Billet Machining: The Ultimate Guide for US Manufacturers & Precision Engineers

In the precision manufacturing world, billet machining stands as a cornerstone process for creating high-quality metal components with exceptional structural integrity. This comprehensive guide explores how modern manufacturers leverage billet processes to achieve superior results, examining the critical differences between billet, cast, and forged manufacturing methods that impact your production decisions.

What Is Billet Machining and Why It Matters

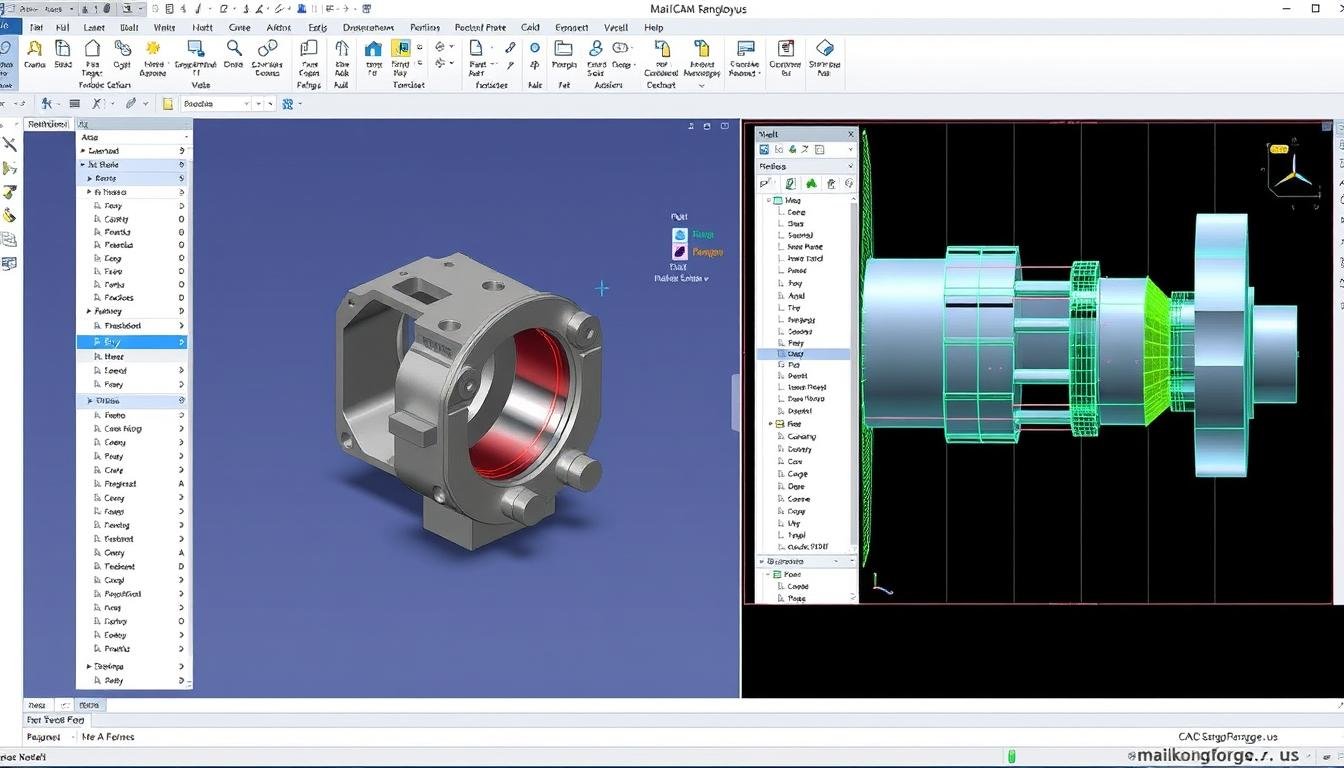

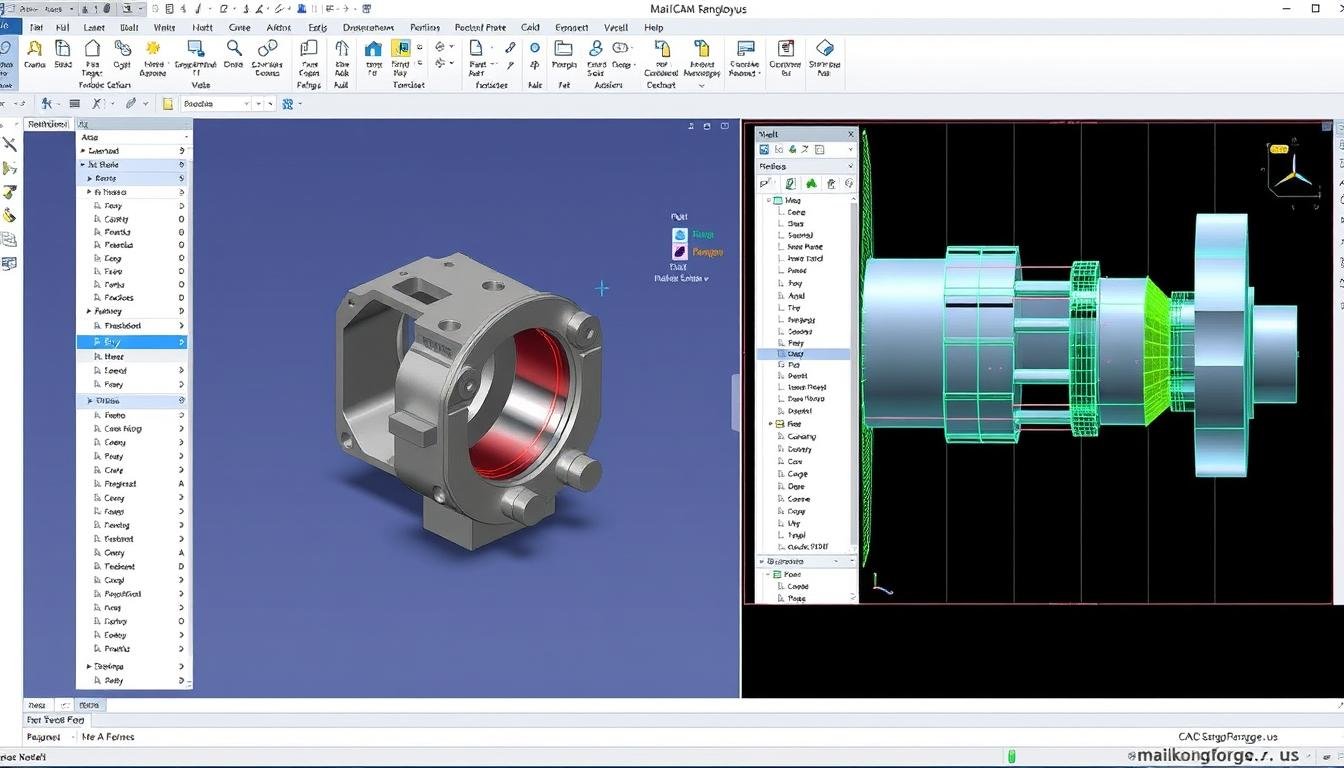

State-of-the-art billet machining process at MAIKONG’s manufacturing facility

State-of-the-art billet machining process at MAIKONG’s manufacturing facility

The term “billet” refers to the solid metal stock used in the manufacturing process rather than the process itself. A billet is a solid length of metal with square or circular cross-sections that serves as the starting material for machining operations. At MAIKONG, we work with billets made from various metals and alloys, including aluminum, steel, brass, and more, precisely sized to meet your project specifications.

Billets are produced through continuous casting or hot rolling methods before being transformed into finished parts through precision machining processes like CNC milling and turning. This subtractive manufacturing approach removes excess material from the workpiece to create the final component with exceptional accuracy.

