The Steel Forging Process stands as one of manufacturing’s most foundational and enduring metalworking techniques. Dating back thousands of years yet continuously evolving with modern technology, steel forging transforms raw metal into components with unmatched strength and durability. This comprehensive guide explores how raw steel becomes precision-engineered parts through the application of heat and pressure, revealing why forged components remain essential in industries where failure is not an option.

Key Aspects of the Steel Forging Process

- Superior Strength – The Steel Forging Process creates components with exceptional strength-to-weight ratios by refining grain structure and eliminating internal defects

- Process Versatility – Multiple forging methods including open die, closed die, and precision forging allow for customization based on part requirements

- Material Optimization – Forging enhances steel’s inherent properties while minimizing waste compared to other manufacturing methods

- Critical Applications – Forged steel components are essential in aerospace, automotive, energy, and defense industries where reliability is paramount

- Quality Assurance – Rigorous testing throughout the Steel Forging Process ensures components meet exact specifications

The Steel Forging Process transforms raw steel into precision components through controlled application of heat and pressure

The Evolution of Steel Forging

The origins of metal forging trace back to ancient civilizations, with evidence of rudimentary forging techniques dating to 4000 BC in Mesopotamia. Early blacksmiths discovered that heating metal in fire made it more malleable and easier to shape with hammers. This fundamental principle remains at the core of modern Steel Forging Process techniques, though today’s methods incorporate advanced technology, precise temperature control, and sophisticated tooling.

The Industrial Revolution marked a pivotal advancement in forging technology with the introduction of steam-powered hammers and hydraulic presses. These innovations enabled the production of larger, more complex steel components with greater consistency. Today’s Steel Forging Process combines these traditional principles with computer-controlled equipment, advanced metallurgy, and precision engineering to create components that meet exacting specifications for the most demanding applications.

The evolution from traditional blacksmithing to modern automated Steel Forging Process equipment

Fundamentals of the Steel Forging Process

At its core, the Steel Forging Process involves applying compressive force to heated steel to shape it into desired forms. Unlike casting, which melts metal completely, forging works with solid metal that has been heated to a malleable state. This fundamental difference results in components with superior grain structure and mechanical properties.

How Forging Strengthens Steel

The Steel Forging Process significantly enhances the mechanical properties of the base material through several mechanisms:

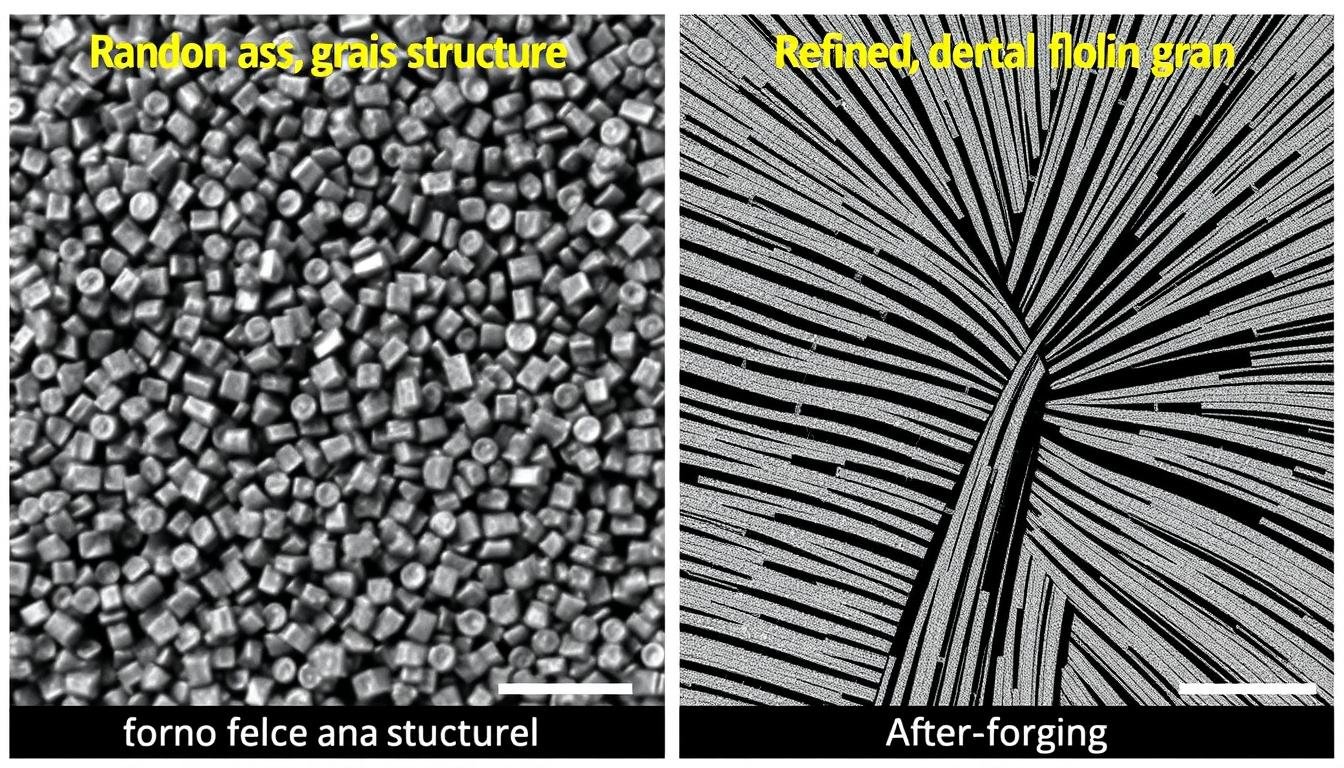

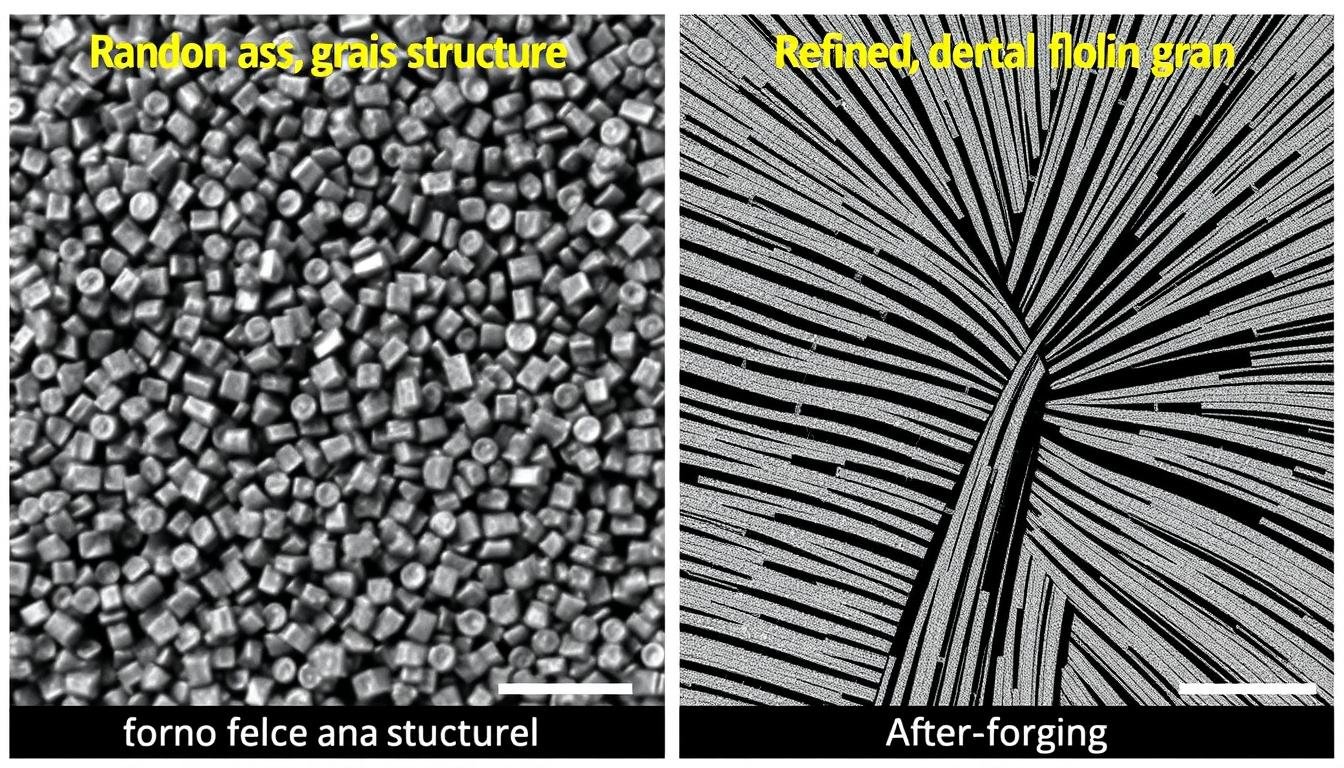

Grain Structure Refinement

During forging, the steel’s internal grain structure is compressed and realigned to follow the contours of the part. This directional grain flow creates a “fiber” structure that dramatically increases strength along primary stress axes. Unlike cast or machined parts with random grain orientation, forged components have predictable, engineered grain patterns that maximize performance under load.

Elimination of Defects

The intense pressure applied during the Steel Forging Process effectively closes internal voids and seals minor cracks that might exist in the raw material. Additionally, impurities in the steel are broken up and redistributed, significantly reducing the presence of inclusions that could serve as stress concentration points in the finished component.

Microscopic view showing how the Steel Forging Process refines and aligns steel’s grain structure

Steel Forging Process Methods and Classifications

The Steel Forging Process encompasses several distinct methods, each offering unique advantages for specific applications. Understanding these variations helps in selecting the optimal approach for particular component requirements.

Classification by Temperature

Hot Forging

Performed at temperatures above steel’s recrystallization point (typically 1100-1250°C), hot forging is the most common Steel Forging Process method. At these elevated temperatures, steel becomes highly malleable, requiring less force to deform. This approach is ideal for creating large components or complex geometries with significant material displacement.

Warm Forging

Operating at intermediate temperatures (700-950°C), warm forging balances the benefits of hot and cold processes. This temperature range provides good material flow while delivering better dimensional accuracy and surface finish than hot forging. Warm forging requires more force than hot methods but typically produces parts with superior mechanical properties.

Cold Forging

Conducted at room temperature or slightly elevated temperatures below recrystallization, cold forging delivers exceptional dimensional precision and surface finish. While limited to less dramatic deformation than hot methods, cold forging produces parts with excellent mechanical properties and often eliminates the need for additional finishing operations.

Classification by Tooling and Equipment

Modern Steel Forging Process facility with various forging equipment types

Open Die Forging

In open die forging, also known as free forging, the steel workpiece is compressed between flat or simply shaped dies that do not completely constrain the metal. This Steel Forging Process method requires skilled operators who manipulate the workpiece between strikes to achieve the desired shape. Open die forging is ideal for large components, custom parts with simple geometries, or low-volume production runs.

Closed Die Forging

Also called impression die forging, this method uses two or more dies with cavities that match the desired part geometry. The heated steel is placed in the lower die, and the upper die descends to force the metal to fill the cavities. Closed die forging delivers more complex geometries with tighter tolerances than open die methods, making it suitable for high-volume production of precision components.

Roll Forging

Roll forging uses rotating dies to progressively shape a heated steel bar or billet. As the workpiece passes between the rolls, its cross-section is reduced while its length increases. This Steel Forging Process technique is particularly effective for producing long components with varying cross-sections, such as axles, shafts, and leaf springs.

Precision Forging

A specialized form of closed die forging, precision forging aims to produce near-net-shape components that require minimal finishing. Using precisely machined dies and carefully controlled process parameters, this method delivers components with exceptional dimensional accuracy and surface finish, often eliminating or significantly reducing secondary machining operations.

Step-by-Step Steel Forging Process

The journey from raw steel to finished forged component involves several critical stages, each contributing to the quality and performance of the final product.

- Material Selection and Preparation – The process begins with selecting the appropriate steel grade based on the component’s requirements. The raw material, typically in the form of billets or ingots, is cut to the required size and inspected for quality.

- Heating – The steel is heated in a furnace to its optimal forging temperature, which varies depending on the specific alloy. Precise temperature control is critical, as overheating can damage the material’s properties while underheating makes deformation difficult.

- Forging – The heated steel is transferred to the forging equipment, where it undergoes controlled deformation through hammering, pressing, or rolling. Complex components may require multiple forging operations with reheating between steps.

- Trimming and Punching – Excess material (flash) created during closed die forging is removed, and any required holes or openings are punched into the still-hot component.

- Heat Treatment – After forging, components undergo heat treatment processes such as normalizing, annealing, quenching, and tempering to achieve the desired mechanical properties.

- Finishing Operations – Depending on specifications, forged parts may undergo machining, grinding, or other finishing operations to achieve final dimensions and surface requirements.

- Quality Inspection – Finished components are subjected to rigorous inspection and testing to verify dimensional accuracy, surface quality, and mechanical properties.

Complete workflow of the Steel Forging Process from raw material to finished component

Essential Equipment in the Steel Forging Process

Modern steel forging relies on specialized equipment that combines traditional principles with advanced technology. Each type of forging equipment offers distinct capabilities and advantages.

Forging Hammers

Hammers deliver rapid, high-energy blows to shape the workpiece. Modern power hammers range from smaller air-powered units to massive steam or hydraulic hammers capable of delivering blows with forces exceeding 50,000 pounds. The impact nature of hammer forging is particularly effective for initial shaping and breaking down larger workpieces.

Hydraulic Presses

Unlike hammers, presses apply steady, controlled pressure to deform the workpiece. Hydraulic presses used in the Steel Forging Process can generate forces from hundreds to tens of thousands of tons. The controlled nature of press forging allows for more precise deformation throughout the entire volume of the workpiece, resulting in more consistent properties.

Forging Furnaces

Specialized heating equipment is essential for bringing steel to optimal forging temperatures. Modern forging operations use gas-fired or electric furnaces with precise temperature control. Advanced facilities may employ induction heating systems that rapidly heat the workpiece while minimizing scale formation and energy consumption.

State-of-the-art hydraulic press used in MAIKONG’s Steel Forging Process

Advantages of the Steel Forging Process Over Other Manufacturing Methods

When compared to alternative manufacturing techniques such as casting, machining, or powder metallurgy, the Steel Forging Process offers several significant advantages for critical applications.

Advantages of Forged Steel Components

- Superior strength and toughness due to refined grain structure

- Excellent fatigue resistance and impact strength

- Consistent mechanical properties throughout the component

- Higher reliability in safety-critical applications

- Better performance under dynamic and shock loading

- Enhanced resistance to wear and deformation

- Excellent structural integrity with minimal internal defects

Limitations to Consider

- Higher initial tooling costs for complex geometries

- Certain complex shapes may be difficult to achieve

- May require secondary machining for tight tolerances

- Higher energy consumption compared to some processes

- Not economical for very small production runs

- Limited to metals with sufficient ductility

Comparison: Steel Forging vs. Casting

| Property |

Steel Forging |

Steel Casting |

| Grain Structure |

Refined, directional grain flow |

Random grain orientation |

| Tensile Strength |

20-40% higher than casting |

Lower due to porosity and inclusions |

| Fatigue Resistance |

Excellent resistance to cyclic loading |

Moderate, limited by internal defects |

| Internal Defects |

Minimal to none |

Potential for porosity and shrinkage |

| Geometric Complexity |

Limited by die design and material flow |

Excellent for complex internal geometries |

| Production Volume |

Economical for medium to high volumes |

Suitable for low to medium volumes |

| Material Utilization |

Efficient with minimal waste |

Requires additional material for risers and gates |

Industrial Applications of the Steel Forging Process

The exceptional mechanical properties and reliability of forged steel components make them indispensable across numerous industries where performance and safety are paramount.

Automotive Industry

The automotive sector relies heavily on forged steel components for critical drivetrain and suspension parts. Crankshafts, connecting rods, transmission gears, and steering knuckles are typically produced using the Steel Forging Process to ensure durability under the constant stress of vehicle operation. The superior fatigue resistance of forged components is particularly valuable in these applications.

Aerospace and Defense

In aerospace applications, where component failure can have catastrophic consequences, forged steel parts are essential. Landing gear components, turbine discs, structural fittings, and critical fasteners benefit from the exceptional strength-to-weight ratio and reliability of forged steel. The Steel Forging Process ensures these components can withstand extreme conditions and stress.

Energy Sector

Power generation and oil & gas industries utilize forged steel components for their durability in harsh environments. Turbine shafts, valve bodies, pressure vessels, and drilling equipment components are manufactured using specialized Steel Forging Process techniques to ensure long-term performance under extreme pressures, temperatures, and corrosive conditions.

Heavy Machinery

Construction and mining equipment operate under punishing conditions that demand exceptional component strength. Excavator arms, bulldozer links, gears, and shafts for heavy machinery are forged to withstand constant shock loading and abrasive environments. The Steel Forging Process creates parts with the necessary durability for these demanding applications.

Railway Industry

Railway systems rely on forged steel components for safety and longevity. Train wheels, axles, coupling systems, and track components are manufactured using specialized Steel Forging Process methods to ensure they can withstand the enormous cyclic loads and impact forces inherent in rail operations.

Hand Tools and Industrial Equipment

Professional-grade hand tools and industrial equipment benefit from the durability of forged steel. Wrenches, hammers, pliers, and specialized industrial tools are forged to provide superior strength and wear resistance. The directional grain structure created during the Steel Forging Process makes these tools resistant to bending and breaking under heavy use.

Diverse applications of components manufactured using the Steel Forging Process

Quality Assurance in the Steel Forging Process

Ensuring the quality and reliability of forged steel components requires rigorous testing and inspection throughout the manufacturing process. Modern quality assurance protocols combine traditional methods with advanced technologies to verify that each component meets exact specifications.

Non-Destructive Testing Methods

Ultrasonic Testing

Ultrasonic inspection uses high-frequency sound waves to detect internal defects without damaging the component. This method is particularly valuable for examining large forged parts where internal integrity is critical. Advanced ultrasonic systems can create detailed 3D maps of a component’s internal structure, revealing even minute flaws that might compromise performance.

Magnetic Particle Inspection

This method detects surface and near-surface defects in ferromagnetic materials. The forged component is magnetized, and fine magnetic particles are applied to the surface. These particles concentrate at discontinuities in the magnetic field caused by defects, making them visible under proper lighting conditions.

Dye Penetrant Inspection

Used primarily for non-ferrous forged components, this method involves applying a visible or fluorescent dye to the surface, which penetrates any surface-breaking defects. After removing excess dye, a developer draws the penetrant out of defects, making them visible for inspection.

Radiographic Testing

X-ray or gamma-ray imaging reveals internal defects in forged components. This technique is particularly valuable for critical components where complete volumetric inspection is necessary to ensure integrity.

Mechanical Testing

Beyond non-destructive methods, mechanical testing verifies that forged components possess the required strength and performance characteristics:

- Tensile Testing – Measures the component’s strength under tension until failure

- Impact Testing – Evaluates the material’s ability to absorb energy during sudden loading

- Hardness Testing – Determines the material’s resistance to indentation

- Fatigue Testing – Assesses performance under cyclic loading conditions

- Metallographic Examination – Analyzes grain structure and material composition

MAIKONG’s quality control specialists performing ultrasonic inspection on forged steel components

MAIKONG’s Advanced Steel Forging Process Capabilities

At MAIKONG, we combine traditional forging expertise with cutting-edge technology to deliver superior quality forged steel components. Our comprehensive capabilities encompass the entire manufacturing process from design to delivery.

State-of-the-Art Equipment

Our manufacturing facility in GD, SZ features advanced forging equipment including hydraulic presses ranging from 800 to 3000 tons, CNC-controlled manipulators, and precision heating systems. This modern machinery allows us to handle a wide range of part sizes and geometries with exceptional precision and consistency.

Material Expertise

MAIKONG’s metallurgists possess extensive knowledge of various steel grades and their optimal forging parameters. We work with carbon steels, alloy steels, tool steels, and specialty grades to deliver components with the exact mechanical properties required for your application.

Comprehensive Services

Beyond our core Steel Forging Process capabilities, we offer integrated services including heat treatment, CNC machining, surface finishing, and comprehensive testing. This full-service approach ensures consistent quality and simplifies your supply chain.

MAIKONG’s state-of-the-art steel forging facility in GD, SZ

Our Steel Forging Process Advantages

Advanced Process Control

MAIKONG employs sophisticated process monitoring and control systems throughout our Steel Forging Process. Digital temperature monitoring, force measurement, and automated material handling ensure consistent quality and repeatability across production runs. This advanced control capability is particularly valuable for critical components with stringent performance requirements.

Design Optimization

Our engineering team utilizes advanced simulation software to optimize die design and process parameters before production begins. This computational approach allows us to identify and address potential issues early in the development process, reducing lead times and ensuring first-article quality.

Experience MAIKONG’s Superior Steel Forging Capabilities

Our team of experts is ready to discuss your specific requirements and demonstrate how our advanced Steel Forging Process can deliver exceptional components for your application.

Request a Consultation

Comprehensive Manufacturing Services at MAIKONG

Beyond our core Steel Forging Process expertise, MAIKONG offers a complete range of manufacturing services to meet your diverse production needs.

CNC Machining Services

Our advanced CNC machining center complements our forging capabilities, allowing us to deliver precision-finished components. With multi-axis machining centers, CNC lathes, and specialized equipment, we provide comprehensive machining services including:

- Precision CNC milling

- CNC turning operations

- Multi-axis machining

- Custom CNC parts production

Additional Metal Forging Capabilities

While steel forging represents a significant portion of our business, MAIKONG also specializes in forging other metals to meet diverse application requirements:

- Aluminum forging services

- Brass forging

- Custom metal parts

- Specialty alloy forging

Complementary Services

To provide truly comprehensive manufacturing solutions, we offer additional services that enhance our core capabilities:

- Heat treatment

- Surface finishing

- Contract manufacturing

- Prototyping services

- Custom metal fabrication

MAIKONG’s precision CNC machining center processing forged steel components

Industries We Serve

MAIKONG’s advanced Steel Forging Process capabilities and comprehensive manufacturing services support critical applications across numerous industries:

Automotive

- Crankshafts

- Connecting rods

- Transmission components

- Steering knuckles

- Suspension parts

Aerospace

- Landing gear components

- Structural fittings

- Engine mounts

- Control system parts

- Critical fasteners

Energy

- Valve bodies

- Turbine components

- Pressure vessel fittings

- Pipeline components

- Drilling equipment

Industrial Equipment

- Heavy machinery parts

- Construction equipment

- Mining components

- Material handling systems

- Industrial tooling

Diverse range of precision components produced through MAIKONG’s Steel Forging Process

Conclusion: The Enduring Value of the Steel Forging Process

The Steel Forging Process remains one of the most reliable manufacturing methods for producing components with exceptional strength, durability, and performance. From ancient blacksmiths to modern computer-controlled forging operations, the fundamental principles of applying heat and pressure to shape metal have stood the test of time while continuously evolving with technological advances.

At MAIKONG, we combine this time-tested process with cutting-edge technology and comprehensive manufacturing capabilities to deliver superior forged components for the most demanding applications. Whether you require high-volume production of standard parts or specialized components for critical applications, our team has the expertise and equipment to exceed your expectations.

Contact us today to discover how our advanced Steel Forging Process capabilities can enhance your products and operations through superior component quality, reliability, and performance.