In the competitive world of metal manufacturing, aluminum forging houses stand as critical partners for industries demanding precision, durability, and performance. MAIKONG has established itself as a leading provider of premium aluminum forging services, combining advanced technology with decades of metallurgical expertise. Our state-of-the-art facilities in GD, SZ deliver exceptional quality forged aluminum components that meet the exacting standards of aerospace, automotive, defense, and other high-demand industries.

MAIKONG’s Aluminum Forging Houses Capabilities

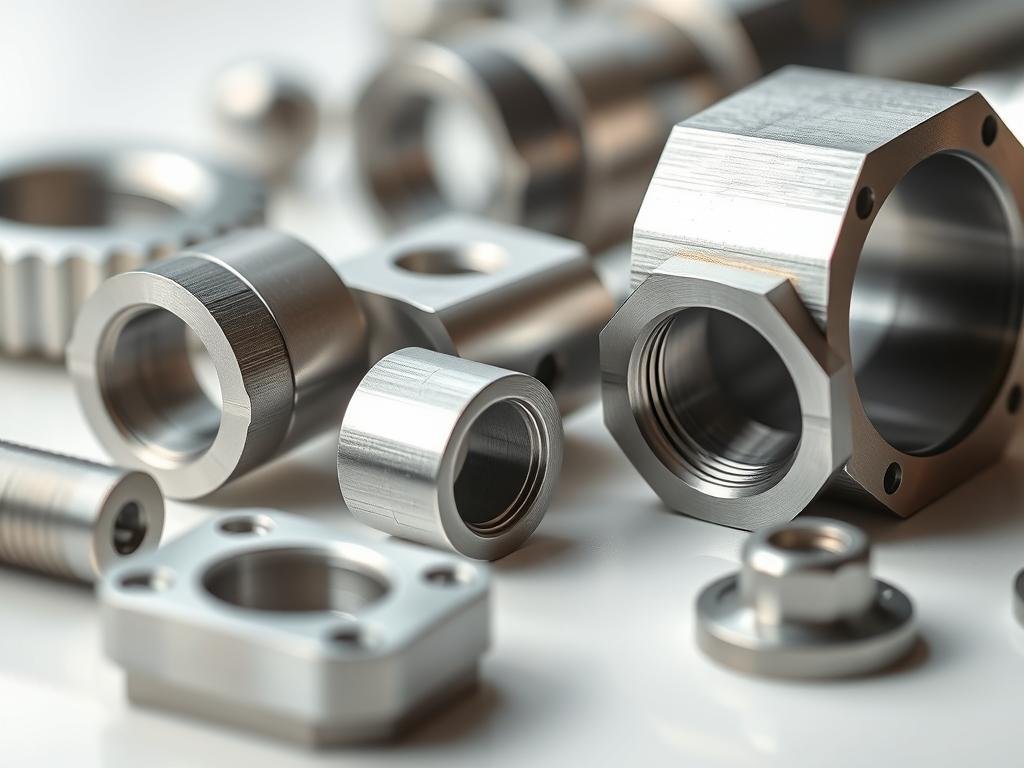

With over 60 CNC machines and a monthly processing capacity exceeding 100 tons, MAIKONG offers comprehensive aluminum forging solutions that blend traditional craftsmanship with cutting-edge technology. Our expertise spans the entire manufacturing process, from initial design consultation to final quality inspection.

Closed Die Forging

Our closed die forging process creates high-strength aluminum components with superior grain structure and mechanical properties. This precision technique allows for intricate designs and tight tolerances, making it ideal for critical applications where performance is paramount.

CNC Machining

MAIKONG’s advanced CNC machining services complement our forging capabilities, allowing for precise finishing of forged components. We specialize in turning, milling, multi-axis machining, and surface grinding to achieve exact specifications.

Heat Treatment

Our in-house heat treatment facilities ensure optimal material properties for every forged aluminum component. We offer various tempers including T6, T651, and T73, enhancing strength, durability, and performance of your parts.

Ready to Elevate Your Manufacturing?

Our engineering team is standing by to discuss your aluminum forging requirements and provide expert guidance.

Get A Quick Quote

Why Choose MAIKONG’s Aluminum Forging Houses

When selecting a manufacturing partner for your aluminum components, the expertise and capabilities of your chosen forging house directly impact your product’s performance, reliability, and cost-effectiveness. MAIKONG delivers exceptional value through our comprehensive approach to aluminum forging.

Technical Excellence

- Advanced CAD/CAM integration with finite element analysis

- Precision tooling design and maintenance for consistent quality

- Comprehensive quality control with statistical process monitoring

- In-house material testing laboratory for verification

Business Benefits

- Cost-effective manufacturing without compromising quality

- Reduced lead times through optimized production processes

- Comprehensive one-stop solution from design to delivery

- Flexible capacity to accommodate both small and large orders

The MAIKONG Aluminum Forging Process

At MAIKONG, we’ve refined our aluminum forging process to deliver exceptional quality and consistency. Our comprehensive approach ensures that every component meets the highest standards of performance and reliability.

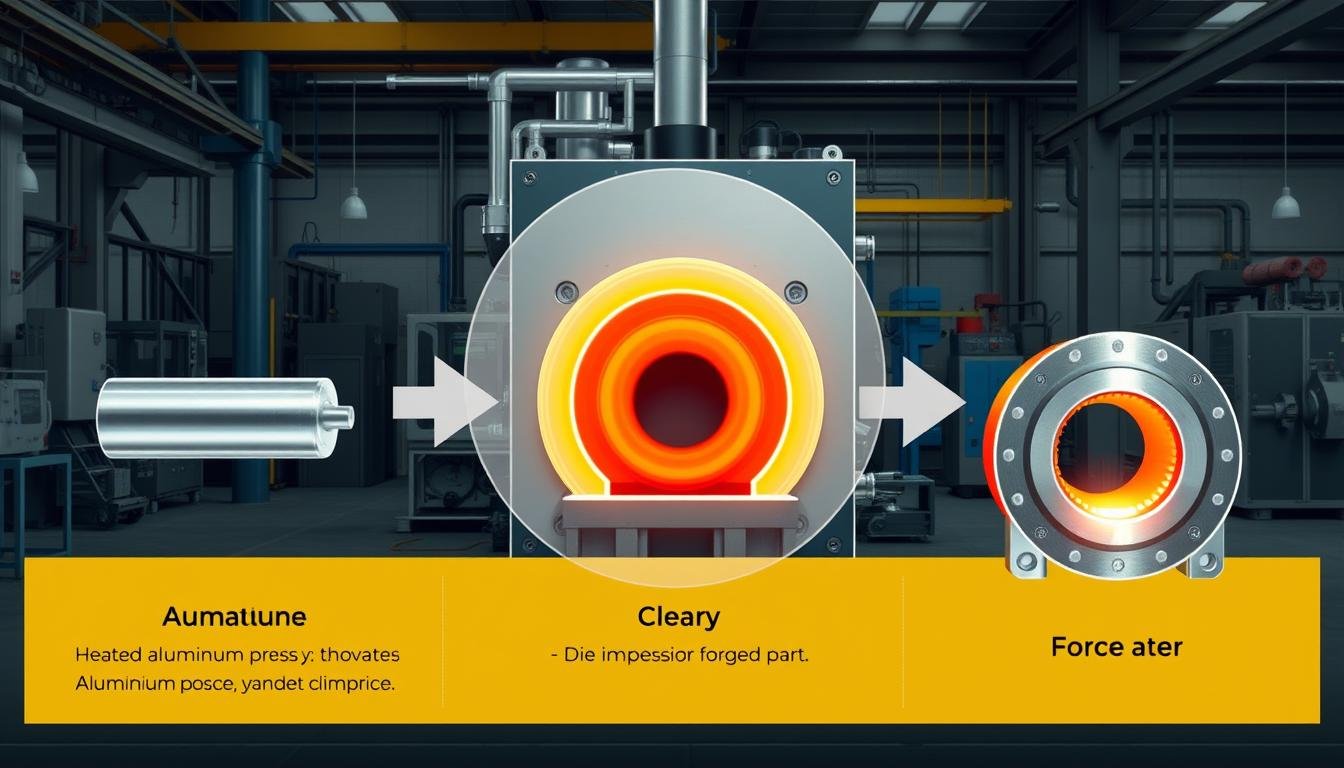

1. Design & Analysis

Our engineering team works closely with clients to optimize designs for the forging process, utilizing advanced CAD/CAM tools and finite element analysis to simulate performance.

2. Tooling & Setup

Precision dies are manufactured to exact specifications, ensuring consistent quality across production runs while minimizing material waste and machining requirements.

3. Forging Operation

Aluminum is heated to optimal temperature and formed under controlled pressure, creating a refined grain structure that enhances strength and durability.

4. Finishing & QC

Comprehensive finishing operations including heat treatment, CNC machining, and surface treatments, followed by rigorous quality inspection.

See Our Forging Process in Action

Contact us today to learn more about how our advanced forging processes can benefit your manufacturing needs.

Email Our Team

Industries Served by Our Aluminum Forging Houses

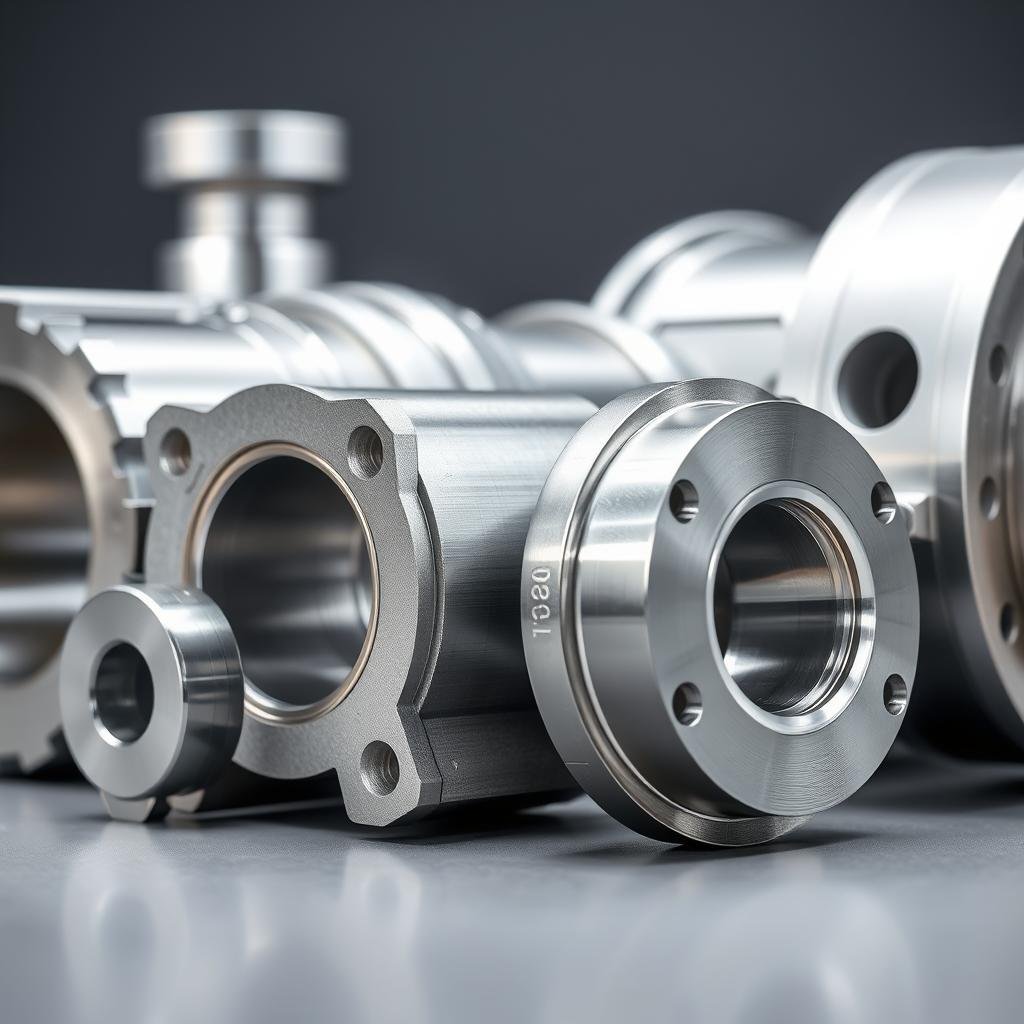

MAIKONG’s aluminum forging capabilities serve diverse industries where performance, reliability, and precision are non-negotiable. Our forged aluminum components excel in demanding applications across multiple sectors.

Aerospace

Our aerospace-grade aluminum forgings deliver the exceptional strength-to-weight ratio and reliability required for critical flight applications. From structural components to engine parts, our forgings meet rigorous industry standards.

Automotive

Performance and safety-critical automotive components benefit from our forged aluminum’s superior strength, fatigue resistance, and weight reduction properties. We supply components for both standard and high-performance vehicles.

Defense & Industrial

Our defense and industrial applications demand uncompromising quality and performance. MAIKONG’s aluminum forgings provide the durability and precision required for these critical applications.

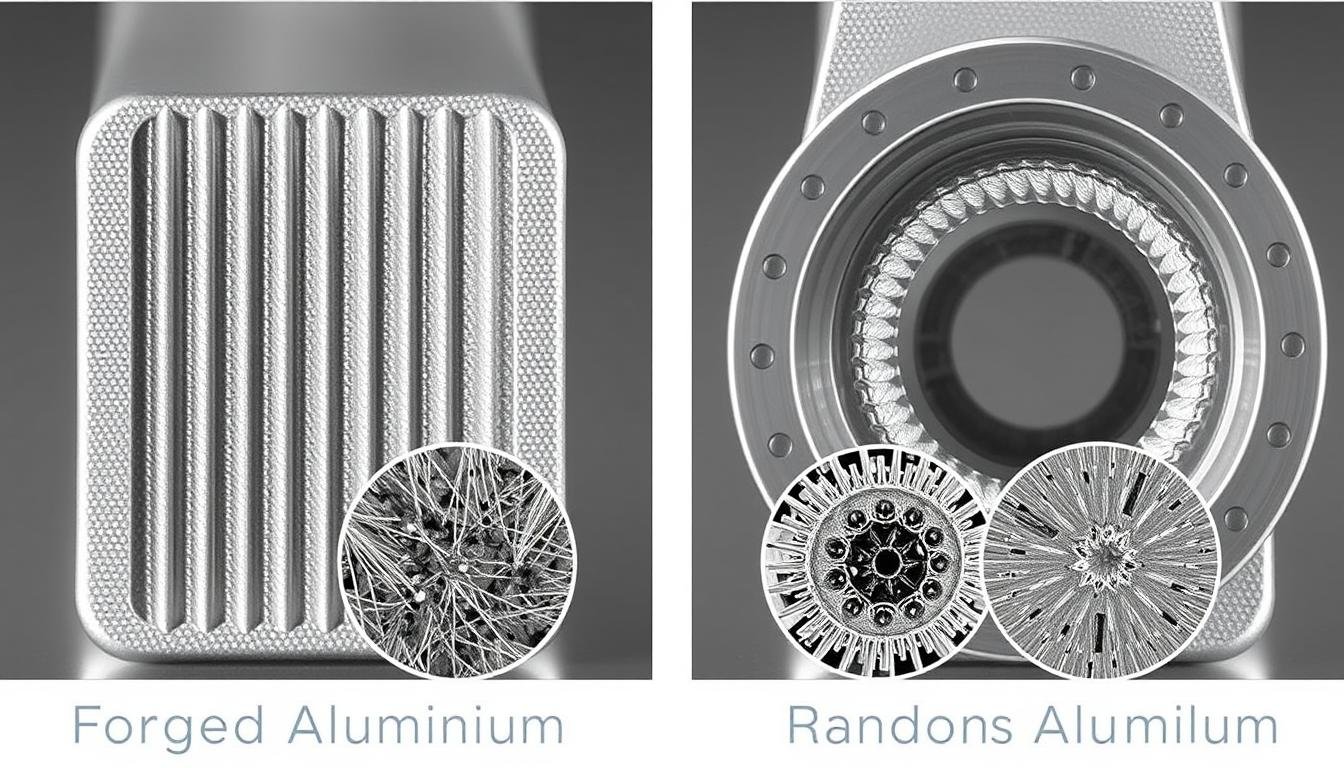

Forged Aluminum vs. Alternative Manufacturing Methods

Understanding the advantages of forged aluminum compared to other manufacturing methods helps in making informed decisions for your components. MAIKONG’s aluminum forging houses deliver superior products through the forging process.

| Comparison Categories |

Aluminum Forging |

Cast Aluminum |

Machined Billet |

| Strength & Durability |

Superior strength due to refined grain structure |

Lower strength with potential for porosity |

Good strength but interrupted grain flow |

| Fatigue Resistance |

Excellent resistance to cyclic loading |

Limited fatigue performance |

Moderate fatigue resistance |

| Material Efficiency |

Optimized material usage with near-net shapes |

Good material efficiency for complex shapes |

High material waste from cutting |

| Production Volume |

Ideal for medium to high volumes |

Suitable for all production volumes |

Best for low volumes or prototypes |

| Cost-Effectiveness |

Higher initial tooling cost, lower per-part cost |

Moderate tooling and production costs |

No tooling costs but higher per-part cost |

Ready to Experience the Forging Advantage?

Contact MAIKONG today to discuss how our aluminum forging capabilities can enhance your product performance.

Request a Consultation

Aluminum Alloys for Optimal Performance

MAIKONG works with a variety of aluminum alloys, each offering specific properties suited to different applications. Our metallurgical expertise ensures we select the optimal material for your component’s requirements.

2000 Series Alloys

High-strength alloys with copper as the primary alloying element. Ideal for aerospace and defense applications requiring maximum strength and excellent fatigue resistance.

- 2014: Excellent for structural components

- 2024: Superior machinability and strength

6000 Series Alloys

Versatile alloys with magnesium and silicon, offering good formability, weldability, and corrosion resistance. Perfect for automotive and general industrial applications.

- 6061: Balanced properties for various applications

- 6082: Higher strength variant with good corrosion resistance

7000 Series Alloys

Ultra-high-strength alloys with zinc, offering the highest strength-to-weight ratio. Ideal for aerospace, defense, and high-performance automotive applications.

- 7075: Exceptional strength for critical components

- 7050: Superior stress corrosion resistance

Heat Treatment Capabilities

Our in-house heat treatment facilities allow us to optimize the mechanical properties of forged aluminum components. We offer various tempers including T6, T651, and T73, tailoring the material properties to your specific requirements for strength, durability, and dimensional stability.

Quality Assurance at MAIKONG

Quality is the cornerstone of MAIKONG’s operations. Our comprehensive quality management system ensures that every component leaving our aluminum forging houses meets the highest standards of excellence.

Testing & Verification

- Material composition analysis

- Mechanical property testing

- Dimensional inspection with advanced CMM

- Non-destructive testing capabilities

- Surface finish verification

Quality Systems

- ISO 9001:2015 certified processes

- Statistical process control

- Comprehensive documentation

- Traceability throughout production

- Continuous improvement programs

Partner with MAIKONG

MAIKONG is seeking US agents to represent our premium aluminum forging services across America. Our cost-effective manufacturing solutions, technical expertise, and commitment to quality make us an ideal partner for distributors and representatives serving industries that demand high-performance metal components.

Become a MAIKONG Partner

Join our network of representatives and grow your business with our premium aluminum forging capabilities.

Contact Us About Partnership

Experience Premium Aluminum Forging with MAIKONG

MAIKONG’s aluminum forging houses combine technical excellence, quality assurance, and cost-effective manufacturing to deliver superior components for demanding applications. Whether you need aerospace-grade precision, automotive performance, or industrial reliability, our comprehensive capabilities ensure your components meet the highest standards.

Ready to Start Your Next Project?

Contact MAIKONG today to discuss your aluminum forging requirements and experience our exceptional service and quality.