The Complete Guide to 4032 Forged Aluminum Pistons: Properties, Benefits, and Applications

December 10, 2025

4032 Forged Aluminum Pistons: Composition and Properties

The 4032 aluminum alloy is distinguished by its high silicon content—approximately 12% silicon—which gives these pistons their unique characteristics. This specific composition makes 4032 forged aluminum pistons particularly well-suited for certain applications where thermal stability and reduced noise are priorities.

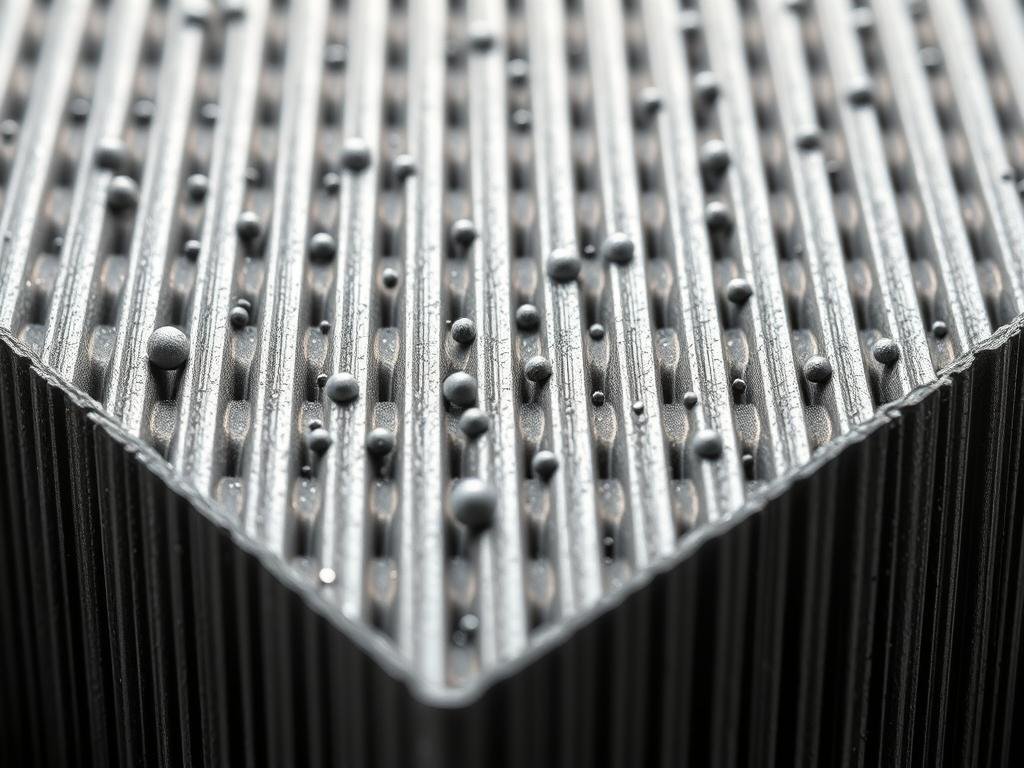

Unlike cast pistons, forged pistons are created through a process that aligns the grain structure of the aluminum, resulting in significantly improved strength. The forging process involves applying intense pressure to heated aluminum billets, creating a denser, more uniform internal structure that can withstand the extreme conditions inside high-performance engines.

Key Properties of 4032 Forged Aluminum Pistons

| Property | Characteristic | Benefit |

| Silicon Content | High (12%) | Reduced thermal expansion, improved wear resistance |

| Thermal Expansion | Low expansion rate | Allows tighter piston-to-wall clearances |

| Noise Level | Quieter operation | Reduced piston slap when cold |

| Hardness | Higher than 2618 alloy | Better wear resistance, especially in ring grooves |

| Ductility | Less ductile than 2618 | Better dimensional stability over time |

| Weight | Lightweight | Reduced reciprocating mass, more power at wheels |

4032 Forged Aluminum Pistons vs. 2618 Alloy: Choosing the Right Material

When selecting forged pistons, engine builders often face the choice between 4032 and 2618 aluminum alloys. Each has distinct advantages that make them suitable for different applications. Understanding these differences is crucial for making the right choice for your specific engine build.

4032 Alloy Advantages

- Tighter piston-to-wall clearance (quieter operation)

- Better dimensional stability over time

- Excellent ring groove durability

- Reduced cold start noise (minimal piston slap)

- Superior for daily driven vehicles

- Slightly lighter weight

4032 Alloy Limitations

- Less ductile (less forgiving under extreme loads)

- Not ideal for extreme boost applications

- Less resistant to detonation damage

- May not be suitable for highest-output race engines

For most street and moderate performance applications, 4032 forged aluminum pistons offer the ideal balance of performance, durability, and reduced noise. The 2618 alloy, with its greater ductility, is typically reserved for extreme racing applications where detonation resistance is paramount.

“For engines that will see primarily street use with occasional track time, 4032 alloy pistons provide the perfect balance of performance and longevity. Their reduced expansion characteristics allow for tighter clearances and quieter operation without sacrificing strength.”

Ideal Applications for 4032 Forged Aluminum Pistons

The unique properties of 4032 alloy make these pistons particularly well-suited for specific applications. Understanding where they excel can help you determine if they’re the right choice for your engine build.

Street Performance

Daily driven vehicles with performance upgrades benefit from the reduced noise and excellent durability of 4032 forged aluminum pistons. The tighter clearances provide smoother operation and better ring seal during daily driving conditions.

