2618 T61 Forged Aluminum: Premium Aerospace-Grade Solutions

December 9, 2025

Need High-Performance 2618 T61 Forged Aluminum?

Our engineering team is ready to assist with your specific requirements and provide competitive pricing for your project.

Key Properties of 2618 T61 Forged Aluminum

2618 T61 forged aluminum is a heat-resistant deformation aluminum alloy strengthened through thermal treatment. The T61 temper designation indicates solution heat treatment followed by artificial aging to achieve peak mechanical properties. This specialized heat treatment process significantly enhances the alloy’s performance characteristics, making it ideal for applications requiring exceptional strength at elevated temperatures.

| Property | Value |

| Density | 2.78 g/cm³ |

| Melting Point | 515-635°C |

| Thermal Conductivity | 127 W/mK |

| Coefficient of Thermal Expansion | 23.2 × 10⁻⁶/K |

| Tensile Strength (T61 condition) | 440-470 MPa |

| Yield Strength (T61 condition) | 370-400 MPa |

Chemical Composition of 2618 T61 Forged Aluminum

The exceptional performance of 2618 T61 forged aluminum stems from its carefully balanced chemical composition. With primary alloying elements including copper, magnesium, and silicon, this alloy achieves an optimal combination of strength, heat resistance, and machinability. At MAIKONG, we strictly adhere to international standards for chemical composition to ensure consistent quality in every forging.

| Element | Composition (%) |

| Aluminum (Al) | 93.0-95.0 |

| Copper (Cu) | 2.20-2.80 |

| Magnesium (Mg) | 1.50-2.50 |

| Silicon (Si) | 0.50-0.90 |

| Iron (Fe) | 0.30 max |

| Manganese (Mn) | 0.10 max |

| Zinc (Zn) | 0.20 max |

| Titanium (Ti) | 0.10 max |

| Chromium (Cr) | 0.10 max |

| Other Elements | 0.05 max each, 0.15 max total |

MAIKONG 2618 T61 Forged Aluminum Specifications

At MAIKONG, we offer comprehensive 2618 T61 forged aluminum manufacturing capabilities to meet diverse industry requirements. Our state-of-the-art forging facilities in GD, SZ can produce components ranging from small precision parts to large structural elements with exceptional dimensional accuracy and material integrity.

| Forging Type | Maximum Weight | Maximum Dimensions |

| Open Die Forging – Cube | ≤9T | Length≤7000mm, Width≤2000mm, Height≤500mm |

| Open Die Forging – Disk | ≤5T | Diameter≤2500mm |

| Open Die Forging – Ring | ≤5T | Outer diameter≤2500mm (quenching), ≤4000mm (non-quenching), Height≤500mm |

| Open Die Forging – Cylinder | ≤5T | Diameter 200-2000mm, Length≤2000mm |

| Closed Die Forging | – | PVA≤3.0㎡ (Diameter≤1950mm) |

Ready to Order 2618 T61 Forged Aluminum Components?

Contact our technical team today for expert consultation and competitive pricing on your custom forging requirements.

Or contact us directly:

Advantages of 2618 T61 Forged Aluminum

The 2618 T61 forged aluminum alloy offers exceptional performance characteristics that make it the material of choice for demanding applications. At MAIKONG, our specialized forging processes further enhance these inherent properties to deliver components with superior strength, durability, and reliability.

Superior Heat Resistance

2618 T61 forged aluminum maintains its mechanical properties at elevated temperatures, making it ideal for components exposed to high thermal stress. The T61 treatment further enhances the alloy’s ability to withstand temperatures up to 200°C without significant property degradation.

Exceptional Strength-to-Weight Ratio

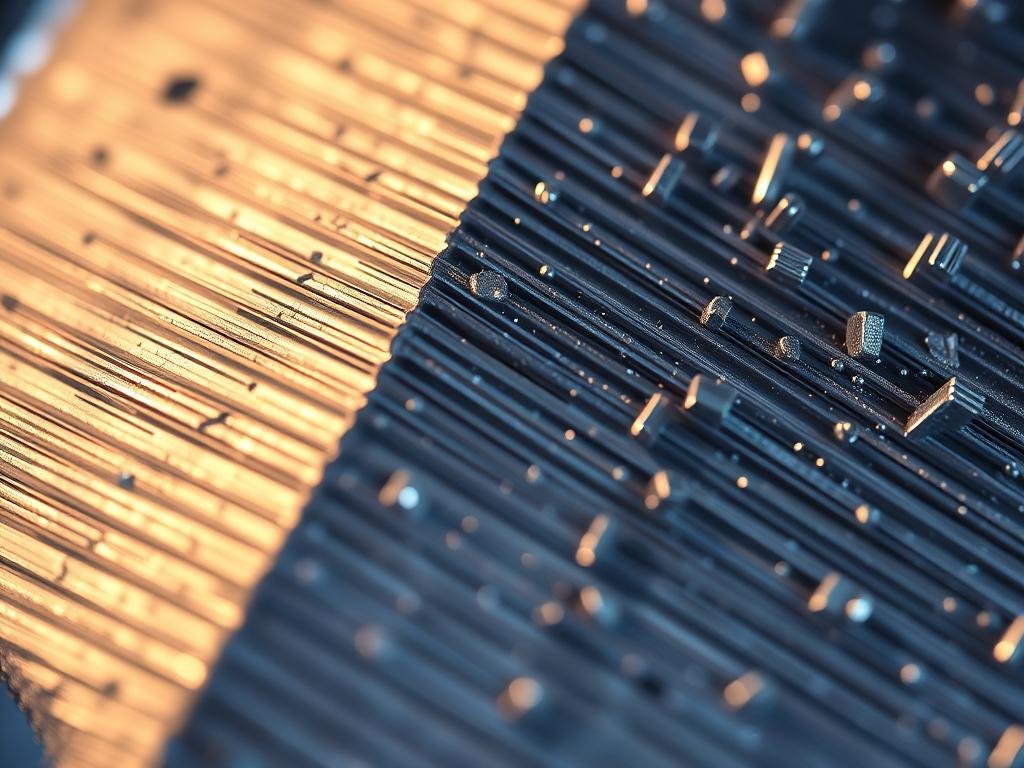

Through our advanced forging processes, MAIKONG optimizes the grain structure of 2618 T61 forged aluminum to achieve maximum strength while maintaining the lightweight advantages of aluminum. This makes our forgings ideal for aerospace and automotive applications where weight reduction is critical.

Enhanced Fatigue Resistance

The directional grain flow achieved through our forging processes significantly improves the fatigue resistance of 2618 T61 forged aluminum components. This ensures reliable performance under cyclic loading conditions typical in aerospace and high-performance mechanical applications.

Excellent Machinability

Despite its high strength, 2618 T61 forged aluminum offers good machinability, allowing for precise secondary operations. MAIKONG’s integrated CNC machining capabilities ensure tight tolerances and superior surface finishes on all forged components.

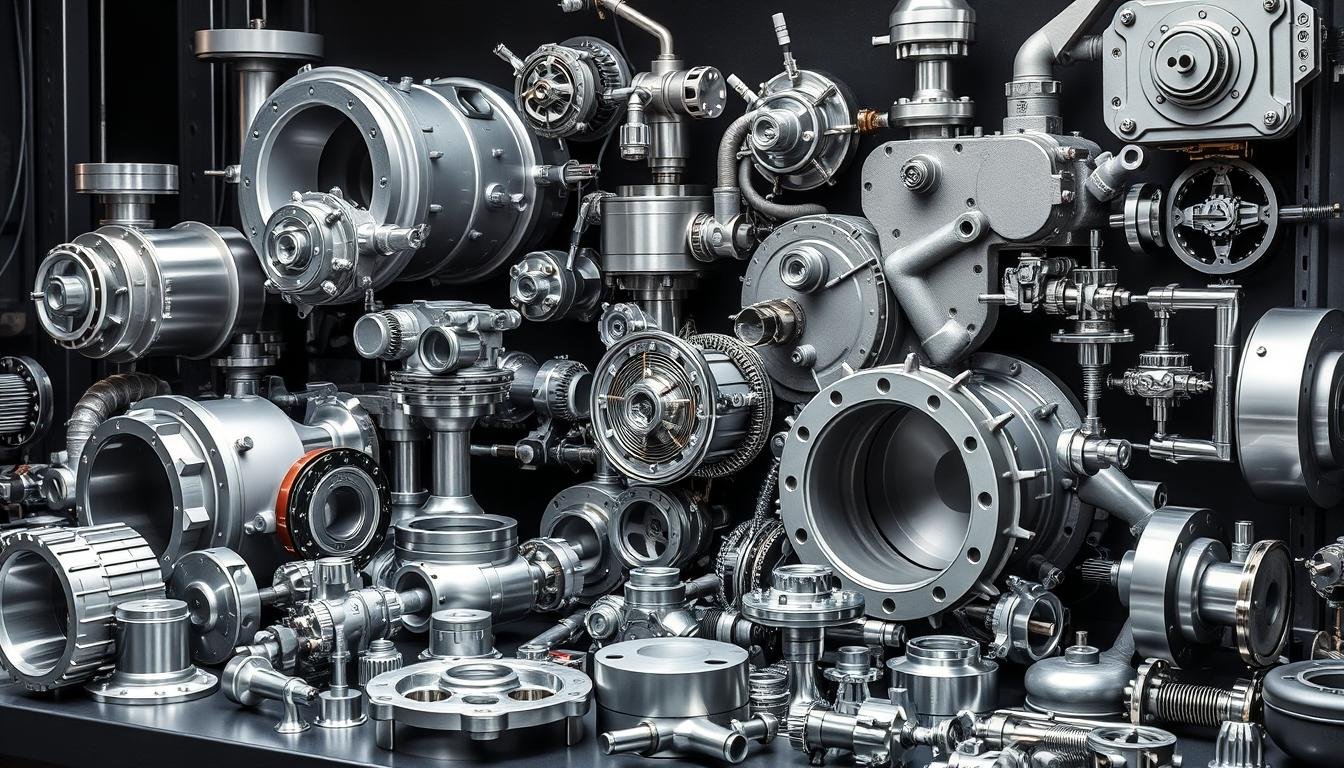

Applications of 2618 T61 Forged Aluminum

The exceptional properties of 2618 T61 forged aluminum make it suitable for a wide range of demanding applications across multiple industries. At MAIKONG, we supply precision-forged components to customers in aerospace, automotive, defense, and industrial sectors worldwide.

Aerospace Applications

- Aircraft engine components

- Structural airframe elements

- Landing gear components

- Fuselage and wing attachments

- High-temperature turbine parts

Automotive Applications

- High-performance engine pistons

- Connecting rods

- Suspension components

- Drivetrain elements

- Racing vehicle structural parts

Industrial Applications

- High-stress machinery components

- Industrial gas turbine parts

- Precision mechanical elements

- High-temperature equipment

- Defense and military hardware

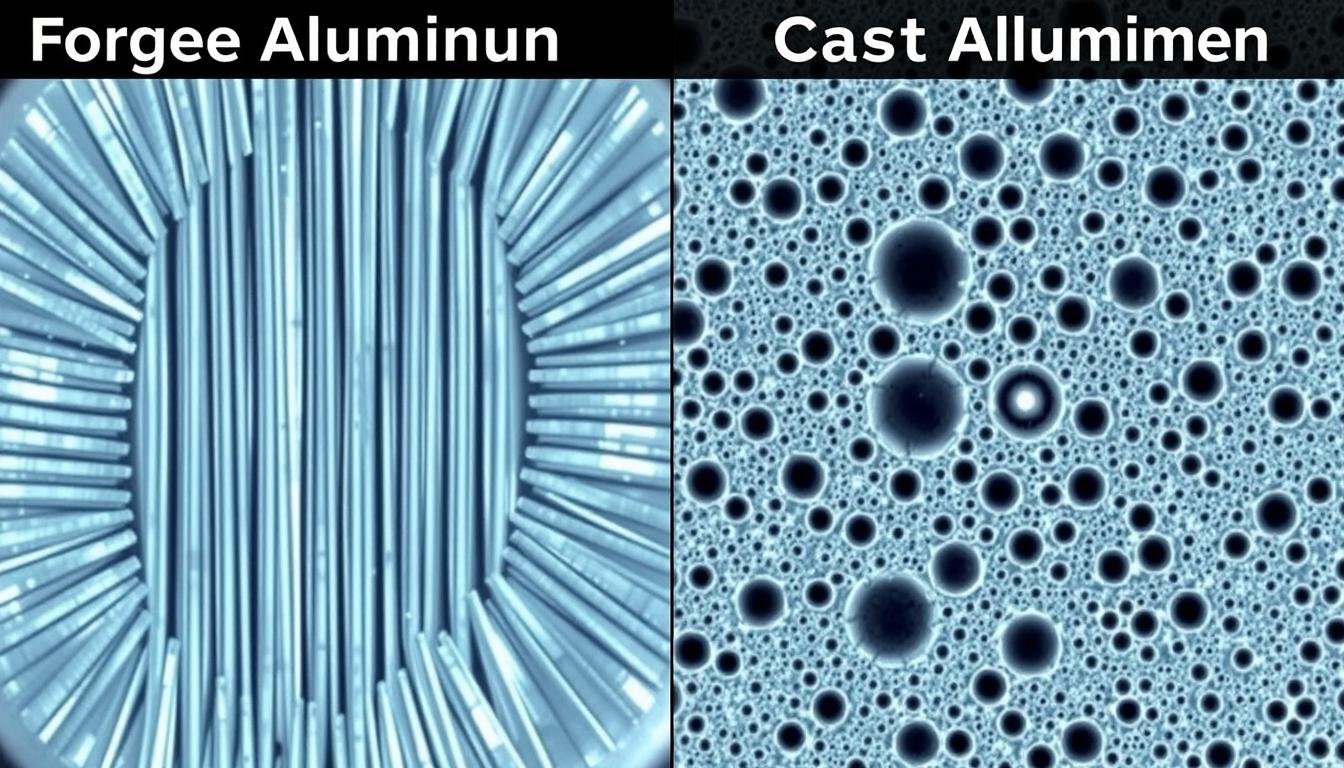

2618 T61 Forged Aluminum vs. Cast Aluminum

Understanding the differences between forged and cast aluminum is crucial when selecting materials for critical applications. At MAIKONG, we specialize in forging processes that maximize the inherent advantages of 2618 T61 forged aluminum for superior performance and reliability.

| Comparison Categories | 2618 T61 Forged Aluminum | Cast Aluminum |

| Strength and Durability | ✅ Higher due to dense, uniform grain structure | Potentially lower due to air pockets and inclusions |

| Tensile Properties | ✅ Superior tensile strength and resistance | Lower tensile strength |

| Fatigue Resistance | ✅ Better resistance against fatigue failure | Potentially lower fatigue resistance |

| Complex Geometries | Require multiple steps to achieve complex shapes | ✅ Can achieve complex shapes in one session |

| Dimensional Accuracy | ✅ Better accuracy and tighter tolerances | Potential inconsistencies |

| Heat Treatment Response | ✅ Responsive for controlled material properties | Less predictable response |

| Critical Applications | ✅ Ideal for structural and load-bearing components | Limited suitability for critical applications |

MAIKONG’s 2618 T61 Forged Aluminum Manufacturing Process

At MAIKONG, we employ a comprehensive manufacturing approach to ensure the highest quality 2618 T61 forged aluminum components. Our integrated process combines advanced forging techniques with precision machining and rigorous quality control to deliver superior products that meet or exceed customer specifications.

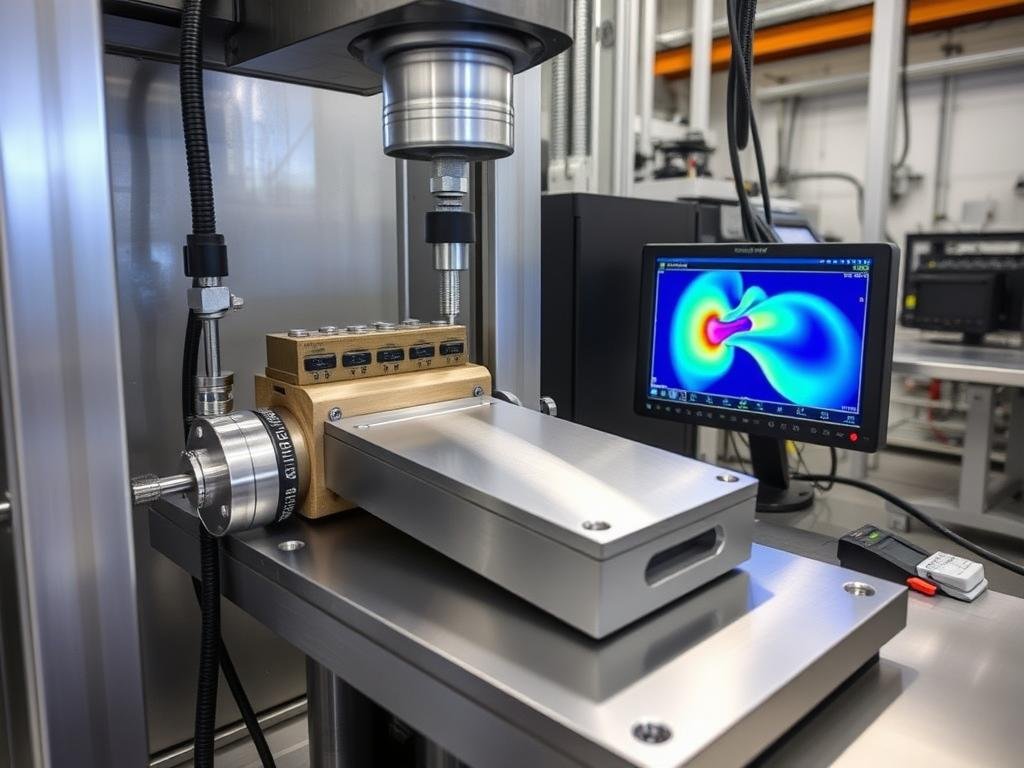

Design & Engineering

- Advanced CAD/CAM design

- Finite element analysis

- Material flow simulation

- Tooling design optimization

- Process parameter development

Forging & Heat Treatment

- Precision billet preparation

- Controlled heating processes

- Hydraulic press forging

- T61 heat treatment

- Controlled cooling

Finishing & Quality Control

- CNC precision machining

- Surface treatment options

- Dimensional inspection

- Material testing

- Certification documentation

Quality Standards for 2618 T61 Forged Aluminum

MAIKONG adheres to stringent quality standards to ensure our 2618 T61 forged aluminum components meet the highest industry requirements. Our quality management system is certified to ISO 9001:2015, and we maintain compliance with aerospace and automotive industry specifications.

Material Specifications

- AMS 4132: 2618-T61 Die & Hand Forgings

- DTD 731B: 2618 T6 Forging Stock and Forgings

- DTD 717A: 2618A-T6 Forging Stock and Forgings

- ASTM B247: Standard Specification for Aluminum and Aluminum-Alloy Die Forgings, Hand Forgings, and Rolled Ring Forgings

Testing Capabilities

- Chemical composition analysis

- Mechanical property testing

- Microstructure examination

- Non-destructive testing

- Dimensional inspection

Partner with MAIKONG for Premium 2618 T61 Forged Aluminum Solutions

Experience the MAIKONG difference with our high-quality forgings, competitive pricing, and exceptional customer service. We’re currently seeking distribution partners across the United States.

Why Choose MAIKONG for 2618 T61 Forged Aluminum

MAIKONG stands as your premier partner for high-quality 2618 T61 forged aluminum components. With our advanced manufacturing capabilities in GD, SZ, comprehensive quality control systems, and competitive pricing, we deliver exceptional value to customers worldwide. Whether you need aerospace-grade components, automotive parts, or industrial elements, our team is ready to meet your most demanding requirements.

Contact our technical team today to discuss your specific 2618 T61 forged aluminum requirements and discover how MAIKONG can support your manufacturing needs with superior quality, competitive pricing, and exceptional service.

Contact Information

Email: Lucy@maikongforge.us

WhatsApp: 8613-51090-74-01

Website: https://maikongforge.us

Contact us online by Whatsapp: