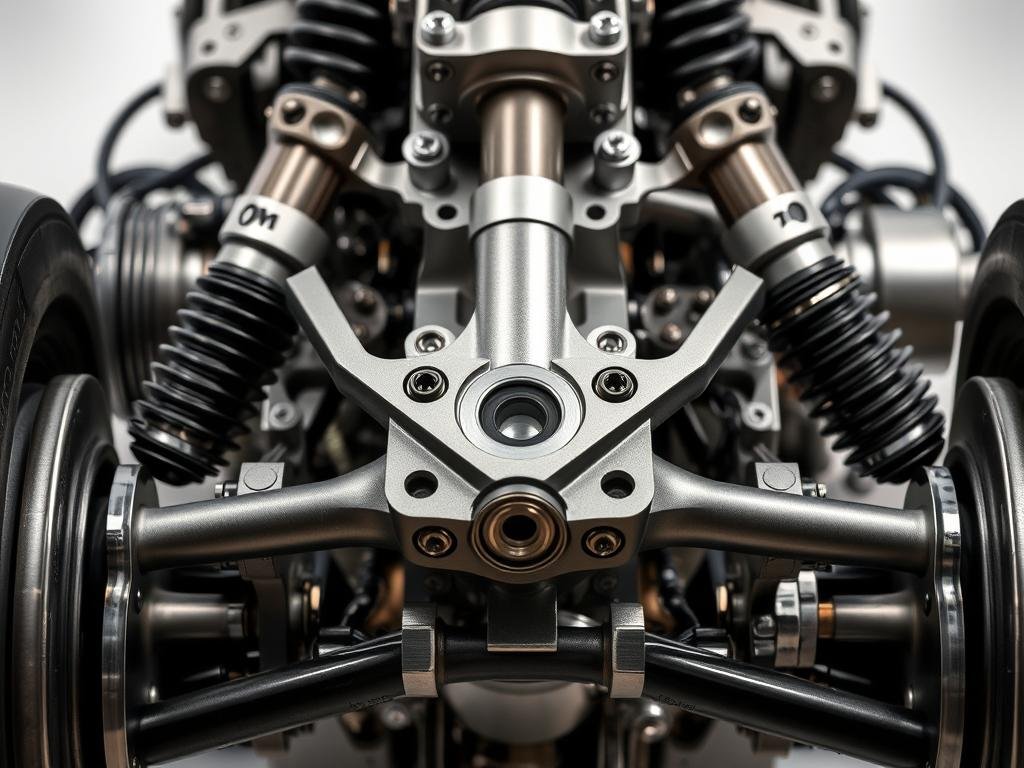

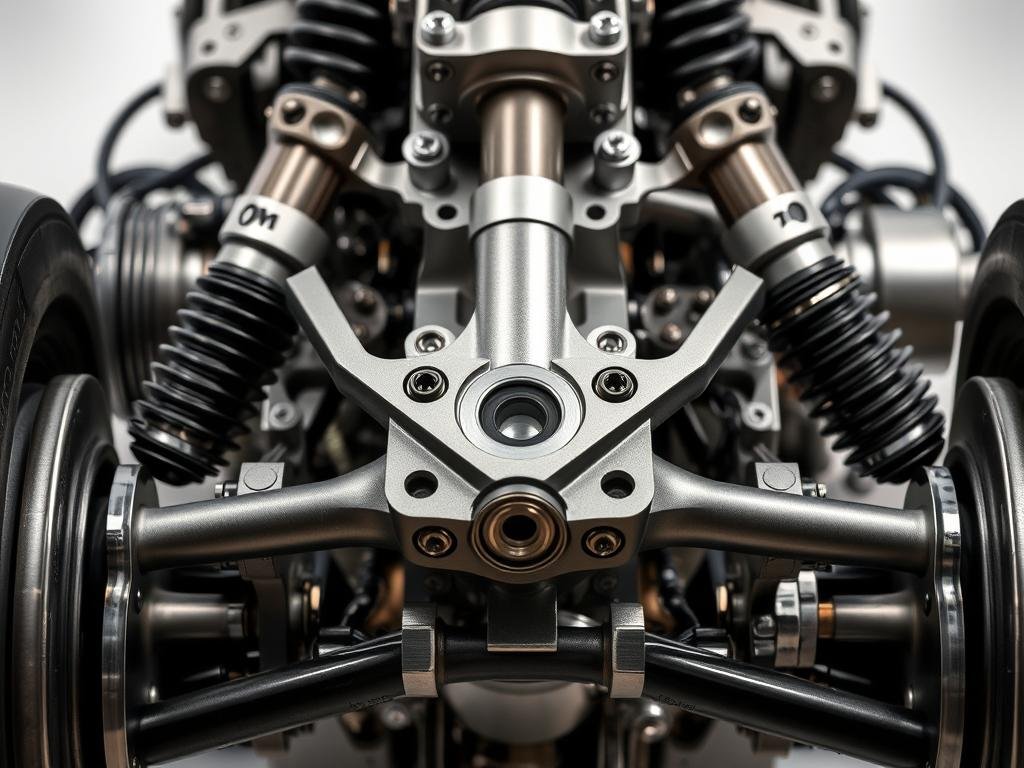

Automotive and Racing Applications

In high-performance automotive applications, the exceptional strength-to-weight ratio of machined aluminum forgings 7075 t6 provides competitive advantages:

- Suspension components

- Engine connecting rods

- Drivetrain components

- Chassis reinforcement structures

- Racing wheel hubs and uprights

High-performance racing components benefit from 7075-T6’s exceptional strength

Industrial and Precision Equipment

The dimensional stability and machinability of machined aluminum forgings 7075 t6 make them excellent choices for industrial equipment where precision and reliability are essential:

- High-pressure hydraulic components

- Precision machinery frames and supports

- Robotic arm components

- Industrial tooling and fixtures

- High-stress mechanical linkages

Specialized Applications Require Expert Manufacturing

MAIKONG’s engineering team can help you determine if 7075-T6 aluminum forgings are right for your specific application requirements.

