In the demanding world of industrial manufacturing, the choice of metal forming process can make the difference between component success and failure. Steel forgings stand apart from other metal manufacturing methods, offering unparalleled strength, durability, and performance characteristics that simply cannot be matched by casting, machining, or other fabrication techniques. At MAIKONG, we’ve perfected the art and science of steel forging to deliver components that perform flawlessly in the most challenging environments.

What Are Steel Forgings and Why They Matter

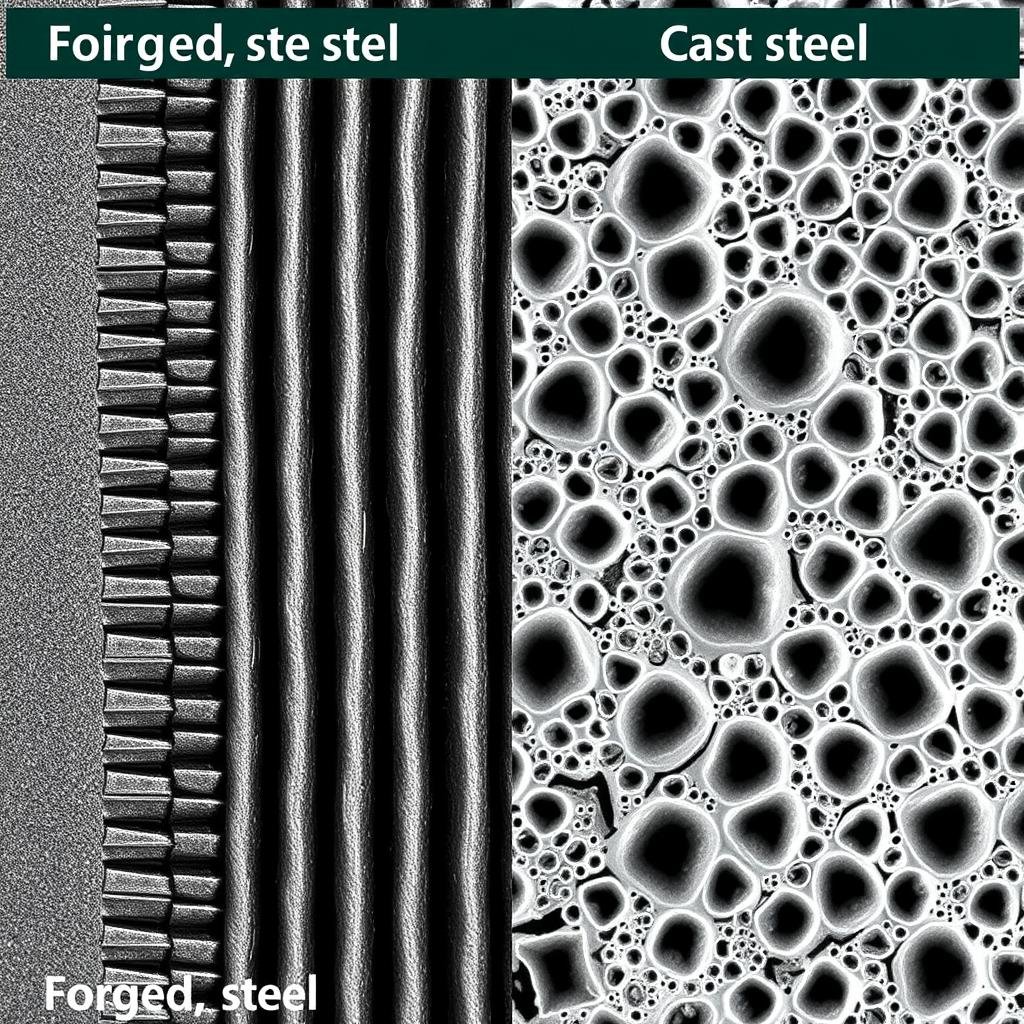

Steel forgings are metal components formed by applying compressive force to steel that has been heated to a specific temperature. This process fundamentally alters the internal grain structure of the metal, aligning it with the shape of the part and eliminating voids or weaknesses. The result is a component with superior mechanical properties that outperforms those manufactured through other methods.

The Science Behind Steel Forgings

During the forging process, steel undergoes plastic deformation under carefully controlled conditions. This restructures the metal’s grain flow to follow the contours of the part, creating a continuous, unbroken grain pattern that significantly enhances strength and toughness. Unlike cast or machined parts, where grain structure is random or interrupted, steel forgings feature optimized metallurgical properties that directly contribute to their superior performance.

Key Advantages of Steel Forgings Over Alternative Processes

When comparing metal manufacturing methods, steel forgings consistently demonstrate superior characteristics across multiple performance metrics. Understanding these advantages is crucial for engineers and procurement specialists seeking optimal components for critical applications.

| Performance Factor |

Steel Forgings |

Cast Steel |

Machined Steel |

| Tensile Strength |

Superior (20-40% higher) |

Moderate |

Good |

| Impact Resistance |

Excellent |

Poor to Fair |

Fair |

| Fatigue Resistance |

Outstanding |

Limited |

Moderate |

| Internal Defects |

Minimal to None |

Common (porosity, inclusions) |

Possible (interrupted grain) |

| Grain Structure |

Continuous, aligned with part shape |

Random, non-directional |

Interrupted |

| Material Utilization |

High (near-net shape) |

High |

Low (significant waste) |

Need High-Performance Steel Components?

MAIKONG delivers superior steel forgings with optimal strength-to-weight ratios and exceptional durability. Our engineering team can help you select the ideal steel grade and forging process for your specific application.

Request a Quote

Unmatched Strength Properties of Properly Forged Steel

The exceptional strength characteristics of steel forgings make them the preferred choice for applications where failure is not an option. Through the controlled deformation process, forged steel components develop superior mechanical properties that directly translate to enhanced performance in the field.

Why Engineers Choose Steel Forgings for Critical Applications

- Superior tensile strength that exceeds cast or machined alternatives by 20-40%

- Enhanced ductility that allows components to deform under stress rather than catastrophically fail

- Exceptional impact resistance for components subject to shock loading

- Superior fatigue life for cyclically loaded parts

- Consistent mechanical properties throughout the entire component

- Excellent performance in extreme temperature environments

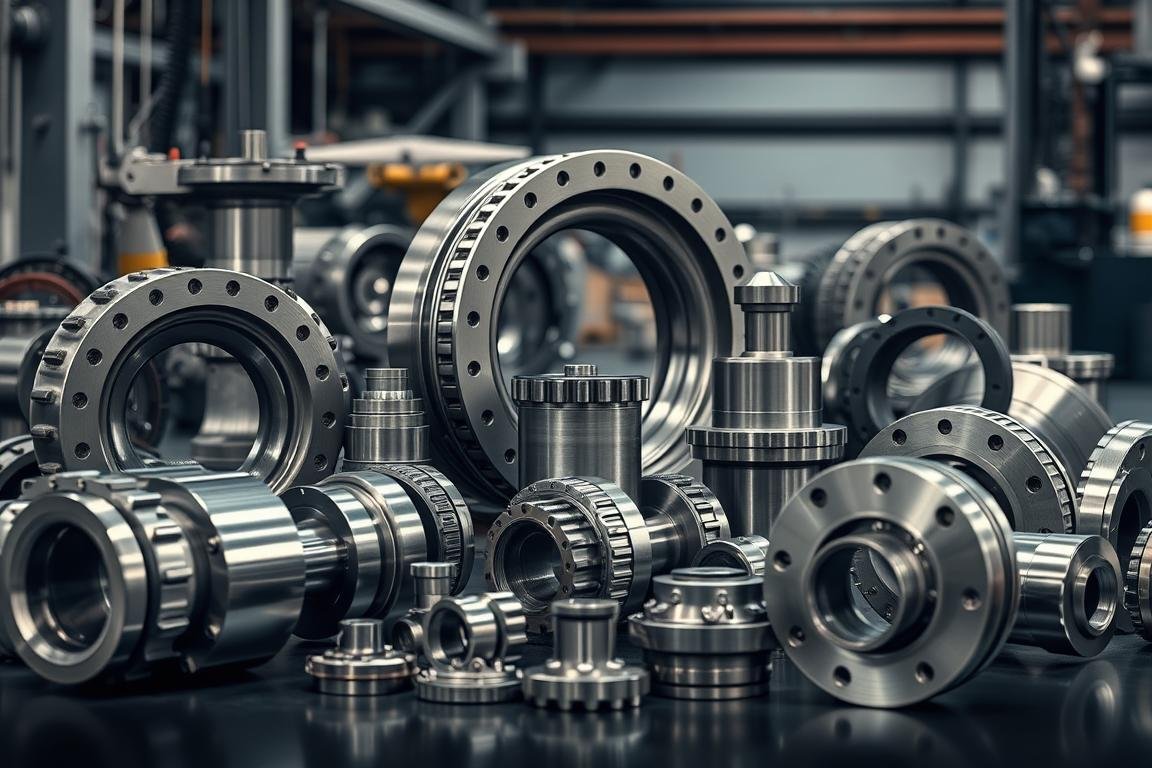

Industries and Applications Where Steel Forgings Excel

The superior mechanical properties of forged steel make it the material of choice across numerous industries where performance, reliability, and safety are paramount. MAIKONG provides custom steel forgings for a wide range of applications that demand the highest levels of strength and durability.

Oil & Gas

- Valve bodies and components

- Pressure-containing equipment

- Wellhead components

- Drill bit bodies and tool joints

- High-pressure fittings and connectors

Aerospace & Defense

- Landing gear components

- Structural airframe parts

- Engine mounts and brackets

- Ordnance components

- Critical load-bearing elements

Heavy Equipment

- Gears and transmission components

- Crankshafts and connecting rods

- Excavator teeth and bucket components

- Heavy-duty axles and spindles

- Structural load-bearing components

These industries rely on the exceptional performance characteristics of steel forgings to ensure safety, reliability, and longevity in demanding operating environments. The forging process creates components that can withstand extreme pressure, temperature, and mechanical stress without failure.

The MAIKONG Steel Forgings Process

At MAIKONG, we’ve refined our steel forging process to deliver components with exceptional quality, consistency, and performance. Our comprehensive approach ensures that every forged steel component meets or exceeds the most demanding specifications.

1. Material Selection & Testing

2. Precision Heating

3. Forging & Forming

4. Heat Treatment

Quality Control in Steel Forgings Production

Quality is built into every step of our forging process. MAIKONG employs rigorous testing and inspection protocols to ensure that each steel forging meets the specified mechanical properties and dimensional requirements:

- Material certification and verification before forging begins

- In-process monitoring of temperature and deformation parameters

- Non-destructive testing including ultrasonic, magnetic particle, and dye penetrant inspection

- Mechanical property testing including tensile, impact, and hardness testing

- Dimensional inspection using precision measurement equipment

- Final visual inspection and surface quality assessment

Experience MAIKONG Quality

Our rigorous quality control process ensures that every steel forging meets your exact specifications. Contact our engineering team to discuss your requirements.

or

Email Our Team

Steel Grades and Material Selection for Optimal Forging Results

The selection of the appropriate steel grade is crucial to achieving the desired mechanical properties in the final forged component. MAIKONG works with a wide range of carbon, alloy, and specialty steels to meet the specific requirements of each application.

| Steel Category |

Common Grades |

Key Properties |

Typical Applications |

| Carbon Steel |

1018, 1045, 1060 |

Good strength, ductility, and machinability |

Shafts, gears, fasteners, general structural components |

| Alloy Steel |

4140, 4340, 8620 |

High strength, toughness, and wear resistance |

Crankshafts, connecting rods, gears, high-stress components |

| Stainless Steel |

304/304L, 316/316L, 17-4PH |

Corrosion resistance, high temperature strength |

Chemical processing equipment, marine components, food processing |

| Tool Steel |

H13, D2, S7 |

Extreme hardness, wear resistance, heat resistance |

Dies, tooling, cutting implements, high-wear components |

Material Selection Expertise for Steel Forgings

MAIKONG’s metallurgical experts work closely with customers to select the optimal steel grade based on:

- Required mechanical properties (strength, toughness, hardness)

- Operating environment (temperature, corrosion exposure)

- Service conditions (static or dynamic loading)

- Post-forging processing requirements

- Cost considerations and material availability

Expert Material Consultation

Our metallurgical team provides comprehensive material selection guidance to ensure your steel forgings deliver optimal performance in your specific application. Contact us to discuss your material requirements.

WhatsApp Consultation

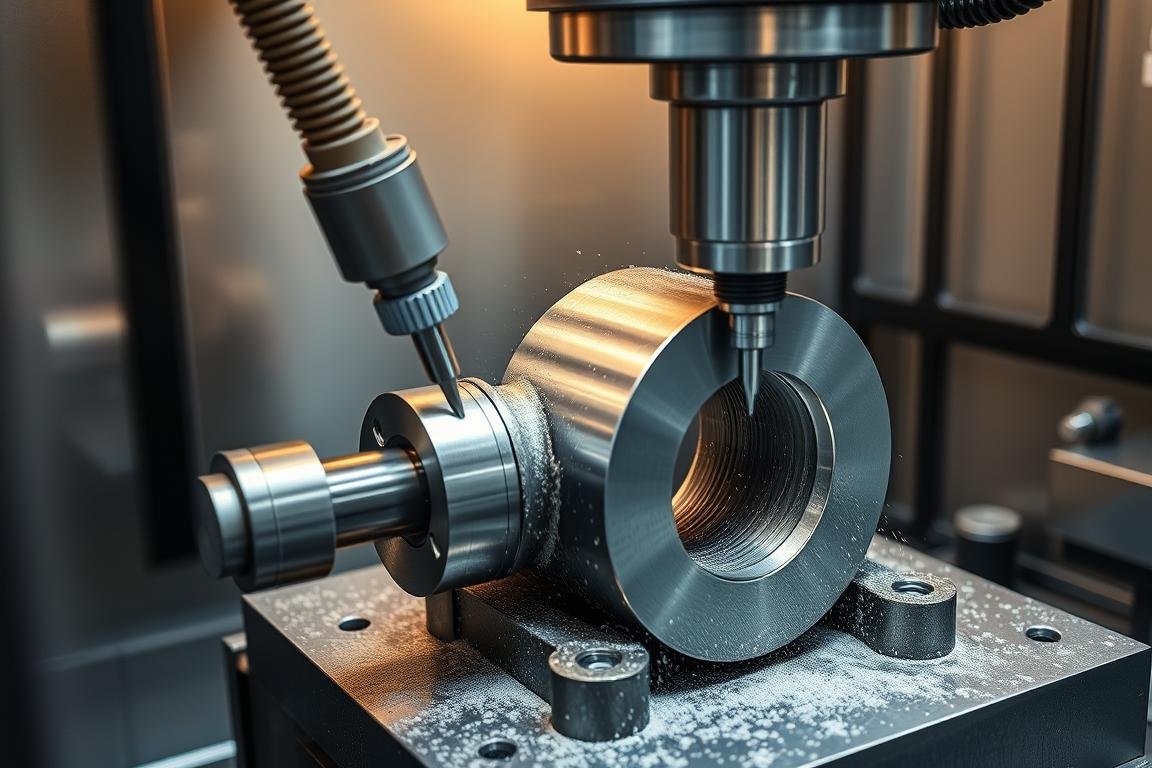

Comprehensive Services Beyond Steel Forgings

MAIKONG offers a complete range of metal manufacturing services to complement our core steel forging capabilities. Our integrated approach allows us to deliver fully finished components ready for your application.

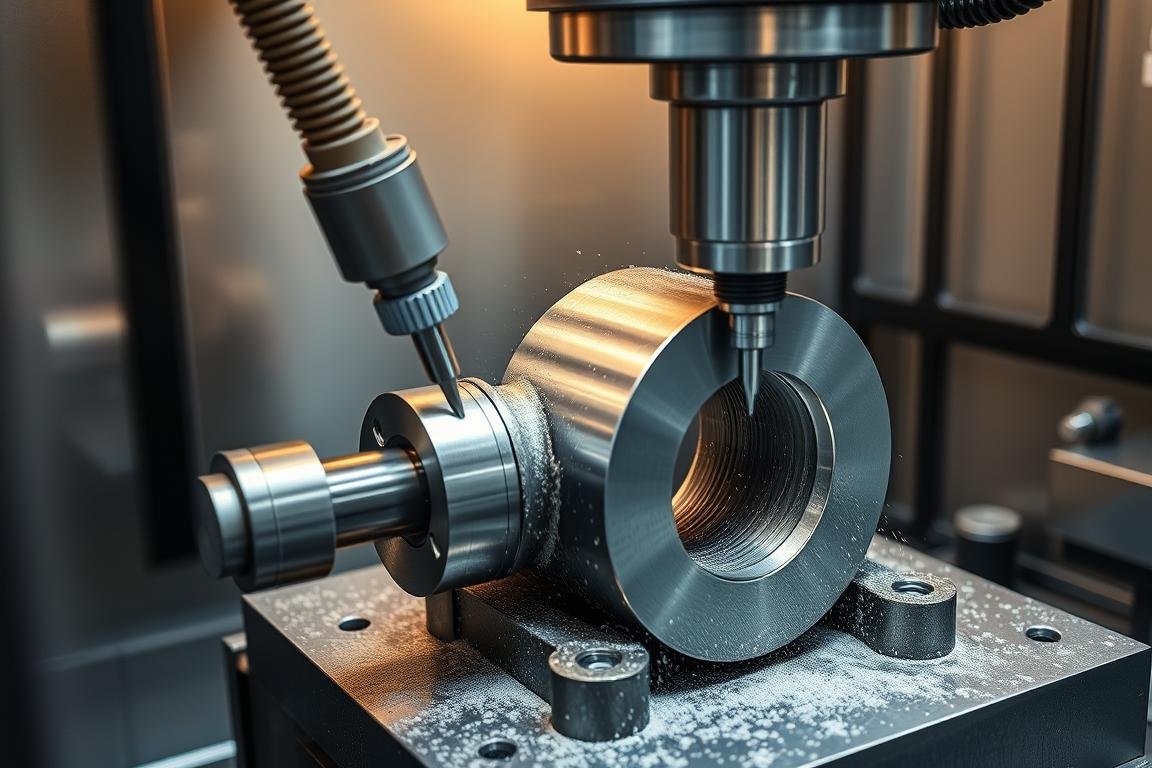

CNC Machining Services

Our state-of-the-art CNC machining center transforms rough forgings into precision-finished components with tight tolerances and excellent surface finish. Services include:

- CNC milling for complex geometries

- CNC turning for cylindrical components

- Multi-axis machining for intricate features

- Precision grinding for critical surfaces

Heat Treatment

Our comprehensive heat treatment capabilities allow us to optimize the mechanical properties of your steel forgings for specific applications:

- Normalizing to refine grain structure

- Quenching and tempering for strength

- Annealing for improved machinability

- Stress relieving to prevent distortion

Testing & Certification

Our comprehensive testing capabilities ensure that your steel forgings meet all specified requirements:

- Chemical composition analysis

- Mechanical property testing

- Non-destructive examination

- Dimensional inspection

- Full material certification

Why Choose MAIKONG for Your Steel Forgings Needs

MAIKONG has established itself as a leading provider of high-quality steel forgings and comprehensive metal manufacturing services. Our commitment to excellence, technical expertise, and customer satisfaction sets us apart in the industry.

The MAIKONG Advantage

- Extensive experience in forging a wide range of steel grades

- State-of-the-art manufacturing facilities in GD, SZ

- Comprehensive quality management system

- Engineering support from concept to production

- Competitive pricing with excellent value

- Reliable delivery performance

- Global distribution capabilities

“At MAIKONG, we understand that your success depends on the quality and reliability of the components you use. That’s why we approach every steel forging project with meticulous attention to detail and a commitment to excellence.”

– MAIKONG Engineering Team

Partner with MAIKONG for Superior Steel Forgings

Experience the MAIKONG difference with steel forgings that deliver exceptional performance, reliability, and value. Contact us today to discuss your requirements or request a quote.

Elevate Your Products with Superior Steel Forgings

The exceptional performance characteristics of steel forgings make them the optimal choice for applications where strength, durability, and reliability are non-negotiable. By choosing MAIKONG as your steel forging partner, you gain access to world-class manufacturing capabilities, technical expertise, and a commitment to your success.

Whether you’re designing components for the oil and gas industry, aerospace applications, heavy equipment, or any other demanding environment, MAIKONG’s steel forgings will provide the performance and reliability you need. Contact us today to discuss your requirements and discover how our steel forging expertise can benefit your next project.

Ready to Get Started?

MAIKONG is currently seeking US distributors for our high-quality, cost-effective steel forgings and metal manufacturing services. Contact us today to explore partnership opportunities.

Become a MAIKONG Distributor