6061 Aluminum Alloy Forgings – Premium Quality & Custom Solutions

December 11, 2025

6061 Aluminum Alloy Forgings and Their Advantages

6061 aluminum alloy forgings represent the pinnacle of aluminum manufacturing technology, offering an optimal balance of strength, weight, and corrosion resistance. This versatile alloy contains magnesium and silicon as its primary alloying elements, creating a material that responds exceptionally well to the forging process.

MAIKONG’s advanced forging process creates superior grain structure in 6061 aluminum alloy forgings

What Makes 6061 Aluminum Alloy Forgings Superior

- Enhanced strength-to-weight ratio compared to cast components

- Superior grain flow structure that follows part contours

- Excellent mechanical properties and dimensional stability

- Outstanding resistance to fatigue and stress

- Exceptional corrosion resistance in various environments

- Improved machinability for precision finishing

- Excellent weldability for complex assemblies

- Reliable performance under dynamic loading conditions

- Consistent quality across production batches

- Extended service life in demanding applications

Need Premium 6061 Aluminum Alloy Forgings?

MAIKONG delivers superior quality at competitive prices. Our engineering team can help optimize your design for manufacturing.

Technical Specifications of 6061 Aluminum Alloy Forgings

Understanding the technical aspects of 6061 aluminum alloy forgings is essential for selecting the right material for your application. MAIKONG ensures all forgings meet or exceed industry standards for composition and mechanical properties.