Email Our Engineering Team

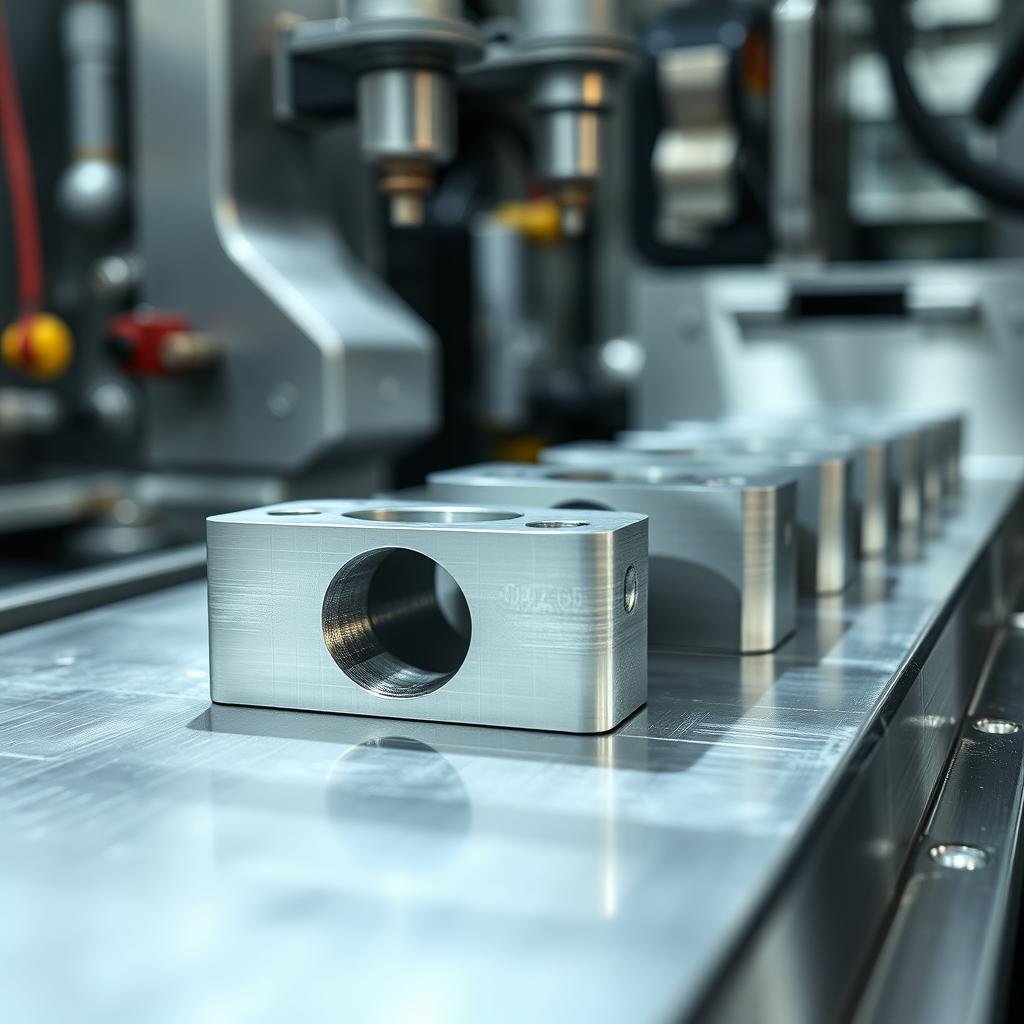

MAIKONG’s Manufacturing Capabilities

MAIKONG offers comprehensive manufacturing solutions for machined aluminum forgings 7075 t6, from initial design consultation through final inspection. Our state-of-the-art facilities in GD, SZ are equipped with advanced machinery and staffed by experienced engineers and technicians dedicated to delivering exceptional quality.

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

Comprehensive Production Capabilities

Forging Equipment

- Hydraulic presses (800-3,000 tons)

- Mechanical presses for precision work

- Specialized dies for complex geometries

- Computer-controlled forging systems

CNC Machining

- 60+ CNC machines with 100+ ton monthly capacity

- 5-axis machining centers for complex geometries

- High-precision turning centers

- Swiss-type machining for small components

Heat Treatment

- Computer-controlled heat treatment furnaces

- Solution heat treatment capabilities

- Precision aging processes

- Comprehensive documentation and verification

Quality Assurance Systems

At MAIKONG, quality is built into every step of our manufacturing process. Our comprehensive quality management system ensures that all machined aluminum forgings 7075 t6 meet or exceed customer specifications and industry standards.

Testing and Inspection

- Dimensional inspection using CMM technology

- Material composition verification

- Mechanical property testing

- Non-destructive testing (ultrasonic, dye penetrant)

- Surface finish measurement

Documentation and Certification

- Material certifications

- Process documentation

- Inspection reports

- Traceability systems

- Quality conformance certificates

Precision quality inspection ensures every component meets exact specifications

Discover Our Manufacturing Capabilities

Contact us today to learn how our advanced manufacturing facilities can support your precision component needs.

