Metal forging is one of the oldest and most reliable metalworking processes, dating back thousands of years. This manufacturing technique shapes metal using compressive forces, delivered through hammering, pressing, or rolling. The result? Components with exceptional strength, durability, and structural integrity that outperform parts made through other manufacturing methods. Today, we’ll explore everything you need to know about this critical manufacturing process and how MAIKONG delivers superior metal forging solutions for industries worldwide.

Key Takeaways About Metal Forging

- Superior Strength: Metal forging creates components with enhanced mechanical properties by refining grain structure and eliminating voids.

- Process Variety: Choose from open die, closed die, cold forging, or roll forging based on your specific requirements for size, complexity, and production volume.

- Material Options: Forge various metals including steel, aluminum, titanium, brass, and specialized alloys for diverse applications.

- Industry Applications: Forged components are essential in automotive, aerospace, agriculture, construction, oil & gas, and many other industries.

- Quality Advantage: Forged parts offer superior fatigue resistance, impact strength, and reliability in critical applications.

Understanding the Metal Forging Process

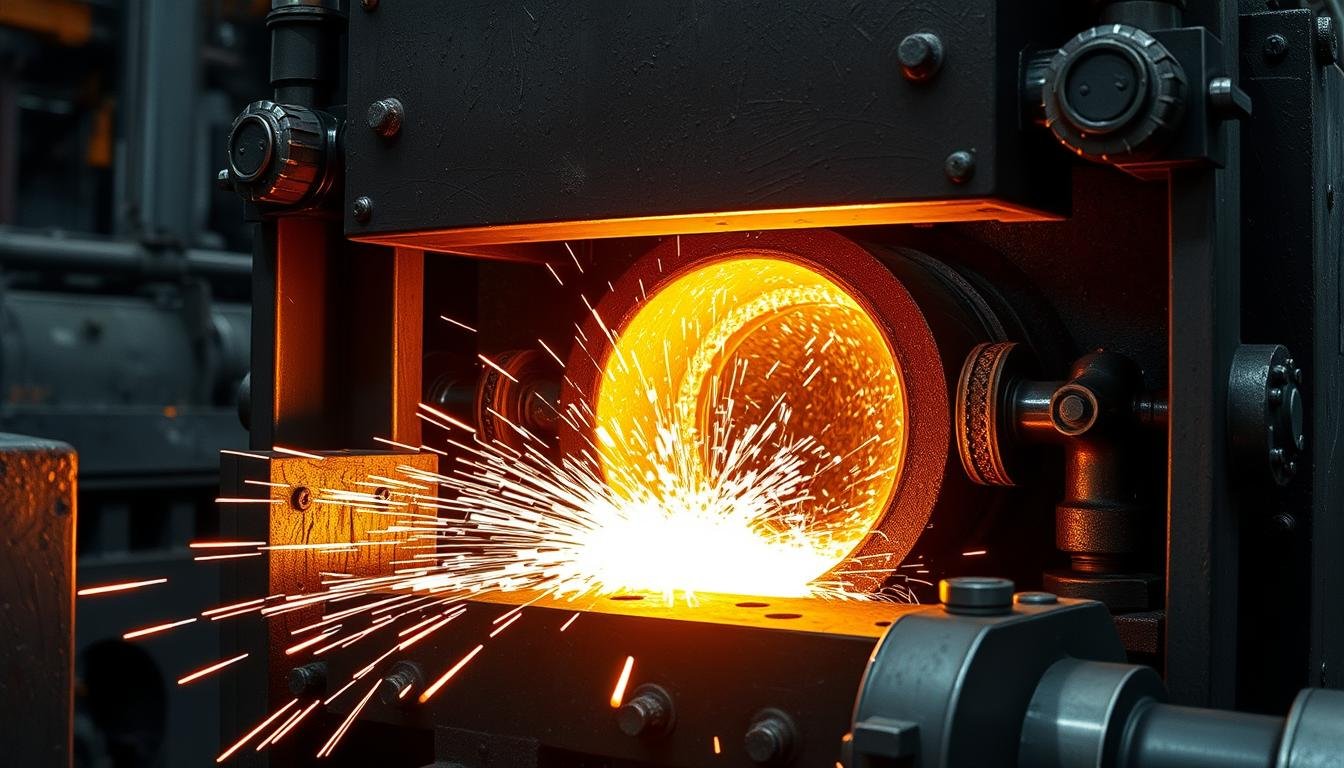

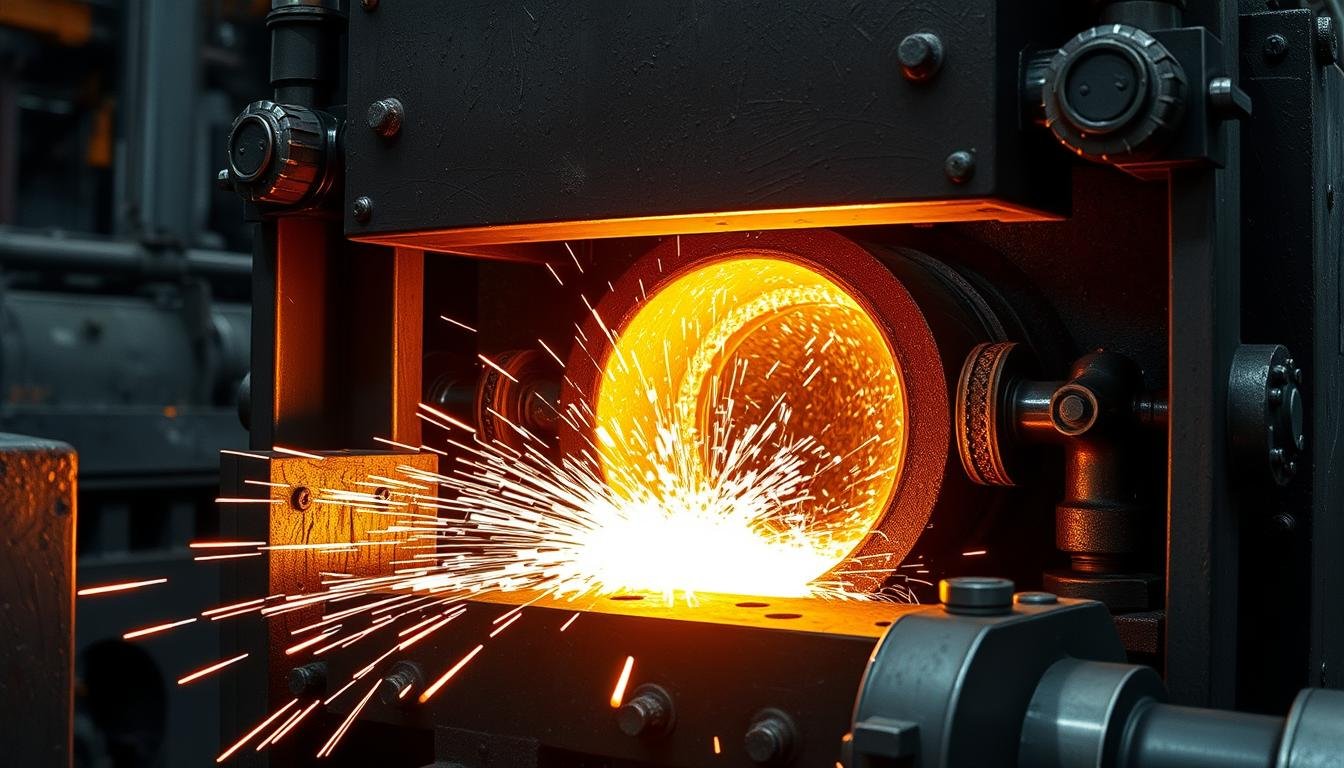

At its core, metal forging is a manufacturing process that shapes metal using localized compressive forces. Unlike casting, which involves pouring molten metal into molds, forging works with solid metal that has been heated to increase malleability. This fundamental difference results in stronger parts with improved grain structure and mechanical properties.

How Metal Forging Strengthens Metal

The metal forging process significantly enhances material properties through several mechanisms:

- Refined Grain Structure: Forging aligns the grain flow of the metal, creating a more favorable structure that increases strength.

- Elimination of Voids: The compressive forces seal minor cracks and close empty spaces within the metal.

- Reduced Impurities: The process breaks up and redistributes impurities, minimizing their negative impact.

- Enhanced Mechanical Properties: Forged parts demonstrate superior tensile strength, ductility, and impact resistance.

- Improved Fatigue Resistance: The aligned grain structure significantly enhances resistance to cyclic loading.

Primary Metal Forging Methods

The metal forging industry employs several distinct methods, each with specific advantages for different applications. These methods can be categorized by tooling approach and operating temperature.

Forging Methods by Tooling

Open Die Forging

In open die forging, metal is shaped between two flat or simply shaped dies that don’t completely enclose the workpiece. This method is ideal for larger parts and allows for greater flexibility in shaping. The metal can flow except where contacted by the dies, requiring skilled operators to achieve the desired shape.

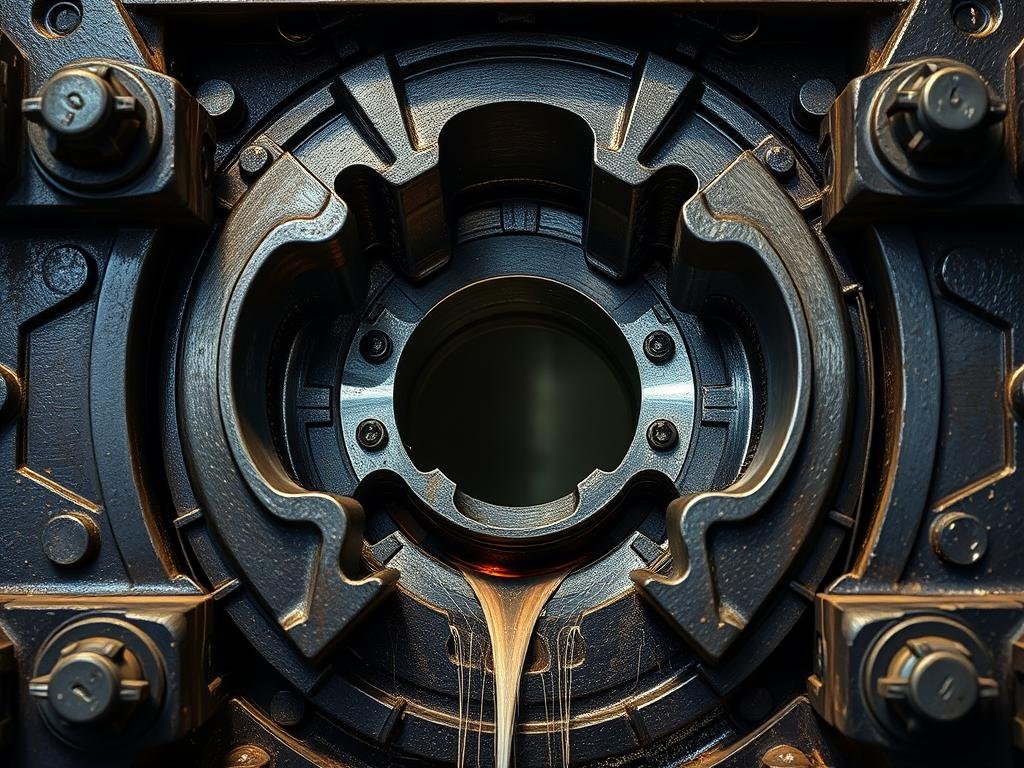

Closed Die Forging

Also known as impression die forging, this method uses dies with cavities that contain the negative image of the desired part. The metal is forced to flow into these cavities, creating complex shapes with excellent dimensional accuracy. Excess material forms “flash” that is later removed.

Roll Forging

Roll forging uses two cylindrical or semi-cylindrical rolls with shaped grooves to progressively form metal. As the heated bar passes through the rolls, its thickness is reduced while its length increases. This method produces parts with excellent grain flow and is commonly used for axles, leaf springs, and hand tools.

Forging Methods by Temperature

Hot Forging

Performed above the metal’s recrystallization temperature (typically 950-1250°C for steel), hot forging offers excellent formability and lower forming forces. The process prevents work hardening through recrystallization, resulting in consistent tensile strength throughout the workpiece.

Warm Forging

Operating at temperatures between cold and hot forging (750-950°C for steel), warm forging offers a balance of benefits. It produces less scaling, achieves tighter tolerances than hot forging, and requires lower forming forces than cold forging.

Cold Forging

Performed at room temperature or slightly elevated temperatures (up to 150°C), cold forging achieves the tightest tolerances and excellent surface finish. However, it requires higher forming forces and increases strength while decreasing ductility due to strain hardening.

Standard Metal Forging Equipment

The metal forging process relies on specialized equipment to apply the necessary forces to shape metal effectively. Each type of equipment offers distinct advantages for different applications.

Forging Hammers

Hammers deliver high-impact blows to shape metal quickly. Drop hammers use gravity or power assistance to raise and drop a heavy weight onto the workpiece. These are ideal for operations requiring deformation through repeated impacts rather than continuous pressure.

Forging Presses

Presses apply continuous pressure rather than impact force. Mechanical presses use cranks, gears, or toggles to generate force, while hydraulic presses use fluid pressure. Presses offer more precise control and are suitable for larger workpieces requiring controlled deformation.

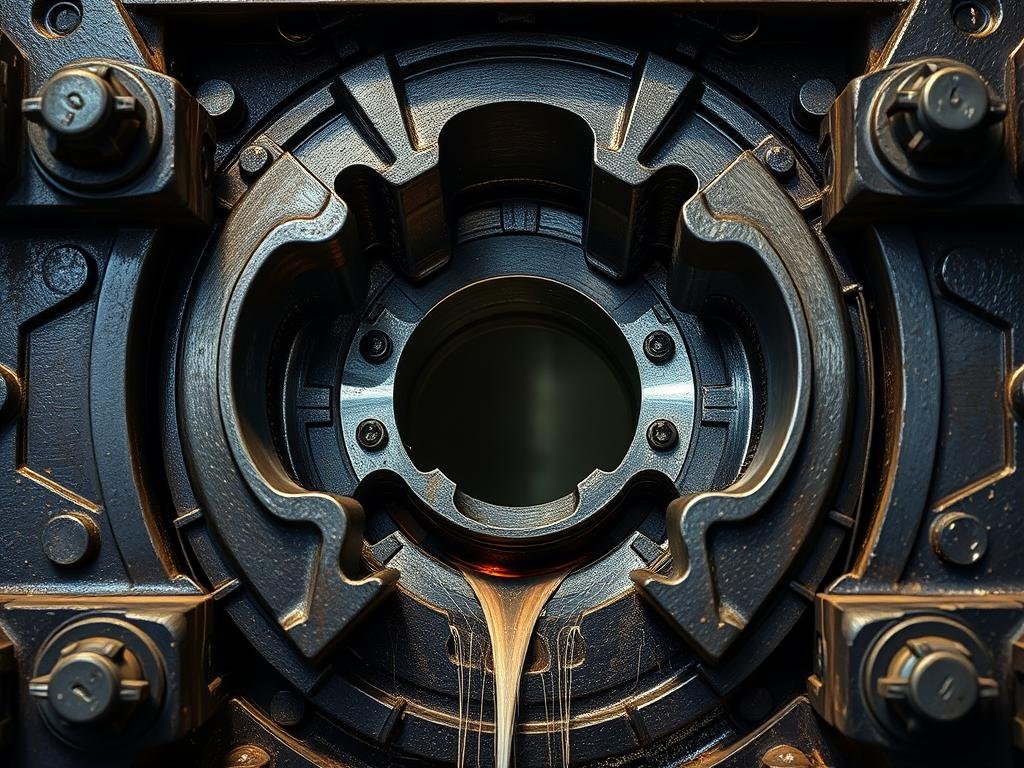

Ring Rollers

Specialized equipment for producing seamless rings with diameters from a few inches to over 300 inches. Ring rollers eliminate the need for welding by squeezing a hollow round piece of metal under extreme pressure against rotating rolls.

Upsetters

Horizontal forging presses used primarily for “upsetting” operations, where a metal bar’s diameter is increased by compressing its length. Commonly used for producing fasteners, valves, and fittings with enlarged sections.

Advantages of Metal Forging Over Other Manufacturing Methods

| Comparison Categories |

Forged Metal |

Cast Metal |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Grain Structure |

Directional grain flow for improved properties |

No directional grain structure |

| Critical Applications |

Ideal for structural members and load-bearing components |

Limited suitability for critical applications |

Need High-Performance Forged Components?

MAIKONG delivers superior metal forging solutions with exceptional strength-to-weight ratios and consistent quality. Our comprehensive capabilities ensure your components meet the most demanding specifications.

Get A Quick Quote

Optimal Materials for Metal Forging

While virtually any metal can be forged, certain materials are particularly well-suited to the metal forging process. The choice of material depends on the specific application requirements, including strength, weight, corrosion resistance, and cost considerations.

Steel Alloys

Carbon, alloy, and stainless steels are the most commonly forged materials due to their excellent formability and resulting mechanical properties. Steel forgings offer exceptional strength, durability, and wear resistance for demanding applications.

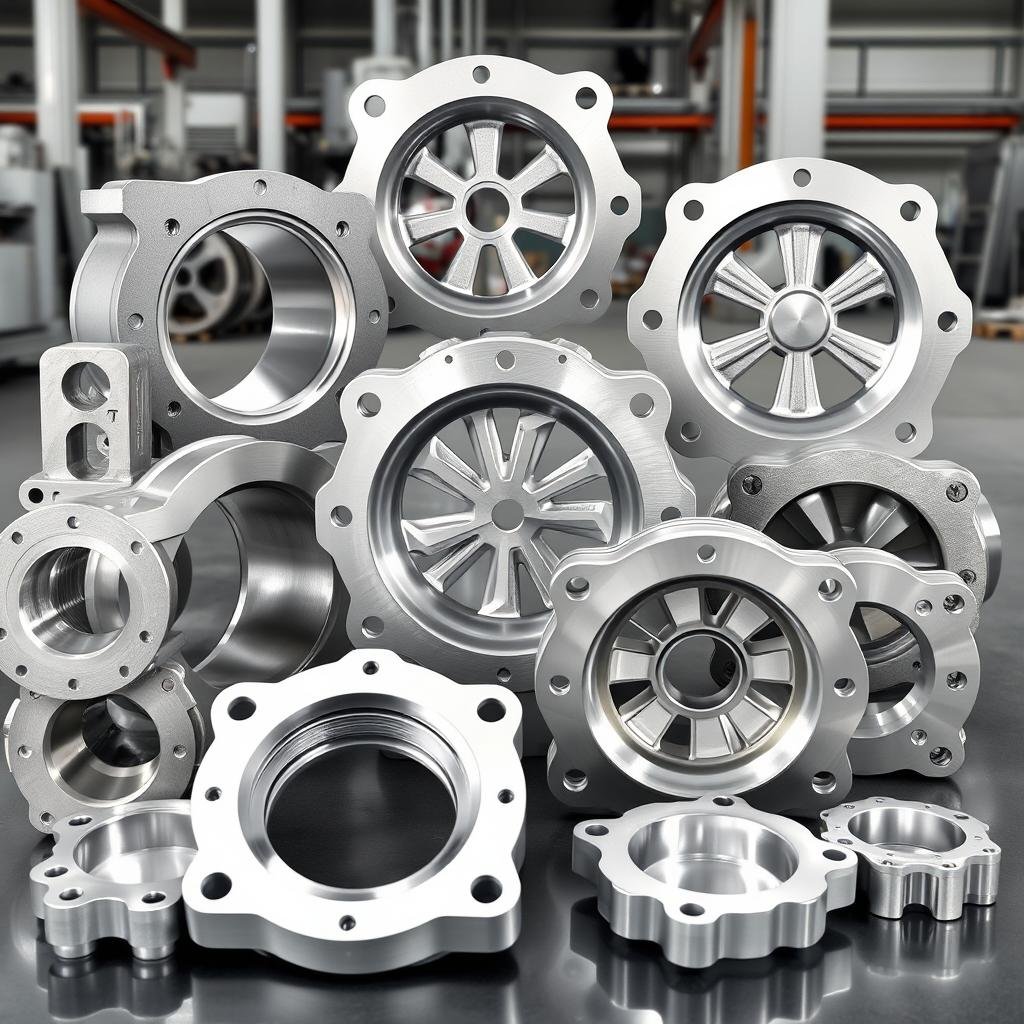

Aluminum Alloys

Aluminum forgings provide an optimal strength-to-weight ratio, making them ideal for aerospace, automotive, and other applications where weight reduction is critical. MAIKONG specializes in aluminum forging services with comprehensive capabilities.

Specialty Metals

Titanium, brass, copper, and high-temperature alloys containing cobalt, nickel, or molybdenum can be forged for specialized applications requiring specific properties such as corrosion resistance, electrical conductivity, or heat resistance.

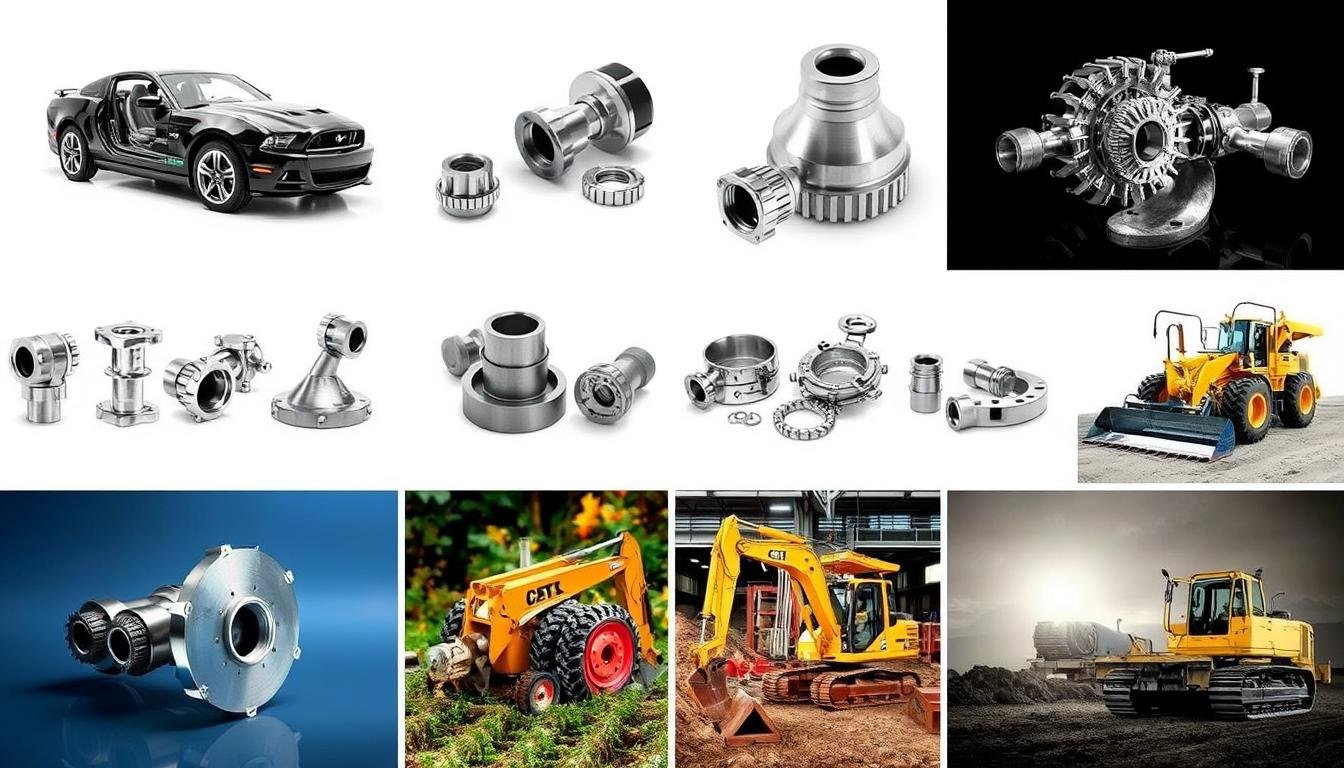

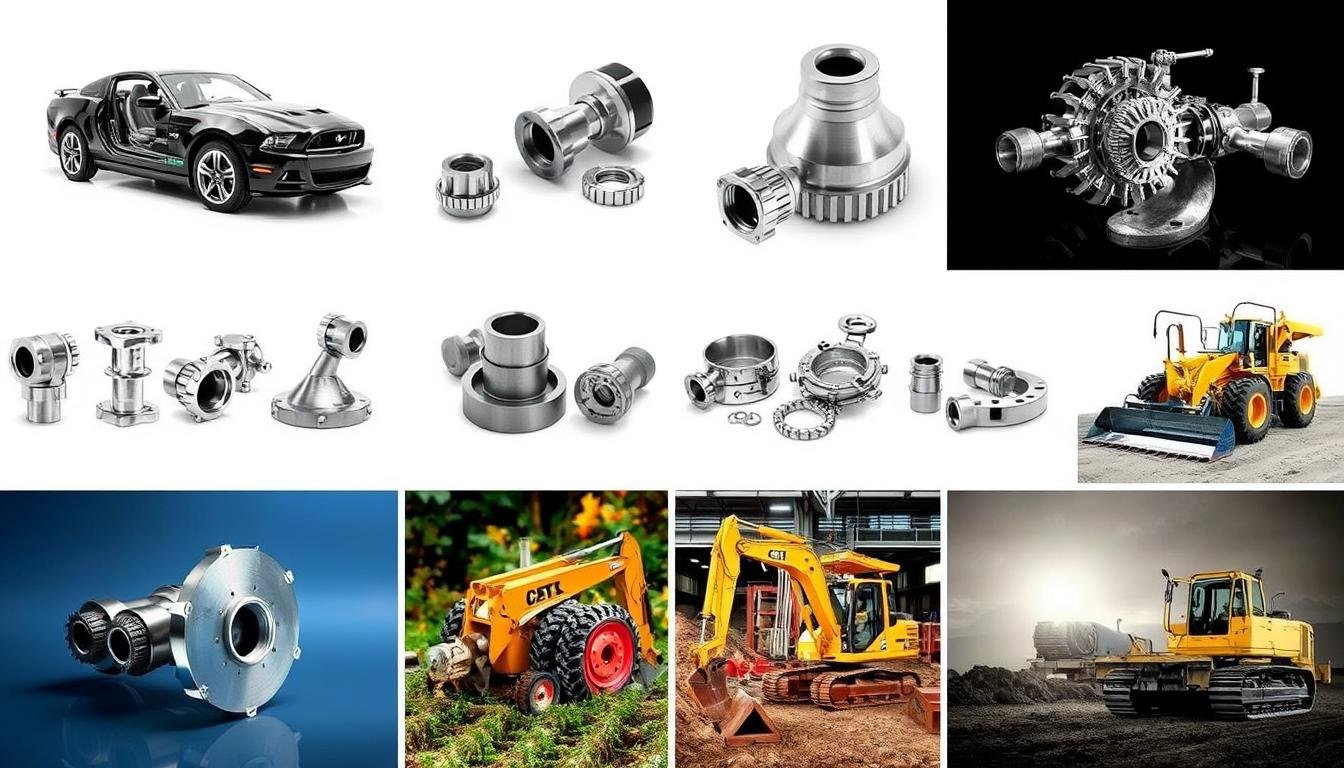

Metal Forging Applications Across Industries

The exceptional strength and reliability of forged components make them essential across numerous industries where performance and safety are paramount.

Automotive & Transportation

Forged components are critical in automotive applications, including crankshafts, connecting rods, transmission gears, and chassis components. Their superior strength and fatigue resistance ensure reliability in these safety-critical systems.

Aerospace & Defense

The aerospace industry relies on precision-forged components for landing gear, turbine discs, structural members, and engine parts where failure is not an option. The exceptional strength-to-weight ratio of forged parts is particularly valuable in this sector.

Agriculture & Construction

Heavy equipment for agriculture and construction incorporates forged components to withstand extreme loads and harsh operating conditions. Tractor parts, excavator components, and structural elements benefit from the durability of forged metal.

Oil & Gas

The oil and gas industry uses forged components in drilling equipment, valves, fittings, and structural elements that must withstand high pressures, extreme temperatures, and corrosive environments.

Power Generation

Forged components are essential in power generation equipment, including turbine rotors, shafts, and structural elements that must maintain integrity under extreme operating conditions.

Hand Tools & Hardware

The superior strength and durability of forged metal make it ideal for hand tools, fasteners, and hardware that must withstand repeated use and high stress.

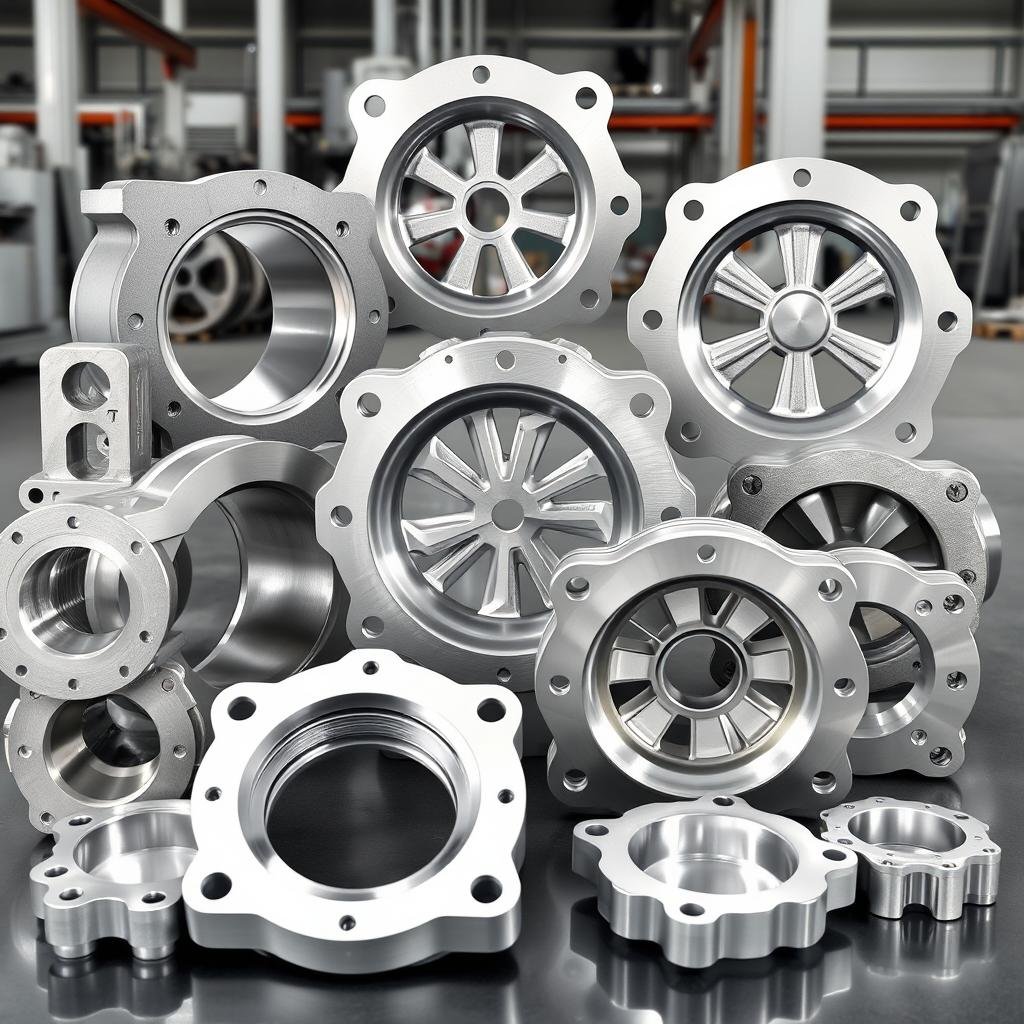

MAIKONG’s Comprehensive Metal Forging Capabilities

At MAIKONG, we offer end-to-end metal forging solutions with a focus on quality, precision, and customer satisfaction. Our state-of-the-art facilities and experienced team ensure your components meet the most demanding specifications.

Our Metal Forging Process

- Design & Engineering: Our team collaborates with you to optimize component design for the forging process, ensuring manufacturability and performance.

- Material Selection: We help you select the optimal material based on your application requirements and performance criteria.

- Tooling Design: Precision tooling is critical for successful forging. Our experienced engineers design and maintain dies to ensure consistent quality.

- Forging Operations: With capabilities in open die, closed die, and roll forging, we can produce components ranging from simple shapes to complex geometries.

- Heat Treatment: In-house heat treatment facilities allow us to optimize the mechanical properties of your forged components.

- Machining & Finishing: Our comprehensive CNC machining capabilities ensure your forged components meet precise dimensional requirements.

- Quality Assurance: Rigorous testing and inspection processes guarantee that every component meets your specifications and quality standards.

Partner with MAIKONG for Your Forging Needs

Experience the MAIKONG difference with our comprehensive metal forging and machining capabilities. Contact us today to discuss your project requirements.

Email Us

Complementary CNC Machining Services

MAIKONG offers comprehensive CNC machining services to complement our metal forging capabilities, providing truly end-to-end manufacturing solutions.

CNC Turning Services

Our CNC turning capabilities are ideal for producing cylindrical shapes, deep holes, and machined threads with superior surface finishes. With rapid turnaround times and precise manufacturing, we deliver components that meet your exact specifications.

CNC Milling Services

MAIKONG’s multi-axis CNC milling services create complex prismatic shapes and flat surfaces for a wide range of industrial products. Our advanced machines require no fixed tooling, offering flexibility and exceptional accuracy.

CNC Swiss-Type Machining

Specializing in precision small parts and long shaft components, our Swiss-type machining equipment features dual spindles and multi-axis capabilities for one-stop manufacturing solutions with the highest level of accuracy.

With over 60 CNC machines and a monthly processing capacity exceeding 100 tons, MAIKONG delivers the scale and precision your projects demand. Our comprehensive capabilities include turning, milling, Swiss machining, multi-axis machining, surface grinding, and laser engraving.

Quality Assurance in Metal Forging

At MAIKONG, quality is built into every step of our metal forging process. Our comprehensive quality management system ensures consistent excellence in every component we produce.

Our Quality Assurance Process

- Material Verification: Our in-house laboratory tests and verifies all raw materials to ensure they meet exact specifications.

- Process Monitoring: Advanced monitoring systems track critical parameters throughout the forging process.

- Dimensional Inspection: Precision measuring equipment verifies that components meet dimensional requirements.

- Non-Destructive Testing: Techniques such as ultrasonic testing, magnetic particle inspection, and radiography identify any internal defects.

- Mechanical Testing: We verify mechanical properties through tensile testing, hardness testing, and impact testing.

- Documentation: Comprehensive documentation ensures traceability throughout the manufacturing process.

MAIKONG maintains ISO 9001:2015 certification, demonstrating our commitment to quality management and continuous improvement. Our dedicated quality engineering staff monitors production processes at all times, ensuring consistency and excellence in every component we produce.

Why Choose MAIKONG for Your Metal Forging Needs

Comprehensive Capabilities

From design and engineering to forging, heat treatment, machining, and finishing, MAIKONG offers truly end-to-end manufacturing solutions. Our integrated approach ensures consistency and quality throughout the production process.

Technical Expertise

Our team possesses deep understanding of materials, their properties, and how they interact during the forging process. This expertise allows us to optimize component design and manufacturing processes for superior results.

Quality Focus

Quality is at the heart of everything we do. Our rigorous quality management system, advanced testing capabilities, and continuous improvement culture ensure that every component meets the highest standards.

Competitive Advantage

MAIKONG combines technical excellence with competitive pricing, offering exceptional value for your manufacturing investment. Our efficient processes and strategic location enable us to deliver high-quality components at attractive prices.

Customer Partnership

We view ourselves as partners in your success, working collaboratively to understand your requirements and deliver solutions that enhance your products’ performance and reliability.

Global Reach

With our international capabilities and logistics expertise, MAIKONG serves customers worldwide, providing consistent quality and reliable delivery regardless of location.

Become a MAIKONG US Agent

MAIKONG is actively recruiting agents throughout the United States. Join our team and represent our high-quality metal forging and CNC machining services in your region. Competitive commission structure and comprehensive support provided.

Apply Today

Conclusion: The MAIKONG Metal Forging Advantage

Metal forging remains one of the most reliable manufacturing processes for producing high-strength, durable components for critical applications. At MAIKONG, we combine traditional forging expertise with modern technology and quality systems to deliver superior components that meet your most demanding requirements.

From material selection and die design to forging, heat treatment, machining, and finishing, our comprehensive capabilities ensure a seamless manufacturing process with consistent quality. Whether you need aluminum forgings, steel components, or specialized alloy parts, MAIKONG has the expertise and equipment to exceed your expectations.

Contact us today to discuss your metal forging requirements and discover the MAIKONG difference. Our team is ready to help you optimize your component design, select the appropriate materials and processes, and deliver high-quality forged parts that enhance your products’ performance and reliability.

Start Your Metal Forging Project Today

Experience the MAIKONG difference with our comprehensive metal forging and machining capabilities. Contact us now to discuss your requirements and receive a competitive quote.

Get A Quick Quote