In the complex world of metal manufacturing, steel forging stands as one of the most critical processes for creating high-strength, reliable components. For procurement professionals navigating this technical landscape, understanding the nuances of steel forging can be the difference between sourcing components that excel in performance and those that fail under pressure. This comprehensive guide demystifies the steel forging process, helping you make informed decisions when sourcing these essential components for your organization.

Understanding Steel Forging: The Fundamental Process

Steel forging is a manufacturing process that shapes metal using localized compressive forces. Unlike casting, where metal is melted and poured into a mold, forging manipulates solid metal into desired shapes through hammering, pressing, or rolling. This ancient metalworking technique has evolved into a sophisticated industrial process that produces some of the strongest manufactured components available today.

The steel forging process transforms raw metal into precision components through controlled deformation

The steel forging process transforms raw metal into precision components through controlled deformation

At MAIKONG, we’ve refined our steel forging processes to deliver exceptional quality while maintaining cost-effectiveness. Our state-of-the-art facilities in GD, SZ combine traditional forging expertise with modern technology to create components that meet the most demanding specifications.

Need Expert Guidance on Steel Forging?

Our engineering team can help you determine the optimal forging process for your specific application.

Get Expert Consultation

Steel Forging Processes: Methods and Applications

The steel forging industry employs several distinct processes, each with unique advantages for specific applications. Understanding these processes is essential for procurement professionals seeking the optimal manufacturing method for their components.

Open Die Forging: Versatility for Large Components

Open die forging, also known as smith forging, involves shaping metal between flat or simply contoured dies. The metal workpiece is not completely confined during the process, allowing for greater manipulation and versatility.

Open die forging allows for the creation of large-scale components with excellent structural integrity

Key advantages of open die forging:

- Ideal for large components weighing up to several tons

- Excellent for low-volume production runs

- Creates favorable grain flow that enhances component strength

- Reduces internal voids and improves material homogeneity

- Suitable for custom, one-off components

Closed Die Forging: Precision and Consistency

Closed die forging (impression die forging) shapes metal by forcing it into die cavities that contain the negative impression of the desired part. This process delivers more complex geometries and tighter tolerances than open die forging.

Closed die forging creates complex components with consistent dimensions and excellent mechanical properties

Key advantages of closed die forging:

- Produces complex geometries with tight tolerances

- Excellent for medium to high-volume production

- Creates consistent parts with minimal variation

- Optimizes material usage with minimal waste

- Delivers superior surface finish compared to open die forging

Temperature-Based Forging Classifications

Forging processes are also classified based on the temperature at which the metal is worked:

| Process Type |

Temperature Range |

Key Characteristics |

Ideal Applications |

| Hot Forging |

Above recrystallization (950-1250°C) |

High formability, lower forming forces, constant tensile strength |

Large components, complex geometries |

| Warm Forging |

Partial recrystallization (750-950°C) |

Reduced scaling, tighter tolerances than hot forging |

Precision components with moderate complexity |

| Cold Forging |

Room temperature (up to 150°C from deformation) |

Tightest tolerances, no scaling, increased strength from strain hardening |

Small precision components, fasteners |

At MAIKONG, we employ all these forging methods, selecting the optimal process based on your component requirements, production volume, and budget considerations.

Unsure Which Forging Process Is Right for Your Project?

Our engineering team can analyze your specifications and recommend the most cost-effective approach.

Consult Our Experts on WhatsApp

The Distinctive Advantages of Steel Forging

When compared to alternative manufacturing methods like casting or machining from solid stock, steel forging offers several significant advantages that make it the preferred choice for critical components.

Superior Mechanical Properties

The forging process fundamentally transforms the metal’s internal structure, creating components with exceptional performance characteristics:

- Enhanced grain flow that follows the component’s geometry

- Elimination of internal voids and porosity

- Improved impact and fatigue resistance

- Greater tensile strength and ductility

- Consistent mechanical properties throughout the component

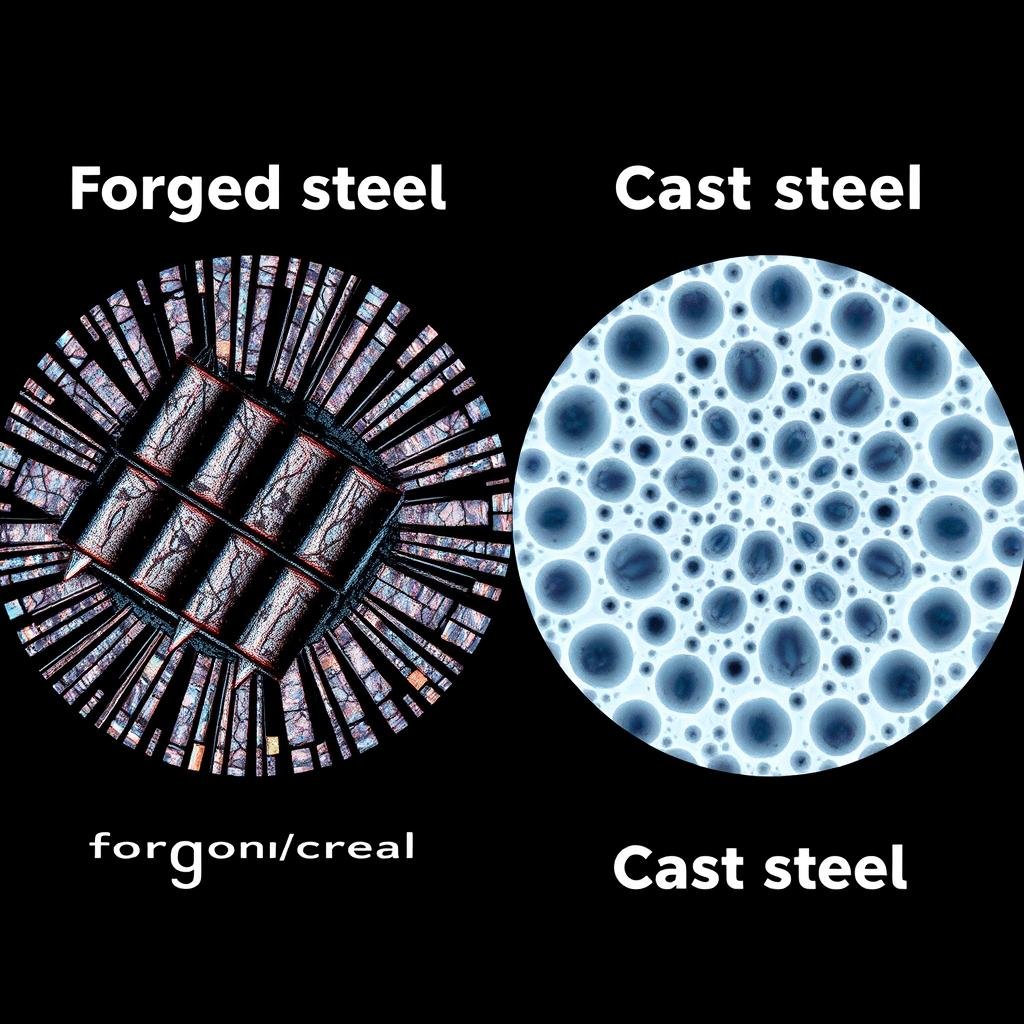

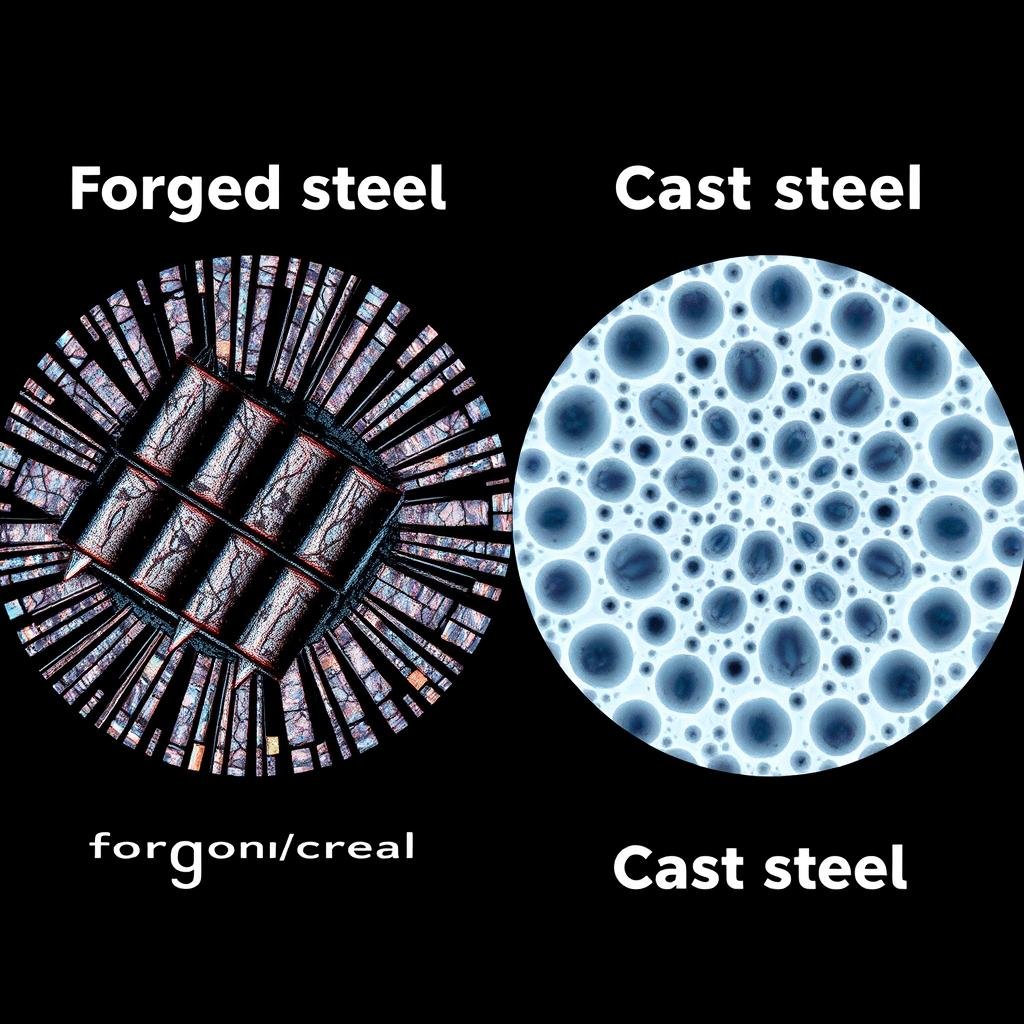

Microscopic comparison showing the refined grain structure of forged steel (left) versus cast steel (right)

Steel Forging vs. Casting: A Critical Comparison

Understanding the differences between forging and casting is essential for procurement professionals making manufacturing method decisions:

| Characteristic |

Steel Forging |

Steel Casting |

| Mechanical Strength |

Superior strength due to refined grain structure and elimination of voids |

Lower strength with potential internal porosity |

| Structural Integrity |

Excellent with directional grain flow that enhances performance |

More prone to defects and inconsistent properties |

| Fatigue Resistance |

Significantly higher resistance to cyclic loading |

Lower fatigue resistance due to internal discontinuities |

| Design Complexity |

Limited to moderately complex geometries |

Can produce highly complex geometries with internal features |

| Dimensional Accuracy |

Good to excellent, depending on the forging method |

Variable, often requiring additional machining |

| Production Volume |

Economical for medium to high volumes |

Cost-effective for low volumes and complex parts |

| Material Waste |

Minimal waste with near-net-shape capabilities |

Low waste with potential for recycling sprues and runners |

MAIKONG’s advanced steel forging production line delivers precision components with superior mechanical properties

For critical applications where component failure is not an option, steel forging provides the reliability and performance that procurement professionals demand.

Critical Applications for Steel Forged Components

Steel forging produces components that excel in demanding applications across numerous industries. Understanding these applications helps procurement professionals identify where forged components deliver the greatest value.

Automotive & Transportation

- Crankshafts and connecting rods

- Transmission gears and shafts

- Steering knuckles and control arms

- Axle beams and components

- Wheel hubs and CV joints

Industrial Machinery

- Gears and gear blanks

- Shafts and spindles

- Hydraulic components

- Press components

- Heavy equipment parts

Oil & Gas

- Valve bodies and components

- Wellhead equipment

- Drill bits and drilling equipment

- Pressure vessel components

- Fittings and flanges

MAIKONG produces a wide range of steel forged components for diverse industrial applications

Why Leading Manufacturers Choose Steel Forging

Industry leaders consistently select steel forging for critical components because:

Advantages of Steel Forging for Critical Applications

- Superior strength-to-weight ratio maximizes performance while minimizing weight

- Enhanced fatigue resistance extends component lifespan in cyclic loading applications

- Improved impact resistance provides safety margins in unpredictable conditions

- Consistent mechanical properties ensure reliable performance across production runs

- Better response to heat treatment allows for precise property optimization

Challenges to Consider

- Higher initial tooling costs compared to casting (though amortized over production runs)

- Limitations in creating complex internal geometries

- May require secondary machining operations for tight tolerances

- Less economical for very low production volumes

- Requires expertise in process selection and design for manufacturability

At MAIKONG, we help procurement professionals navigate these considerations, recommending steel forging when it delivers the optimal balance of performance, cost, and manufacturability for your specific application.

Explore Steel Forging Solutions for Your Industry

Our team specializes in custom steel forged components for diverse industrial applications.

Email Our Industry Specialists

Steel Alloys for Forging: Selecting the Optimal Material

The selection of the appropriate steel alloy is critical to the success of any forging project. Different alloys offer varying combinations of strength, toughness, corrosion resistance, and heat treatment response.

MAIKONG works with a wide range of steel alloys to meet diverse performance requirements

Common Steel Alloys for Forging Applications

| Alloy Type |

Common Grades |

Key Properties |

Typical Applications |

| Carbon Steel |

1018, 1045, 1060 |

Good strength, excellent forgeability, cost-effective |

Shafts, gears, fasteners, general structural components |

| Alloy Steel |

4140, 4340, 8620 |

High strength, good toughness, excellent heat treatment response |

Crankshafts, connecting rods, gears, heavy-duty components |

| Stainless Steel |

304, 316, 17-4PH |

Corrosion resistance, good high-temperature properties |

Food processing equipment, chemical processing, marine applications |

| Tool Steel |

H13, D2, S7 |

Extreme hardness, wear resistance, heat resistance |

Dies, tools, industrial knives, high-wear components |

| Microalloy Steel |

HSLA grades |

High strength-to-weight ratio, good weldability |

Automotive structural components, lightweight applications |

MAIKONG’s metallurgical expertise ensures that we recommend and use the optimal steel alloy for your specific application requirements, balancing performance characteristics with cost considerations.

Quality Assurance in Steel Forging

For procurement professionals, ensuring consistent quality in steel forging is paramount. MAIKONG implements comprehensive quality control measures throughout the forging process.

MAIKONG’s rigorous quality control ensures every forged component meets precise specifications

Our Comprehensive Quality Control Process

Material Verification

- Chemical composition analysis

- Material certification verification

- Mechanical property testing

- Traceability documentation

In-Process Inspection

- Die condition monitoring

- Temperature control verification

- Dimensional checking

- Visual inspection for defects

Final Component Testing

- Non-destructive testing (NDT)

- Dimensional measurement

- Mechanical property verification

- Surface finish inspection

Advanced Testing Methods for Steel Forged Components

MAIKONG employs state-of-the-art testing technologies to ensure the integrity of every forged component:

- Ultrasonic Testing: Detects internal flaws, voids, or inclusions within the forged component

- Magnetic Particle Inspection: Identifies surface and near-surface defects in ferromagnetic materials

- Dye Penetrant Testing: Reveals surface discontinuities in non-magnetic materials

- Hardness Testing: Confirms proper heat treatment and material properties

- Metallographic Examination: Analyzes grain structure and material integrity

- Coordinate Measuring Machine (CMM): Provides precise dimensional verification

Our commitment to quality ensures that components meet or exceed industry standards, including ASTM, ASME, and customer-specific requirements.

MAIKONG: Your Partner for Premium Steel Forging Solutions

MAIKONG stands as a leading provider of high-quality steel forging and precision machining services, delivering cost-effective manufacturing solutions to clients across the United States.

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ combines traditional forging expertise with advanced technology

Our Comprehensive Manufacturing Capabilities

Steel Forging Expertise

- Open die forging for large components

- Closed die forging for precision parts

- Hot, warm, and cold forging processes

- Custom forging solutions for unique requirements

- Wide range of steel alloys processed

Precision Machining Services

- CNC milling for complex geometries

- CNC turning for cylindrical components

- Multi-axis machining capabilities

- Precision grinding and finishing

- Prototyping and production runs

Additional Value-Added Services

- Heat treatment for optimal material properties

- Surface treatments and coatings

- Non-destructive testing and inspection

- Assembly and sub-assembly services

- Engineering support and design optimization

Quality Assurance

- Comprehensive quality management system

- Advanced testing and inspection equipment

- Material certification and traceability

- Dimensional verification and reporting

- Compliance with international standards

MAIKONG produces a diverse range of steel forged components for critical applications

Industries We Serve

MAIKONG provides steel forging solutions for diverse industries with demanding requirements:

Automotive & Transportation

Precision components for engines, transmissions, and chassis systems that deliver reliability and performance.

Industrial Machinery

Durable components for manufacturing equipment, power generation, and heavy machinery applications.

Oil & Gas

High-strength components that withstand extreme pressures, temperatures, and corrosive environments.

Aerospace

Critical components where reliability, weight optimization, and performance are paramount.

Construction & Mining

Robust components that endure heavy loads, abrasive conditions, and continuous operation.

Energy & Power Generation

Precision components for conventional and renewable energy systems requiring long-term reliability.

Partner with MAIKONG for Your Steel Forging Needs

Experience the MAIKONG difference: superior quality, competitive pricing, and exceptional service.

Get A Quick Quote

Procurement Guide: Selecting the Right Steel Forging Partner

For procurement professionals, selecting the right steel forging supplier is a critical decision that impacts product quality, cost, and delivery timelines. Consider these key factors when evaluating potential partners:

Thorough supplier evaluation is essential for successful steel forging procurement

Essential Supplier Evaluation Criteria

Technical Capabilities

- Equipment capacity and tonnage range

- Available forging processes and methods

- Material handling capabilities

- Secondary processing options

- Engineering support and design assistance

Quality Systems

- Quality certifications and standards

- Inspection equipment and capabilities

- Material traceability systems

- Process control methodologies

- Documentation and reporting practices

Business Considerations

- Cost competitiveness and transparency

- Production capacity and lead times

- Communication and responsiveness

- Financial stability and longevity

- Geographic location and logistics

Questions to Ask Potential Steel Forging Suppliers

What is your experience with components similar to ours?

Look for suppliers with proven experience in your specific industry and application. Ask for case studies or examples of similar components they’ve produced successfully.

What quality control measures do you implement?

Evaluate their quality management system, inspection protocols, and testing capabilities. Request information about their defect rates and quality improvement initiatives.

How do you handle design optimization for manufacturability?

The best suppliers offer value-added engineering support to optimize designs for the forging process, potentially reducing costs and improving performance.

What is your typical lead time and on-time delivery rate?

Understand their production scheduling, capacity constraints, and track record for meeting delivery commitments.

How do you handle communication and project management?

Effective communication is essential, especially when working with overseas suppliers. Evaluate their responsiveness, English proficiency, and project management systems.

At MAIKONG, we welcome these questions and are committed to transparent communication throughout the procurement process. Our team of experts is ready to assist you in evaluating whether our steel forging capabilities align with your specific requirements.

Conclusion: Leveraging Steel Forging for Competitive Advantage

In today’s competitive manufacturing landscape, procurement professionals who understand the strategic advantages of steel forging can deliver significant value to their organizations. By selecting the right forging process, material, and supplier, you can ensure that critical components meet performance requirements while optimizing costs.

MAIKONG stands ready as your partner in steel forging excellence, offering comprehensive capabilities, competitive pricing, and exceptional service. Our team of experts is committed to helping you navigate the complexities of steel forging procurement, delivering components that meet your exact specifications and contribute to your product’s success in the market.

MAIKONG’s team of experts ensures every steel forged component meets the highest quality standards

Ready to Discuss Your Steel Forging Requirements?

Contact MAIKONG today to explore how our steel forging expertise can benefit your next project.

The steel forging process transforms raw metal into precision components through controlled deformation

The steel forging process transforms raw metal into precision components through controlled deformation