Engineering excellence begins with proper material selection and manufacturing process specifications. When designing critical components that demand superior strength, durability, and performance under extreme conditions, steel forged components offer unparalleled advantages over alternative manufacturing methods. This comprehensive guide explores the essential technical considerations, material properties, and quality control measures necessary when specifying steel forged parts for your applications.

The Superior Advantages of Steel Forged Components

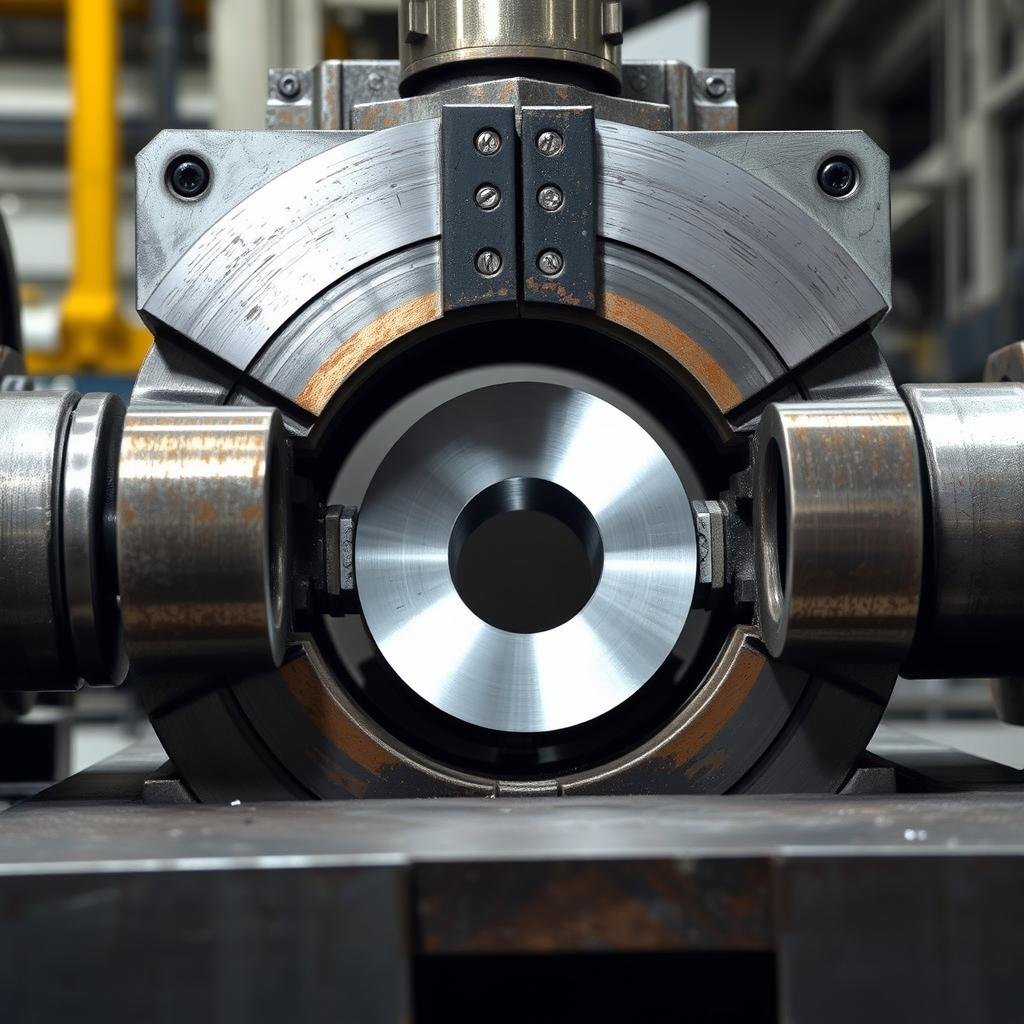

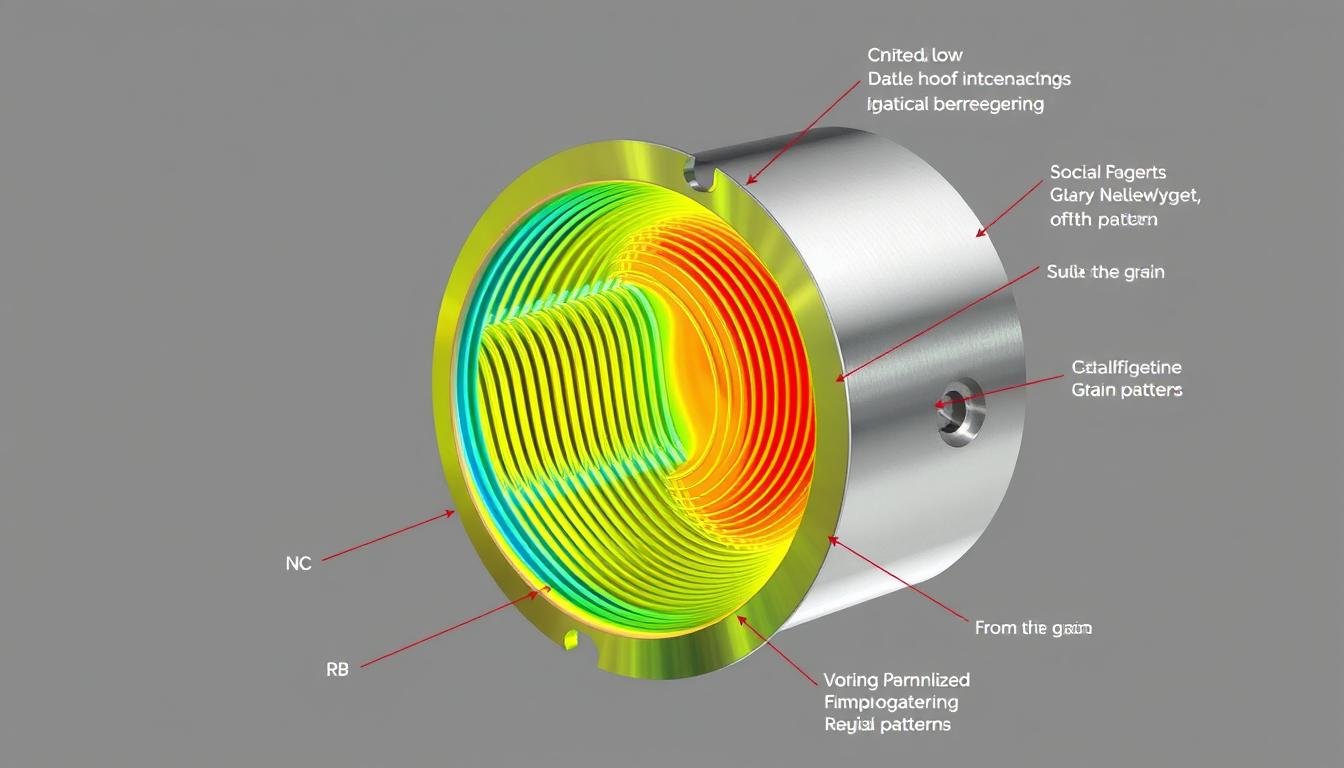

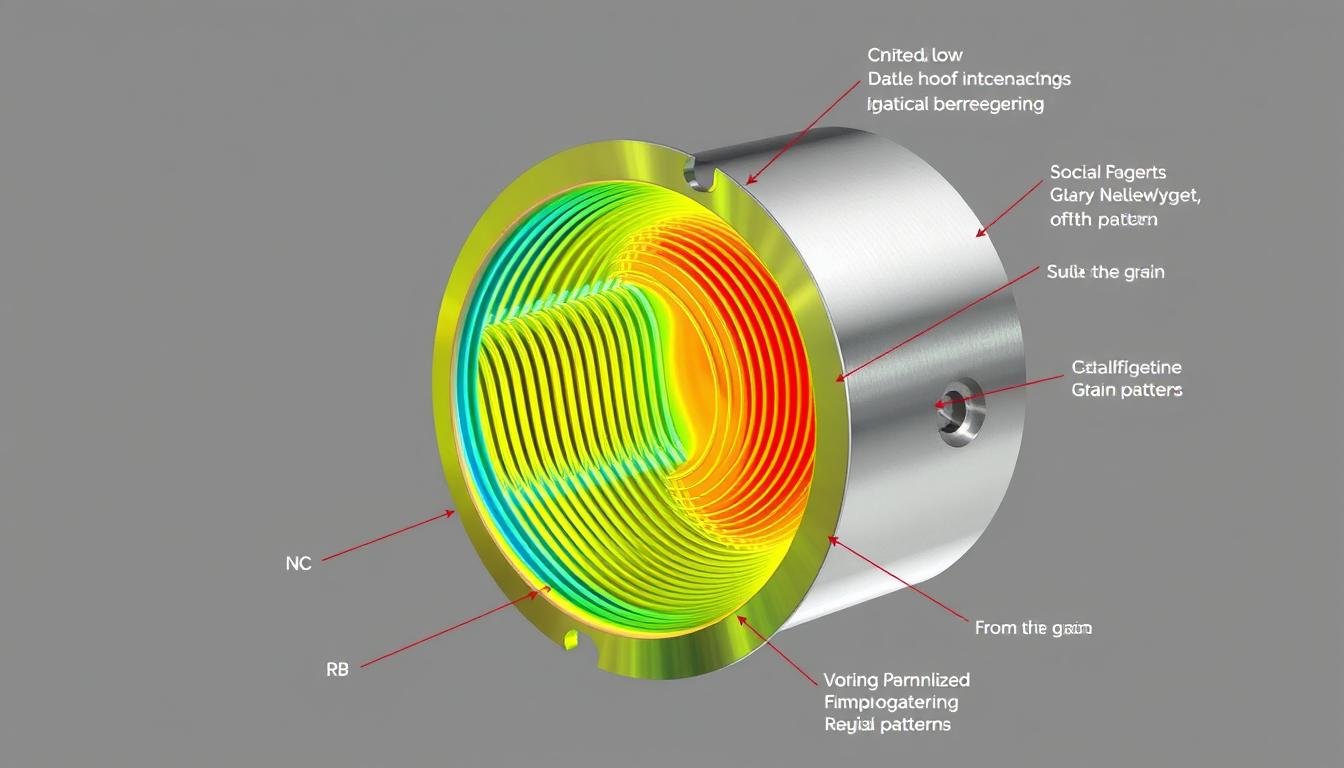

Superior grain structure of steel forged components provides enhanced mechanical properties

Superior grain structure of steel forged components provides enhanced mechanical properties

The forging process fundamentally transforms the internal structure of steel, creating components with exceptional mechanical properties that simply cannot be achieved through casting or machining alone. When metal is forged, it undergoes controlled deformation under pressure, which aligns and refines the grain structure while eliminating internal voids and porosity.

Advantages of Steel Forged Components

- Superior strength-to-weight ratio

- Enhanced fatigue resistance

- Improved impact toughness

- Consistent mechanical properties

- Refined grain structure

- Elimination of internal voids

- Greater reliability in critical applications

Limitations to Consider

- Higher initial tooling costs

- Design constraints for complex geometries

- Longer lead times for custom tooling

- Higher unit costs for low-volume production

- Surface finish may require secondary operations

Need Expert Guidance on Steel Forged Components?

Our engineering team can help determine if forging is the optimal manufacturing process for your application.

Get Expert Advice

Forging vs. Casting: Critical Performance Differences

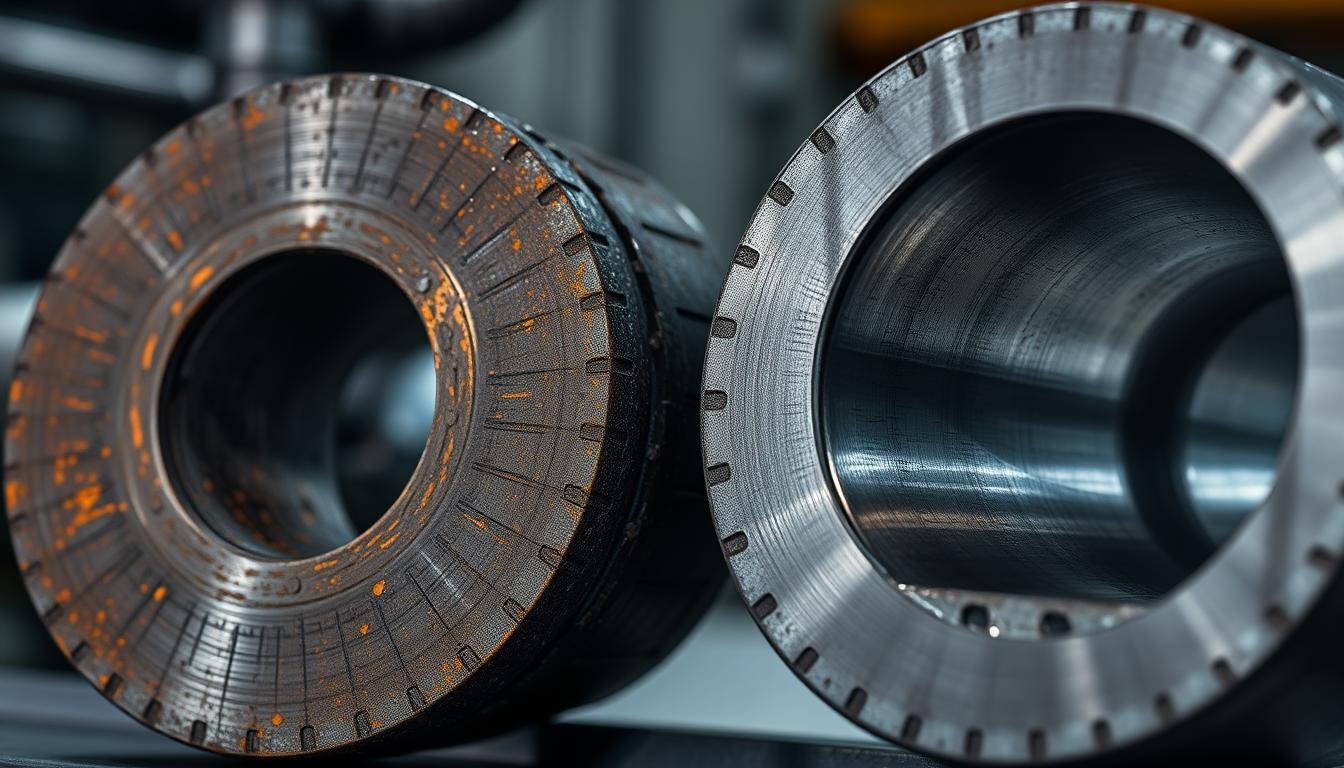

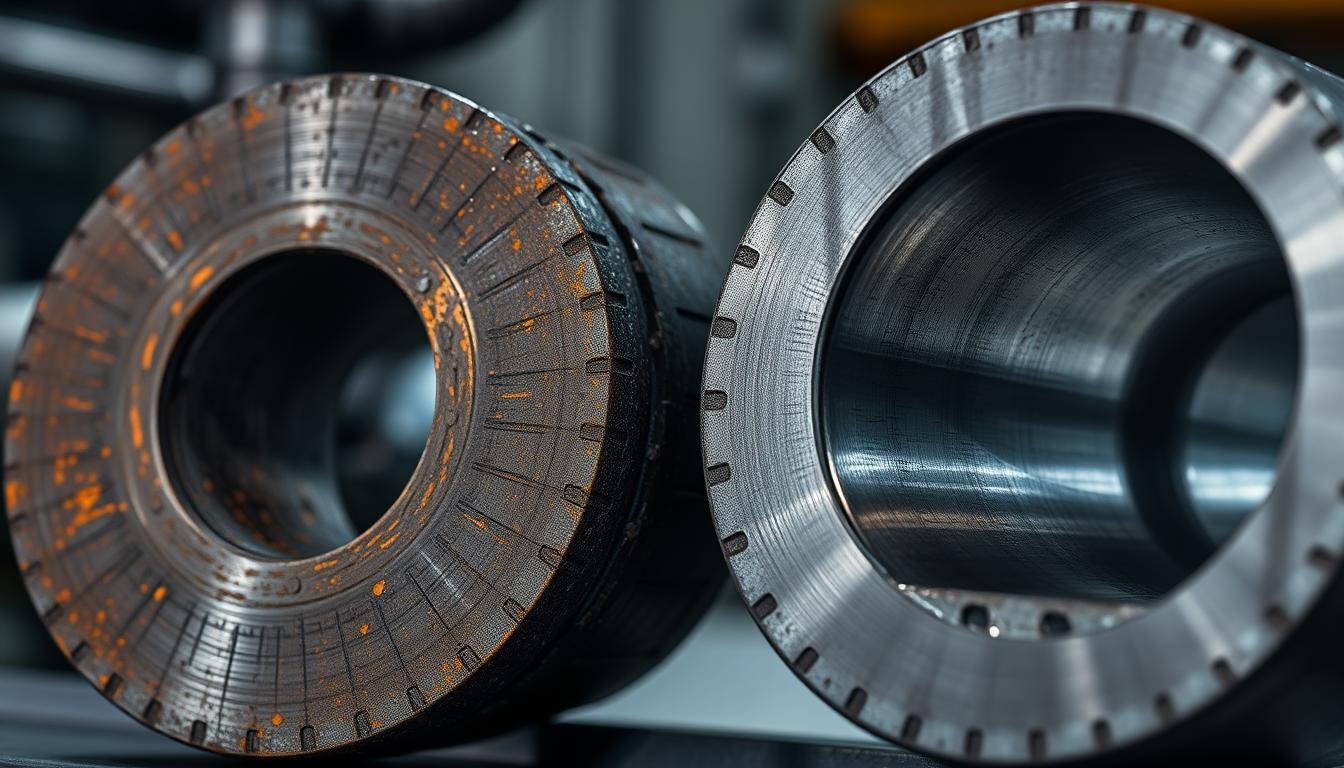

Stress testing reveals superior performance of steel forged components

When specifying components for critical applications, understanding the fundamental differences between forging and casting is essential for making informed engineering decisions. The manufacturing process directly impacts the mechanical properties, reliability, and service life of the finished component.

| Performance Criteria |

Steel Forged Components |

Cast Steel Components |

| Tensile Strength |

20-40% higher than casting |

Lower due to porosity and inclusions |

| Fatigue Resistance |

Superior due to aligned grain structure |

Limited by random grain orientation |

| Impact Toughness |

Significantly higher |

Reduced due to internal defects |

| Internal Integrity |

Dense, void-free structure |

Prone to shrinkage, porosity, inclusions |

| Grain Structure |

Refined, directional, controlled |

Coarse, random orientation |

| Dimensional Accuracy |

Requires machining for precision |

Can achieve near-net shape for complex geometries |

| Weight Optimization |

Better strength-to-weight ratio |

Requires thicker sections for equivalent strength |

For applications where component failure could lead to catastrophic consequences, the superior mechanical properties of steel forged components provide an essential safety margin. The controlled deformation during forging creates a refined, directional grain structure that significantly enhances strength, toughness, and fatigue resistance.

Material Selection for Steel Forged Components

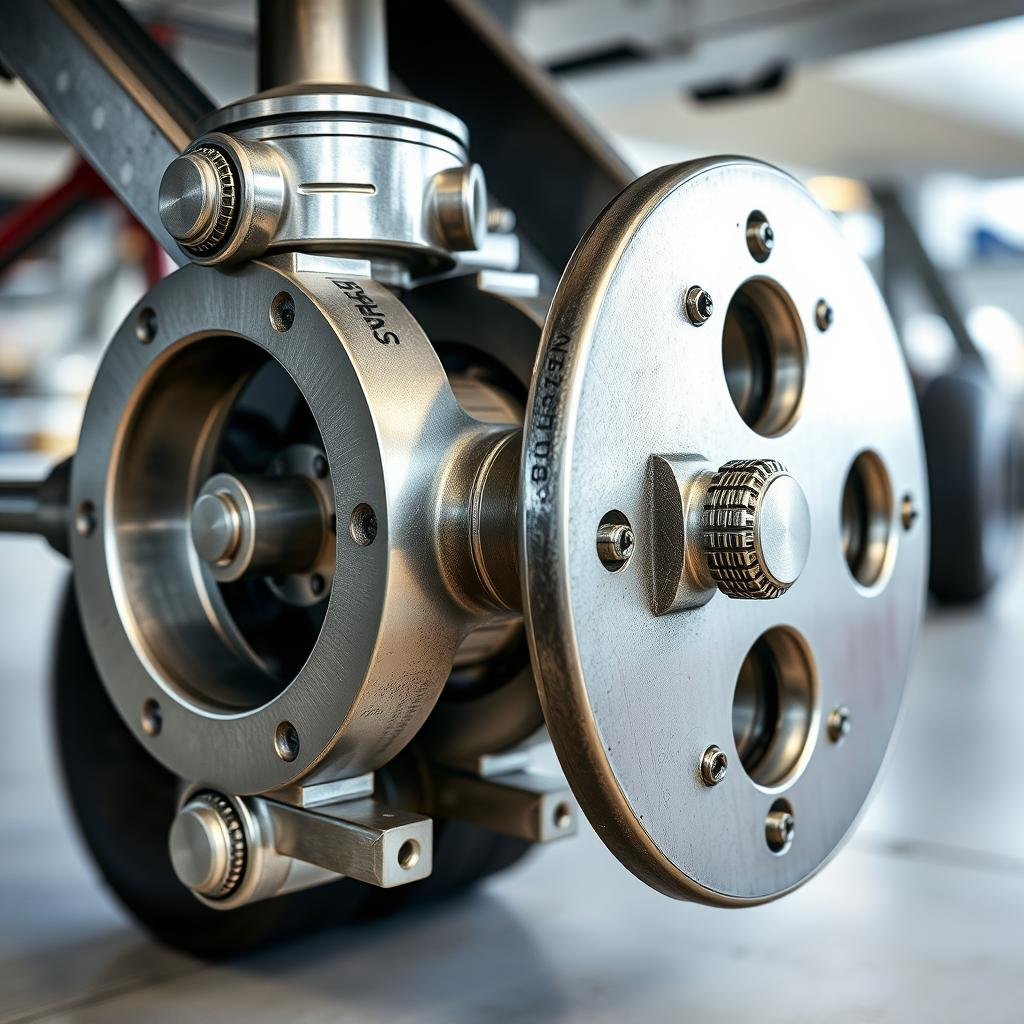

Selection of appropriate steel alloys is critical for optimal forging results

Selecting the appropriate steel alloy is a critical first step in specifying steel forged components. Different alloy compositions offer varying mechanical properties, heat treatment responses, and performance characteristics in specific operating environments.

Common Steel Alloys for Steel Forged Components

Carbon Steels

- 1020/1045: General-purpose applications

- 1060/1095: High-strength requirements

- Excellent formability during forging

- Cost-effective for many applications

Alloy Steels

- 4140/4340: High-strength applications

- 8620/8630: Carburizing grades

- Superior mechanical properties

- Excellent response to heat treatment

Stainless Steels

- 304/316: Corrosion-resistant applications

- 17-4PH: Precipitation-hardening

- Combines strength with corrosion resistance

- Suitable for aggressive environments

Tool Steels

- H13/D2: High wear resistance

- A2/O1: Precision tooling applications

- Excellent hardness after heat treatment

- Superior wear and abrasion resistance

Microalloyed Steels

- HSLA grades: Optimized strength-to-weight

- Vanadium/niobium additions

- Reduced heat treatment requirements

- Cost-effective high-performance option

Specialty Alloys

- Maraging steels: Aerospace applications

- PH stainless: Corrosive environments

- Exceptional strength characteristics

- Application-specific performance

Need Help Selecting the Right Steel Alloy?

MAIKONG’s metallurgical experts can recommend the optimal material for your specific application requirements.

Contact Our Materials Experts

Understanding Steel Forged Manufacturing Processes

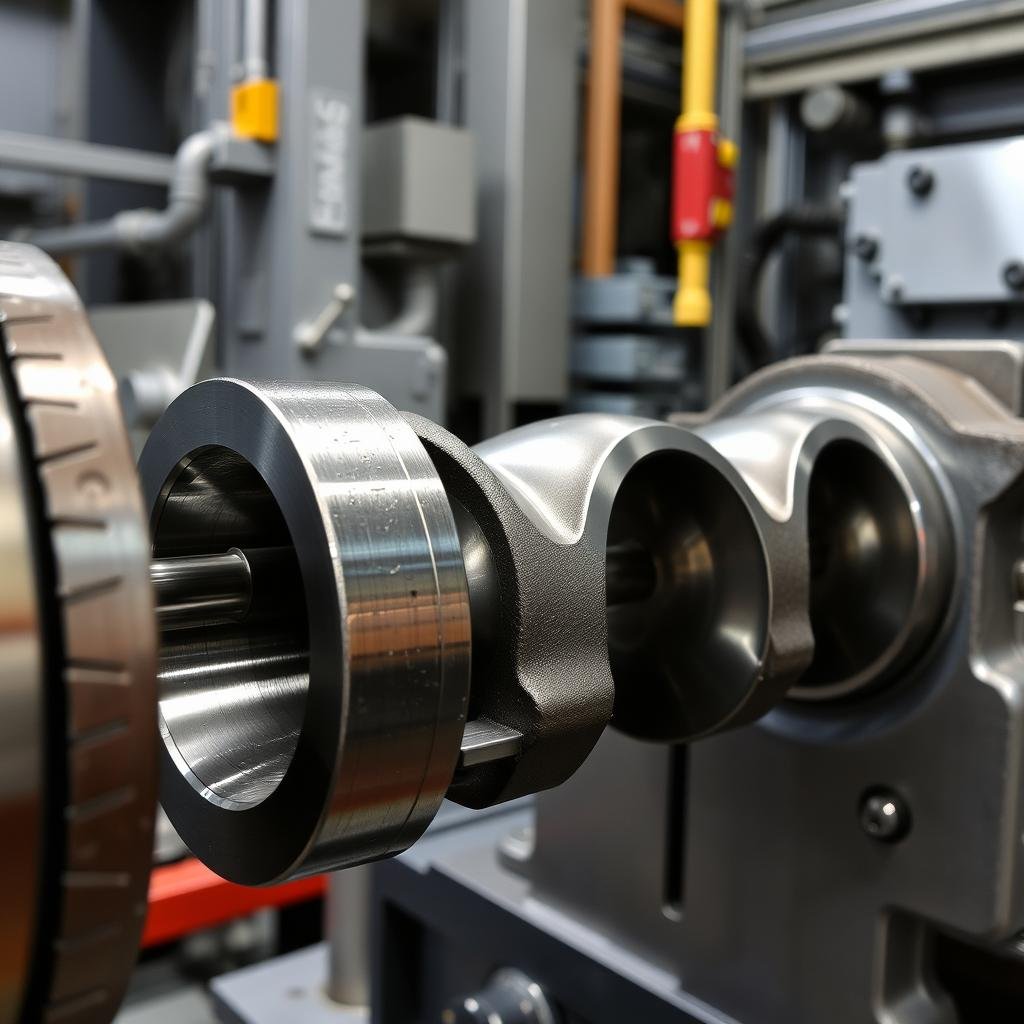

Open die forging process creates superior grain structure in large components

The forging process selected significantly impacts the final properties, dimensional accuracy, and cost of steel forged components. Each forging method offers distinct advantages for specific applications and production volumes.

Primary Steel Forged Manufacturing Methods

Open Die Forging

- Ideal for large components

- Highly versatile for custom shapes

- Lower tooling costs

- Suitable for low to medium volumes

- Requires more machining to finish

Closed Die Forging

- Near-net shape capability

- Excellent dimensional control

- Higher tooling costs

- Economical for higher volumes

- Complex geometries possible

Seamless Rolled Ring Forging

- Specialized for ring-shaped components

- Continuous grain flow pattern

- Excellent for bearings and gears

- Wide range of sizes possible

- Superior circumferential strength

At MAIKONG, we utilize advanced forging equipment and techniques to produce high-quality steel forged components across all these process categories. Our comprehensive capabilities ensure we can recommend and implement the most appropriate forging method for your specific application requirements.

“The selection of the appropriate forging process is as critical as the material specification itself. Each method imparts different characteristics to the final component, which must be aligned with the performance requirements of the application.”

– MAIKONG Engineering Team

Quality Assurance for Steel Forged Components

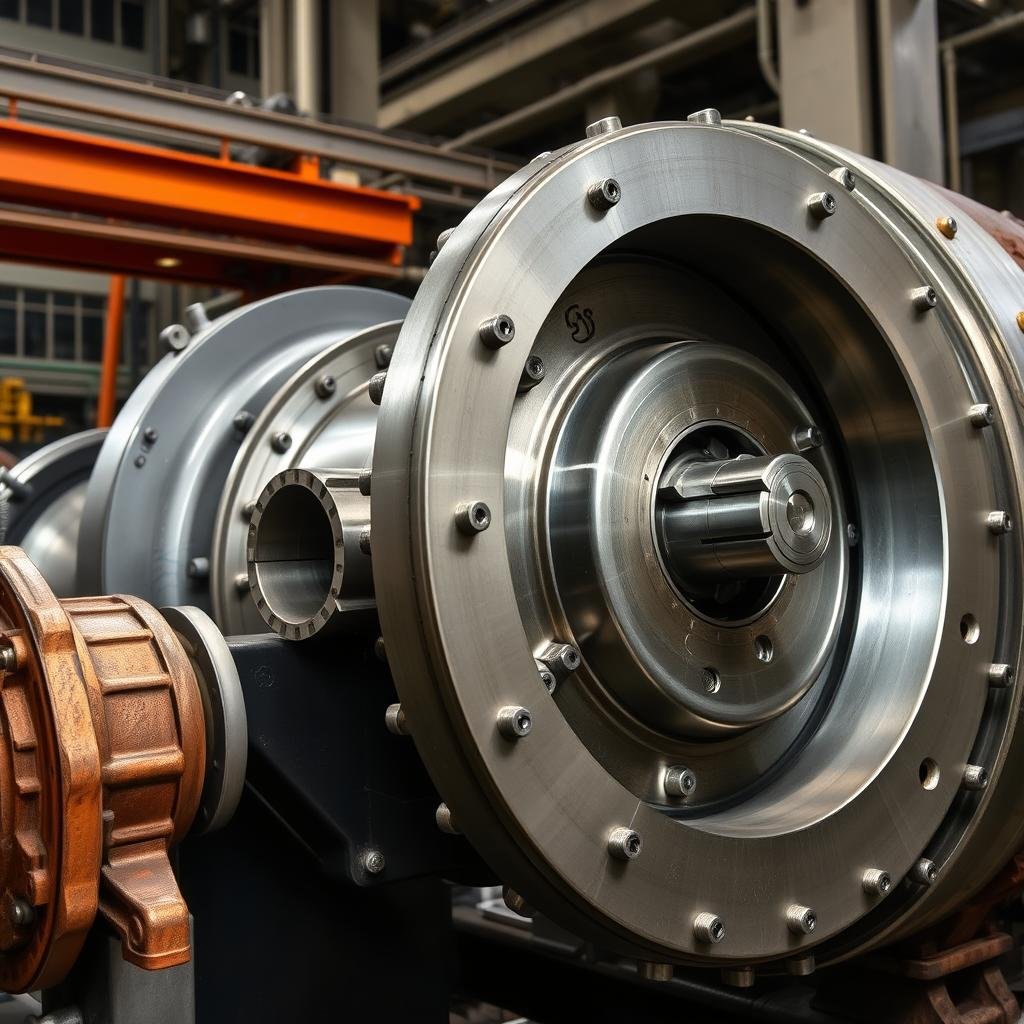

Comprehensive testing ensures steel forged components meet stringent quality standards

Ensuring the quality and reliability of steel forged components requires comprehensive testing and inspection protocols. At MAIKONG, we implement rigorous quality control measures throughout the entire manufacturing process, from raw material verification to final inspection.

Essential Quality Control Measures for Steel Forged Parts

Material Verification

- Chemical composition analysis

- Mechanical property testing

- Material certification verification

- Traceability documentation

Non-Destructive Testing

- Ultrasonic testing for internal defects

- Magnetic particle inspection

- Dye penetrant testing

- Radiographic examination when required

Dimensional Inspection

- Coordinate measuring machine (CMM)

- Laser scanning for complex geometries

- Precision gauging for critical dimensions

- First article inspection reports

Mechanical Testing

- Tensile strength testing

- Hardness testing (Rockwell, Brinell)

- Impact testing (Charpy)

- Fatigue testing for critical applications

Metallurgical Analysis

- Microstructure examination

- Grain flow pattern verification

- Heat treatment validation

- Inclusion and cleanliness assessment

Surface Quality Inspection

- Visual inspection for surface defects

- Surface roughness measurement

- Coating thickness verification

- Corrosion resistance testing

MAIKONG Quality Management System

4.9

ISO 9001:2015 Certified

Material Verification

4.9

Industry Applications for Steel Forged Components

Steel forged components serve critical functions across diverse industries

The exceptional mechanical properties and reliability of steel forged components make them indispensable across numerous industries where performance, safety, and durability are paramount. Understanding these applications helps engineers specify the appropriate forging parameters for their specific requirements.

Aerospace & Defense

- Landing gear components

- Engine mounting structures

- Structural airframe components

- Critical fastening systems

Automotive & Transportation

- Crankshafts and connecting rods

- Transmission components

- Steering knuckles and joints

- Suspension components

Oil & Gas

- Valve bodies and bonnets

- Wellhead components

- Pressure vessel components

- Subsea equipment

Power Generation

- Turbine shafts and rotors

- Generator components

- Pressure-retaining parts

- Structural support components

Heavy Machinery

- Excavator and loader components

- Gears and shafts

- Track links and rollers

- Structural pivot points

Mining & Minerals

- Crusher components

- Shovel and dragline components

- Conveyor system parts

- High-wear application components

Specialized in Your Industry?

MAIKONG has extensive experience providing steel forged components across diverse industries. Let us bring our expertise to your specific application.

Discuss Your Industry Requirements

Design Considerations for Steel Forged Components

Proper design for steel forged components optimizes grain flow and mechanical properties

Designing components specifically for the forging process requires understanding the unique capabilities and constraints of forging technology. Proper design considerations can significantly enhance performance while reducing manufacturing costs.

Key Design Principles for Steel Forged Parts

Draft Angles

Incorporate appropriate draft angles (typically 3-7°) to facilitate part removal from dies and reduce tooling wear.

Corner Radii

Specify generous corner and fillet radii to improve metal flow during forging and reduce stress concentrations in the final part.

Parting Line Location

Optimize parting line placement to simplify die design and minimize flash formation during the forging process.

Web and Rib Proportions

Design webs and ribs with appropriate thickness-to-height ratios to ensure complete die fill and prevent folding defects.

Grain Flow Optimization

Orient critical features to align with the predicted grain flow pattern to maximize strength in high-stress areas.

Tolerance Specifications

Specify appropriate tolerances based on forging capabilities, recognizing that tighter tolerances may require additional machining operations.

Design for Manufacturability (DFM)

Early collaboration between design engineers and forging specialists can identify potential manufacturing challenges and optimize component design for both performance and cost-effectiveness. MAIKONG offers comprehensive DFM consultation to ensure your steel forged components are optimized for both function and manufacturability.

MAIKONG’s Steel Forged Component Capabilities

MAIKONG’s state-of-the-art forging and machining facilities in GD, SZ

MAIKONG combines advanced forging technology with comprehensive machining capabilities to deliver complete steel forged component solutions. Our integrated manufacturing approach ensures quality control throughout the entire production process.

Our Comprehensive Manufacturing Capabilities

Forging Capabilities

- Open die forging up to 5,000 kg

- Closed die forging precision components

- Seamless rolled ring forging

- Wide range of steel alloys processed

- Advanced simulation for process optimization

Heat Treatment

- Normalizing and annealing

- Quenching and tempering

- Solution and precipitation hardening

- Stress relieving

- Controlled atmosphere processing

CNC Machining

- 60+ CNC machines for precision finishing

- Multi-axis machining capabilities

- Large component capacity

- High-precision tolerance achievement

- 100+ tons monthly processing capacity

Quality Testing

- Material verification laboratory

- Non-destructive testing capabilities

- Dimensional inspection equipment

- Mechanical property testing

- ISO 9001:2015 certified processes

Additional Services

- Surface treatments and coatings

- Assembly services

- Custom packaging solutions

- Logistics management

- Documentation and certification

Engineering Support

- Design for manufacturability consultation

- Material selection guidance

- Process optimization

- Prototype development

- Cost reduction strategies

“Our integrated approach to manufacturing steel forged components—from initial design consultation through forging, heat treatment, machining, and finishing—ensures consistent quality and optimal performance for our customers’ most demanding applications.”

– MAIKONG Engineering Team

Partner with MAIKONG for Your Steel Forged Component Needs

Our engineering team works closely with clients to optimize steel forged component designs

MAIKONG is seeking distribution partners across the United States to represent our comprehensive steel forged component manufacturing capabilities. Our cost-effective, high-quality forging and machining services offer competitive advantages for distributors serving industrial markets.

Why Partner with MAIKONG?

- Comprehensive manufacturing capabilities from forging through finishing

- Superior quality control and testing protocols

- Competitive pricing structure with excellent margins for distributors

- Responsive engineering support and technical consultation

- Reliable delivery schedules and logistics management

- Extensive experience across diverse industrial applications

Distributor Support Program

- Dedicated technical support for your customers

- Comprehensive product documentation and certifications

- Marketing materials and technical specifications

- Competitive pricing structure

- Sample components for demonstration

- Regular technical updates and training

Become a MAIKONG Distribution Partner

Join our network of successful distributors representing MAIKONG’s steel forged components across the United States.

Contact via WhatsApp

Elevate Your Engineering with Premium Steel Forged Components

Specifying steel forged components requires careful consideration of material properties, manufacturing processes, and quality control measures. By partnering with MAIKONG, you gain access to comprehensive forging and machining capabilities backed by extensive technical expertise and rigorous quality assurance.

Whether you’re designing critical components for aerospace, automotive, energy, or heavy industrial applications, our team is ready to help you optimize your steel forged components for maximum performance, reliability, and cost-effectiveness.

Ready to Discuss Your Steel Forged Component Requirements?

Contact MAIKONG today to speak with our engineering team about your specific application needs.

Get A Quick Quote

Superior grain structure of

Superior grain structure of