Welcome to MAIKONG, where precision engineering meets manufacturing excellence. As a leading provider of metal forge and CNC machining solutions, we deliver superior quality custom components with cost-effective pricing. Our comprehensive capabilities span aluminum forging, brass extrusion, steel forging, and precision CNC machining services, all backed by rigorous quality control and industry certifications.

MAIKONG’s state-of-the-art

metal forge facility in GD, SZ

MAIKONG’s Comprehensive Metal Forge Capabilities

With over 60 CNC machines and a monthly processing capacity exceeding 100 tons, MAIKONG stands as your reliable partner for all precision metal manufacturing needs. Our expertise in metal forge technology allows us to deliver exceptional quality components across diverse industries including automotive, aerospace, electronics, and industrial equipment.

Ready to Experience Premium Manufacturing?

Discover how our precision metal forge solutions can enhance your products.

Get A Quick Quote

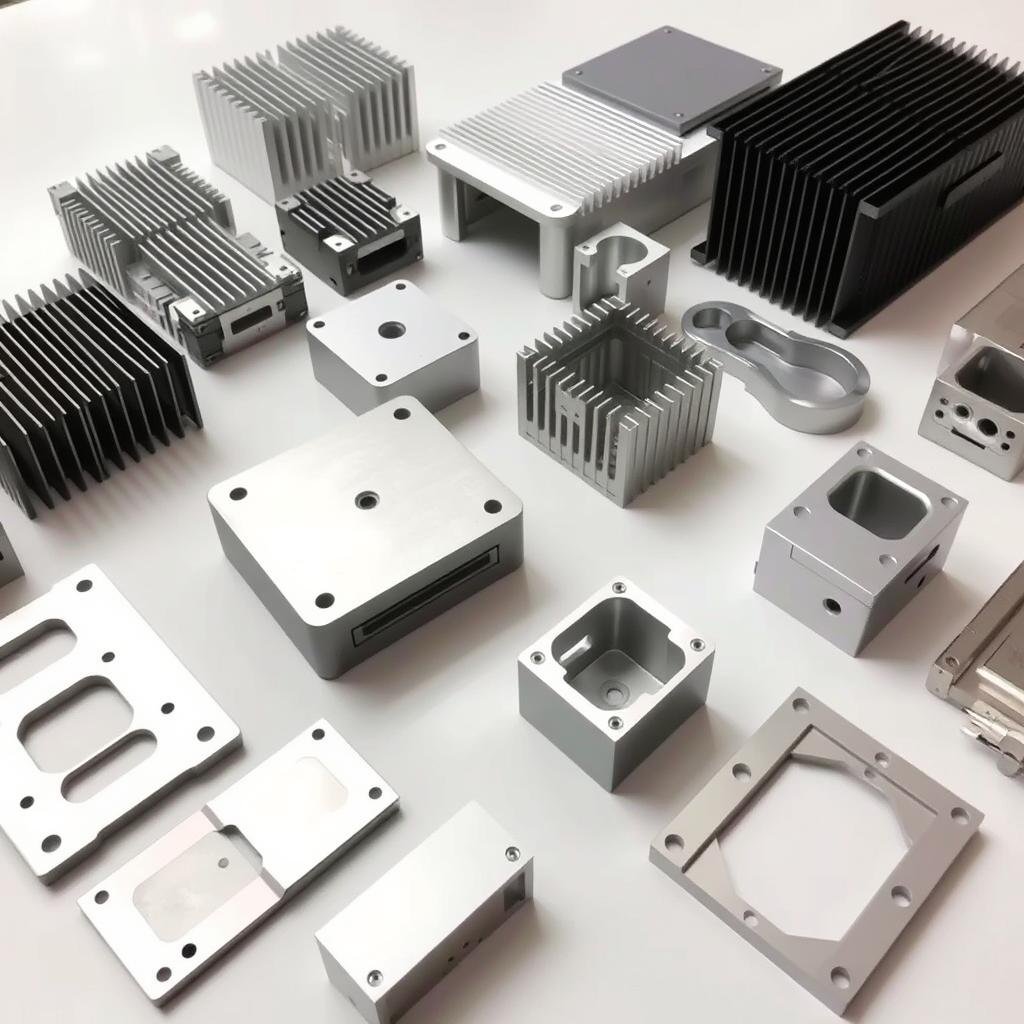

Precision CNC Machining Services

Our advanced CNC machining capabilities deliver exceptional precision and consistency for your most demanding applications. From prototypes to high-volume production runs, MAIKONG ensures superior quality with every component.

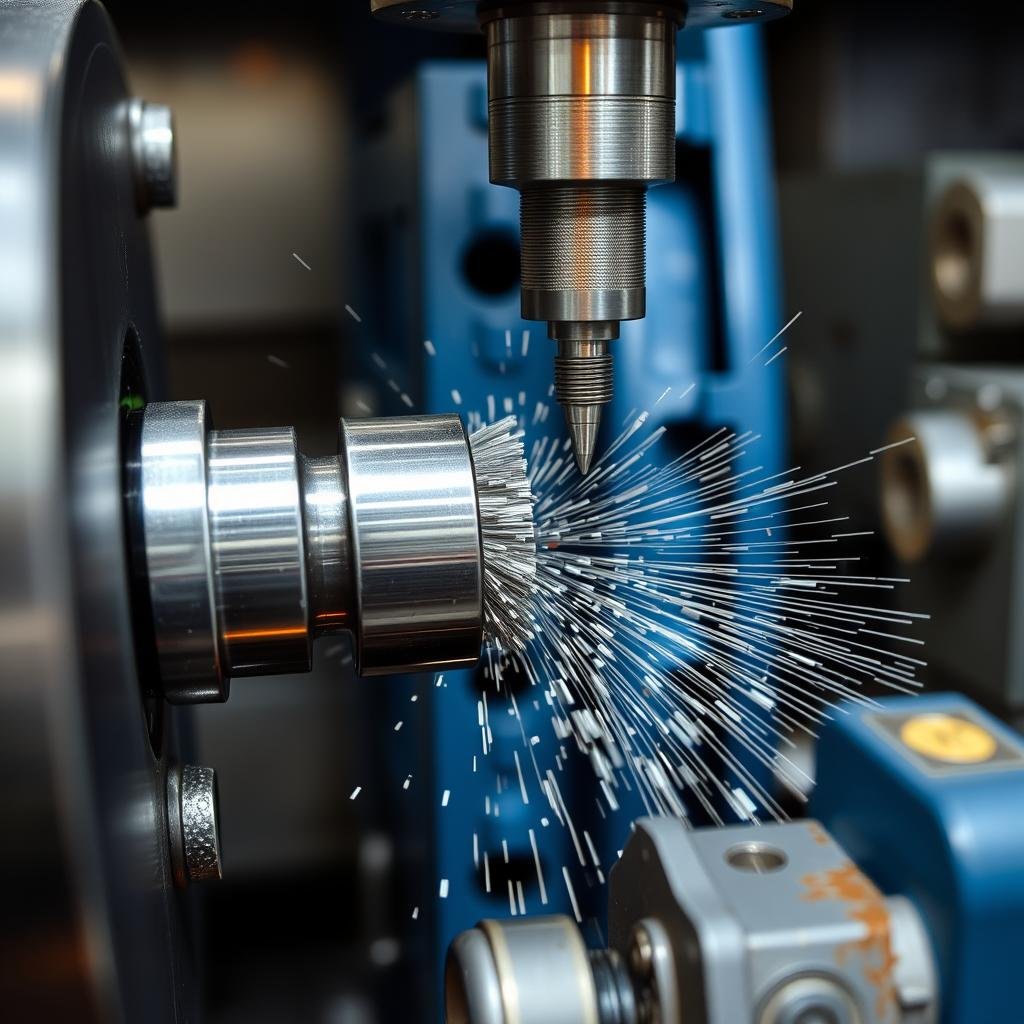

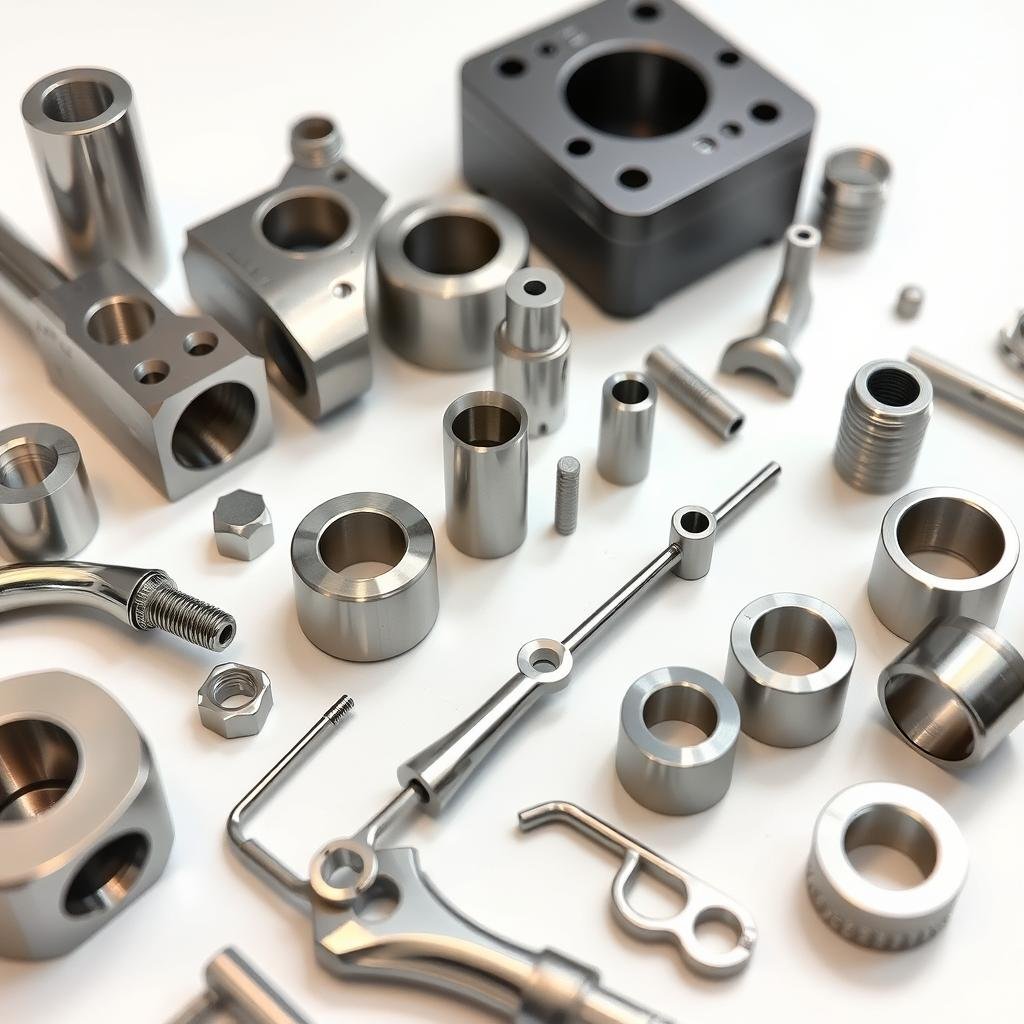

CNC Turning Services

Ideal for cylindrical components requiring superior surface finishes, deep holes, and machined threads. Our CNC turning capabilities deliver exceptional precision with fast turnaround times.

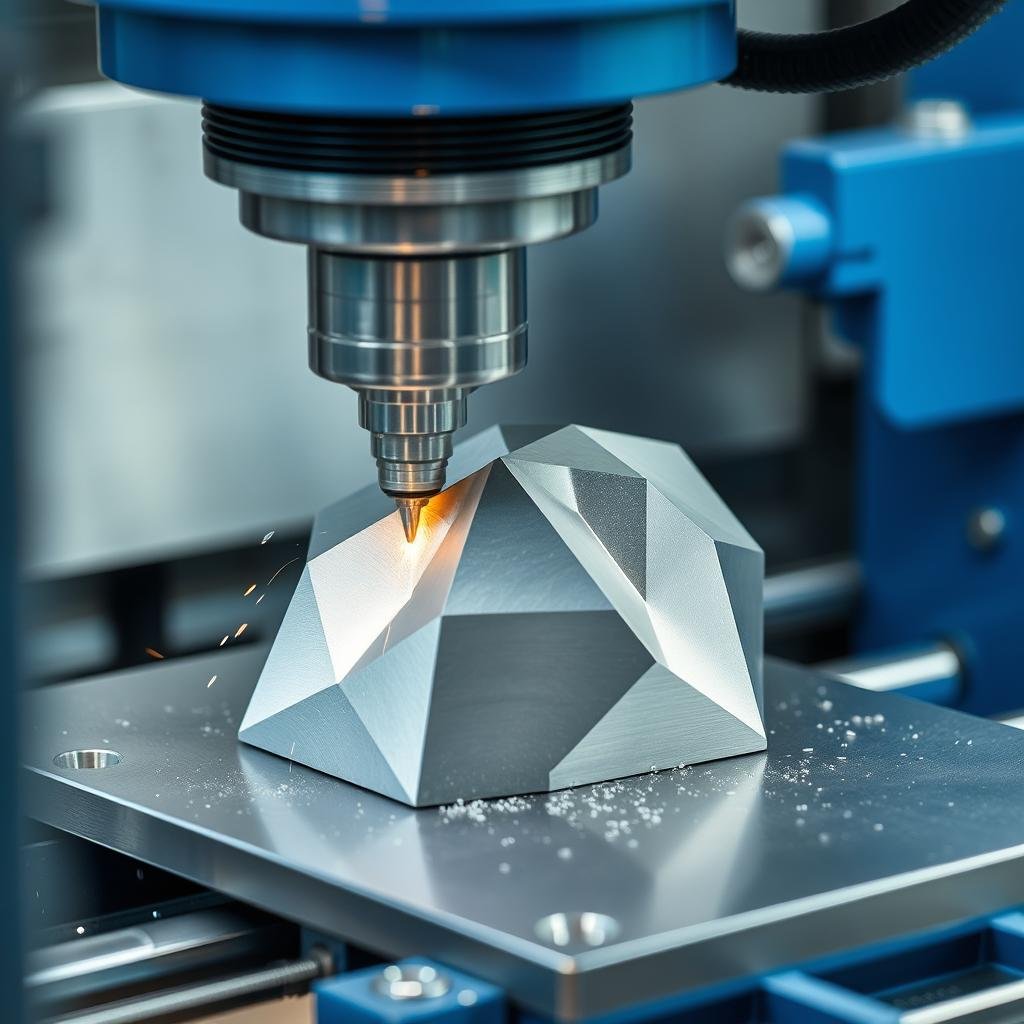

CNC Milling Services

Perfect for complex prismatic shapes and flat surfaces across various industrial applications. Our multi-axis CNC milling machines deliver high flexibility and accuracy without fixed tooling.

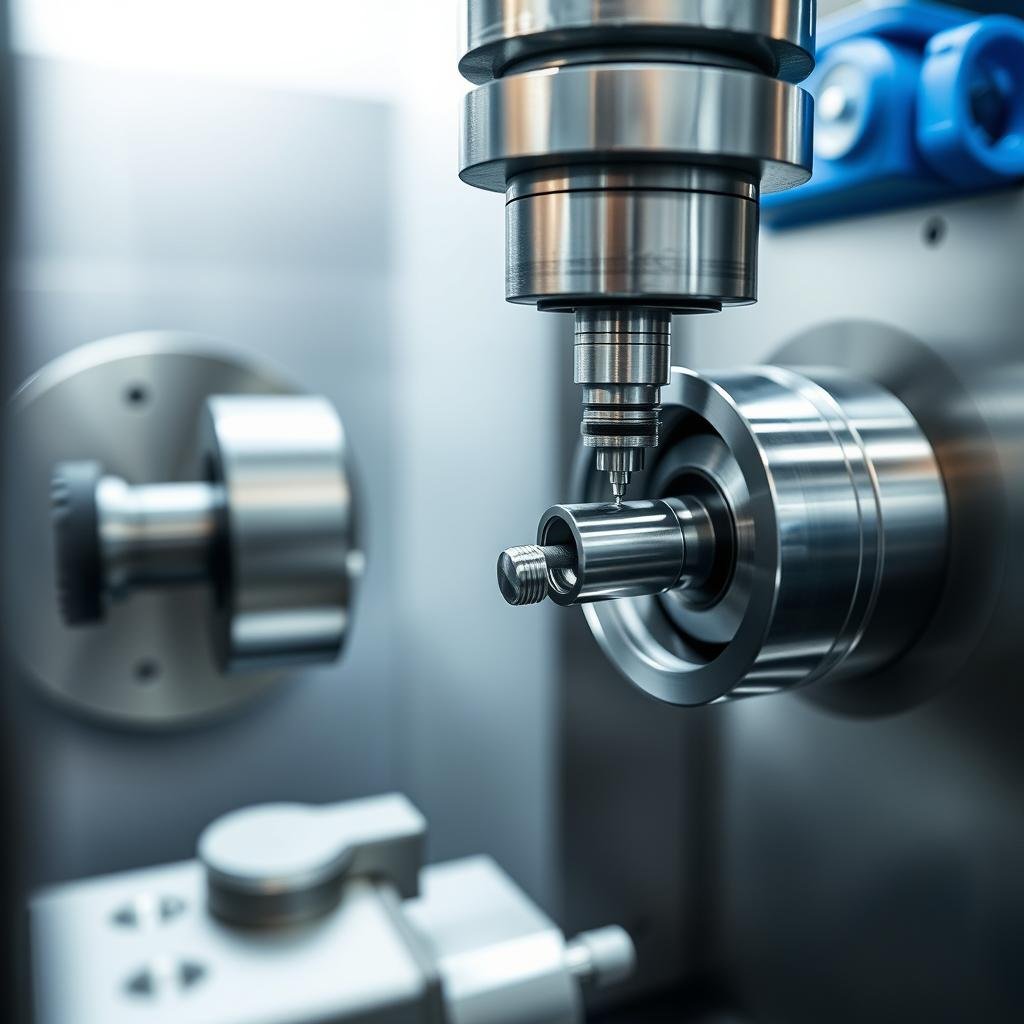

Swiss-Type Machining

Specialized for small precision parts and long shaft components. Our Swiss-type machines feature dual spindles and multi-axis capabilities for complete one-stop manufacturing solutions.

Advanced Metal Forging Techniques

At MAIKONG, we understand that consistent strength, precision, and weight are crucial for every forged component. Our advanced metal forge processes ensure optimal grain flow and material homogeneity, maximizing mechanical properties for demanding applications.

Aluminum Forging Excellence

Our aluminum forging processes create components with superior strength-to-weight ratios, ideal for applications where performance and safety are critical. Through proper deformation and controlled grain flow, we maximize impact toughness, fracture resistance, and fatigue strength.

Steel Forging Precision

MAIKONG’s steel forging capabilities deliver exceptional strength and durability for the most demanding industrial applications. Our precision forging techniques ensure consistent quality and dimensional accuracy across production runs.

Brass Extrusion Specialization

MAIKONG excels in precision brass extrusion, creating complex profiles with tight tolerances and exceptional surface finishes. Our specialized processes ensure consistent quality across production runs while maintaining cost-effectiveness.

Custom Brass Components

Our brass extrusion capabilities support diverse applications across industries:

- Architectural components with complex profiles

- Electrical connectors requiring superior conductivity

- Plumbing fixtures with precise dimensions

- Decorative elements with exceptional surface finish

- Industrial components requiring corrosion resistance

Need Custom Brass Components?

Contact our specialists to discuss your brass extrusion requirements.

Request Consultation

Aluminum Forging Excellence

MAIKONG’s aluminum forging processes create components with exceptional strength-to-weight ratios, ideal for applications where performance and safety are critical. Our comprehensive capabilities include design optimization, material selection, precision forging, and complete finishing services.

Why Choose Aluminum Forging

Understanding the advantages of aluminum forging over casting is crucial for selecting the right manufacturing process for your components:

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Critical Applications |

✅ Structural members and load-bearing components |

Limited suitability for critical applications |

Enhance Your Products with Superior Aluminum Forging

Discover how MAIKONG’s aluminum forging capabilities can improve your components’ performance.

Get A Quote Today

Our Comprehensive Manufacturing Process

MAIKONG’s integrated approach ensures quality and consistency throughout the entire manufacturing journey:

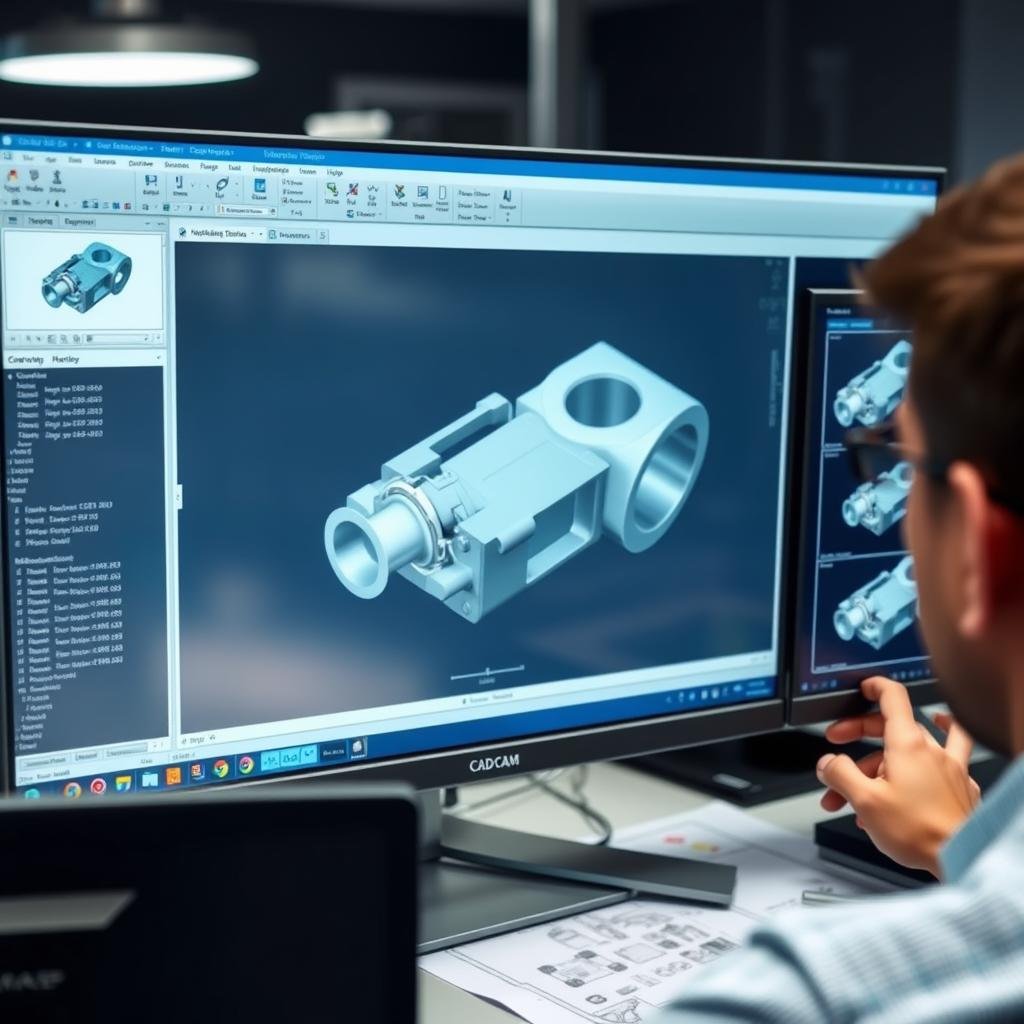

CAD/CAM Design

Advanced analysis software identifies potential issues early, optimizing designs before production.

Material Selection

Careful consideration of mechanical properties, machinability, heat treatment characteristics, and cost-effectiveness.

Tooling

Precision tooling design ensures initial quality, while regular maintenance preserves consistency.

Forging

Our forging workshop accommodates diverse specifications with precision and consistency.

Heat Treatment

Comprehensive statistical analysis and documentation for our in-house heat treatment processes.

CNC Machining

State-of-the-art CNC machines perform precise and intricate operations on forged components.

Experience Our End-to-End Manufacturing Excellence

From design to finished component, MAIKONG delivers superior quality at every step.

Start Your Project

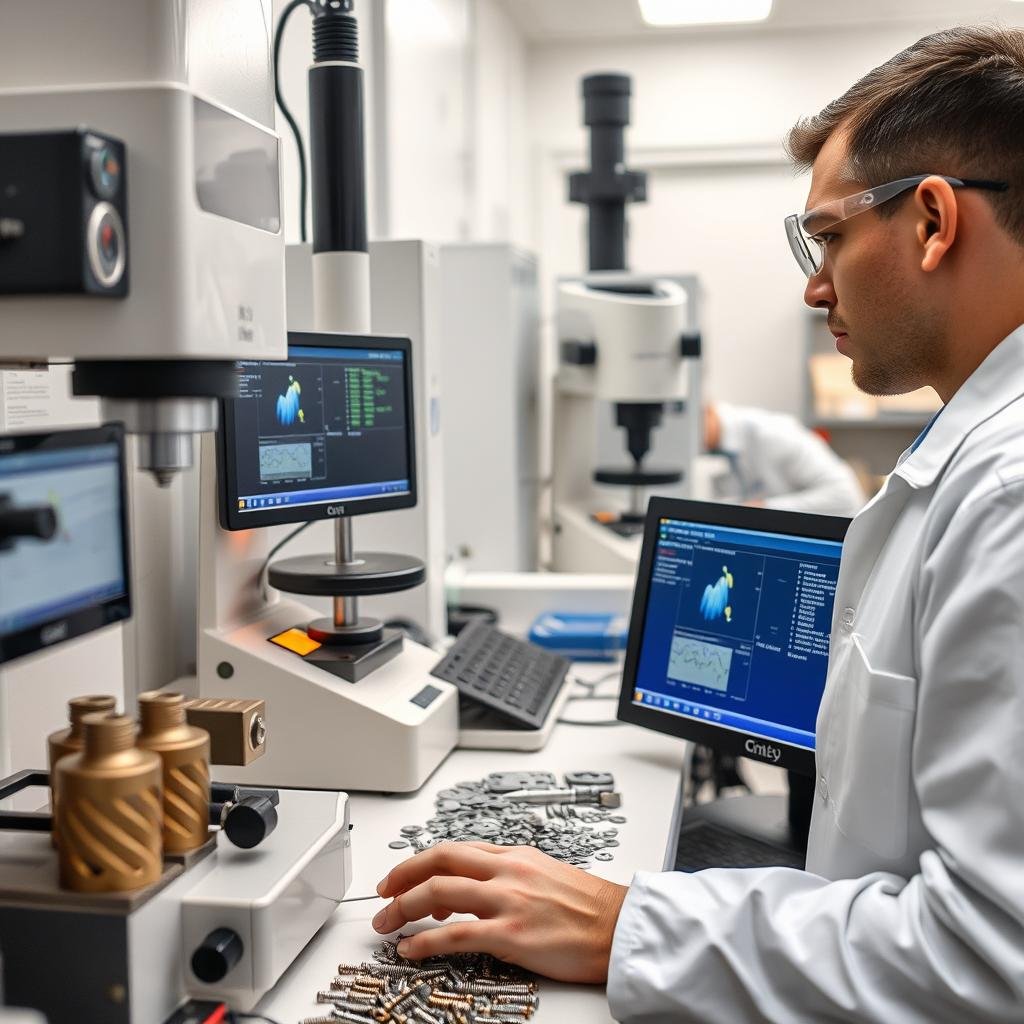

Quality Assurance at MAIKONG

Our commitment to quality is embedded in every aspect of our operations. MAIKONG implements rigorous quality control procedures to ensure that every component meets the most stringent standards.

Certifications

- ISO 9001:2015 certified quality management system

- IATF 16949 implementation for automotive components

- Comprehensive statistical process control

- Rigorous material testing and verification

Quality Control Processes

- Advanced dimensional inspection equipment

- Material composition verification

- Mechanical property testing

- Surface finish analysis

- Comprehensive documentation and traceability

4.8

Overall Quality Rating

Dimensional Accuracy

4.8/5

Industries Served

MAIKONG’s precision metal forge and machining capabilities support diverse industries with custom components that meet the most demanding specifications:

Automotive

Precision components for engines, transmissions, suspension systems, and structural elements requiring exceptional strength and durability.

Aerospace

Lightweight, high-strength components for aircraft structures, landing gear, and engine systems where reliability is paramount.

Electronics

Thermal management components, chassis elements, and structural parts requiring precise dimensions and excellent thermal conductivity.

Medical

Surgical instruments, implant components, and medical equipment parts requiring biocompatibility and exceptional reliability.

Industrial Equipment

Heavy-duty components for machinery, hydraulic systems, and structural applications requiring strength and wear resistance.

Consumer Products

High-performance components for sporting goods, bicycles, and premium consumer devices where aesthetics meet functionality.

Why Partner with MAIKONG

Choosing MAIKONG as your metal forge and machining partner delivers significant advantages for your business:

MAIKONG Advantages

- Comprehensive capabilities from design to finished components

- 60+ CNC machines with 100+ tons monthly capacity

- Superior quality with ISO 9001:2015 certification

- Cost-effective manufacturing without compromising quality

- Expertise across diverse materials and processes

- Consistent on-time delivery performance

- Responsive communication and technical support

Cost-Effective Manufacturing Solutions

MAIKONG delivers exceptional value through optimized manufacturing processes, efficient resource utilization, and strategic facility location. Our integrated approach eliminates unnecessary costs while maintaining the highest quality standards, providing you with competitive advantages in your market.

Become a MAIKONG US Agent

We’re actively seeking representatives throughout the United States to expand our market presence. As a MAIKONG agent, you’ll benefit from our exceptional manufacturing capabilities, competitive pricing, and comprehensive support.

- Represent a leading metal forge and precision machining provider

- Offer competitive solutions to your existing customer base

- Access comprehensive technical support and documentation

- Benefit from attractive commission structures

- Grow your business with our expanding capabilities

Interested in Becoming a US Agent?

Contact us today to discuss partnership opportunities.

Explore Partnership

Experience MAIKONG Excellence

At MAIKONG, we’re committed to delivering exceptional metal forge and precision machining solutions that exceed your expectations. From initial design to finished components, our comprehensive capabilities ensure superior quality, competitive pricing, and reliable delivery. Contact us today to discover how our expertise can enhance your products and streamline your manufacturing processes.

Ready to Start Your Next Project?

Contact MAIKONG today for expert metal forge solutions.

Get Started Now

MAIKONG’s state-of-the-art metal forge facility in GD, SZ

MAIKONG’s state-of-the-art metal forge facility in GD, SZ