Chemical Composition of 6061 Aluminum Alloy

| Element | Percentage Range (wt. %) |

| Silicon (Si) | 0.4-0.8 |

| Iron (Fe) | 0.7 max |

| Copper (Cu) | 0.15-0.40 |

| Manganese (Mn) | 0.15 max |

| Magnesium (Mg) | 0.8-1.2 |

| Chromium (Cr) | 0.04-0.35 |

| Zinc (Zn) | 0.25 max |

| Titanium (Ti) | 0.15 max |

| Aluminum (Al) | Balance |

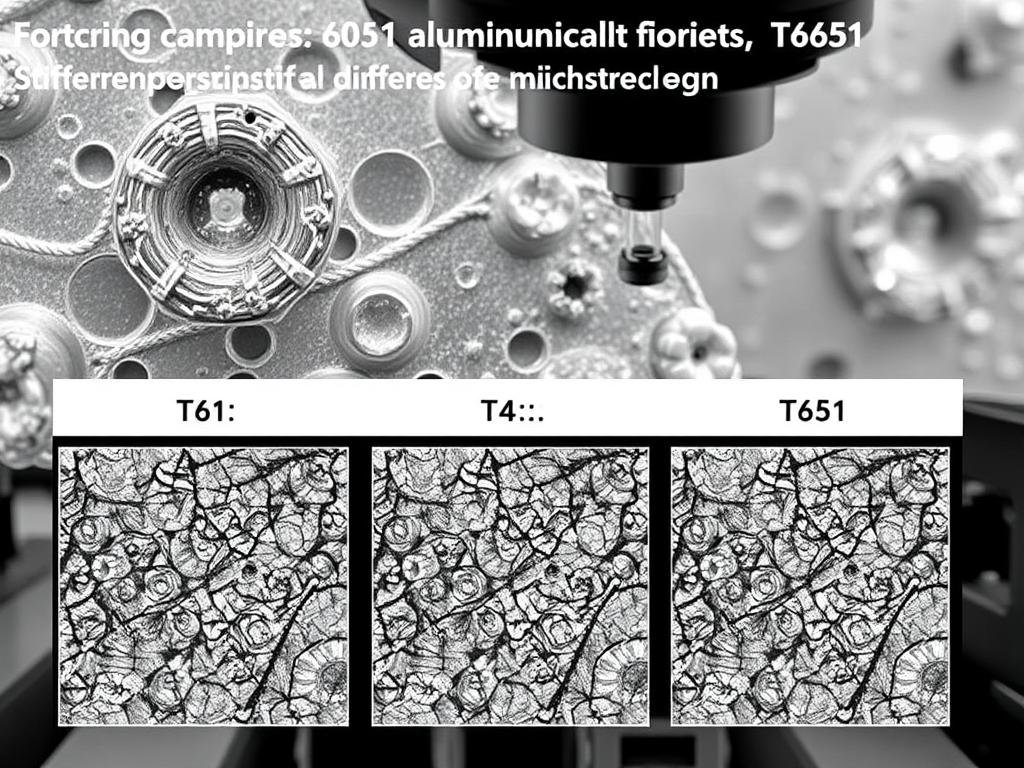

Mechanical Properties of 6061 Aluminum Forgings by Temper

| Property | T6 Temper | T4 Temper | T651 Temper |

| Tensile Strength | 310 MPa (45,000 psi) | 241 MPa (35,000 psi) | 310 MPa (45,000 psi) |

| Yield Strength | 275 MPa (40,000 psi) | 145 MPa (21,000 psi) | 275 MPa (40,000 psi) |

| Elongation at Break | 12% | 22% | 12% |

| Hardness (Brinell) | 95 HB | 65 HB | 95 HB |

| Modulus of Elasticity | 68.9 GPa (10,000 ksi) | 68.9 GPa (10,000 ksi) | 68.9 GPa (10,000 ksi) |

Microstructural comparison of 6061 aluminum forgings in different temper conditions

6061 Aluminum Alloy Forgings vs. Cast Aluminum: The MAIKONG Advantage

When comparing manufacturing methods for aluminum components, the forging process offers significant advantages over casting, particularly for applications requiring superior mechanical properties and reliability.

| Comparison Criteria | 6061 Aluminum Alloy Forgings | Cast Aluminum |

| Strength & Durability | Superior strength due to dense, uniform grain structure | Lower strength with potential porosity issues |

| Grain Structure | Directional grain flow enhances mechanical properties | Random grain structure with no directional advantages |

| Fatigue Resistance | Excellent resistance to cyclic loading and stress | More susceptible to fatigue failure |

| Dimensional Accuracy | Tight tolerances with excellent repeatability | Potential for dimensional inconsistencies |

| Surface Finish | Superior surface quality requiring minimal finishing | Often requires extensive machining to remove defects |

| Weight-to-Strength Ratio | Optimized design allows for lighter components | Requires thicker sections for equivalent strength |

| Critical Applications | Ideal for safety-critical and high-performance uses | Better suited for non-critical components |

Cross-section comparison: Forged 6061 aluminum (left) vs. cast aluminum (right) showing structural integrity differences

Experience the Forging Difference

MAIKONG’s 6061 aluminum alloy forgings deliver superior performance for critical applications. Contact us to discuss how our forging expertise can enhance your products.

MAIKONG’s Advanced Manufacturing Process for 6061 Aluminum Alloy Forgings

At MAIKONG, we’ve developed a comprehensive manufacturing workflow that ensures consistent quality and precision in every 6061 aluminum alloy forging we produce. Our process combines traditional forging expertise with modern technology and rigorous quality control.

MAIKONG’s state-of-the-art forging facility in GD, SZ specializes in premium 6061 aluminum alloy forgings

Our Comprehensive Forging Workflow

- Design & Engineering – Our CAD/CAM experts collaborate with clients to optimize designs for the forging process, ensuring manufacturability while maintaining critical specifications.

- Material Selection – We source premium-grade 6061 aluminum alloy, conducting thorough material testing to verify composition and properties before production.

- Tooling Development – Custom die design and fabrication using advanced simulation software to predict material flow and prevent defects.

- Preheating – Controlled heating of aluminum billets to optimal forging temperature (typically 800-950°F) for ideal plasticity.

- Forging Operation – Application of precisely controlled pressure using hydraulic presses ranging from 800 to 3,000 tons to shape the material.

- Heat Treatment – Specialized thermal processing to achieve desired temper (T4, T6, or T651) and mechanical properties.

