In today’s advanced manufacturing landscape, steel forging continues to be an irreplaceable process for creating high-strength, reliable components across numerous industries. Despite technological advancements in manufacturing methods, the fundamental benefits of steel forging – superior strength, enhanced grain structure, and exceptional durability – remain unmatched for critical applications. As global industries evolve, understanding why this time-tested process continues to be essential can help manufacturers make informed decisions about component production methods.

The Fundamentals of Steel Forging Processes

Steel forging is a manufacturing process that shapes metal using localized compressive forces. Unlike casting, which involves pouring molten metal into molds, forging works by applying pressure to solid metal, typically heated to increase malleability. This pressure causes the metal to deform plastically, aligning its grain structure and eliminating internal voids or weaknesses.

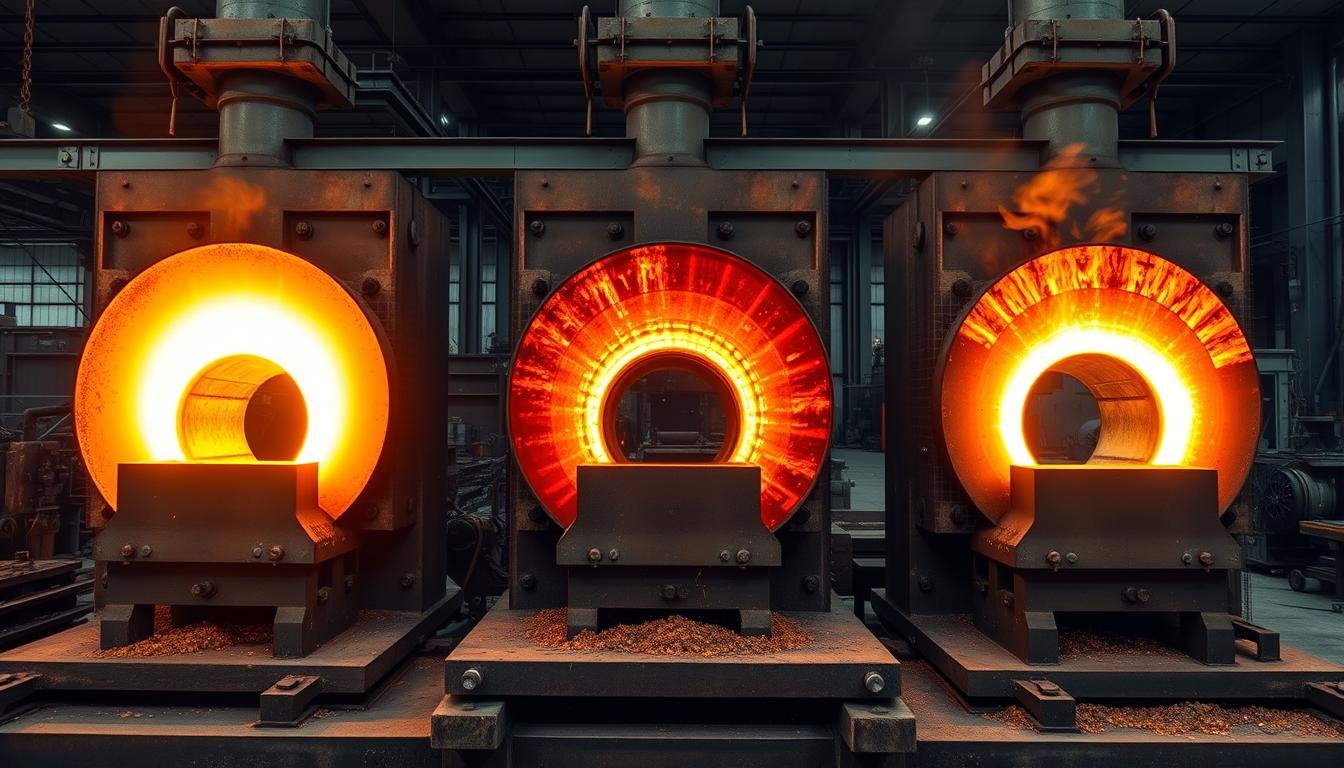

Modern steel forging operation showing heated metal being shaped between precision dies

The process begins with raw steel stock, typically in the form of ingots, billets, or bars. This material is heated to temperatures ranging from 900°C to 1250°C, depending on the specific alloy and desired properties. At these temperatures, steel becomes more malleable, allowing it to be shaped more easily while still maintaining its solid state.

Primary Steel Forging Methods

There are several methods used in modern steel forging, each offering specific advantages for different applications:

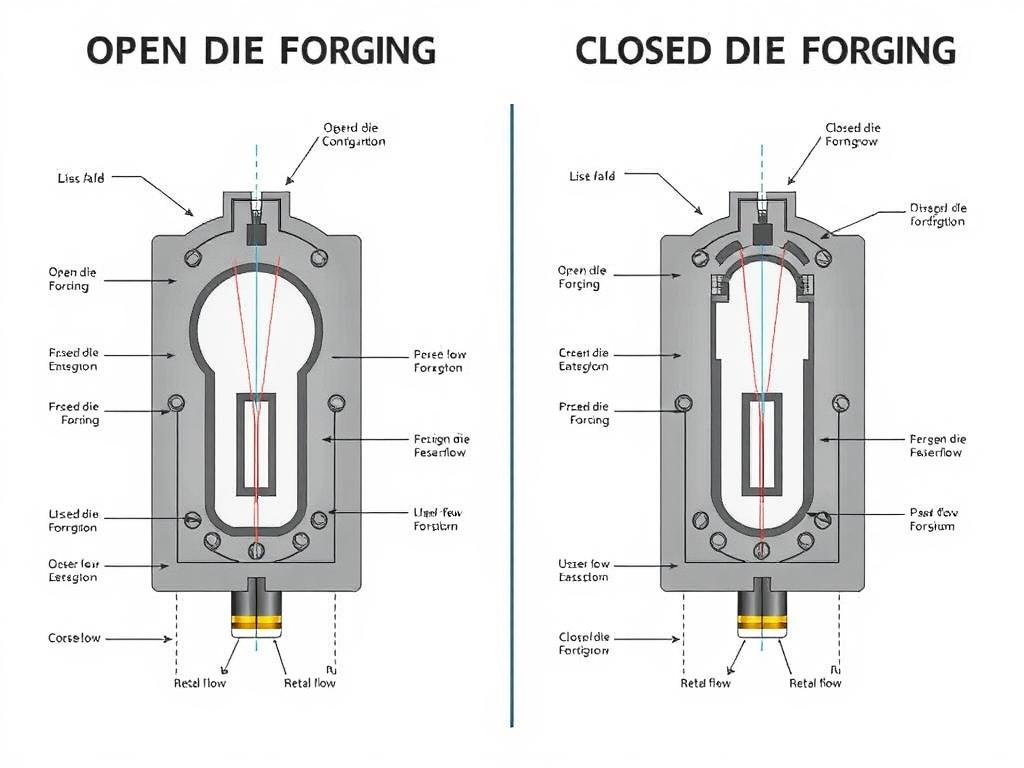

Open Die Forging

In open die forging, heated steel is placed between flat or simply shaped dies that don’t completely enclose the workpiece. The metal is compressed and shaped through a series of blows or continuous pressure, with the operator manipulating the workpiece between strikes to achieve the desired form. This method is particularly valuable for large components or when only a limited number of parts are needed.

