In today’s precision-driven manufacturing landscape, modern metal forge processes represent the pinnacle of metallurgical engineering. These sophisticated techniques transform raw metal into high-performance components with superior structural integrity and mechanical properties. At MAIKONG, we combine centuries-old forging wisdom with cutting-edge technology to deliver exceptional metal components that meet the most demanding specifications across industries.

The Evolution of Metal Forge Technology

Evolution from traditional blacksmithing to modern industrial forging at MAIKONG

The journey of metal forge technology spans thousands of years, evolving from primitive hammering techniques to today’s precision-controlled hydraulic presses. Early blacksmiths relied on manual hammering and simple tools to shape heated metal. The industrial revolution introduced steam-powered hammers, dramatically increasing production capacity and consistency.

Today’s advanced metal forge operations employ computer-controlled hydraulic presses capable of exerting thousands of tons of pressure with pinpoint accuracy. This technological leap has enabled unprecedented precision, efficiency, and material optimization in the forging process.

Experience MAIKONG’s Advanced Forging Technology

Our state-of-the-art facility in GD, SZ features the latest in forging technology, delivering superior quality components with exceptional structural integrity.

Explore Our Capabilities

Core Metal Forge Processes at MAIKONG

At MAIKONG, we employ a comprehensive range of forging techniques to meet diverse manufacturing requirements. Our expertise spans the complete spectrum of metal forging processes, each offering unique advantages for specific applications.

Hot Forging Techniques

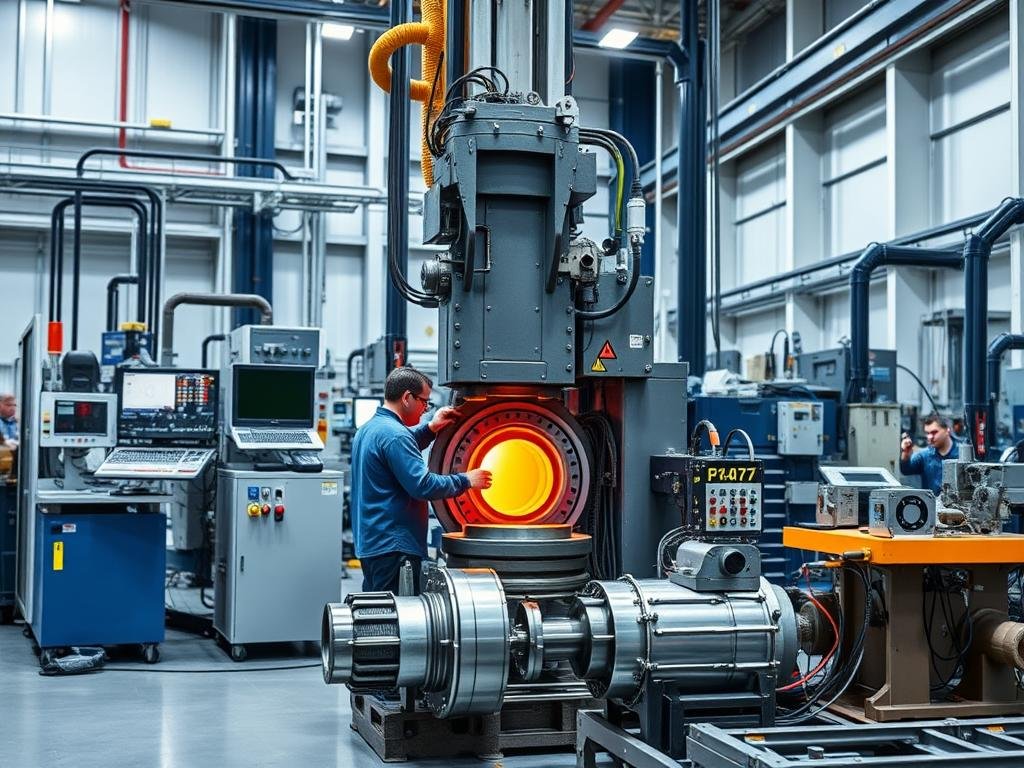

Hot forging operations at MAIKONG’s GD facility

Hot forging involves shaping metal at temperatures above its recrystallization point, typically between 2100°F and 2300°F. This process significantly reduces the force required to deform the metal while improving its microstructure through recrystallization. At MAIKONG, our hot forging capabilities include:

- Open-die forging for large or custom components

- Closed-die forging for precision and complex geometries

- Upset forging for increasing cross-sectional areas

- Roll forging for creating tapered or stepped shafts

Cold Forging Methods

Precision cold forging at MAIKONG’s advanced manufacturing facility

Cold forging shapes metal at room temperature, below its recrystallization point. This process delivers exceptional dimensional accuracy, superior surface finish, and enhanced mechanical properties. Our cold forging expertise includes:

- Extrusion for creating complex cross-sections

- Coining for precise detail and surface finishes

- Sizing for achieving tight tolerances

- Cold heading for fasteners and specialized components

Precision Metal Forge Operations

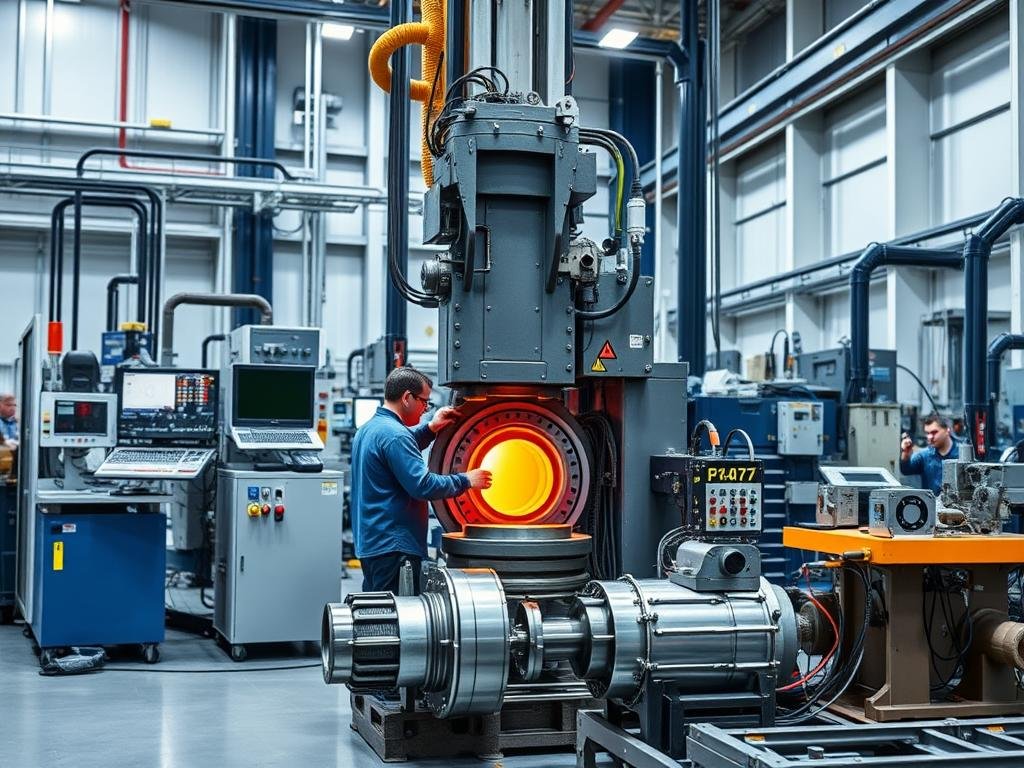

Computer-controlled precision forging systems at MAIKONG

Our precision forging operations combine advanced die design, computer-controlled presses, and rigorous quality control to produce components with exceptional dimensional accuracy and consistency. These specialized processes include:

- Near-net shape forging to minimize machining requirements

- Isothermal forging for difficult-to-work alloys

- Precision forging with tolerances as tight as ±0.005 inches

- Multi-directional forging for complex geometries

Need Custom Forging Solutions?

Our engineering team can develop tailored forging processes to meet your specific requirements.

Contact Our Engineers

Materials in Modern Metal Forge

High-performance alloys processed at MAIKONG’s forging facility

Material selection is critical to the success of any forging operation. At MAIKONG, we work with a comprehensive range of metals and alloys, each offering unique properties for specific applications.

Aluminum Alloys

Our aluminum forging capabilities include series 2xxx, 6xxx, and 7xxx alloys, offering exceptional strength-to-weight ratios for aerospace, automotive, and consumer applications.

Steel Varieties

We process carbon, alloy, tool, and stainless steels, delivering components with superior strength, hardness, and corrosion resistance for demanding industrial applications.

Brass and Other Metals

Our expertise extends to brass, bronze, copper, and titanium alloys, providing specialized properties like electrical conductivity, corrosion resistance, and biocompatibility.

| Material Category |

Common Alloys |

Key Properties |

Typical Applications |

| Aluminum |

2024, 6061, 7075 |

Lightweight, corrosion resistant |

Aerospace, automotive, sporting goods |

| Steel |

4140, 4340, H13 |

High strength, wear resistant |

Industrial machinery, tools, automotive |

| Brass |

C36000, C38500 |

Corrosion resistant, electrically conductive |

Plumbing, electrical components |

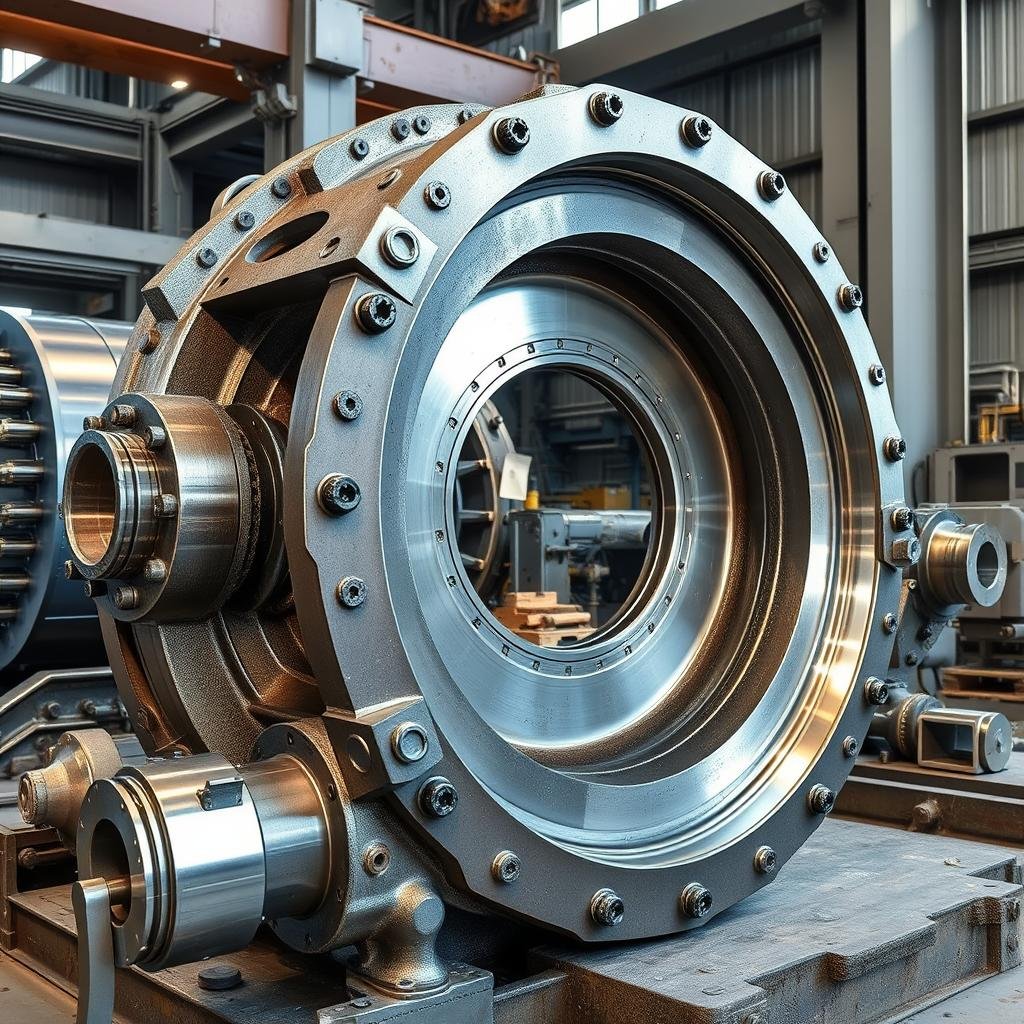

MAIKONG’s Comprehensive Metal Forge Services

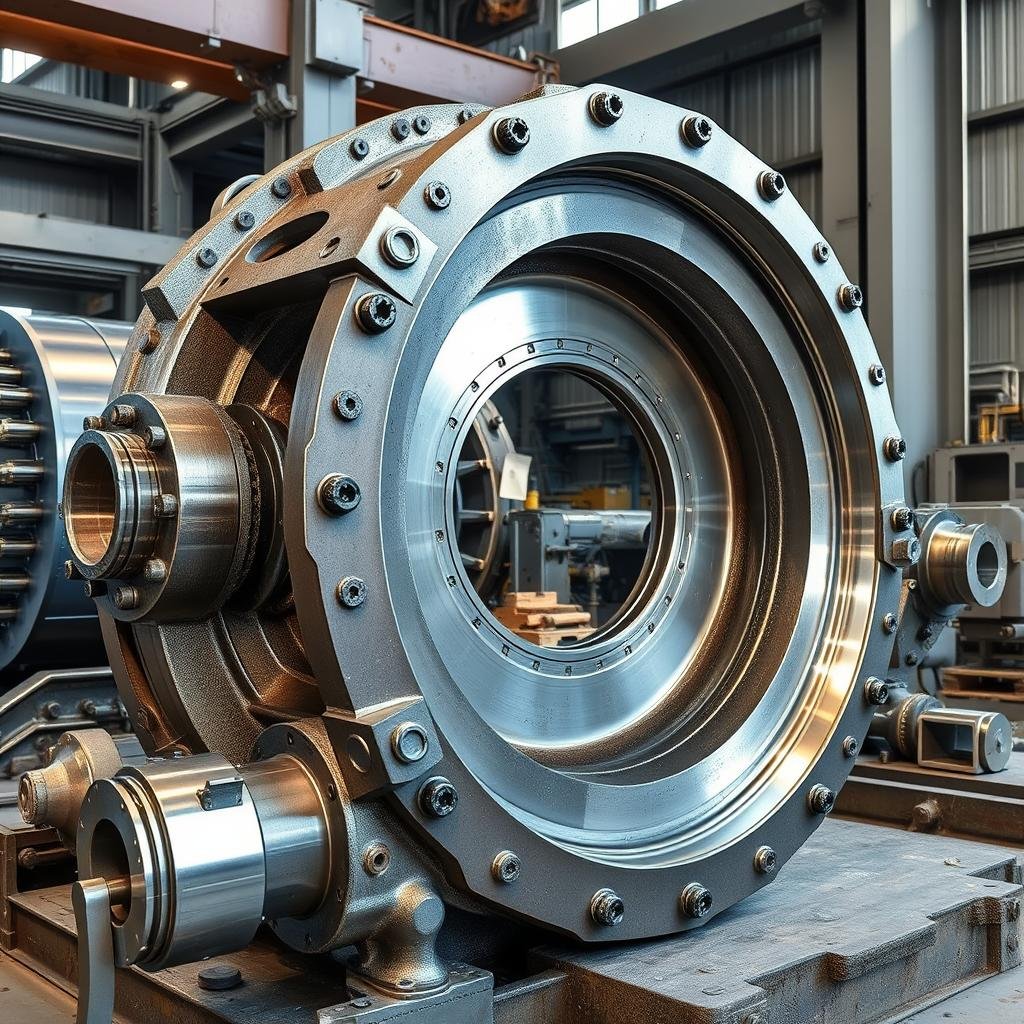

MAIKONG’s state-of-the-art forging and machining facility in GD, SZ

MAIKONG offers end-to-end metal forging and machining services, from initial design consultation through final inspection and delivery. Our comprehensive capabilities ensure seamless production of high-quality components that meet the most demanding specifications.

Equipment Capabilities

Our advanced manufacturing facility features:

- 60+ CNC machines for precision machining

- Hydraulic presses ranging from 300 to 3,000 tons

- Automated forging lines for high-volume production

- 100+ tons monthly production capacity

- State-of-the-art heat treatment facilities

- Advanced surface treatment capabilities

Quality Assurance

Our commitment to quality is reflected in our comprehensive quality control processes:

- Material certification and testing

- In-process dimensional verification

- Non-destructive testing (ultrasonic, magnetic particle)

- Mechanical property testing

- Final inspection and documentation

- ISO 9001:2015 certified quality management system

Ready to Discuss Your Project?

Our engineering team is available to review your requirements and provide expert guidance on the optimal forging solution.

Request a Consultation

Advantages of Metal Forge Over Alternative Methods

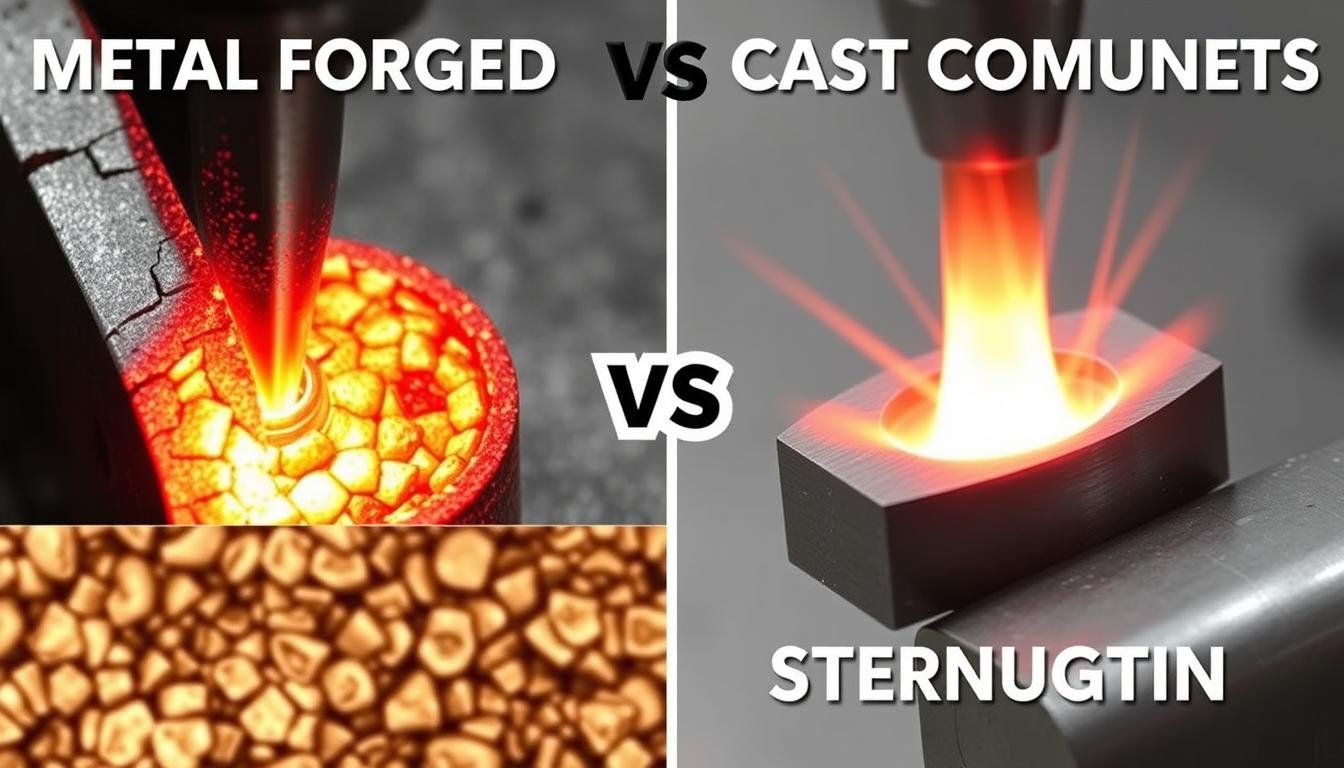

Structural comparison between forged and cast components

Metal forging offers significant advantages over alternative manufacturing methods like casting, machining, and powder metallurgy. Understanding these benefits is crucial when selecting the optimal production process for critical components.

| Comparison Categories |

Metal Forging |

Casting |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

Key Performance Benefits

Structural Integrity

The forging process aligns the metal’s grain structure along the part’s geometry, significantly enhancing strength and fatigue resistance. This aligned grain flow is particularly beneficial for components subject to dynamic loading and stress.

Mechanical Properties

Forged components exhibit superior mechanical properties, including higher tensile strength, improved ductility, and enhanced impact resistance. These characteristics make forged parts ideal for critical applications where failure is not an option.

Quality Control in Metal Forge Processes

MAIKONG’s advanced quality control laboratory

At MAIKONG, quality is built into every step of our forging process. Our comprehensive quality management system ensures consistent production of components that meet or exceed customer specifications and industry standards.

Material Testing Laboratory

Our in-house material testing laboratory performs comprehensive analysis of raw materials and finished components, including:

- Chemical composition analysis

- Mechanical property testing (tensile, hardness, impact)

- Microstructural examination

- Non-destructive testing (ultrasonic, magnetic particle)

In-Process Quality Management

Quality control measures are integrated throughout our production process:

- Statistical process control

- Automated dimensional verification

- Visual and surface inspection

- Process parameter monitoring and documentation

“Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction and skillful execution. At MAIKONG, we are committed to excellence in every component we produce.”

– MAIKONG Quality Management Team

Applications of MAIKONG Metal Forge Products

Aerospace Components

Aerospace Components

Automotive Parts

Automotive Parts

Industrial Applications

Industrial Applications

MAIKONG’s forged components serve critical applications across diverse industries, where performance, reliability, and safety are paramount. Our expertise in material selection, process optimization, and quality control ensures that each component meets the specific requirements of its intended application.

Aerospace

Our aerospace components meet stringent industry standards for structural integrity, weight optimization, and reliability in critical applications including landing gear components, structural fittings, and engine parts.

Automotive

We produce high-performance automotive components including connecting rods, crankshafts, steering knuckles, and suspension components that deliver exceptional durability and performance under demanding conditions.

Industrial

Our industrial components include gears, shafts, flanges, and structural elements for heavy machinery, power generation, and manufacturing equipment where reliability is essential.

MAIKONG’s Full-Service Metal Forge Solutions

MAIKONG’s integrated production facility in GD, SZ

MAIKONG offers comprehensive metal forging solutions that extend far beyond basic forging operations. Our integrated approach encompasses every aspect of component production, from initial design through final delivery.

CAD/CAM Integration

Our engineering team utilizes advanced CAD/CAM systems to optimize component design for manufacturability, performance, and cost-effectiveness. Finite element analysis enables us to predict and address potential issues before production begins.

Tooling Design

We design and manufacture precision forging dies and tooling in-house, ensuring optimal performance and longevity. Our tooling expertise enables the production of complex geometries with exceptional consistency and accuracy.

Heat Treatment

Our comprehensive heat treatment capabilities include annealing, normalizing, quenching, tempering, and aging processes tailored to achieve specific mechanical properties and microstructural characteristics.

CNC Machining

With over 60 CNC machines, we provide precision secondary operations including milling, turning, drilling, and grinding to achieve final dimensions and features with exceptional accuracy.

Surface Treatment

We offer comprehensive surface treatment options including anodizing, painting, plating, and passivation to enhance appearance, corrosion resistance, and functional properties.

Quality Assurance

Our rigorous quality control processes ensure that every component meets or exceeds customer specifications and industry standards, with comprehensive documentation and traceability.

Experience Our One-Stop Forging Solution

From design to delivery, MAIKONG provides comprehensive metal forging and machining services to meet your most demanding requirements.

Discover Our Capabilities

Why Choose MAIKONG for Your Metal Forge Needs

MAIKONG’s expert team and state-of-the-art facilities

The MAIKONG Advantage

- 60+ CNC machines and 100+ tons monthly capacity

- Comprehensive in-house capabilities from forging to finishing

- ISO 9001:2015 certified quality management system

- Advanced material testing and verification laboratory

- Experienced engineering team for design optimization

- Competitive pricing with exceptional value

- Global logistics and delivery capabilities

Our Commitment to Excellence

At MAIKONG, we understand that our success depends on the success of our customers. That’s why we are committed to delivering exceptional quality, value, and service in every project we undertake. Our team works closely with customers to understand their specific requirements and develop optimal solutions that enhance performance while controlling costs.

What makes MAIKONG different from other forging companies?

MAIKONG offers a unique combination of advanced technology, comprehensive capabilities, and customer-focused service. Our integrated approach encompasses every aspect of component production, from initial design through final delivery, providing a seamless experience and exceptional value.

Can MAIKONG handle both small and large production volumes?

Yes, our flexible manufacturing capabilities enable us to efficiently produce both prototype quantities and high-volume production runs. We work closely with customers to develop the optimal production approach based on their specific requirements and timeline.

How does MAIKONG ensure consistent quality?

Quality is built into every step of our process, from material selection through final inspection. Our ISO 9001:2015 certified quality management system, advanced testing capabilities, and rigorous process controls ensure consistent production of components that meet or exceed customer specifications.

Partner with MAIKONG for Superior Metal Forge Solutions

MAIKONG combines advanced technology, comprehensive capabilities, and customer-focused service to deliver exceptional metal forging solutions for the most demanding applications. From aerospace and automotive to industrial and consumer products, our expertise ensures components with superior performance, reliability, and value.

Contact us today to discuss your specific requirements and discover how MAIKONG can help you achieve your manufacturing objectives with precision-forged metal components of the highest quality.

Ready to Start Your Next Project?

Contact MAIKONG today to discuss your metal forging requirements and receive a customized solution proposal.

Contact Us Now

Aerospace Components

Aerospace Components Automotive Parts

Automotive Parts Industrial Applications

Industrial Applications