Professional Steel Forging Services: Quality Manufacturing Solutions

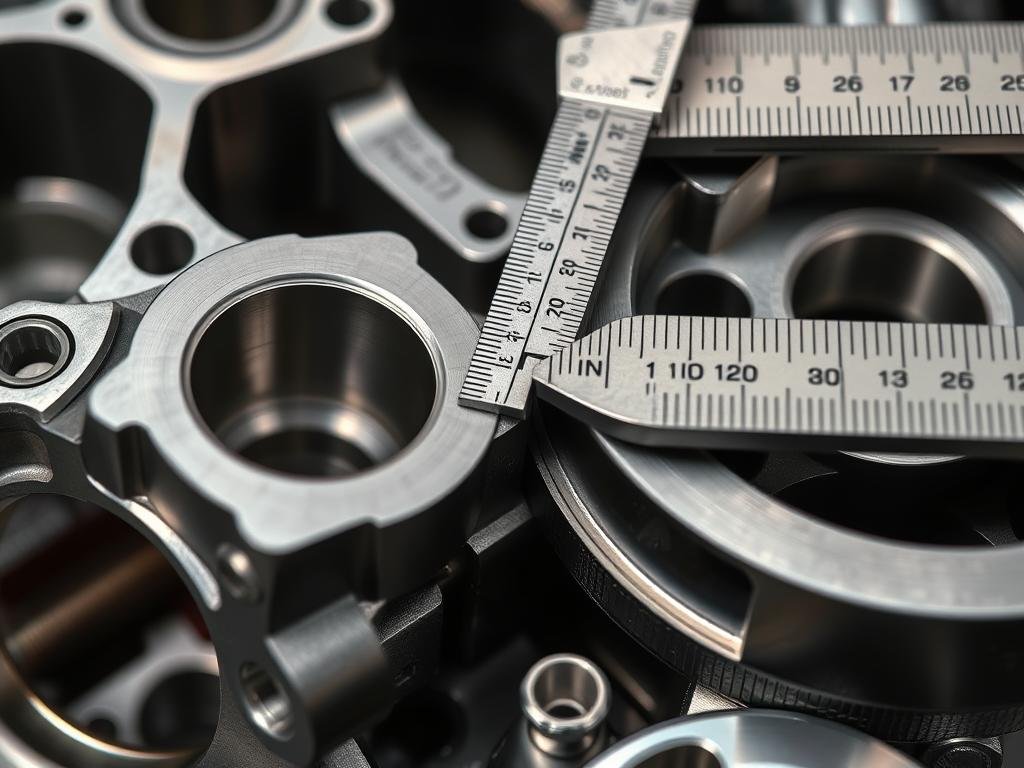

MAIKONG is a leading manufacturer of steel forging components based in Shenzhen, China, serving global markets with premium quality and cost-effective manufacturing solutions. Our advanced production facilities and expert engineering team deliver exceptional forged steel components for industries ranging from automotive and aerospace to medical and industrial automation. Whether you need drop forged steel parts, cold forged components, or custom metal solutions, our comprehensive capabilities ensure your specifications are met with precision and reliability.

Understanding Steel Forging Processes

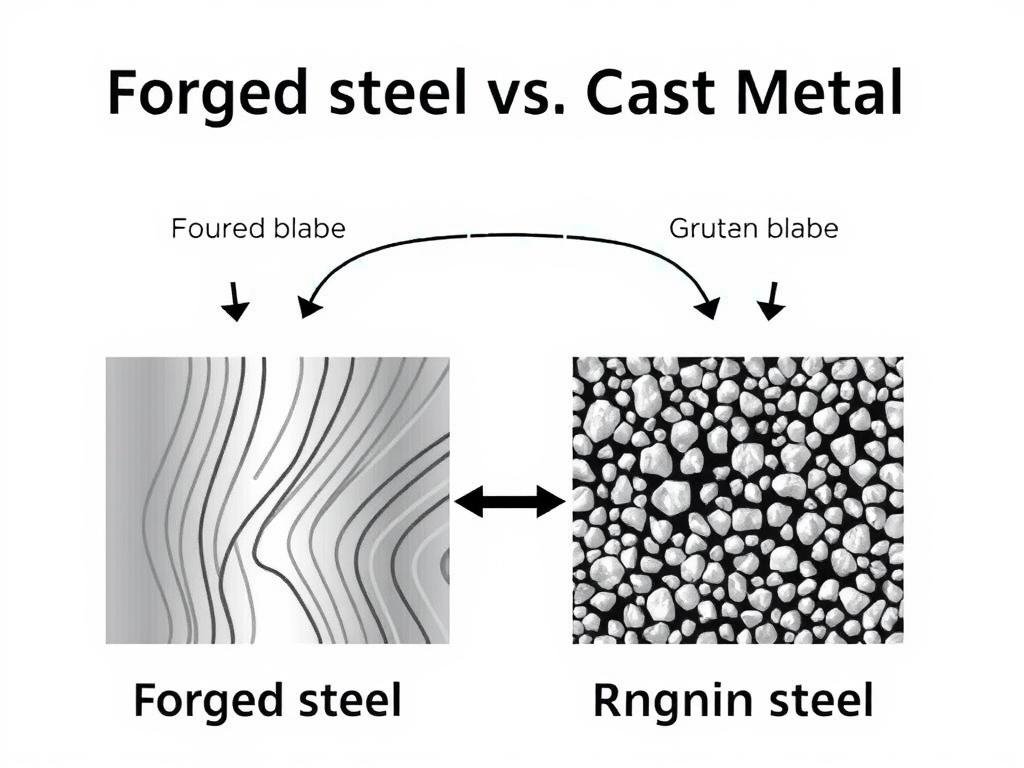

Steel forging is a manufacturing process that shapes metal using compressive forces. The process involves heating steel to specific temperatures and then applying pressure to form it into the desired shape. This technique creates components with superior strength, durability, and structural integrity compared to casting or machining alone.

The Science Behind Steel Forging

When metal is forged by steel dies, its grain structure follows the component contours, enhancing strength and reducing the risk of failure. This fundamental advantage makes steel forged parts essential for applications requiring high performance under stress. Unlike casting, which can create internal voids, forging produces dense, consistent material structures that withstand extreme conditions.

Key Benefits of Steel Forging

- Superior strength-to-weight ratio

- Enhanced structural integrity

- Improved impact and fatigue resistance

- Consistent mechanical properties

- Reduced material waste

- Excellent surface finish capabilities

- Dimensional stability under stress

Primary Steel Forging Methods at MAIKONG

At MAIKONG, we employ various steel forging techniques to meet diverse manufacturing requirements. Each method offers specific advantages for different applications, material types, and production volumes.

Drop Forge Steel Process

Our drop forge steel process uses gravity or power-assisted hammers to strike heated metal with significant force. The dropped forged steel components produced by this method feature excellent mechanical properties and are ideal for high-stress applications in automotive, agricultural, and industrial sectors.

Cold Forging Steel Technique

Cold forging steel occurs at room temperature or slightly elevated temperatures below recrystallization point. This technique produces parts with excellent dimensional accuracy, superior surface finish, and enhanced mechanical properties through work hardening. Our cold forging capabilities are particularly valuable for precision components in electronics and medical devices.

Impression Die Forging

Impression die forging (closed-die forging) uses specially designed dies to produce complex shapes with excellent dimensional control. The metal is compressed between two dies containing the negative of the desired part shape. This method is ideal for producing complex forged steel components with consistent quality in medium to high volumes.

Need Technical Guidance on Forging Methods?

Our engineering team can help determine the optimal forging process for your specific application. Contact our technical support for expert consultation.

WhatsApp Technical Support

Materials and Technical Capabilities

MAIKONG works with a wide range of steel for forging applications, ensuring we can meet diverse industry requirements. Our material selection expertise helps customers identify the optimal alloy for their specific performance needs.

Steel Grades for Forging

| Steel Type |

Applications |

Key Properties |

| Carbon Steel (1018-1095) |

General components, shafts, gears |

Good strength, machinability, cost-effective |

| Alloy Steel (4140, 4340) |

High-stress components, automotive parts |

High strength, toughness, wear resistance |

| Stainless Steel (304, 316) |

Corrosive environments, food processing |

Corrosion resistance, high temperature stability |

| Tool Steel (H13, D2) |

Tooling, dies, industrial equipment |

Extreme hardness, wear resistance, heat resistance |

| Micro-Alloy Steel |

Automotive, structural components |

High strength-to-weight ratio, formability |

Technical Specifications

- Weight Range: 0.1 kg to 50 kg per piece

- Dimensional Tolerance: ±0.2mm to ±0.5mm (process dependent)

- Surface Finish: Ra 1.6-6.3 (process dependent)

- Production Capacity: 5,000 to 100,000 pieces monthly

- Heat Treatment: Annealing, normalizing, quenching, tempering

- Testing Capabilities: Mechanical, chemical, metallurgical

Industry Applications for Steel Forgings

Our steel forged components serve critical functions across multiple industries. Each sector benefits from the superior strength, reliability, and performance of forged parts compared to alternative manufacturing methods.

Automotive

- Crankshafts

- Connecting rods

- Steering knuckles

- Transmission gears

- CV joints

Aerospace

- Landing gear components

- Turbine discs

- Structural fittings

- Engine mounts

- Control system parts

Industrial Equipment

- Gears and sprockets

- Hydraulic components

- Valves and fittings

- Bearing housings

- Structural connectors

Looking for Industry-Specific Solutions?

Our engineering team specializes in developing custom forging solutions for specific industry requirements. Let us help you optimize your components.

Email Our Engineering Team

Our Steel Forging Manufacturing Process

MAIKONG implements a comprehensive manufacturing process that ensures quality at every stage. From initial design consultation to final inspection, our systematic approach delivers consistent, high-quality forged steel components.

1. Design & Engineering

Our process begins with thorough design analysis and engineering consultation. We work closely with customers to optimize designs for the forging process, ensuring manufacturability while maintaining critical performance requirements.

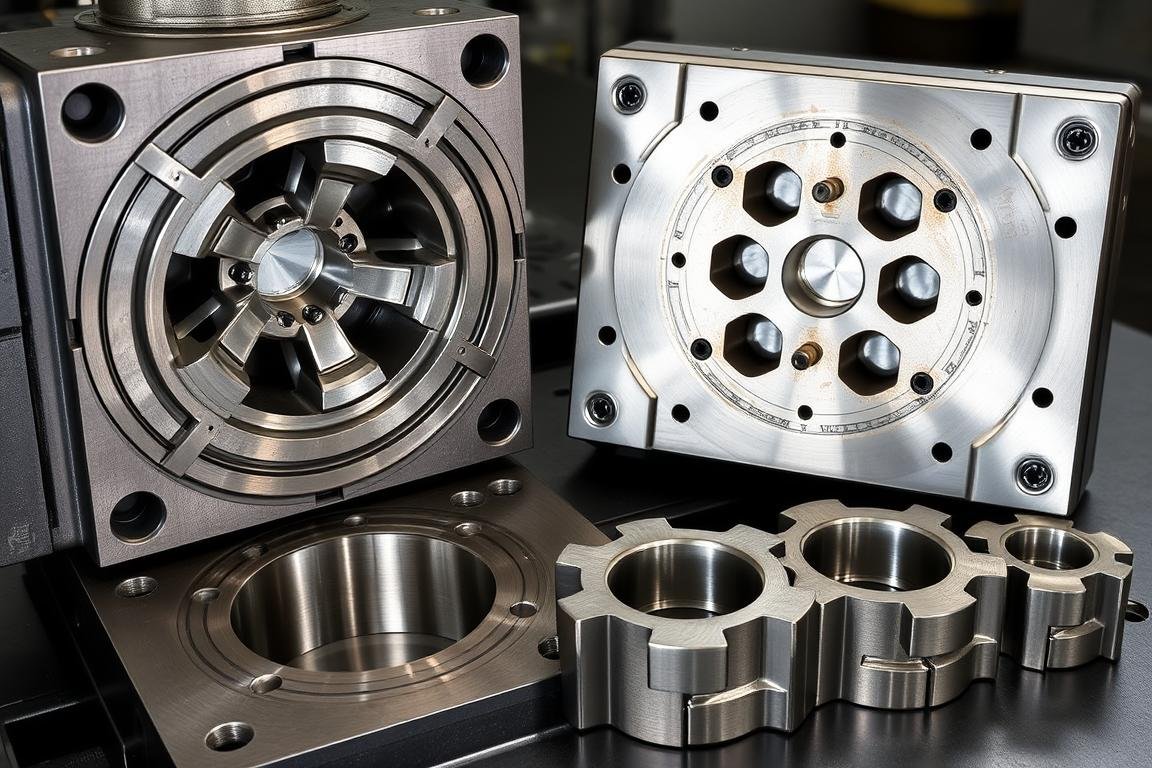

2. Tooling & Die Development

Our skilled toolmakers create precision dies for drop forge steel and impression die forging processes. We utilize advanced CAD/CAM systems and simulation software to validate die designs before production.

3. Material Selection

We source high-quality steel for forging from certified suppliers. Each batch undergoes chemical composition testing to verify material properties before entering our production process.

4. Forging Operations

Depending on part requirements, we employ drop forged steel techniques, cold forging steel methods, or impression die forging. Our equipment includes hydraulic presses ranging from 300 to 2,500 tons and drop hammers for various applications.

5. Heat Treatment

Post-forging heat treatment optimizes the mechanical properties of steel forged components. Our in-house heat treatment facilities provide annealing, normalizing, quenching, and tempering services to achieve specified hardness and strength requirements.

6. Secondary Operations

We offer comprehensive secondary operations including CNC machining, grinding, and surface treatments to deliver finished components ready for assembly. This integrated approach reduces lead times and ensures quality control throughout the process.

Quality Assurance for Steel Forgings

Quality is the cornerstone of MAIKONG’s manufacturing philosophy. Our comprehensive quality management system ensures that every steel forging component meets or exceeds customer specifications and industry standards.

Quality Control Measures

- Material Verification: Chemical composition testing and material certification

- In-Process Inspection: Dimensional checks during production stages

- Non-Destructive Testing: Ultrasonic, magnetic particle, and dye penetrant testing

- Mechanical Testing: Tensile, hardness, and impact testing

- Metallurgical Analysis: Microstructure examination and grain flow analysis

- Final Inspection: Comprehensive dimensional verification and visual inspection

Certifications & Standards

- ISO 9001:2015 Quality Management System

- IATF 16949 Automotive Quality Management

- AS9100D Aerospace Quality Standard

- ASTM International Material Standards

- RoHS and REACH Compliance

“Our commitment to quality isn’t just about meeting specifications—it’s about delivering components that perform reliably in the most demanding applications. Every steel forging we produce undergoes rigorous testing to ensure it meets our exacting standards.”

– MAIKONG Quality Assurance Team

The MAIKONG Advantage in Steel Forging

Choosing MAIKONG as your steel forging partner provides numerous advantages that contribute to your product’s success and your company’s competitive edge.

Why Choose MAIKONG for Steel Forging

- Advanced Manufacturing Technology: State-of-the-art forging equipment and tooling capabilities

- Engineering Expertise: Dedicated team of metallurgists and forging specialists

- Competitive Pricing: Cost-effective manufacturing without compromising quality

- Comprehensive Capabilities: From design assistance to finished components

- Flexible Production: Accommodating both prototype and high-volume requirements

- Global Supply Chain: Reliable material sourcing and logistics management

- 24/7 Technical Support: Responsive communication via WhatsApp and email

Ready to Experience the MAIKONG Difference?

Contact us today to discuss your steel forging requirements and discover how our expertise can benefit your projects.

Request a Quote

Steel Forging Success Stories

Our track record of successful projects demonstrates our capabilities in delivering high-quality forged steel components across diverse applications. Here are some examples of how we’ve helped customers overcome manufacturing challenges.

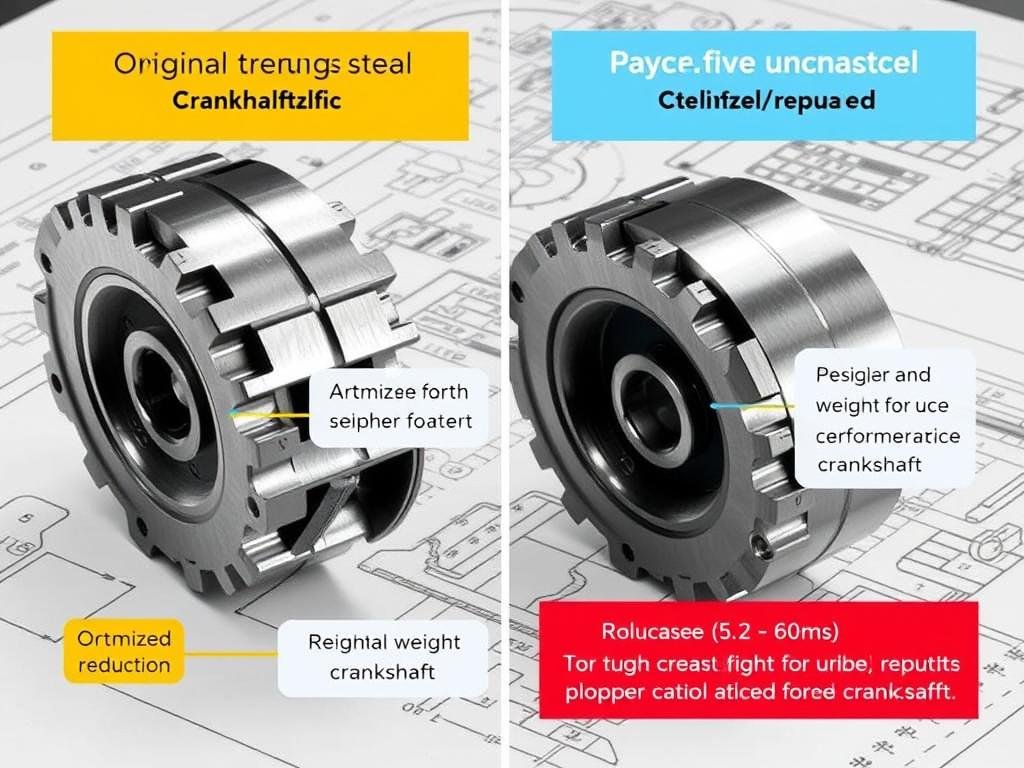

Automotive Crankshaft Optimization

Challenge: An automotive manufacturer needed to reduce weight in their crankshaft design while maintaining strength requirements.

Solution: Our engineering team redesigned the drop forged steel component using advanced simulation tools, optimizing material distribution and forging parameters.

Result: 15% weight reduction, 8% cost savings, and improved fatigue performance in high-stress applications.

Aerospace Component Production

Challenge: An aerospace supplier required complex structural components with extremely tight tolerances and 100% traceability.

Solution: We implemented a specialized steel forging process with enhanced quality control measures and comprehensive documentation.

Result: Zero-defect components delivered on schedule, exceeding customer specifications and passing all qualification testing.

Frequently Asked Questions About Steel Forging

What is the difference between forging and casting?

Forging shapes metal through compressive force, resulting in improved grain structure and strength. Casting involves pouring molten metal into a mold. Steel forged components typically offer superior mechanical properties, including better strength-to-weight ratio, improved fatigue resistance, and enhanced structural integrity compared to cast parts.

What types of steel are best suited for forging?

Many steel grades are suitable for forging, with selection depending on the application requirements. Common steel for forging includes carbon steels (1018-1095), alloy steels (4140, 4340), stainless steels (304, 316), and tool steels. The optimal choice depends on factors like strength requirements, operating environment, temperature conditions, and cost considerations.

What are the minimum and maximum sizes for steel forgings?

At MAIKONG, we can produce steel forged components ranging from small precision parts weighing as little as 0.1 kg to larger components up to 50 kg. The specific size limitations depend on the forging method, equipment capabilities, and material properties. Our engineering team can advise on feasibility for your specific requirements.

What is the typical lead time for steel forged components?

Lead times vary based on complexity, quantity, and current production schedule. Typical timeframes are:

- Tooling development: 2-4 weeks

- Sample production: 1-2 weeks after tooling

- Production runs: 3-6 weeks after approval

We offer expedited services for urgent requirements when possible.

How does MAIKONG ensure quality for overseas customers?

We implement comprehensive quality assurance measures including:

- Detailed inspection reports with each shipment

- Digital documentation and traceability systems

- Pre-shipment approval processes with customer review

- Video conferences for critical inspection points

- Sample approval workflows before mass production

- Third-party inspection services when requested

Why MAIKONG is Your Ideal Steel Forging Partner

MAIKONG combines advanced manufacturing capabilities, technical expertise, and customer-focused service to deliver exceptional steel forging solutions. Our commitment to quality, competitive pricing, and responsive communication makes us the preferred partner for businesses seeking reliable manufacturing from China.

From drop forged steel components to precision cold forging steel parts, we provide comprehensive solutions that help you optimize performance while controlling costs. Partner with MAIKONG for your next project and experience the difference that expertise and dedication can make in your supply chain.

Start Your Manufacturing Journey with MAIKONG Today

Contact our team to discuss your steel forging requirements and discover how we can support your manufacturing goals.