In today’s demanding industrial applications, component reliability and longevity are not just desirable—they’re essential. Steel forging stands as a cornerstone manufacturing process that significantly enhances these critical qualities. At MAIKONG, we’ve perfected the art and science of steel forging to deliver components that consistently outperform alternatives in the most challenging environments.

What Is Steel Forging and Why It Matters

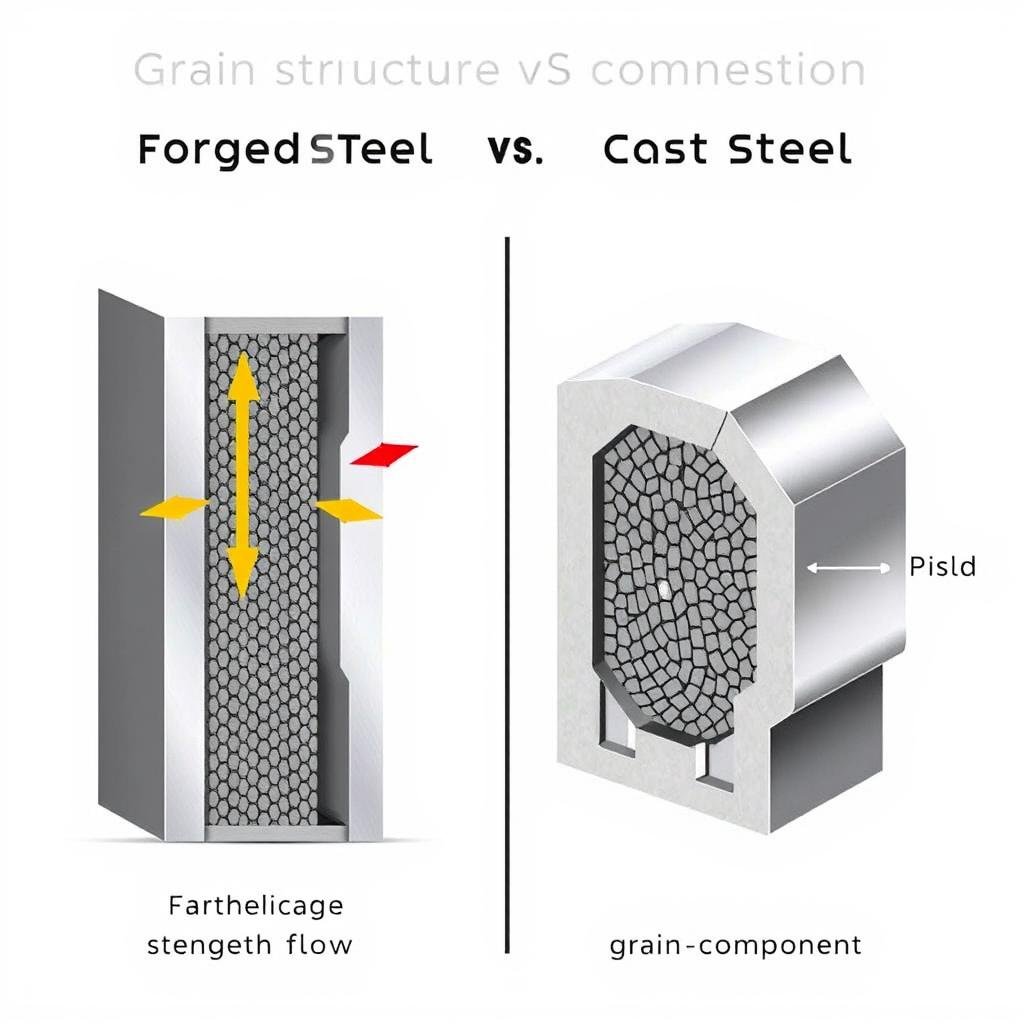

Steel forging is a metal forming process where steel is heated to a specific temperature and shaped using compressive forces. Unlike casting, which involves pouring molten metal into a mold, forging manipulates solid metal to achieve the desired shape. This fundamental difference creates a stronger internal grain structure that follows the component’s shape.

The Science Behind Steel Forging Strength

During the forging process, the metal’s grain structure is compressed and aligned to follow the general shape of the part. This directional grain flow significantly enhances mechanical properties including:

- Superior tensile strength

- Enhanced impact resistance

- Improved fatigue resistance

- Greater structural integrity

- Better wear resistance

Advantages of Steel Forging vs. Casting

When reliability and component lifespan are critical, understanding the fundamental differences between forging and casting becomes essential. The following comparison highlights why steel forging is preferred for applications where failure is not an option.

| Comparison Criteria |

Steel Forging |

Steel Casting |

| Strength and Durability |

Superior strength due to dense, uniform grain structure |

Lower strength due to potential porosity and inclusions |

| Tensile Properties |

Higher tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Excellent resistance against cyclic loading |

More susceptible to fatigue failure |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies in dimensions |

| Internal Defects |

Minimal to none due to compression process |

Prone to porosity, shrinkage, and inclusions |

| Grain Structure |

Directional grain flow for improved properties |

Random grain structure |

| Critical Applications |

Ideal for load-bearing and safety-critical components |

Better suited for complex geometries with lower stress |

Types of Steel Forging Processes at MAIKONG

At MAIKONG, we employ various steel forging techniques to meet specific application requirements. Each process offers unique advantages depending on component complexity, production volume, and performance specifications.

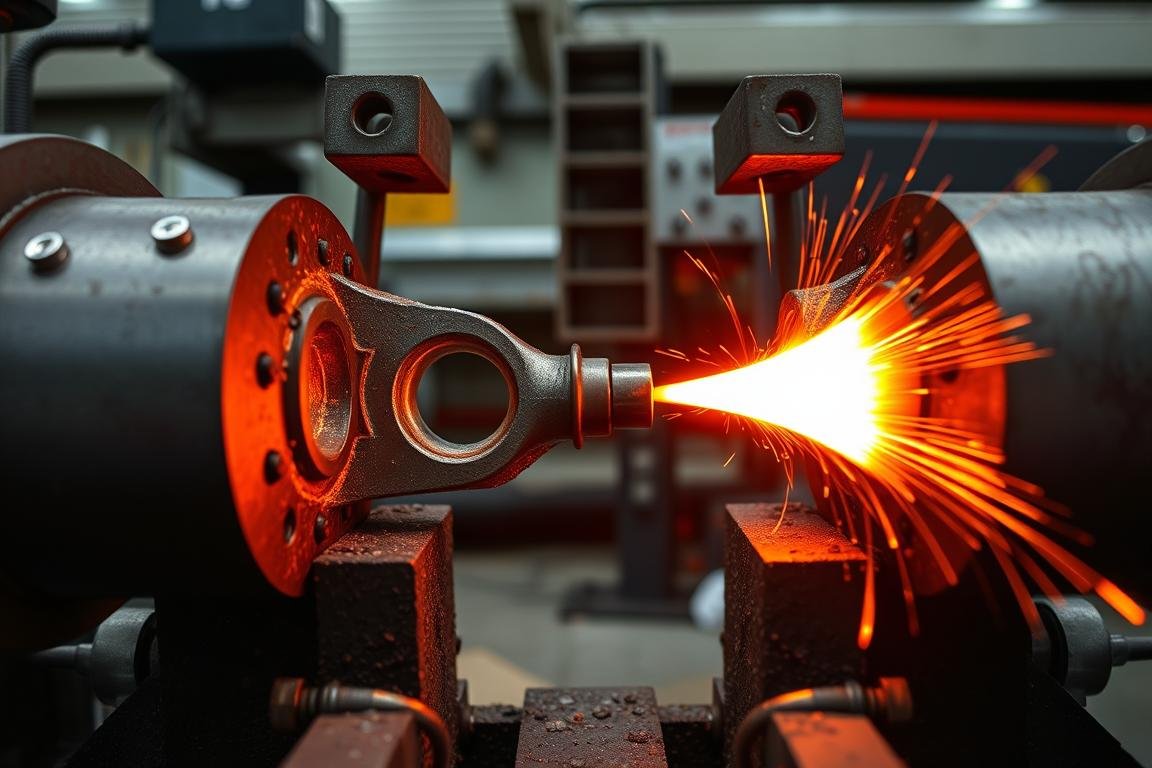

Open Die Forging

Ideal for large components with simple geometries. Metal is worked between flat or simply shaped dies, allowing for greater flexibility in producing custom shapes with excellent mechanical properties.

Closed Die Forging

Provides superior precision for complex geometries. Metal is shaped within two dies that contain a cavity of the desired final shape, creating components with tight tolerances and excellent structural integrity.

Precision Forging

Specialized process for components requiring minimal machining and exceptional dimensional accuracy. Ideal for high-performance applications where material optimization and precise specifications are critical.

Find the Right Forging Process for Your Application

Our engineering team can help determine the optimal forging technique for your specific requirements, ensuring maximum performance and cost-effectiveness.

Get Expert Recommendation

Industries Benefiting from MAIKONG Steel Forging

The exceptional reliability and extended lifespan of forged steel components make them ideal for industries where performance and safety are paramount. MAIKONG serves diverse sectors with specialized forging solutions.

Automotive

- Crankshafts

- Connecting rods

- Transmission components

- Steering knuckles

Aerospace

- Landing gear components

- Turbine discs

- Structural fittings

- Engine mounts

Energy

- Valve bodies

- Pressure vessel components

- Turbine shafts

- Fittings and flanges

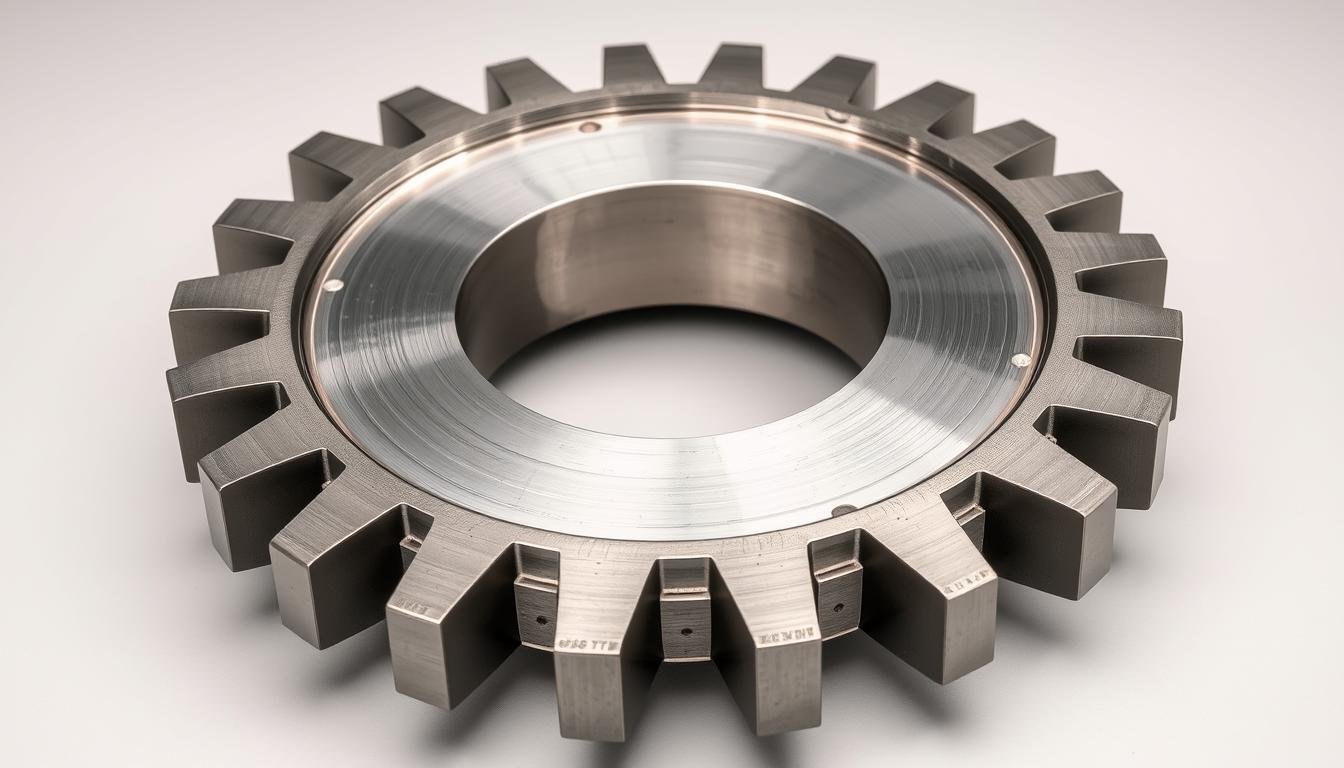

Heavy Equipment

- Gears and sprockets

- Hydraulic components

- Track links

- Structural components

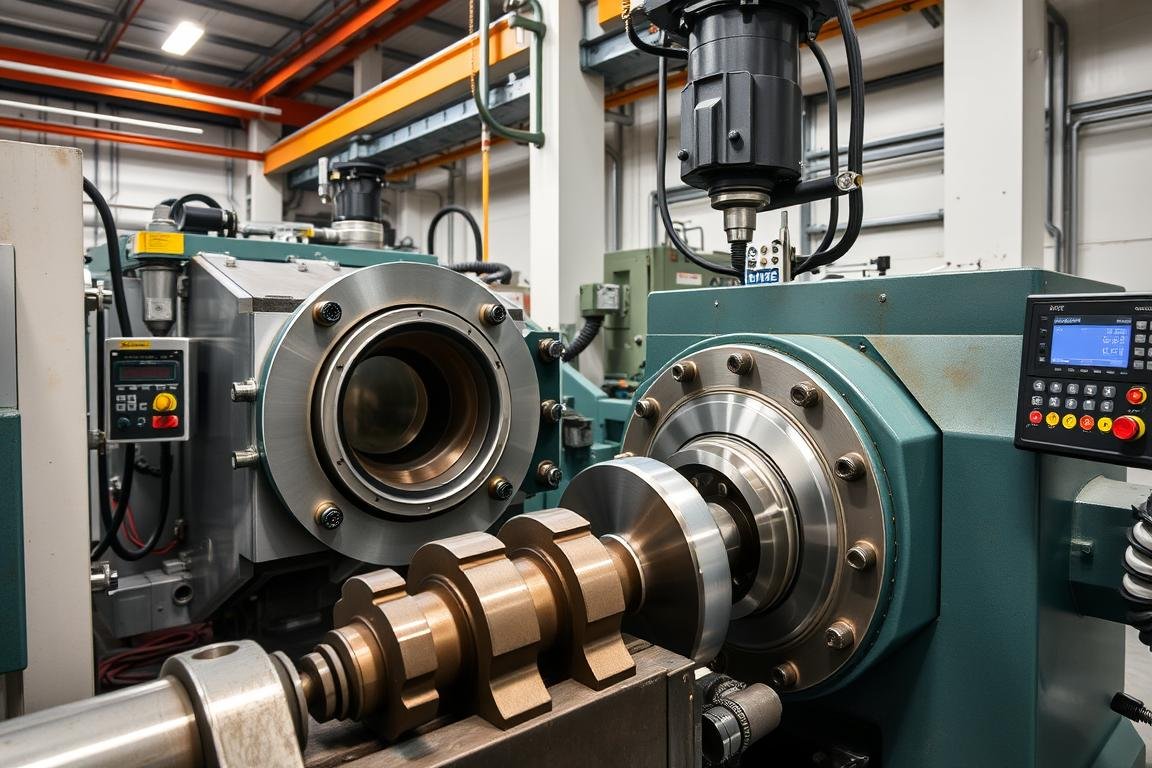

MAIKONG’s Steel Forging Manufacturing Capabilities

With over 60 CNC machines and a monthly metal processing capacity exceeding 100 tons, MAIKONG delivers exceptional quality and value across our comprehensive steel forging and machining operations.

Advanced Equipment

- Hydraulic presses ranging from 800 to 4000 tons

- Precision CNC machining centers

- State-of-the-art heat treatment facilities

- Advanced testing and quality control equipment

- Automated surface finishing systems

Technical Specifications

| Capability |

Specification |

Benefit |

| Weight Range |

0.5 kg to 500 kg |

Versatility for various component sizes |

| Dimensional Tolerance |

±0.1mm to ±0.5mm |

Precision for critical applications |

| Material Options |

Carbon, alloy, stainless, tool steels |

Optimal material selection for application |

| Surface Finish |

Ra 0.8-3.2 |

Excellent aesthetics and performance |

| Heat Treatment |

Annealing, normalizing, quenching, tempering |

Customized mechanical properties |

Comprehensive Steel Forging Services

MAIKONG offers a complete range of services from initial design to final finishing, ensuring quality control at every stage of production. Our integrated approach delivers superior components while optimizing costs and lead times.

Design & Engineering

- CAD/CAM design optimization

- Material selection consulting

- FEA simulation for performance validation

- Design for manufacturability (DFM)

Forging & Heat Treatment

- Open and closed die forging

- Precision forging for near-net shapes

- Controlled heating and cooling cycles

- Customized heat treatment for optimal properties

Machining & Finishing

- CNC turning and milling

- Multi-axis machining for complex geometries

- Surface grinding and finishing

- Coating and surface treatment options

Experience Our End-to-End Service Advantage

From design consultation to finished components, MAIKONG delivers comprehensive solutions that optimize quality, cost, and delivery time.

Get A Quick Quote

Quality Assurance in Steel Forging

At MAIKONG, quality isn’t just inspected—it’s built into every process. Our comprehensive quality management system ensures consistent excellence in all steel forging operations.

Testing & Certification

- Material composition analysis

- Mechanical property testing

- Non-destructive testing (NDT)

- Dimensional inspection

- Surface quality verification

- ISO 9001:2015 certified processes

Our commitment to quality and self-improvement is relentless. Shift by shift, day by day, we’re in a constant mode of getting better than we were yesterday. It’s something we take very seriously and it never stops.

– MAIKONG Quality Director

Case Studies: Steel Forging Success Stories

See how MAIKONG’s steel forging solutions have helped customers overcome challenges and achieve superior performance in demanding applications.

Automotive Crankshaft Optimization

Challenge: An automotive manufacturer needed crankshafts with 30% longer service life while maintaining cost-effectiveness.

Solution: MAIKONG developed a precision forging process with optimized grain flow and custom heat treatment.

Result: 40% increase in fatigue life, 15% weight reduction, and 12% cost savings through near-net shape forging.

Heavy Equipment Gear Reliability

Challenge: A mining equipment manufacturer experienced premature gear failures in extreme conditions.

Solution: MAIKONG engineered a custom alloy steel forging with specialized heat treatment and precision machining.

Result: 3x increase in service life, elimination of unplanned downtime, and 22% reduction in total ownership cost.

Why Choose MAIKONG for Steel Forging

When you partner with MAIKONG for your steel forging needs, you gain access to world-class capabilities combined with exceptional value and customer service.

Technical Excellence

- 60+ CNC machines for precision finishing

- 100+ tons monthly metal processing capacity

- Advanced metallurgical laboratory

- Comprehensive in-house capabilities

Superior Value

- Competitive pricing without quality compromise

- Optimized production for cost efficiency

- Reduced lead times through process integration

- Value engineering to maximize performance

Customer Focus

- Dedicated project management

- Responsive communication

- Flexible production scheduling

- Long-term partnership approach

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

Elevate Your Components with MAIKONG Steel Forging

In industries where component reliability and lifespan directly impact operational success, steel forging provides the superior metallurgical properties needed for peak performance. MAIKONG combines technical expertise, advanced manufacturing capabilities, and customer-focused service to deliver forged steel components that exceed expectations.

From automotive and aerospace to energy and heavy equipment, our comprehensive steel forging solutions enhance component reliability while optimizing costs. Contact MAIKONG today to discover how our forging expertise can benefit your next project.

Start Your Next Project with MAIKONG

Ready to experience the MAIKONG difference? Our team is standing by to assist with your steel forging requirements.

Get A Quick Quote Today