Moderate Boost Applications

Engines with mild to moderate forced induction (up to approximately 15-20 psi) can utilize 4032 pistons effectively. The alloy provides good strength while maintaining quieter operation compared to 2618 alternatives.

Endurance Applications

Vehicles that require long-term durability benefit from the superior wear characteristics of 4032 alloy, particularly in maintaining ring groove dimensions over extended use, resulting in better compression retention.

When to Consider 4032 Forged Aluminum Pistons

- Building a high-performance street engine that will see daily use

- Seeking reduced cold-start noise compared to typical race pistons

- Applications requiring excellent ring seal over extended periods

- Moderate forced induction setups (supercharged or turbocharged)

- Engines that cycle through frequent cold starts and warm-ups

Need Expert Advice on Piston Selection?

Our engineering team can help determine if 4032 forged aluminum pistons are right for your specific application.

MAIKONG’s Manufacturing Process for Premium 4032 Forged Aluminum Pistons

At MAIKONG, we’ve developed a sophisticated manufacturing process that ensures our 4032 forged aluminum pistons meet the highest standards of quality and performance. Our comprehensive approach encompasses every stage from design to final inspection.

Our Precision Manufacturing Workflow

Design & Engineering

- Advanced CAD/CAM design optimization

- Finite element analysis for stress testing

- Precision tolerance specification

- Custom profile development

Material Selection

- Premium grade 4032 aluminum alloy

- Rigorous material testing

- Certified composition verification

- Batch consistency control

Forging Process

- Controlled heating to optimal temperature

- High-pressure forging (100+ tons)

- Precision die alignment

- Controlled cooling procedures

CNC Machining

- 5-axis precision machining

- Automated tolerance verification

- Custom ring groove specifications

- Surface finish optimization

Heat Treatment

- Controlled aging process

- Hardness optimization

- Stress relief procedures

- Dimensional stability verification

Quality Control

- Dimensional inspection (±0.001″)

- Material hardness testing

- Surface finish verification

- Final visual inspection

Our state-of-the-art facility in GD, SZ is equipped with over 60 CNC machines and provides 100+ tons of metal processing capacity per month. This advanced manufacturing capability ensures consistent quality and precise specifications for every 4032 forged aluminum piston we produce.

Tour Our Manufacturing Facility

See how MAIKONG creates premium quality 4032 forged aluminum pistons with our advanced manufacturing processes.

Custom 4032 Forged Aluminum Pistons for Your Specific Requirements

At MAIKONG, we understand that many performance applications require custom solutions. Our engineering team specializes in developing custom 4032 forged aluminum pistons tailored to your exact specifications and performance goals.

Customization Options for 4032 Forged Aluminum Pistons

Design Customization

- Custom compression ratios (flat top, dished, or domed)

- Specialized valve reliefs for high-lift camshafts

- Custom skirt designs for specific applications

- Optimized ring land dimensions

- Pin location modifications

Performance Enhancements

- Hard anodized ring grooves for extended durability

- Anti-friction skirt coatings

- Thermal barrier crown coatings

- Weight optimization for high-RPM applications

- Custom ring packages

Our engineering team works closely with customers to understand their specific performance goals, operating conditions, and engine specifications. This collaborative approach ensures that every custom 4032 forged aluminum piston we produce is optimized for its intended application.

Request a Custom Piston Quote

Tell us about your specific requirements, and our engineering team will develop a custom solution for your application.

Become a MAIKONG 4032 Forged Aluminum Pistons Distributor

MAIKONG is actively seeking distribution partners throughout the United States for our premium quality 4032 forged aluminum pistons and other forged components. Our distributor program offers competitive pricing, reliable supply, and comprehensive technical support.

Benefits of Becoming a MAIKONG Distributor

Competitive Pricing

Direct manufacturer relationship ensures excellent margins and competitive market positioning for distributors.

Technical Support

Comprehensive product training and ongoing technical support from our engineering team to assist with customer inquiries.

Marketing Support

Access to professional marketing materials, product photography, and technical documentation to support your sales efforts.

Join Our Distributor Network

Become a distributor of MAIKONG’s premium quality 4032 forged aluminum pistons and other forged components.

Contact MAIKONG for Premium 4032 Forged Aluminum Pistons

Ready to experience the MAIKONG difference? Our team of experts is standing by to assist with your 4032 forged aluminum piston needs, whether you require standard components or custom-engineered solutions for your specific application.

Contact Information

- Phone/WhatsApp: 8613-51090-74-01

- Email: Lucy@maikongforge.us

- Website: https://maikongforge.us

Quick Links

Ready to Upgrade Your Engine Performance?

Contact MAIKONG today for premium quality 4032 forged aluminum pistons engineered for reliability and performance.

Why Choose MAIKONG for Your 4032 Forged Aluminum Pistons

MAIKONG combines advanced manufacturing technology with metallurgical expertise to produce 4032 forged aluminum pistons of exceptional quality and performance. Our commitment to precision, reliability, and customer satisfaction has made us a trusted partner for performance engine builders and automotive manufacturers worldwide.

With our comprehensive capabilities in forging, CNC machining, and quality control, we provide complete solutions from design to delivery. Whether you need standard components or custom-engineered pistons for specific applications, MAIKONG delivers the perfect balance of performance, durability, and value.

Experience the MAIKONG Difference

Contact us today to learn how our premium 4032 forged aluminum pistons can enhance your engine’s performance and reliability.

Contact us online by Whatsapp: