In the demanding world of industrial manufacturing, the method used to shape metal components can make the difference between exceptional performance and premature failure. Metal forge technology stands as the gold standard for creating components that require superior strength, durability, and structural integrity. At MAIKONG, we’ve mastered the art and science of metal forging to deliver components that consistently outperform alternatives across the most challenging industrial applications.This comprehensive guide explores why metal forge processes deliver unmatched results, how our precision techniques enhance component performance, and why leading manufacturers trust MAIKONG for their most critical metal components.

The Science Behind Superior Metal Forge Results

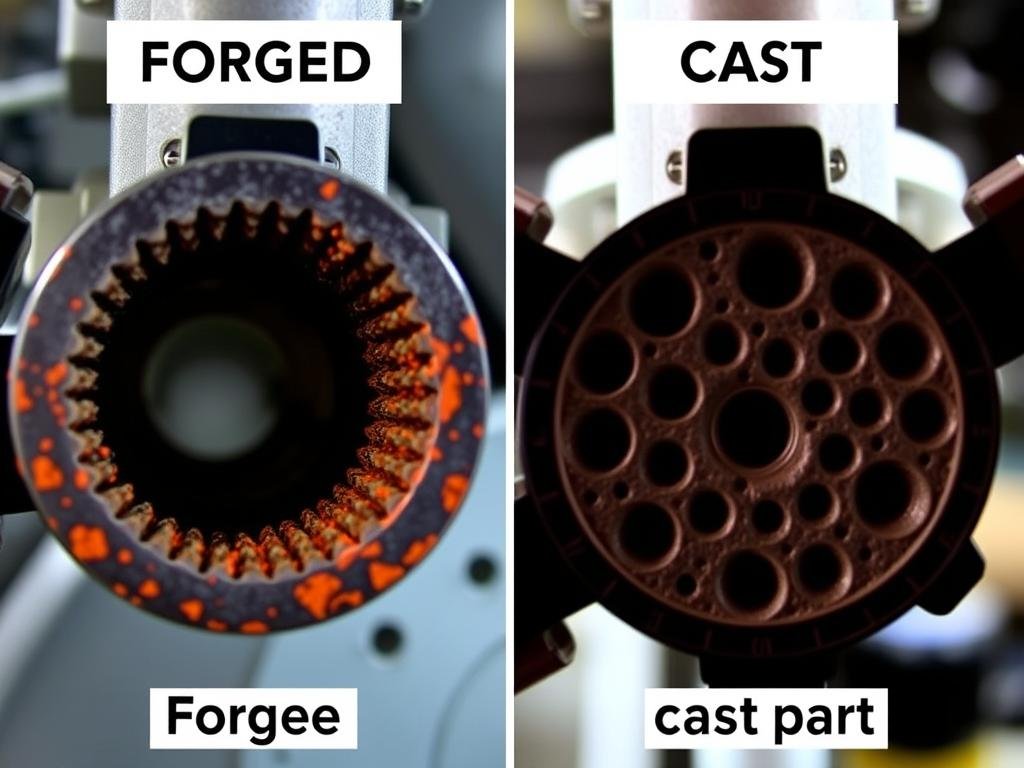

At its core, metal forge technology relies on the application of compressive force to reshape metal while maintaining and enhancing its internal structure. Unlike casting methods that melt metal completely, forging works with the metal’s natural grain structure, aligning and strengthening it through controlled deformation.

How the Metal Forge Process Works

The forging process begins with heating metal to a precise temperature where it becomes malleable without fully liquefying. This heated metal is then shaped using specialized dies and powerful presses that apply carefully calculated pressure. This compression fundamentally alters the metal’s microstructure, eliminating voids and aligning the grain flow to follow the contours of the part.

At MAIKONG, our advanced metal forge facilities in GD, SZ utilize state-of-the-art hydraulic presses capable of exerting up to 100+ tons of pressure, ensuring optimal grain refinement and superior mechanical properties in every component we produce.

Expert Forging Consultation

Discover how MAIKONG’s advanced forging techniques can enhance your component performance and reliability.

Request Expert Consultation

Why Choose Metal Forge Over Casting Methods

When designing critical components, manufacturers must carefully consider production methods. While casting offers certain advantages for complex geometries, metal forge processes deliver superior mechanical properties that are essential for high-stress applications.

| Performance Factor |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Superior due to dense, uniform grain structure |

Lower due to potential air pockets and inclusions |

| Tensile Properties |

20-30% higher tensile strength |

Lower tensile strength |

| Fatigue Resistance |

300% better resistance against fatigue failure |

More susceptible to fatigue cracking |

| Dimensional Accuracy |

Precision tolerances to ±0.005″ |

Potential inconsistencies from shrinkage |

| Grain Structure |

Directional grain flow for improved properties |

Random grain orientation |

| Weight Optimization |

Higher strength allows for lighter components |

Often requires thicker walls for equivalent strength |

“The superior grain structure achieved through MAIKONG’s precision forging processes results in components with up to 300% better fatigue resistance compared to cast alternatives. This translates directly to longer service life and improved safety margins in critical applications.”

– MAIKONG Engineering Team

Industrial Applications That Demand Metal Forge Quality

The exceptional mechanical properties achieved through metal forge processes make forged components the preferred choice across numerous industries where performance cannot be compromised.

Aerospace

Aircraft landing gear, turbine discs, and structural components where failure is not an option rely on the superior strength-to-weight ratio and fatigue resistance of forged parts.

Automotive

Engine crankshafts, connecting rods, and suspension components benefit from the improved durability and performance characteristics of forged metal.

Heavy Machinery

Construction equipment, mining machinery, and industrial systems rely on forged components to withstand extreme loads and harsh operating conditions.

Industry-Specific Forging Solutions

MAIKONG specializes in custom forging solutions optimized for your specific industry requirements.

Explore Industry Solutions

MAIKONG’s Advanced Metal Forge Capabilities

With decades of experience and continuous investment in technology, MAIKONG has established itself as a leader in precision metal forging and comprehensive manufacturing services.

Comprehensive Forging Services

- Aluminum forging with superior strength-to-weight ratio

- Steel forging for maximum durability applications

- Brass forging for electrical and decorative components

- Custom alloy forging to meet specialized requirements

- Precision CNC machining of forged components

- Heat treatment for optimized material properties

- Surface finishing and treatment options

- Comprehensive quality testing and certification

Our Manufacturing Excellence

The MAIKONG Metal Forge Process

Our comprehensive approach ensures quality at every stage from concept to finished component.

-

Design & Engineering

Our engineering team works closely with clients to optimize component design for the forging process, utilizing advanced CAD/CAM systems to simulate material flow and predict performance.

-

Material Selection

We carefully select optimal alloys based on mechanical requirements, machining capabilities, heat treatment characteristics, and cost-effectiveness for each application.

-

Tooling Design & Fabrication

Precision tooling is critical for forging quality. Our tooling experts design and maintain dies that ensure consistent results and optimal material flow during the forging process.

-

Forging Operation

Using our advanced hydraulic presses, we apply precisely controlled force to shape metal into components with superior grain structure and mechanical properties.

-

Heat Treatment

Our in-house heat treatment facilities allow precise control of material properties, with comprehensive statistical analysis and documentation for consistent quality.

-

Precision Machining

State-of-the-art CNC machines perform secondary operations to achieve final dimensions and features with exceptional precision.

-

Surface Treatment

We offer comprehensive surface finishing options including anodizing, painting, and laser engraving to enhance appearance and performance.

-

Quality Assurance

Rigorous inspection and testing procedures ensure every component meets or exceeds specifications before shipment.

Partner With MAIKONG For Superior Results

Experience the difference that precision metal forging can make in your component performance and reliability.

Contact Us on WhatsApp

Quality Assurance in Metal Forge Manufacturing

At MAIKONG, quality isn’t just a department—it’s a fundamental aspect of our entire operation. Our comprehensive quality management system ensures that every forged component meets the highest standards of performance and reliability.

Our Quality Commitment

MAIKONG holds ISO 9001:2015 certification, demonstrating our commitment to consistent quality management practices. Our in-house testing capabilities include:

- Dimensional inspection with precision CMM equipment

- Material composition verification

- Mechanical property testing (tensile, hardness, impact)

- Non-destructive testing (ultrasonic, magnetic particle)

- Microstructure analysis

- Fatigue and load testing for critical components

4.9

Customer Satisfaction

Experience the MAIKONG Difference in Metal Forge Manufacturing

From aerospace components to automotive parts, industrial equipment to specialized machinery, MAIKONG delivers forged metal components with superior performance characteristics. Our commitment to quality, precision, and customer satisfaction has made us a trusted partner for manufacturers who demand the best.

Contact our team today to discuss your specific requirements and discover how our advanced metal forge capabilities can enhance your product performance, reliability, and competitive advantage.

Ready to Elevate Your Component Performance?

Connect with MAIKONG’s engineering team to discuss your specific metal forging requirements.

Email Our Engineering Team