- Precision Machining – CNC machining to achieve final dimensions and tolerances as tight as ±0.005″.

- Surface Treatment – Options including anodizing, painting, or other finishes to enhance appearance and performance.

- Quality Inspection – Comprehensive testing including dimensional verification, material properties testing, and non-destructive examination.

Precision CNC machining of 6061 aluminum alloy forgings ensures exact dimensional specifications

MAIKONG’s Forging Equipment Capabilities

| Equipment Type | Specifications | Capabilities |

| Hydraulic Presses | 800-3,000 ton capacity | Large structural components up to 1.5m in length |

| Heat Treatment Furnaces | Computer-controlled with ±5°C accuracy | Precise temper control for T4, T6, and T651 conditions |

| CNC Machining Centers | 5-axis capability with 0.005mm precision | Complex geometries and tight tolerance finishing |

| CMM Inspection | Accuracy to 0.001mm | 100% dimensional verification of critical components |

| Material Testing Lab | Tensile, hardness, and chemical analysis | Comprehensive material certification |

Applications of 6061 Aluminum Alloy Forgings Across Industries

The exceptional combination of strength, weight, and corrosion resistance makes 6061 aluminum alloy forgings ideal for numerous applications across multiple industries. MAIKONG supplies custom forgings for all these sectors with consistent quality and competitive pricing.

Aerospace Applications

- Structural components for aircraft frames

- Wing attachment fittings and connectors

- Landing gear components

- Engine mounting brackets

- Fuel system components

Automotive Applications

- Suspension components

- Wheel hubs and forged wheels

- Drivetrain components

- Engine brackets and mounts

- Steering system components

Industrial Applications

- Hydraulic system components

- Structural elements for machinery

- High-pressure fittings and connectors

- Robotic arm components

- Precision equipment frames

MAIKONG manufactures custom 6061 aluminum alloy forgings for diverse applications across multiple industries

Need Custom 6061 Aluminum Alloy Forgings for Your Industry?

MAIKONG’s engineering team can develop custom solutions for your specific application requirements with competitive pricing and reliable delivery.

Quality Assurance for MAIKONG 6061 Aluminum Alloy Forgings

At MAIKONG, quality is built into every step of our manufacturing process. Our comprehensive quality management system ensures that all 6061 aluminum alloy forgings meet or exceed industry standards and customer specifications.

MAIKONG’s quality control laboratory conducts rigorous testing on all 6061 aluminum alloy forgings

Our Quality Control Process

Material Verification

- Chemical composition analysis

- Mechanical property testing

- Traceability documentation

- Supplier certification verification

In-Process Inspection

- Die condition monitoring

- Temperature control verification

- Dimensional checks during production

- Visual inspection for defects

Final Inspection

- Coordinate Measuring Machine (CMM) verification

- Hardness testing

- Surface finish evaluation

- Non-destructive testing (as required)

Documentation & Certification

- Material test reports

- Dimensional inspection reports

- Heat treatment certification

- Full traceability documentation

“MAIKONG’s commitment to quality ensures that every 6061 aluminum alloy forging we produce meets the highest standards for performance and reliability. Our comprehensive testing and inspection protocols guarantee components that perform as expected in the most demanding applications.”

MAIKONG maintains comprehensive quality certifications and advanced testing capabilities

Why Choose MAIKONG for Your 6061 Aluminum Alloy Forgings

MAIKONG offers a unique combination of technical expertise, manufacturing capabilities, and customer service that makes us the ideal partner for your 6061 aluminum alloy forging needs.