Closed Die Forging

Also known as impression die forging, this method uses two or more dies with impressions (cavities) that shape the metal as it’s compressed. The heated steel is placed in the lower die, and the upper die descends, forcing the metal to flow into the die cavities. This process creates more complex shapes with tighter tolerances than open die forging and is ideal for high-volume production.

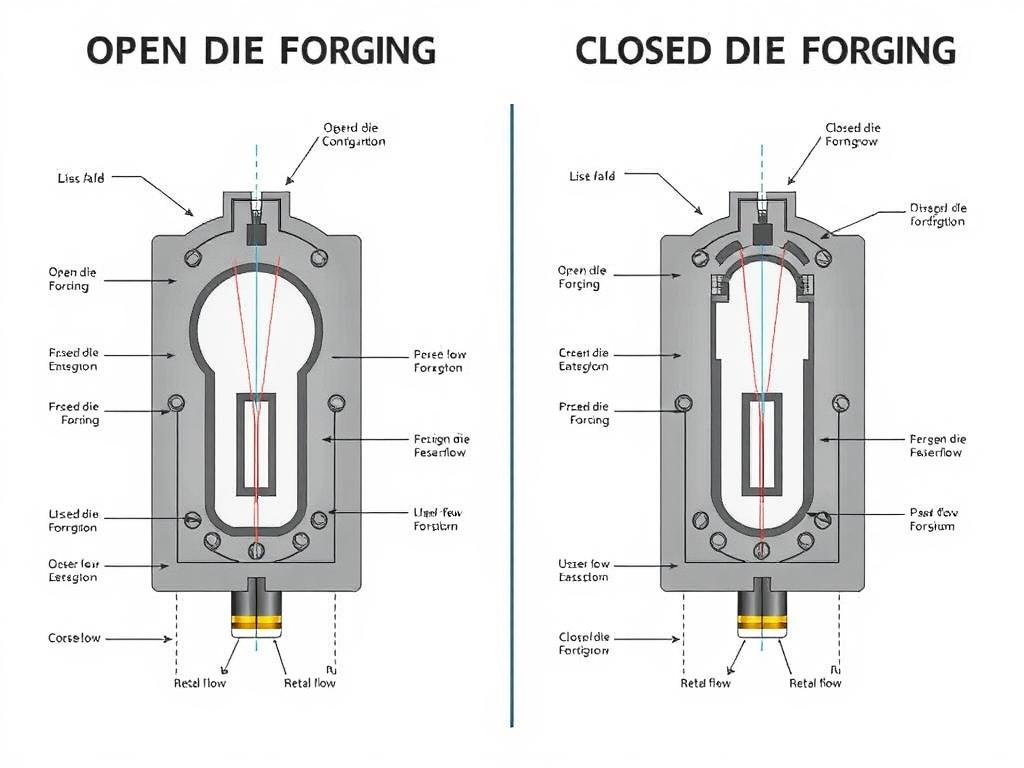

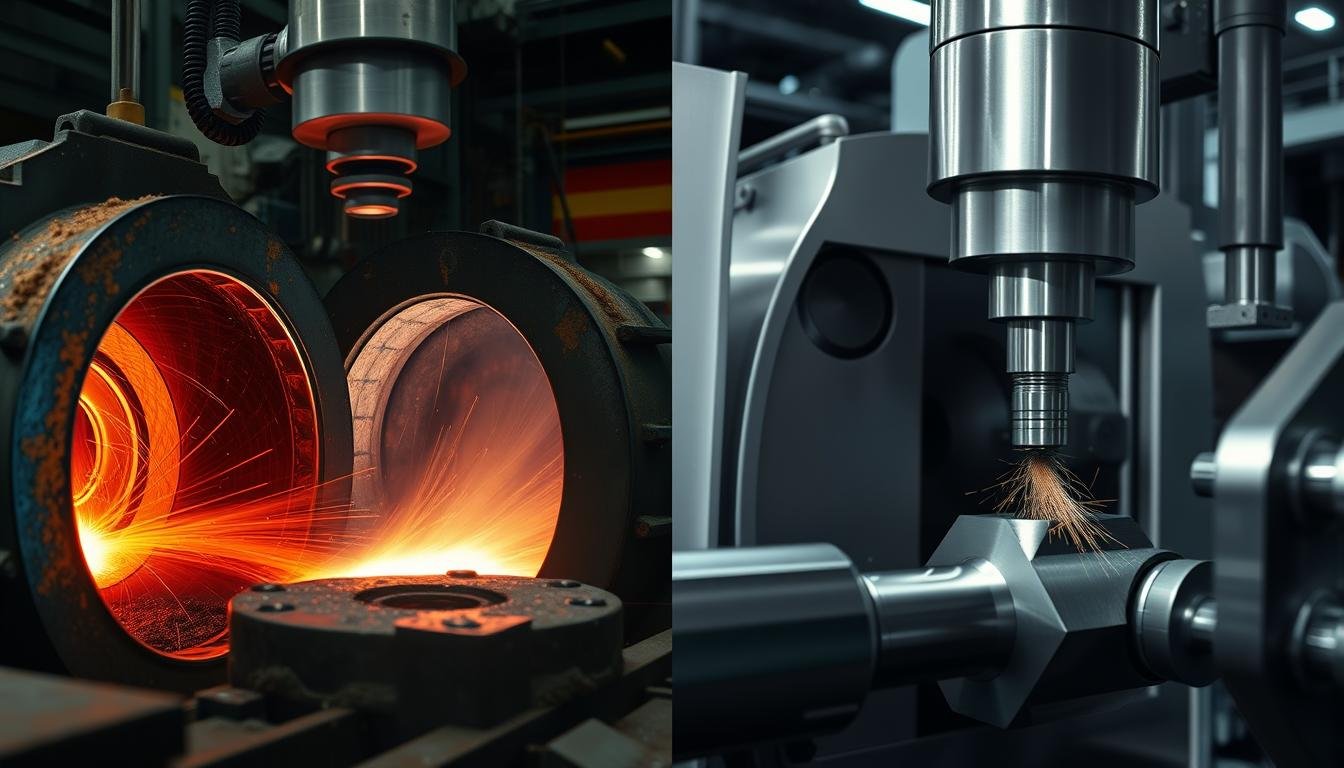

Comparison between open die (left) and closed die (right) forging techniques

Roll Forging

Roll forging reduces the cross-section of heated steel bars or billets while increasing their length. The process uses two semi-cylindrical rolls with shaped grooves that rotate in opposite directions. As the steel passes through these rolls, it’s progressively shaped to the desired form. This method is particularly effective for producing parts with elongated shapes, such as axles, leaf springs, and hand tools.

Upset Forging

Upset forging increases the diameter of the workpiece by compressing its length. This process is commonly used to create heads on bolts, valves, and similar components. The heated steel is placed in a die, and a ram compresses it axially, causing the metal to “upset” or flow perpendicular to the applied force.

Temperature Classification in Steel Forging Operations

The temperature at which steel forging is performed significantly impacts the process characteristics and the final properties of the forged component. Based on temperature, forging operations are classified into three main categories:

Hot Forging

Performed at temperatures above the steel’s recrystallization temperature (typically 950-1250°C), hot forging offers excellent formability and lower forming forces. The high temperature allows for significant deformation with relatively low pressure, making it ideal for creating complex shapes. Hot forging also results in consistent tensile strength throughout the workpiece.

Warm Forging

Conducted at intermediate temperatures (750-950°C), warm forging offers a balance between the benefits of hot and cold forging. This process produces less scaling on the workpiece surface and achieves narrower tolerances than hot forging, while requiring lower forming forces than cold forging.

Cold Forging

Performed at room temperature or slightly elevated temperatures (up to 150°C due to deformation heating), cold forging achieves the tightest tolerances and excellent surface finish. However, it requires significantly higher forming forces and has limited formability compared to hot forging. Cold forging also increases strength through strain hardening.

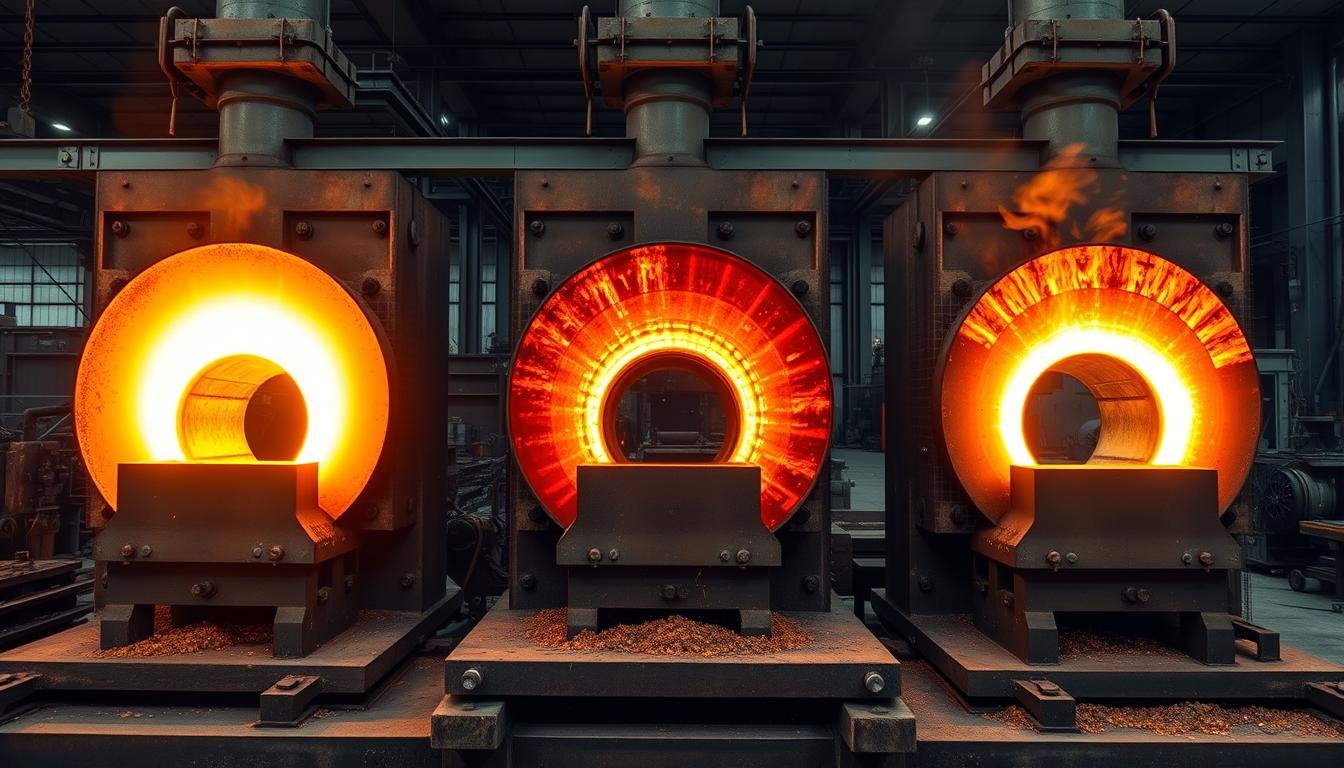

Visual comparison of steel at different forging temperatures: hot (left), warm (center), and cold (right)

Why Steel Forging Creates Superior Strength Components

The exceptional strength of forged steel components stems from several metallurgical advantages inherent to the forging process:

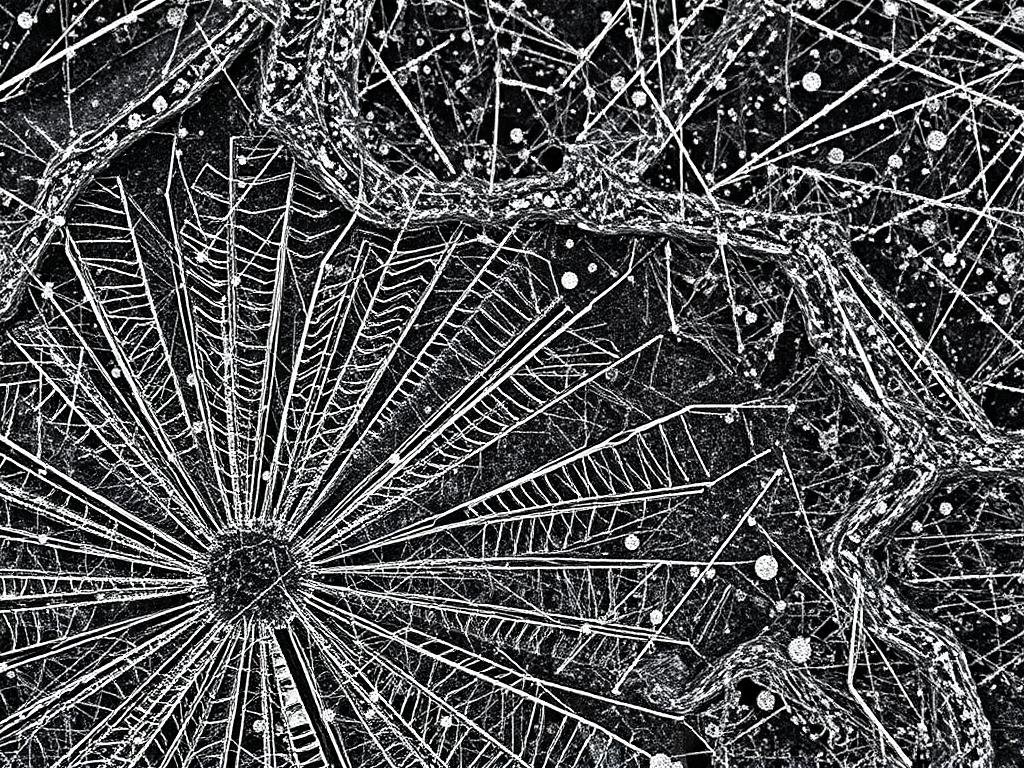

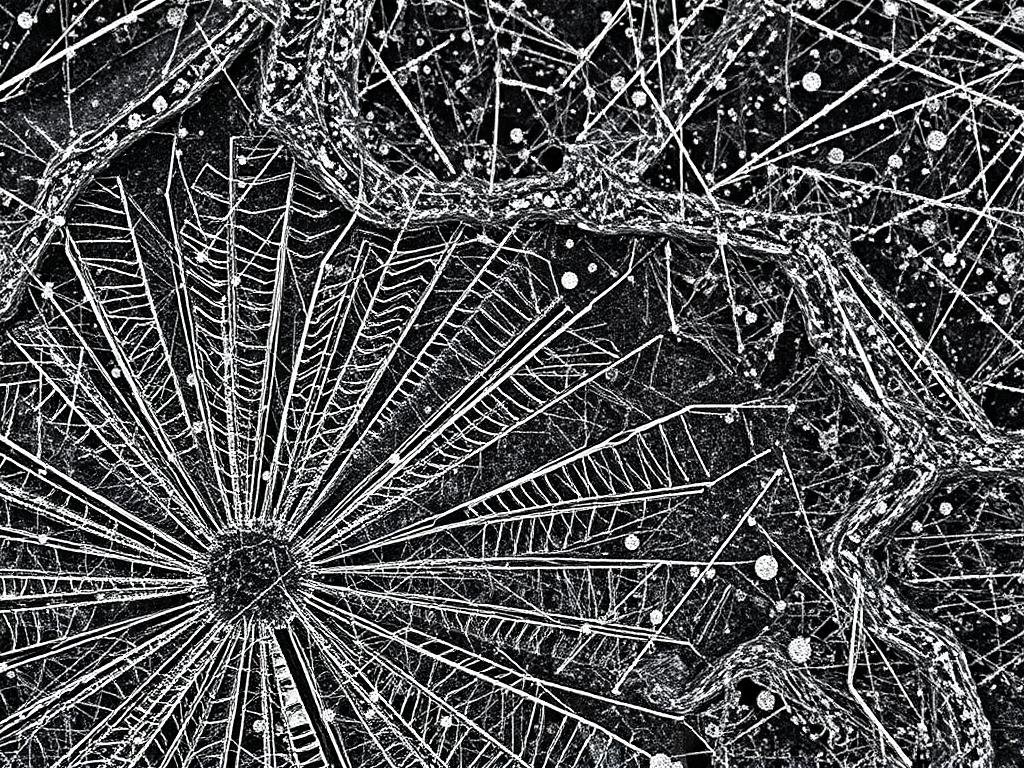

Microscopic view showing aligned grain structure in forged steel

Enhanced Grain Structure Through Steel Forging

One of the most significant advantages of steel forging is how it refines and aligns the metal’s grain structure. During the forging process, the steel’s internal grain structure deforms and flows in the direction of metal movement. This creates a continuous, aligned grain flow that follows the contours of the part, significantly enhancing its strength and toughness.

Unlike cast components, which have a random grain structure, forged parts have grains that are specifically oriented to provide maximum strength in the directions where the component will experience the greatest stress during use. This directional strength is particularly valuable in applications subject to high loads or impact forces.

Elimination of Internal Defects

The compressive forces applied during steel forging effectively close any internal voids or porosity that might exist in the original material. This consolidation creates a denser, more homogeneous structure that is less prone to failure under stress. Additionally, the process helps break up and distribute any inclusions (non-metallic particles) in the steel, minimizing their negative impact on the component’s strength.

| Property |

Forged Steel |

Cast Steel |

Machined Steel |

| Tensile Strength |

Superior |

Good |

Good |

| Impact Resistance |

Excellent |

Fair |

Good |

| Fatigue Resistance |

Excellent |

Fair |

Good |

| Internal Integrity |

Excellent |

Fair (potential porosity) |

Good |

| Grain Structure |

Directional, aligned |

Random |

Cut/interrupted |

Steel Forging vs. Alternative Manufacturing Methods

When comparing steel forging to other manufacturing processes, several key differences emerge that highlight why forging remains essential for critical applications:

Forging vs. Casting

While casting offers advantages in creating complex geometries and is often more economical for certain applications, steel forging produces components with superior mechanical properties:

Forging Advantages

- 20-30% higher strength-to-weight ratio

- Superior fatigue resistance

- Directional grain structure for enhanced strength

- Absence of internal porosity

- Better impact resistance

- More predictable mechanical properties

Casting Limitations

- Potential for internal porosity and shrinkage

- Lower mechanical strength

- Random grain structure

- Less predictable performance under stress

- Reduced fatigue resistance

- Limited directional strength properties

Forging vs. Machining

Machining from solid stock is another common manufacturing method, but it has significant differences compared to steel forging:

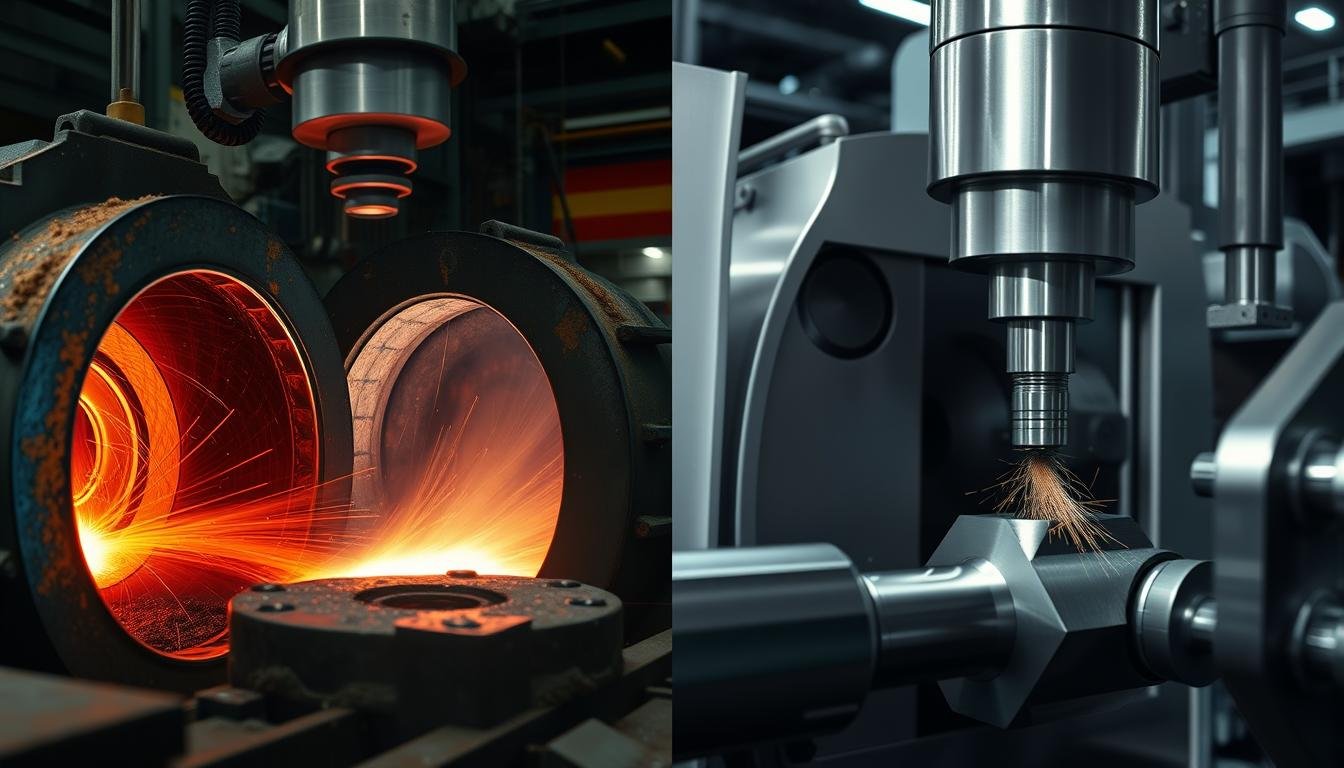

Comparison between forging (left) and CNC machining (right) manufacturing processes

Forging Advantages

- Preserves and enhances grain structure

- Improves strength through grain alignment

- Less material waste in many applications

- Superior performance in high-stress applications

- Better fatigue resistance

Machining Limitations

- Cuts through grain structure, potentially weakening parts

- Higher material waste

- Limited to available stock sizes

- Can be more expensive for high-volume production

- May require more raw material

Critical Industrial Applications for Steel Forging

Steel forging plays a vital role across numerous industries where component strength, reliability, and performance are non-negotiable requirements:

Automotive Industry

Forged steel components are essential in automotive applications where safety and durability are paramount. Critical components like crankshafts, connecting rods, transmission gears, steering knuckles, and axle beams are typically forged to withstand the high stresses and cyclical loading experienced during vehicle operation.

Aerospace Sector

The aerospace industry relies heavily on forged components for structural integrity and safety. Landing gear components, engine mounts, turbine discs, shafts, and structural airframe parts are commonly produced through forging to ensure they can withstand extreme conditions and provide reliable performance throughout their service life.

Oil & Gas Industry

In oil and gas extraction and processing, equipment must withstand harsh environments, high pressures, and corrosive substances. Forged components like valve bodies, wellhead equipment, pressure vessel components, and fittings provide the necessary strength and integrity for these demanding applications.

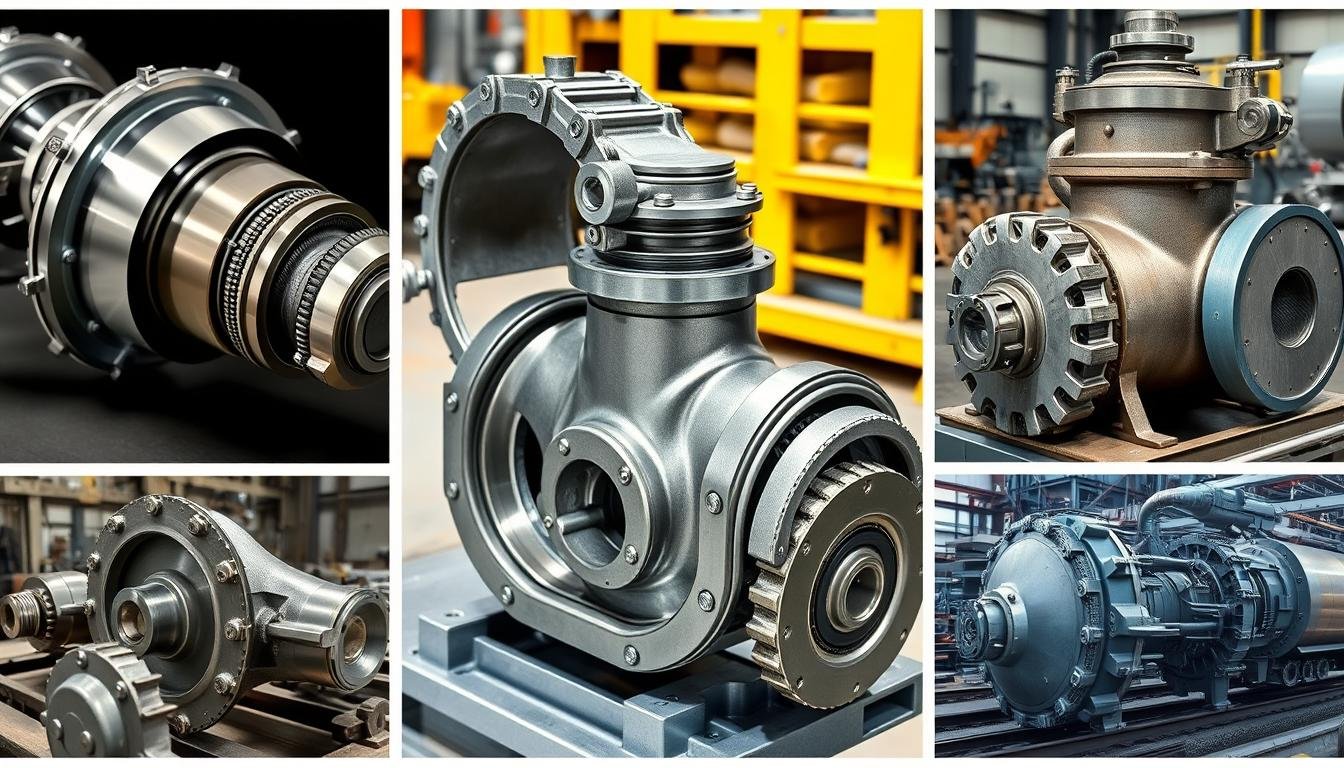

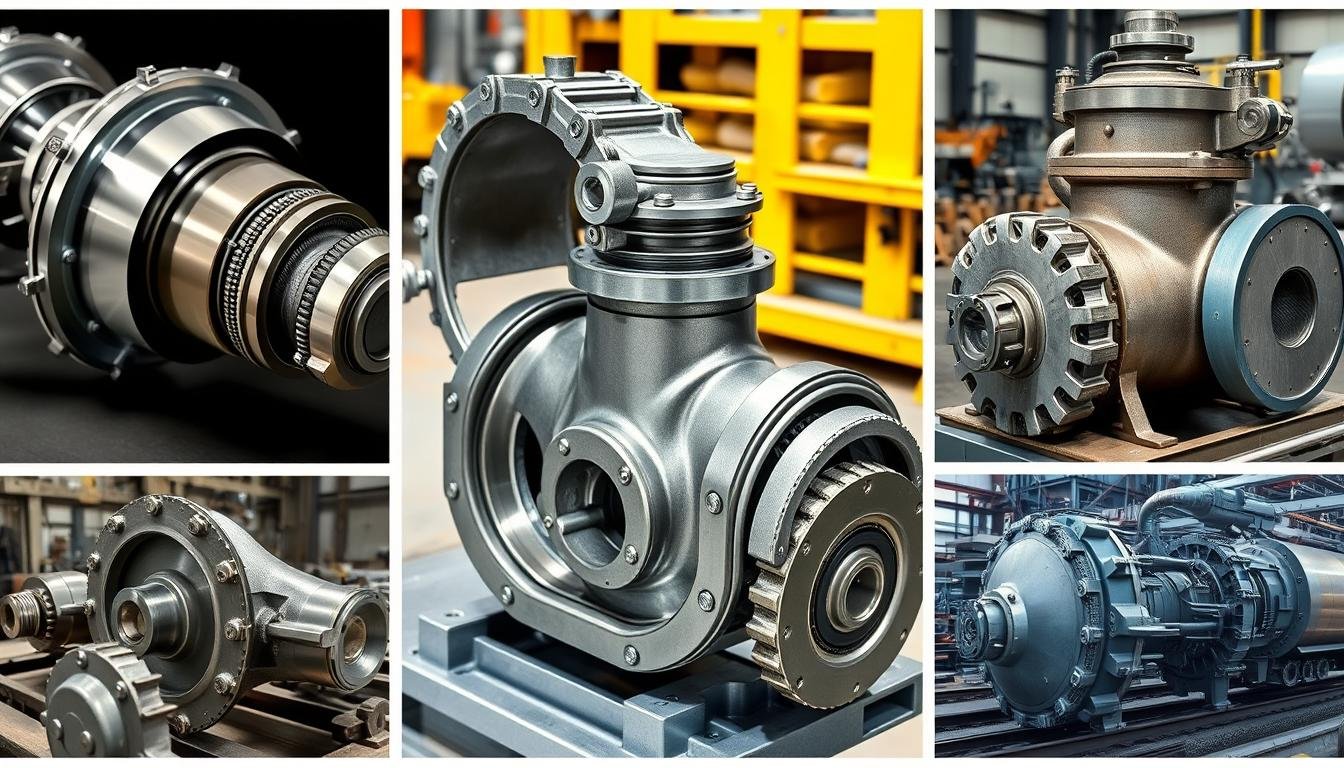

Steel forged components used in various industrial applications (left to right): automotive, aerospace, oil & gas, heavy machinery, and railway

Heavy Machinery

Construction and mining equipment operate under extreme conditions and heavy loads. Forged components such as gears, shafts, hydraulic cylinder components, and structural elements provide the necessary strength and durability for these demanding applications, ensuring reliable operation and minimizing downtime.

Railway Industry

Railway systems require components that can withstand enormous loads and continuous operation. Forged wheels, axles, couplings, and suspension components are critical for safety and reliability in rail transport, where failure could have catastrophic consequences.

Power Generation

In power plants, forged components are used in turbines, generators, and pressure vessels. These components must maintain their integrity under high temperatures, pressures, and mechanical stresses for decades of continuous operation, making the superior properties of forged steel essential.

MAIKONG’s Advanced Steel Forging Capabilities

At MAIKONG, we combine traditional steel forging expertise with modern technology to deliver superior components for demanding applications. Our comprehensive capabilities ensure we can meet the most challenging requirements across various industries.

MAIKONG’s state-of-the-art steel forging facility in GD, SZ

Comprehensive Steel Forging Services

Our steel forging capabilities encompass the full spectrum of processes required to deliver finished, high-quality components:

Design & Engineering

Our engineering team utilizes advanced CAD/CAM software to optimize component design for the forging process. We analyze material flow, stress distribution, and die filling to ensure optimal results. This engineering-driven approach helps identify and resolve potential issues before production begins, saving time and resources.

Material Selection

We work with a wide range of steel alloys, including carbon steels, alloy steels, tool steels, and stainless steels. Our metallurgical expertise ensures we select the optimal material for each application, considering factors such as strength requirements, operating environment, and cost-effectiveness.

Forging Processes

MAIKONG offers multiple forging methods, including open die, closed die, and roll forging. Our facility is equipped with modern hydraulic presses, mechanical presses, and hammers capable of producing components ranging from small precision parts to large industrial components.

Heat Treatment

Our in-house heat treatment capabilities allow us to precisely control the mechanical properties of forged components. We offer various heat treatment processes, including normalizing, annealing, quenching, and tempering, to achieve the desired hardness, strength, and toughness for each application.

Precision Machining

To provide complete solutions, we offer CNC machining services that complement our forging capabilities. Our advanced CNC machines can perform turning, milling, drilling, and grinding operations to achieve tight tolerances and superior surface finishes on forged components.

Quality Assurance

Our comprehensive quality control system includes material testing, dimensional inspection, non-destructive testing, and mechanical property verification. We maintain strict quality standards throughout the production process to ensure every component meets or exceeds customer specifications.

Quality inspection of precision steel forged components at MAIKONG

Steel Alloys Commonly Used in Forging Applications

The selection of appropriate steel alloys is crucial for achieving the desired properties in forged components. At MAIKONG, we work with a wide range of steel alloys, each offering specific advantages for different applications:

| Alloy Type |

Common Grades |

Key Properties |

Typical Applications |

| Carbon Steel |

1018, 1045, 1060 |

Good strength, ductility, and machinability; cost-effective |

Gears, shafts, fasteners, automotive components |

| Alloy Steel |

4140, 4340, 8620 |

Higher strength and hardenability than carbon steel; good toughness |

Crankshafts, connecting rods, gears, heavy machinery components |

| Stainless Steel |

304, 316, 410, 17-4PH |

Excellent corrosion resistance; good high-temperature properties |

Valve components, marine applications, food processing equipment |

| Tool Steel |

H13, D2, A2, S7 |

High hardness, wear resistance, and heat resistance |

Dies, tools, industrial knives, high-wear components |

| Microalloyed Steel |

HSLA grades |

High strength with good formability; reduced heat treatment requirements |

Automotive components, structural parts, fasteners |

Our metallurgical expertise allows us to recommend the optimal steel alloy for each application, considering factors such as mechanical requirements, operating environment, cost constraints, and processing characteristics. This ensures that the final forged components deliver the performance and reliability our customers expect.

Quality Assurance in Steel Forging Production

At MAIKONG, we implement rigorous quality control measures throughout the steel forging process to ensure consistent, high-quality components that meet or exceed customer specifications:

MAIKONG’s material testing laboratory for comprehensive quality verification

Comprehensive Testing Protocols

Our quality assurance program includes a range of testing methods to verify the integrity and performance of our forged components:

Material Verification

- Chemical composition analysis

- Microstructure examination

- Grain size and flow evaluation

- Inclusion content assessment

Mechanical Testing

- Tensile strength testing

- Yield strength verification

- Hardness testing

- Impact resistance testing

- Fatigue testing when required

Non-Destructive Testing

- Ultrasonic inspection

- Magnetic particle testing

- Dye penetrant inspection

- Radiographic testing when required

- Visual inspection

Our in-house testing capabilities allow us to verify that each component meets the specified requirements before shipment. This comprehensive approach to quality assurance gives our customers confidence in the reliability and performance of our forged components, even in the most demanding applications.

Cost-Efficiency Considerations in Steel Forging

While steel forging offers superior mechanical properties, cost considerations are also important for many applications. At MAIKONG, we focus on optimizing the cost-efficiency of our forging processes without compromising quality:

Factors Affecting Forging Costs

- Material selection: Choosing the appropriate steel alloy that meets performance requirements without unnecessary cost premium

- Design optimization: Engineering components to minimize material usage while maintaining required strength

- Process selection: Selecting the most efficient forging method for each component

- Production volume: Leveraging economies of scale for higher volume production

- Tooling design: Creating efficient, durable dies that minimize waste and maximize productivity

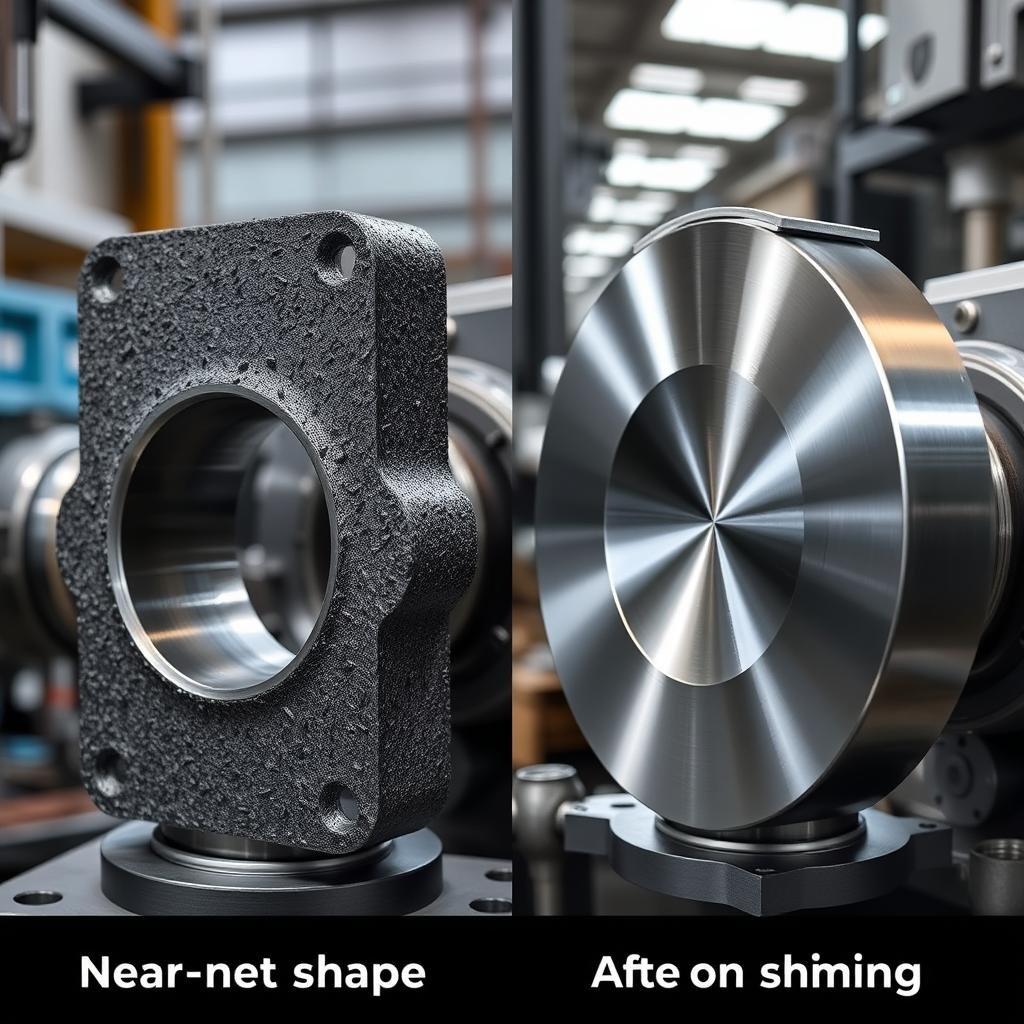

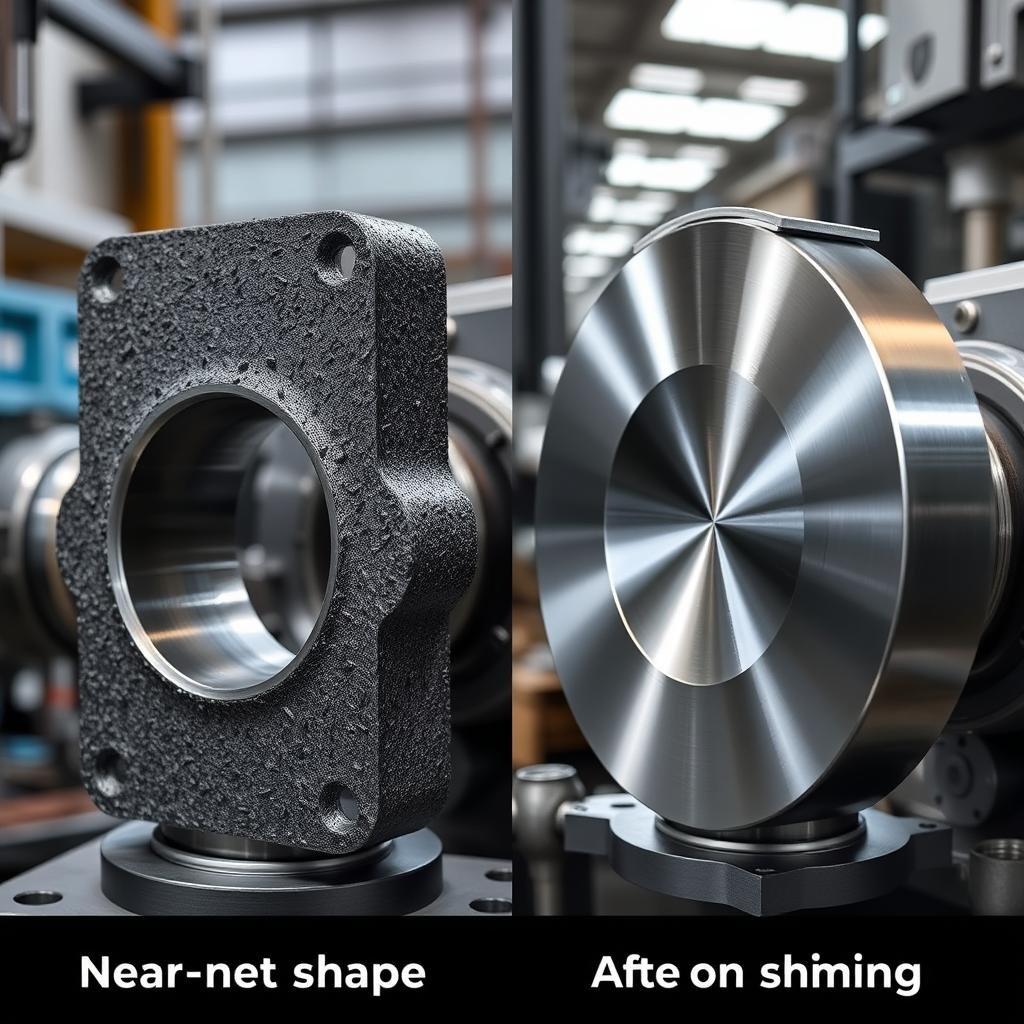

- Near-net shape forging: Reducing secondary machining requirements through precision forging

Near-net shape forging (left) reduces machining requirements for finished components (right)

MAIKONG’s Cost-Efficiency Advantage

At MAIKONG, we provide exceptional value through our integrated approach to steel forging:

- Vertical integration: Our comprehensive in-house capabilities from design to finishing reduce outsourcing costs and lead times

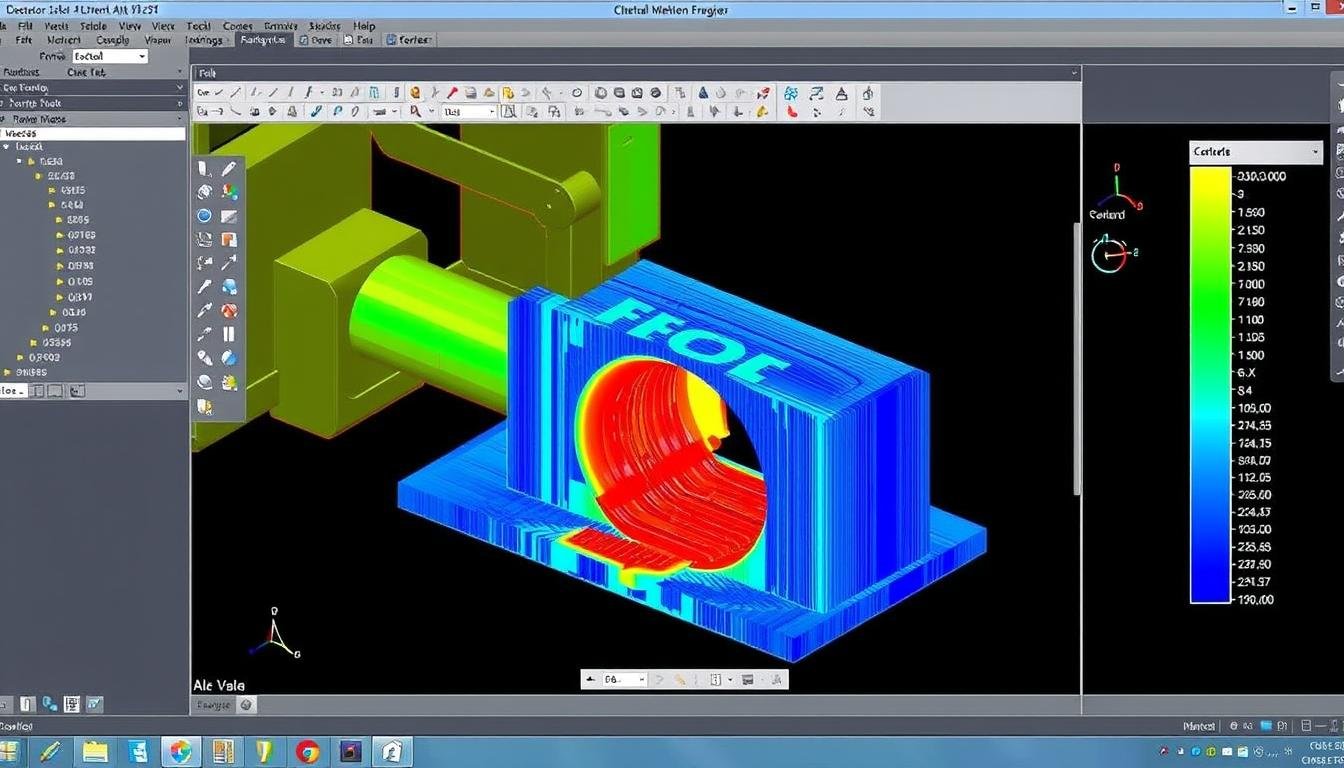

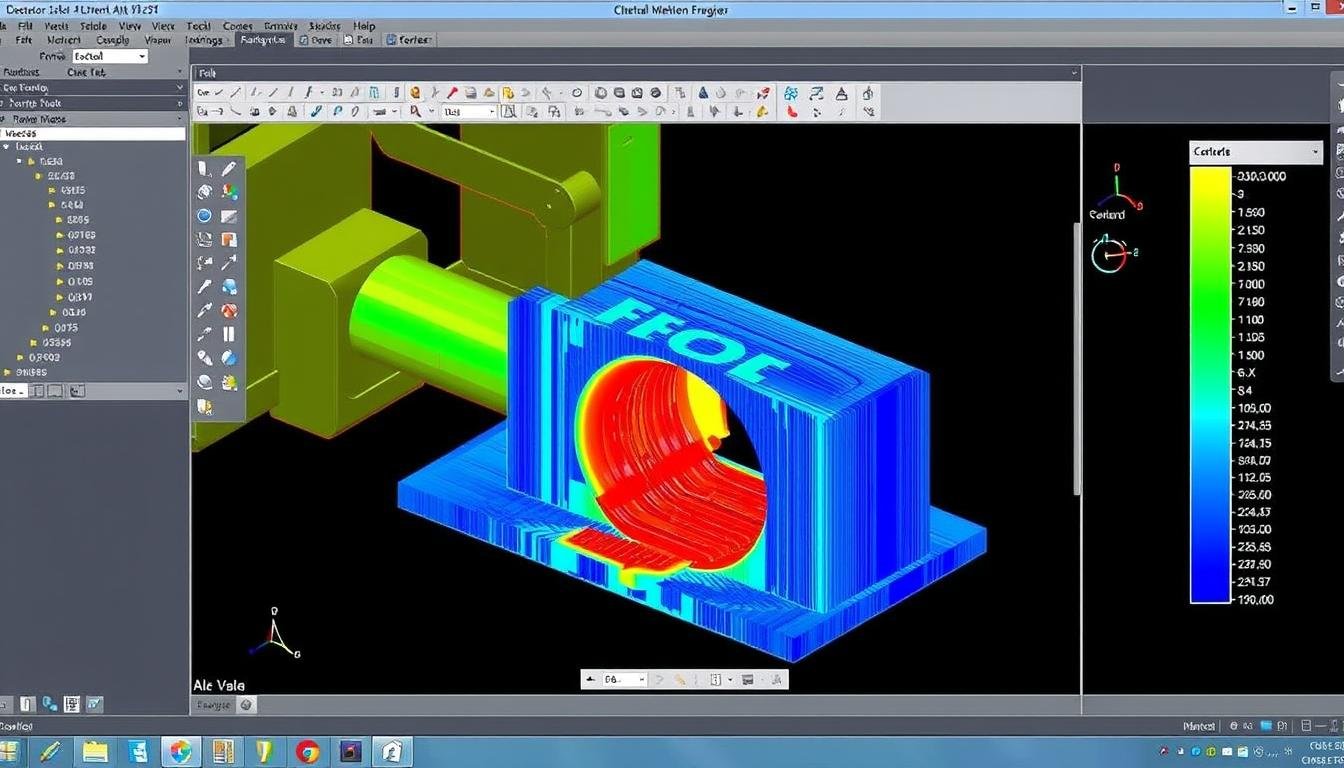

- Advanced simulation: Computer modeling of the forging process minimizes trial-and-error and reduces waste

- Lean manufacturing: Efficient production processes minimize waste and maximize productivity

- Strategic location: Our facilities in GD, SZ provide cost advantages while maintaining high quality standards

- Volume flexibility: We efficiently handle both high-volume production and smaller specialty runs

Computer simulation used at MAIKONG to optimize steel forging processes and reduce costs

Future Trends in Steel Forging Technology

The steel forging industry continues to evolve, with several emerging trends shaping the future of this critical manufacturing process:

Precision Forging

Advanced precision forging techniques are reducing or eliminating the need for secondary machining operations. By achieving near-net shape components with tighter tolerances directly from the forging process, manufacturers can significantly reduce production costs and lead times while maintaining the superior mechanical properties of forged components.

Simulation and Modeling

Sophisticated computer simulation tools are revolutionizing the forging design process. Finite element analysis (FEA) and computational fluid dynamics (CFD) allow engineers to model material flow, predict defects, and optimize die designs before physical production begins. This reduces development time and costs while improving first-time quality.

Advanced Alloys

The development of new steel alloys with enhanced properties is expanding the capabilities of forged components. These advanced materials offer improved combinations of strength, toughness, corrosion resistance, and high-temperature performance, enabling forged components to meet increasingly demanding application requirements.

At MAIKONG, we stay at the forefront of these technological advancements, continuously investing in new capabilities to provide our customers with the most advanced steel forging solutions available.

Why Steel Forging Remains Essential for Modern Manufacturing

Despite advances in alternative manufacturing methods, steel forging continues to be irreplaceable for applications where strength, reliability, and performance are critical. The unique combination of directional grain structure, material integrity, and mechanical properties achieved through forging cannot be matched by casting or machining alone.

At MAIKONG, we combine traditional forging expertise with modern technology to deliver superior components that meet the most demanding requirements. Our comprehensive capabilities from design through production and our commitment to quality and cost-efficiency make us the ideal partner for your critical component needs.

Contact us today to discuss how our steel forging solutions can enhance the performance and reliability of your products while optimizing your total manufacturing costs.