Get A Quick Quote

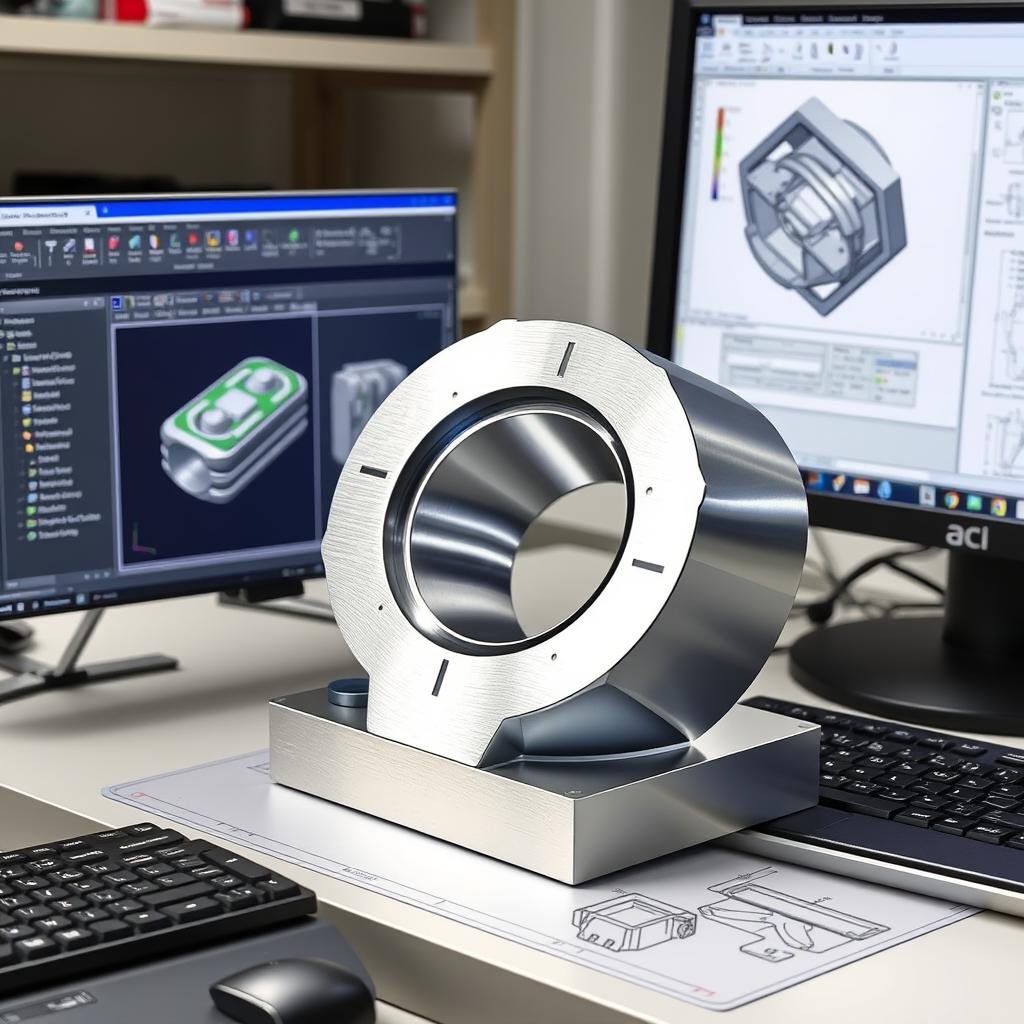

Full-Service Solutions for Machined Aluminum Forgings 7075 T6

MAIKONG offers a comprehensive range of services to support your aluminum forging requirements from concept to completion. Our integrated approach ensures consistency, quality, and efficiency throughout the manufacturing process.

Design & Engineering

Our engineering team collaborates with clients to optimize designs for manufacturability, performance, and cost-efficiency. Services include:

- CAD/CAM design assistance

- Finite Element Analysis (FEA)

- Material selection consultation

- Design for manufacturability (DFM)

Tooling & Prototyping

We develop and maintain precision tooling to ensure consistent quality in every production run:

- Custom die design and fabrication

- Rapid prototyping capabilities

- Tool maintenance programs

- Low-volume production options

Surface Treatments

We offer various surface treatments to enhance performance and aesthetics:

- Anodizing (Type I, II, and III)

- Chemical conversion coating

- Painting and powder coating

- Laser engraving and marking

Additional Value-Added Services

Assembly & Integration

Beyond manufacturing individual components, MAIKONG can provide assembly services to deliver ready-to-use subassemblies:

- Component assembly

- Hardware installation

- Functional testing

- Packaging for shipment

Logistics & Supply Chain

We offer comprehensive logistics solutions to ensure timely delivery of your components:

- Inventory management

- Just-in-time delivery options

- International shipping coordination

- Documentation for customs clearance

One-Stop Solution for Your Forging Needs

From design assistance to finished components, MAIKONG provides comprehensive manufacturing solutions.

Or email us at: Lucy@maikongforge.us

Success Stories: Machined Aluminum Forgings 7075 T6 in Action

At MAIKONG, we’ve helped numerous clients solve complex engineering challenges through our expertise in machined aluminum forgings 7075 t6. Here are some examples of how our solutions have delivered exceptional results across various industries.

Aerospace Landing Gear Component

Challenge: An aerospace client needed a landing gear structural component with 30% weight reduction while maintaining strength requirements for certification.

Solution: MAIKONG engineers redesigned the component using machined aluminum forgings 7075 t6 with optimized grain flow and precision machining to remove non-critical material.

Result: The redesigned component achieved 32% weight reduction while exceeding strength requirements by 15%, contributing to improved fuel efficiency and increased payload capacity.

Racing Suspension Component

Challenge: A motorsport team required suspension components that could withstand extreme forces while minimizing unsprung weight.

Solution: MAIKONG developed custom machined aluminum forgings 7075 t6 with integrated reinforcement in high-stress areas and precision CNC machining to remove excess material.

Result: The components delivered a 40% increase in fatigue life compared to the previous design while reducing weight by 18%, contributing to improved handling and performance.

Defense Industry Structural Component

Challenge: A defense contractor needed a complex structural component with exceptional strength and corrosion resistance for a marine environment.

Solution: MAIKONG engineered a machined aluminum forgings 7075 t6 solution with specialized heat treatment and proprietary surface treatment to enhance corrosion resistance.

Result: The component exceeded all performance requirements in accelerated environmental testing, demonstrating superior corrosion resistance while maintaining structural integrity.

Why Choose MAIKONG for Machined Aluminum Forgings 7075 T6

When selecting a manufacturing partner for critical components, experience, capabilities, and commitment to quality make all the difference. MAIKONG offers distinct advantages that ensure your machined aluminum forgings 7075 t6 meet the highest standards of performance and reliability.

Our dedicated quality team ensures every component meets exact specifications

Technical Expertise

Our engineering team brings decades of combined experience in aluminum forging and precision machining, providing valuable insights to optimize your components for performance and manufacturability.

Advanced Manufacturing

Our state-of-the-art facilities feature the latest in forging and CNC machining technology, enabling us to produce complex components with exceptional precision and consistency.

Quality Commitment

From material selection to final inspection, our comprehensive quality management system ensures that every component meets or exceeds your specifications and industry standards.

Competitive Pricing

Our efficient manufacturing processes and strategic location in GD, SZ allow us to offer premium quality machined aluminum forgings 7075 t6 at highly competitive prices.

Responsive Service

We pride ourselves on clear communication and responsive customer service, ensuring that your questions are answered promptly and your project stays on schedule.

Full-Service Capabilities

From design assistance to finishing and assembly, our comprehensive capabilities streamline your supply chain and ensure consistency throughout the manufacturing process.

“MAIKONG consistently delivers high-quality machined aluminum forgings that meet our exacting specifications. Their technical expertise and responsive service make them a valuable manufacturing partner for our critical components.”

— Aerospace Industry Client

Excellence in Machined Aluminum Forgings 7075 T6

MAIKONG is committed to delivering exceptional quality machined aluminum forgings 7075 t6 that meet the demanding requirements of aerospace, defense, automotive, and industrial applications. Our comprehensive capabilities, technical expertise, and dedication to customer satisfaction make us the ideal manufacturing partner for your critical components.

From initial design consultation through final inspection and delivery, we provide the support, quality, and value that help your projects succeed. Contact us today to learn how our machined aluminum forgings 7075 t6 can enhance the performance, reliability, and efficiency of your products.

MAIKONG: Your trusted partner for premium quality machined aluminum forgings 7075 t6

Partner with MAIKONG for Superior Results

Experience the MAIKONG difference in quality, service, and value for your machined aluminum forgings 7075 t6.

Get A Quick Quote