In today’s competitive manufacturing landscape, finding a reliable metal forge partner can be the difference between project success and costly delays. At MAIKONG, we combine advanced forging technology with precision machining to deliver custom metal components that meet the most demanding industrial specifications. Our comprehensive approach to metal forge services ensures optimal material properties, dimensional accuracy, and cost-effectiveness for applications across aerospace, automotive, construction, and more.

MAIKONG’s Comprehensive Metal Forge Services

Partner With a Metal Forge Expert

Our team of metallurgists and forging specialists can help determine the optimal process for your application.

Request a Consultation

Precision Metal Forge Capabilities

With over 60 CNC machines and 100+ tons of monthly processing capacity, MAIKONG delivers precision-forged components with exceptional dimensional accuracy and material properties. Our comprehensive approach includes:

Aluminum Forging Services

Specialized aluminum forging delivering exceptional strength-to-weight ratio for aerospace, automotive, and high-performance applications.

Learn More

Steel Forging Company

Comprehensive steel forging capabilities for high-strength components used in construction, heavy machinery, and industrial equipment.

Learn More

Brass Forging Expertise

Precision brass forging for electrical components, plumbing fixtures, and decorative applications requiring excellent corrosion resistance.

Learn More

Custom Metal Forge Solutions

Every industry has unique requirements for forged components. MAIKONG’s custom metal forge solutions are tailored to your specific application needs:

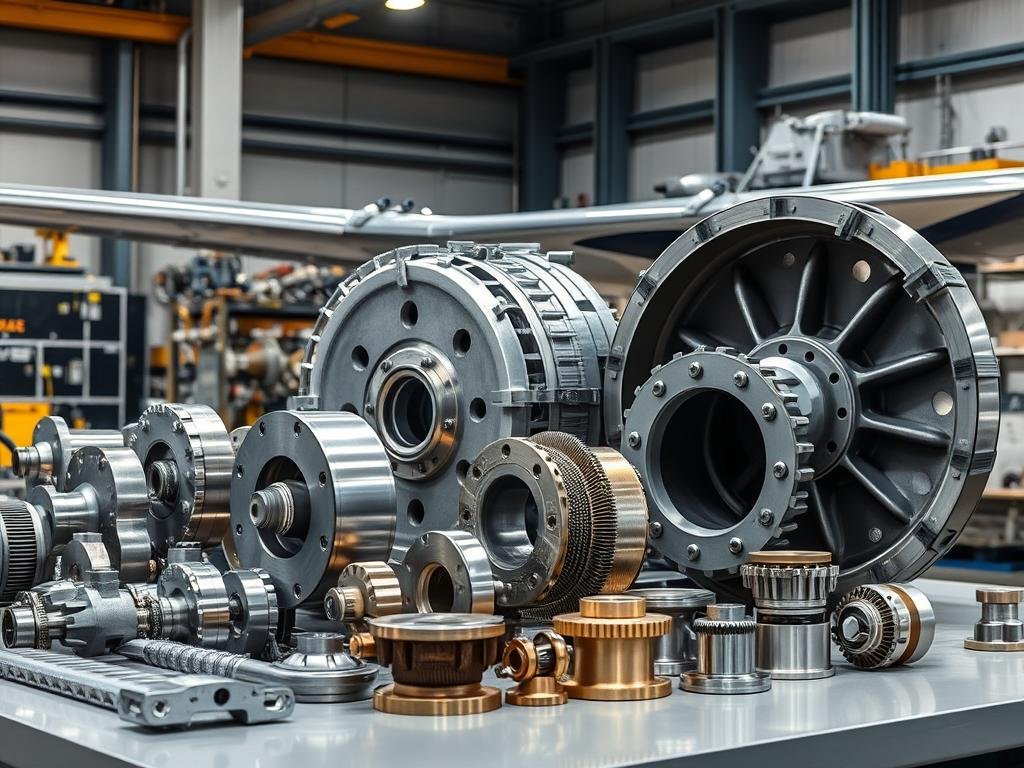

MAIKONG’s custom metal forge production line in GD, SZ

Material Selection Expertise

Our metallurgists help select the optimal alloy for your application, considering mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness.

Advanced Tooling Design

Precision tooling is critical for forging quality. Our engineering team designs and maintains specialized dies that ensure consistent part quality and optimal material flow during the forging process.

Comprehensive Testing

Our in-house material laboratory conducts rigorous testing to verify mechanical properties, dimensional accuracy, and surface quality of all forged components.

Secondary Processing

Beyond forging, we offer heat treatment, precision machining, and surface finishing to deliver complete, ready-to-use components that meet your exact specifications.

Need Custom Metal Forge Parts?

Our engineering team can help develop the optimal forging solution for your application.

Get a Quick Quote

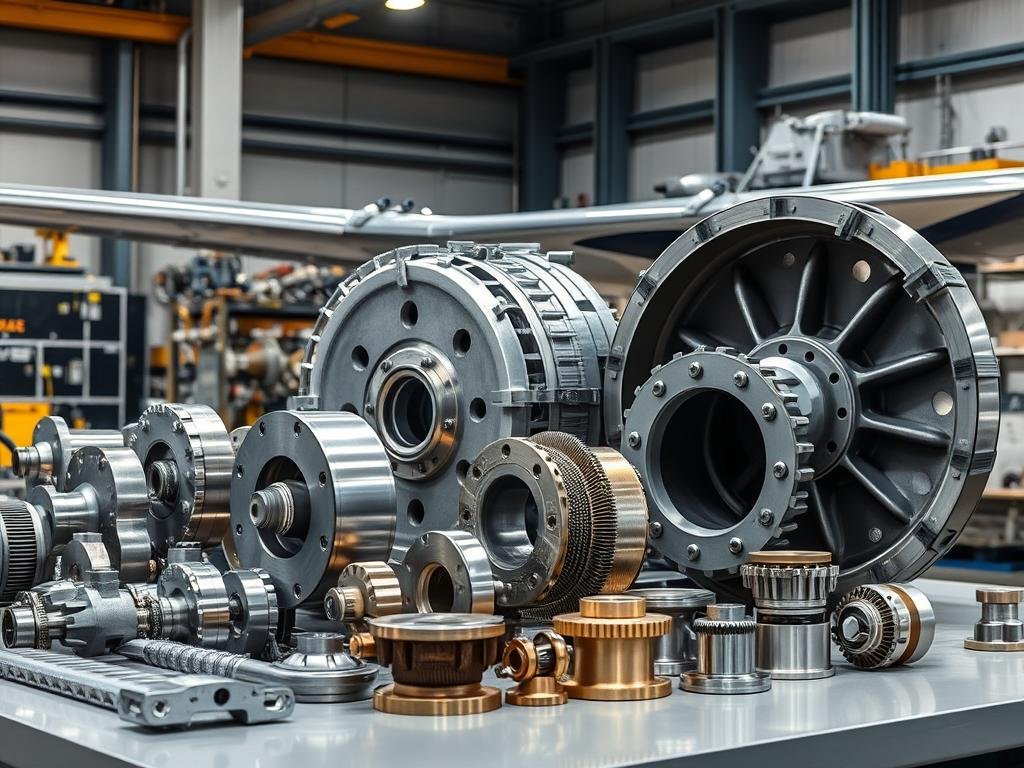

Industrial Applications of Metal Forge

The superior mechanical properties of forged components make them ideal for demanding applications across numerous industries:

Aerospace Components

Aerospace Components

Automotive Parts

Automotive Parts

Construction Equipment

Construction Equipment

Energy Sector

Energy Sector

Marine Applications

Marine Applications

Medical Devices

Medical Devices

Case Study: Automotive Metal Forge Components

Precision automotive connecting rods manufactured through MAIKONG’s metal forge process

A leading automotive manufacturer needed high-strength connecting rods that could withstand extreme operating conditions while maintaining tight tolerances. MAIKONG’s engineering team developed a custom forging process that:

- Increased fatigue strength by 35% compared to previously cast components

- Reduced weight by 12% while maintaining structural integrity

- Achieved dimensional tolerances within ±0.05mm

- Decreased production costs through optimized material usage

The result was a superior component that extended engine life while improving performance and fuel efficiency.

Why Choose MAIKONG for Your Metal Forge Needs

The MAIKONG Advantage

- 60+ CNC machines for comprehensive processing capabilities

- 100+ tons monthly metal processing capacity

- ISO 9001:2015 certified quality management system

- In-house material testing laboratory

- Comprehensive secondary processing capabilities

- Competitive pricing with exceptional value

- Experienced engineering team for technical support

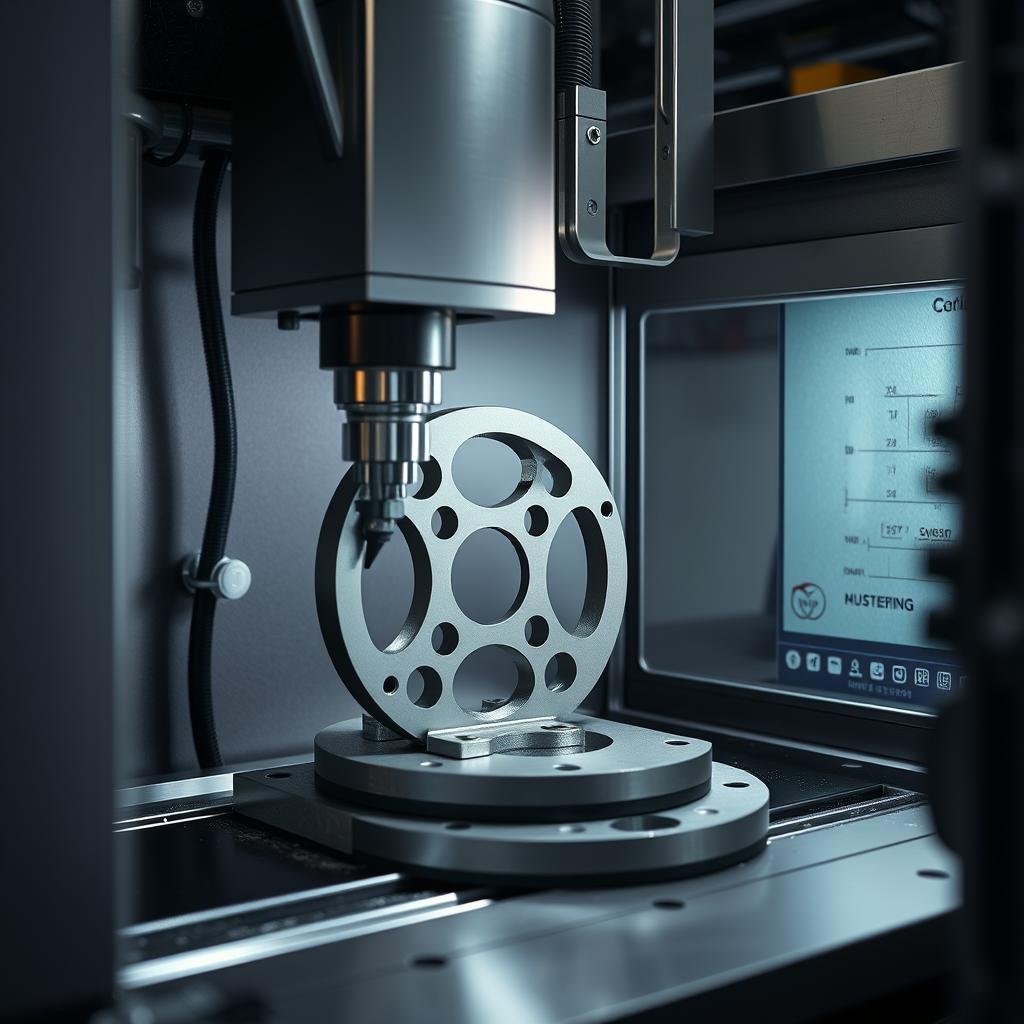

Quality Assurance in Metal Forge Production

Rigorous quality control inspection of metal forge components at MAIKONG

Quality is built into every step of our metal forge process. From material selection to final inspection, we implement rigorous controls to ensure your components meet or exceed specifications:

Material Verification

Every batch of raw material undergoes chemical composition analysis and mechanical property testing before entering production.

Process Monitoring

Advanced sensors and monitoring systems track critical parameters throughout the forging process, ensuring consistency and quality.

Dimensional Inspection

Precision measuring equipment verifies that all components meet dimensional specifications within required tolerances.

Non-Destructive Testing

Ultrasonic, magnetic particle, and other NDT methods detect any internal or surface defects that could compromise component integrity.

Experience the MAIKONG Difference

Discover how our comprehensive metal forge capabilities can enhance your product quality while reducing costs.

Contact Our Team

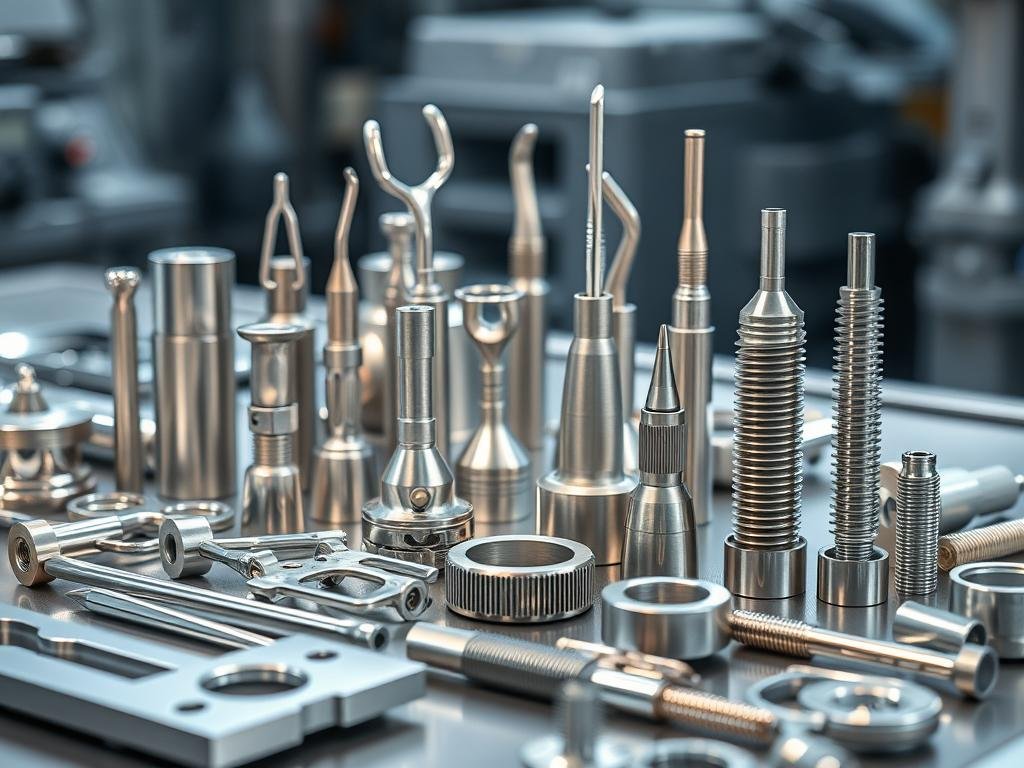

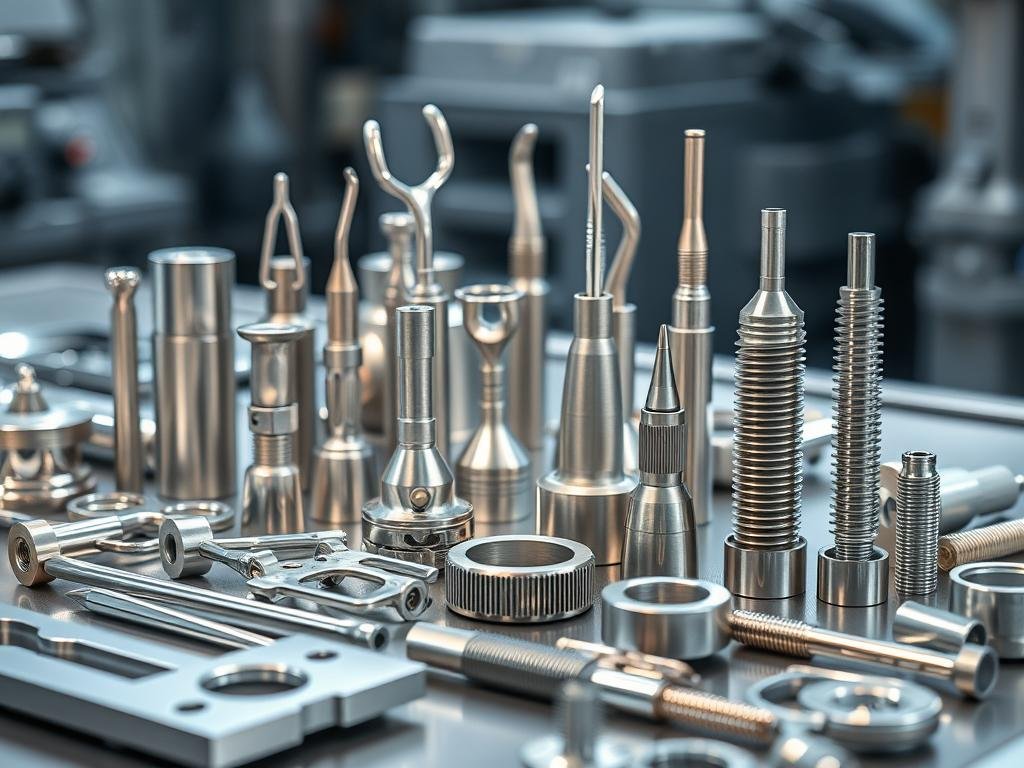

Additional Manufacturing Services

Beyond our core metal forge capabilities, MAIKONG offers a comprehensive suite of manufacturing services to meet all your metal component needs:

CNC Machining Services

Precision CNC turning, milling, and multi-axis machining for complex geometries and tight tolerances.

Learn More

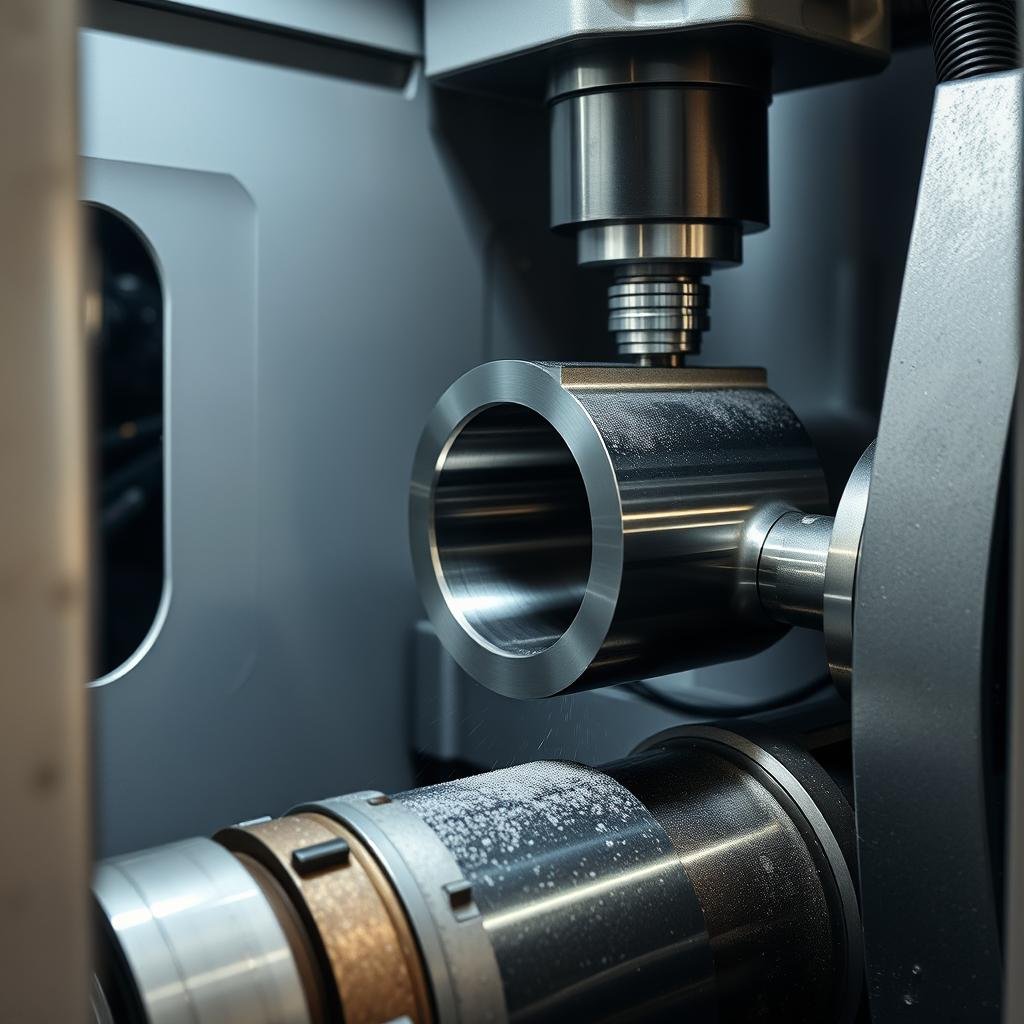

CNC Turning Services

Specialized turning for cylindrical components, deep holes, and precision threads with superior surface finishes.

Learn More

CNC Milling Services

Multi-axis milling for complex prismatic shapes and flat surfaces with exceptional accuracy.

Learn More

CNC Swiss-Type Machining

Specialized machining for precision small parts and long shaft components with dual spindles and multi-axis capabilities.

Learn More

CNC Prototyping

Rapid prototyping services for concept validation and design optimization before full production.

Learn More

Custom Metal Fabrication

Comprehensive fabrication services including welding, assembly, and finishing for complete metal components.

Learn More

One-Stop Manufacturing Solution

By combining our metal forge capabilities with comprehensive machining and finishing services, MAIKONG delivers complete components that are ready for assembly. This integrated approach offers several advantages:

- Simplified supply chain with a single point of contact

- Reduced logistics costs and lead times

- Consistent quality control across all manufacturing processes

- Optimized production flow for maximum efficiency

- Comprehensive technical support from a single team

Elevate Your Products With MAIKONG Metal Forge Solutions

In today’s competitive manufacturing environment, the quality of your components directly impacts your product’s performance, reliability, and market success. MAIKONG’s comprehensive metal forge and machining capabilities deliver the precision, strength, and value your applications demand.

From material selection through forging, heat treatment, machining, and finishing, our integrated approach ensures superior components that meet your exact specifications. Experience the MAIKONG difference today and discover why leading manufacturers trust us as their metal forge partner.

Start Your Next Project With MAIKONG

Contact our team today to discuss your metal forge requirements.

Request a Consultation

Advanced metal forge process at MAIKONG’s GD, SZ facility

Advanced metal forge process at MAIKONG’s GD, SZ facility

Aerospace Components

Aerospace Components Automotive Parts

Automotive Parts Construction Equipment

Construction Equipment Energy Sector

Energy Sector Marine Applications

Marine Applications Medical Devices

Medical Devices