Advantages of Billet Machining

- Cost-effective for low-volume production runs

- Exceptional precision and dimensional accuracy

- Superior structural integrity and material consistency

- Shorter lead times from raw material to finished parts

- Greater design flexibility for complex components

- Excellent surface finish quality

Limitations to Consider

- Higher material costs for large production volumes

- More material waste compared to additive methods

- Potentially longer machining times for complex geometries

- Higher weight compared to cast alternatives (30-60% heavier)

- May require additional post-processing for certain applications

Billet Machining vs. Cast Manufacturing: Key Differences

Visual comparison: Billet machined component (left) vs. cast component (right)

Understanding the fundamental differences between billet machining and casting is crucial for selecting the right manufacturing method for your project. While both approaches have their place in modern manufacturing, they offer distinct advantages depending on your specific requirements.

Cast Manufacturing Process

Casting involves heating metal to a molten state, pouring it into a preformed mold, and allowing it to cool and solidify. This additive manufacturing process creates parts that take the interior form of the mold, making it suitable for creating complex shapes in a single operation.

| Comparison Factor |

Billet Machining |

Cast Manufacturing |

| Manufacturing Process |

Subtractive (material removed from solid block) |

Additive (molten metal poured into mold) |

| Structural Integrity |

Excellent – consistent grain structure |

Good – potential for inclusions and porosity |

| Dimensional Accuracy |

±0.0005″ typical tolerance |

±0.005″ typical tolerance |

| Surface Finish |

Excellent (16-32 RMS typical) |

Fair to Good (requires post-processing) |

| Cost Efficiency |

Better for low volumes |

Better for high volumes |

| Material Waste |

Higher (excess material removed) |

Lower (near-net-shape production) |

| Lead Time |

Shorter for initial production |

Longer setup but faster per-unit production |

MAIKONG’s Advanced Billet Machining Capabilities

MAIKONG’s state-of-the-art manufacturing facility with 60+ CNC machines

At MAIKONG, we’ve established ourselves as industry leaders in precision billet machining with our comprehensive manufacturing capabilities. Our facility in GD, SZ houses over 60 advanced CNC machines with a monthly metal processing capacity exceeding 100 tons, enabling us to handle projects of any scale with consistent quality and precision.

CNC Turning Services

Our CNC turning capabilities excel in creating precise cylindrical shapes, deep holes, and machined threads with superior surface finishes. This process is ideal for shafts, bushings, and other rotational components requiring tight tolerances.

CNC Milling Services

MAIKONG’s multi-axis CNC milling services create complex prismatic shapes and flat surfaces with exceptional accuracy. Our advanced equipment requires no fixed tooling, offering flexibility and precision for your most demanding projects.

Swiss-Type Machining

Our specialized Swiss-type machining excels in producing precision small parts and long shaft components. With dual spindles and multi-axis capabilities, we provide one-stop solutions with the highest level of accuracy.

Experience MAIKONG’s Precision Billet Machining Services

Our team of expert engineers is ready to evaluate your project requirements and recommend the optimal manufacturing approach for your specific application.

Get a Free Quote

Contact via WhatsApp

Forged Manufacturing: An Alternative to Billet Machining

MAIKONG’s precision forging process creates components with exceptional strength

Forged manufacturing represents another important metal forming process that complements billet machining in certain applications. Unlike casting, forging involves heating metal until it’s malleable (but not molten) and then shaping it using various compressive methods.

Key Advantages of Forged Manufacturing

- Exceptional strength and durability due to aligned grain structure

- Superior resistance to impact and fatigue failure

- Excellent strength-to-weight ratio for critical applications

- Cost-effective for appropriate production volumes

- Reduced material waste compared to billet machining

At MAIKONG, we offer comprehensive forging capabilities alongside our billet machining services, allowing us to recommend and implement the optimal manufacturing approach for each component based on its specific requirements and application.

Microscopic comparison: Grain structure in billet machined (left) vs. forged (right) components

Industries Benefiting from Precision Billet Machining

Precision billet machined components by MAIKONG serving diverse industries

The exceptional quality and precision of billet machining make it invaluable across numerous industries where performance, reliability, and precision are paramount. At MAIKONG, we serve clients across these sectors with customized manufacturing solutions.

Aerospace

The aerospace industry demands components with uncompromising quality and reliability. Our precision billet machined parts meet stringent aerospace standards for critical applications where failure is not an option.

Automotive

From high-performance racing components to precision parts for production vehicles, our billet machining services deliver the quality and consistency automotive manufacturers require.

Medical Devices

Medical equipment demands the highest levels of precision and reliability. Our billet machined components meet strict medical industry standards for critical applications.

Electronics

Precision housings, heat sinks, and structural components for electronic devices benefit from the dimensional accuracy and surface finish quality of billet machining.

Defense

Military and defense applications require components that perform flawlessly under extreme conditions. Our billet machined parts deliver the reliability these applications demand.

Robotics

Modern robotics systems rely on precisely machined components for accurate movement and reliable operation. Our billet machining services deliver the precision these systems require.

Quality Assurance in Billet Machining at MAIKONG

MAIKONG’s rigorous quality control process ensures consistent precision

At MAIKONG, quality isn’t just a goal—it’s a fundamental aspect of our manufacturing process. Our comprehensive quality assurance system ensures that every billet machined component meets or exceeds your specifications and industry standards.

Our Quality Control Process

- Material verification through our advanced testing laboratory

- In-process inspections at critical manufacturing stages

- Dimensional verification using precision measurement equipment

- Surface finish analysis to ensure specification compliance

- Final inspection and documentation of all quality parameters

- ISO 9001:2015 certified quality management system

This rigorous approach to quality control ensures that components produced through our billet machining process consistently deliver the performance and reliability your applications demand.

Design Considerations for Billet Machining

MAIKONG’s advanced CAD/CAM processes optimize billet machining efficiency

Effective design for billet machining requires understanding the process’s capabilities and limitations. Our engineering team works closely with clients to optimize designs for manufacturability while maintaining critical functional requirements.

Key Design Considerations

- Material selection based on application requirements and machinability

- Feature accessibility for machining tools

- Appropriate tolerances that balance precision with cost-effectiveness

- Minimizing deep pockets and internal features that require specialized tooling

- Optimizing part orientation to reduce setups and improve accuracy

- Considering surface finish requirements in the design phase

By addressing these considerations early in the design process, we can help you create components that maximize the benefits of billet machining while minimizing costs and production time.

Let Our Engineers Optimize Your Design

MAIKONG’s experienced engineering team can review your designs and provide valuable feedback to enhance manufacturability and reduce costs.

Email Our Engineering Team

Or call/WhatsApp: 8613-51090-74-01

Partner with MAIKONG for Superior Billet Machining Solutions

The MAIKONG team brings decades of combined experience to your projects

MAIKONG stands as your premier partner for precision billet machining and metal forging services, offering an unmatched combination of technical expertise, manufacturing capabilities, and customer service. With our 60+ CNC machines, comprehensive quality control systems, and experienced engineering team, we deliver exceptional components that meet your most demanding requirements.

We’re actively seeking representatives and partners throughout the United States to bring our cost-effective, high-quality manufacturing solutions to more American businesses. Whether you need prototype development, low-volume production, or high-volume manufacturing, MAIKONG has the capabilities and commitment to ensure your success.

Ready to Experience the MAIKONG Difference?

Contact us today to discuss your project requirements and discover how our precision billet machining services can enhance your products and streamline your manufacturing process.

Get Your Custom Quote Today

Website: https://maikongforge.us

State-of-the-art billet machining process at MAIKONG’s manufacturing facility

State-of-the-art billet machining process at MAIKONG’s manufacturing facility