MAIKONG’s comprehensive manufacturing facility in GD, SZ specializes in premium aluminum forgings

The MAIKONG Advantage

- Over 20 years of specialized experience in aluminum forging

- Comprehensive in-house capabilities from design to finishing

- Advanced equipment for consistent quality and precision

- Competitive pricing with transparent quotation process

- Flexible production capacity for both small and large orders

- Rigorous quality control exceeding industry standards

- Experienced engineering team for design optimization

- Global shipping capabilities with reliable logistics

Challenges With Other Suppliers

- Limited technical expertise leading to design issues

- Outsourced processes causing quality inconsistencies

- Outdated equipment resulting in dimensional variations

- Hidden costs and unclear pricing structures

- Inflexible minimum order quantities

- Inadequate quality control and documentation

- Lack of engineering support for optimization

- Unreliable shipping and logistics management

Partner With MAIKONG for Superior 6061 Aluminum Alloy Forgings

Experience the difference that technical expertise, quality manufacturing, and customer-focused service can make for your components.

Frequently Asked Questions About 6061 Aluminum Alloy Forgings

Get answers to common questions about 6061 aluminum alloy forgings and MAIKONG’s manufacturing capabilities.

What are the main advantages of 6061 aluminum alloy forgings compared to other manufacturing methods?

6061 aluminum alloy forgings offer superior strength-to-weight ratio, enhanced grain structure, improved fatigue resistance, and better overall mechanical properties compared to casting or machining from billet. The forging process aligns the grain structure with the part geometry, resulting in components that can withstand higher stress and have longer service lives in demanding applications.

What industries typically use MAIKONG’s 6061 aluminum alloy forgings?

MAIKONG supplies 6061 aluminum alloy forgings to numerous industries including aerospace, automotive, defense, marine, industrial equipment, sporting goods, and medical equipment manufacturers. Any application requiring high strength, light weight, and excellent corrosion resistance can benefit from our forged 6061 components.

What is the typical lead time for custom 6061 aluminum alloy forgings from MAIKONG?

Lead times vary based on complexity, size, and quantity, but typically range from 3-5 weeks for new designs requiring tooling development and 2-3 weeks for repeat orders. MAIKONG offers expedited services for time-critical projects when possible. Contact our sales team for specific lead time estimates for your project.

What quality certifications does MAIKONG maintain for 6061 aluminum alloy forgings?

MAIKONG maintains ISO 9001:2015 quality management certification and can provide material certifications, dimensional reports, and testing documentation as required. We can also work with customers to meet specific industry standards such as aerospace or automotive requirements.

Can MAIKONG provide both small prototype runs and high-volume production of 6061 aluminum alloy forgings?

Yes, MAIKONG has the flexibility to accommodate both small prototype runs and high-volume production orders. Our manufacturing setup allows us to efficiently transition from development to full-scale production while maintaining consistent quality and competitive pricing.

MAIKONG’s engineering team provides expert consultation on 6061 aluminum alloy forging designs

Contact MAIKONG for Premium 6061 Aluminum Alloy Forgings

Ready to discuss your 6061 aluminum alloy forging requirements? MAIKONG’s team of experts is available to provide technical consultation, custom quotations, and comprehensive manufacturing solutions.

Get in Touch

- Phone/WhatsApp: +86 13-51090-74-01

- Email: Lucy@maikongforge.us

- Website: https://maikongforge.us

- Location: GD, SZ – with global shipping capabilities

Request a Custom Quote

Our engineering team will review your specifications and provide a detailed quotation within 24 hours.

US Agency Opportunities

MAIKONG is actively seeking representatives throughout the United States to expand our premium 6061 aluminum alloy forgings business. We offer competitive commission structures, comprehensive technical support, and reliable delivery schedules.

- Exclusive territorial rights available

- Comprehensive product training provided

- Marketing and technical support

- Competitive pricing structures

- Reliable delivery schedules

MAIKONG delivers premium quality 6061 aluminum alloy forgings worldwide with reliable logistics

Experience the MAIKONG Difference in 6061 Aluminum Alloy Forgings

MAIKONG combines technical expertise, advanced manufacturing capabilities, and customer-focused service to deliver superior 6061 aluminum alloy forgings for demanding applications. Our commitment to quality, competitive pricing, and reliable delivery makes us the ideal partner for your aluminum forging needs.

Contact our team today to discuss your specific requirements and discover how MAIKONG can provide the perfect forging solution for your application.

Contact us online by Whatsapp: