Premium 2024 Aluminum Forgings Orange County – MAIKONG’s Expert Solutions

December 6, 2025

Need Premium 2024 Aluminum Forgings For Your Project?

Our expert team is ready to provide you with a detailed quote tailored to your specific requirements. Experience the MAIKONG difference with our competitive pricing and industry-leading quality.

Why Choose MAIKONG for 2024 Aluminum Forgings in Orange County

At MAIKONG, we understand that quality, reliability, and precision are paramount when it comes to aluminum forgings. Our specialized processes for 2024 aluminum alloy deliver components with exceptional mechanical properties that consistently exceed customer expectations.

Superior Strength-to-Weight Ratio

Our 2024 aluminum forgings offer an optimal balance of lightweight properties and robust mechanical characteristics, making them ideal for aerospace and high-performance applications.

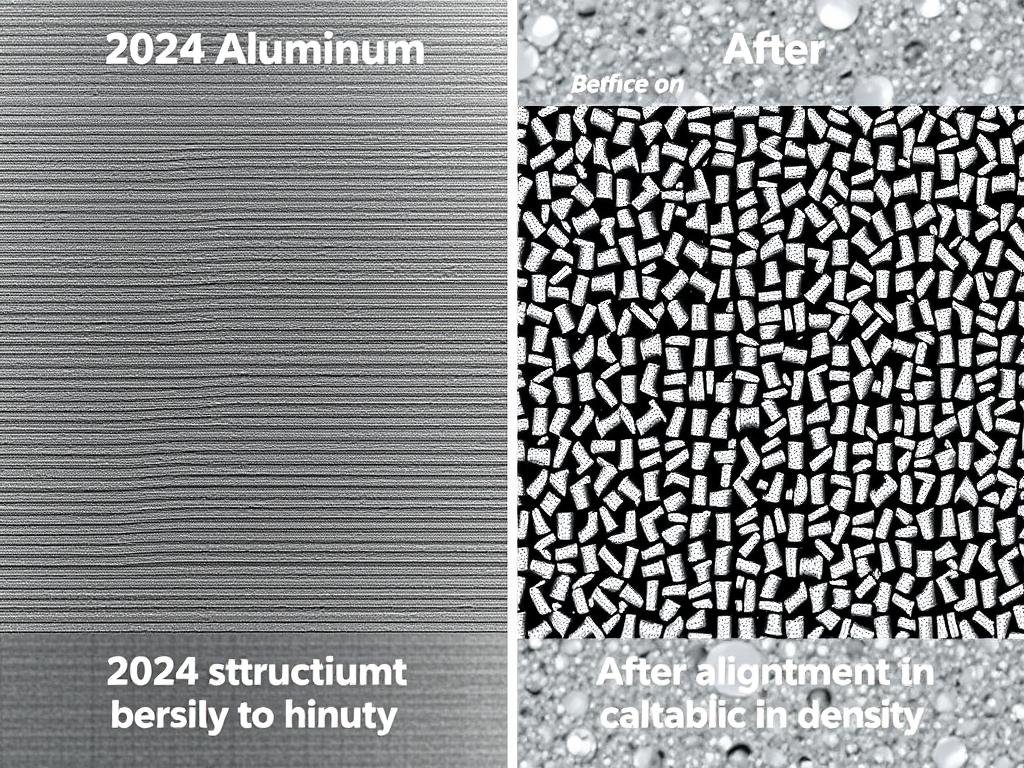

Enhanced Grain Structure

Our forging process aligns the grain structure of 2024 aluminum, significantly improving strength, durability, and fatigue resistance compared to cast components.

Precision Engineering

With tolerances as tight as ±0.005″, our 2024 aluminum forgings deliver the dimensional accuracy required for mission-critical applications.

Comprehensive Quality Control

Every 2024 aluminum forging undergoes rigorous testing and inspection to ensure it meets or exceeds all specified requirements and industry standards.

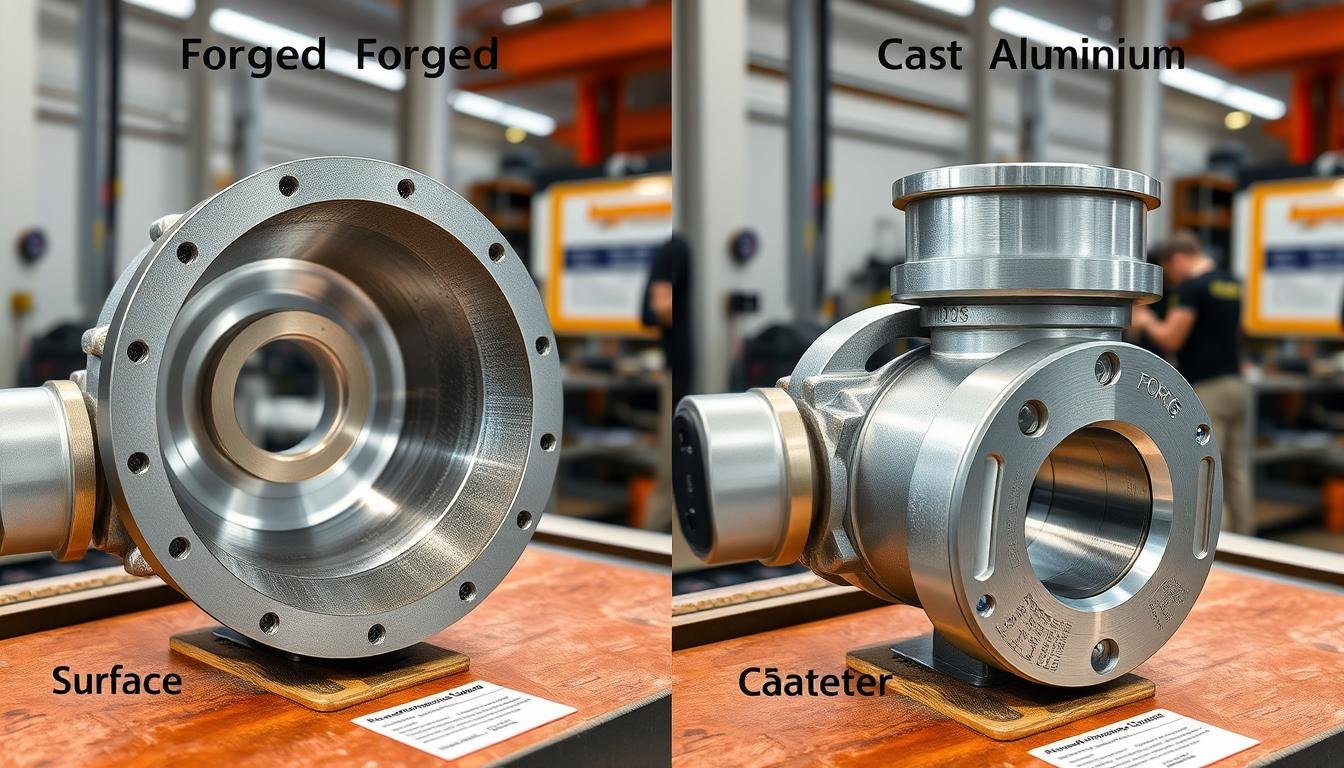

The MAIKONG Advantage: 2024 Aluminum Forgings vs. Casting

Understanding the differences between forged and cast aluminum components is crucial when selecting the right manufacturing process for your application. Our 2024 aluminum forgings offer significant advantages over cast alternatives:

| Comparison Categories | MAIKONG’s 2024 Aluminum Forgings | Cast Aluminum |

| Strength and Durability | Superior strength due to dense, uniform grain structure | Lower strength with potential air pockets and inclusions |

| Tensile Properties | Exceptional tensile strength and resistance | Reduced tensile strength and structural integrity |

| Fatigue Resistance | Enhanced resistance to cyclic loading and fatigue failure | More susceptible to fatigue-related failures |

| Dimensional Accuracy | Precise tolerances and consistent dimensions | Potential inconsistencies and dimensional variations |

| Weight-to-Strength Ratio | Optimal balance for lightweight, high-strength applications | Requires bulkier designs to achieve comparable strength |

Industry Applications for 2024 Aluminum Forgings

MAIKONG’s precision 2024 aluminum forgings serve critical roles across multiple industries where performance, reliability, and safety are paramount:

Aerospace

- Structural components

- Landing gear parts

- Engine mounts

- Nacelle components

Automotive

- Suspension components

- Chassis parts

- Drivetrain elements

- Performance upgrades

Industrial

- Machinery components

- Hydraulic systems

- Precision equipment

- Robotic elements

Defense

- Tactical equipment

- Vehicle components

- Communication systems

- Specialized hardware

Ready to Elevate Your Projects with Premium 2024 Aluminum Forgings?

Contact our team today to discuss your specific requirements and discover how MAIKONG can deliver the precision components your application demands.

Our Comprehensive 2024 Aluminum Forging Process

At MAIKONG, we’ve developed a meticulous process to ensure every 2024 aluminum forging meets the highest standards of quality and precision. Our comprehensive approach covers every aspect from initial design to final delivery:

-

CAD/CAM Design & Analysis

Our engineering team utilizes advanced software to identify potential issues early and optimize the forging process for your specific component requirements.

-

Material Selection & Testing

We carefully select and test 2024 aluminum alloy stock to ensure optimal mechanical properties, machining capabilities, and heat treatment characteristics.

-

Precision Tooling

Custom tooling designed specifically for your component ensures initial quality and consistency throughout production runs of any size.

-

Forging Process

Our state-of-the-art forging workshop accommodates diverse specifications, with hydraulic presses ranging from 500 to 2500 tons for optimal forming of 2024 aluminum.

-

Heat Treatment

In-house heat treatment with comprehensive statistical analysis ensures your 2024 aluminum forgings achieve the precise mechanical properties required.

-

Precision Machining

Advanced CNC machines perform precise and intricate operations to achieve final dimensions and features with exceptional accuracy.

-

Surface Treatment

Optional surface treatments enhance appearance, performance, and corrosion resistance according to your specifications.

-

Quality Assurance

Rigorous inspection and testing procedures ensure every component meets or exceeds your requirements and applicable industry standards.

Quality Assurance for 2024 Aluminum Forgings

At MAIKONG, quality isn’t just a department—it’s a core value embedded in every aspect of our operation. Our comprehensive quality management system ensures that every 2024 aluminum forging meets or exceeds the most stringent requirements:

Certifications & Standards

- ISO 9001:2015 certified quality management system

- AS9100 Rev D aerospace standard compliance

- NADCAP accreditation for special processes

- Material certifications and traceability

Testing & Inspection

- Dimensional verification with CMM technology

- Material composition analysis

- Mechanical property testing

- Non-destructive testing capabilities

- Surface finish inspection

As both a producer and consumer of our customers’ products, we recognize the crucial importance of consistency, strength, and weight in each forged part for the final product. Our material laboratory plays a vital role in our production process, enabling us to achieve the precise results you demand.

Why Partner with MAIKONG for Your 2024 Aluminum Forgings Needs

Choosing the right partner for your aluminum forging requirements is a critical decision that impacts product quality, performance, and your bottom line. Here’s why leading companies in Orange County and beyond trust MAIKONG:

The MAIKONG Advantage

- 60+ CNC machines with 100+ tons monthly processing capacity

- Comprehensive in-house capabilities from design to delivery

- Specialized expertise in 2024 aluminum alloy properties and applications

- Competitive pricing with exceptional value

- Quick turnaround times and reliable delivery

- Dedicated customer service and technical support

- Nationwide distribution network

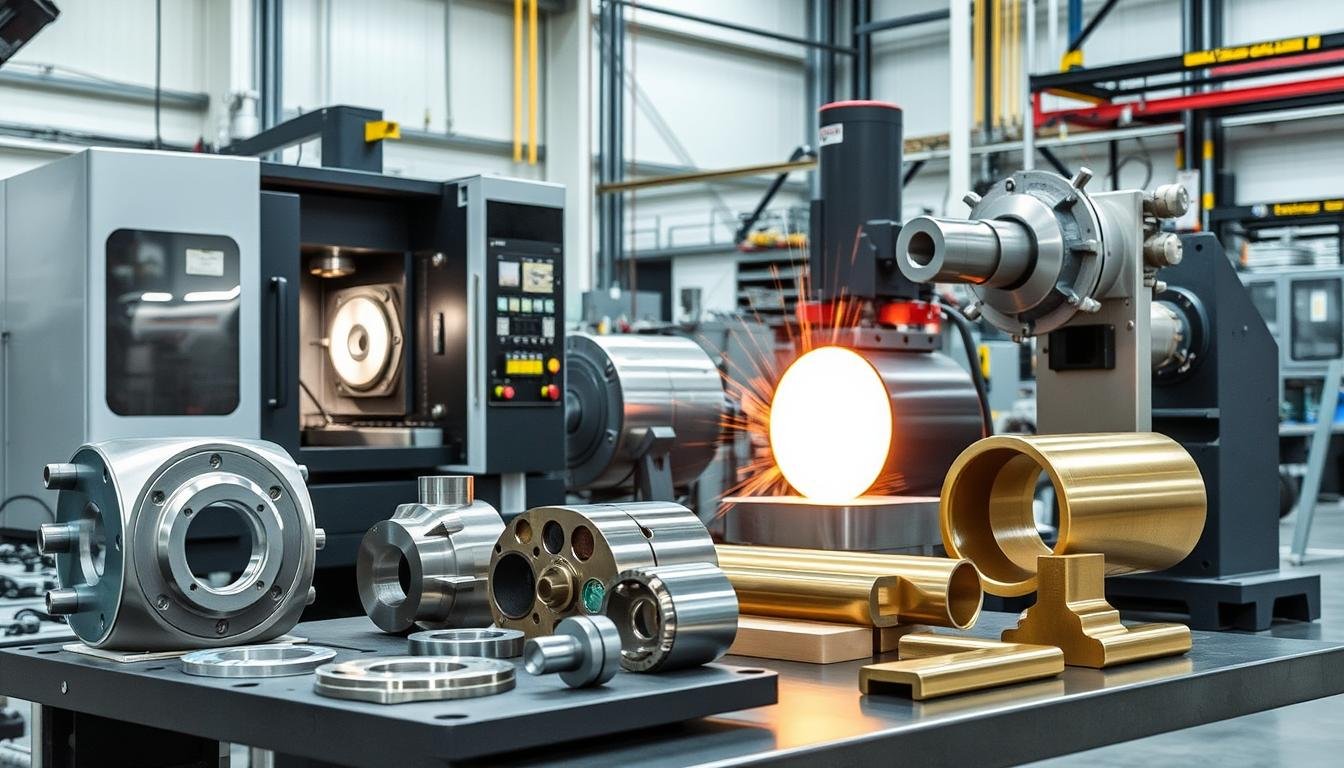

Additional Services Complementing Our 2024 Aluminum Forgings

Beyond our core expertise in 2024 aluminum forgings, MAIKONG offers a comprehensive suite of complementary services to provide complete solutions for your manufacturing needs:

CNC Machining Services

Our advanced CNC turning and milling capabilities deliver precision-machined components with exceptional surface finishes and tight tolerances.

- Multi-axis machining

- Swiss-type precision

- Complex geometries

Steel Forging Services

Complement your aluminum components with our high-strength steel forgings for applications requiring maximum durability and wear resistance.

- Carbon and alloy steels

- Stainless steel options

- Heat treatment services

Brass Extrusion Services

Our brass extrusion capabilities provide additional material options for applications requiring specific electrical, thermal, or aesthetic properties.

- Custom profiles

- Precision tolerances

- Various brass alloys

Contact MAIKONG for Premium 2024 Aluminum Forgings in Orange County

Ready to experience the MAIKONG difference? Our team of experts is standing by to discuss your 2024 aluminum forging requirements and provide a detailed quote tailored to your specific needs.

Get in Touch

- Phone/WhatsApp: +86 13510907401

- Email: Lucy@maikongforge.us

- Website: https://maikongforge.us

We’re currently recruiting distributors across the United States. Contact us to learn about our distributor program and how you can represent MAIKONG’s premium aluminum forging solutions in your region.

Experience Superior 2024 Aluminum Forgings with MAIKONG

When quality, precision, and reliability matter for your 2024 aluminum forgings, MAIKONG delivers excellence at every step. Our comprehensive capabilities, technical expertise, and customer-focused approach make us the preferred partner for discerning manufacturers in Orange County and nationwide.

Contact us today to discuss your specific requirements and discover how our premium aluminum forging solutions can enhance your products and streamline your supply chain.

Ready to Get Started?

Take the first step toward superior 2024 aluminum forgings by contacting our team today.

Contact us online by Whatsapp: