Engineering excellence demands precision components that deliver consistent performance under demanding conditions. Metal forge components offer superior mechanical properties that can significantly enhance the structural integrity, durability, and overall performance of your designs. MAIKONG specializes in advanced metal forge processes that transform raw materials into high-performance components with exceptional strength-to-weight ratios and reliability.Our comprehensive capabilities in CNC machining, precision manufacturing, and custom metal fabrication allow us to deliver components that meet the most exacting specifications across industries. This guide explores the mechanical advantages of incorporating metal forge components in your engineering designs and how MAIKONG’s expertise can elevate your products.

Mechanical Benefits of Metal Forge Components

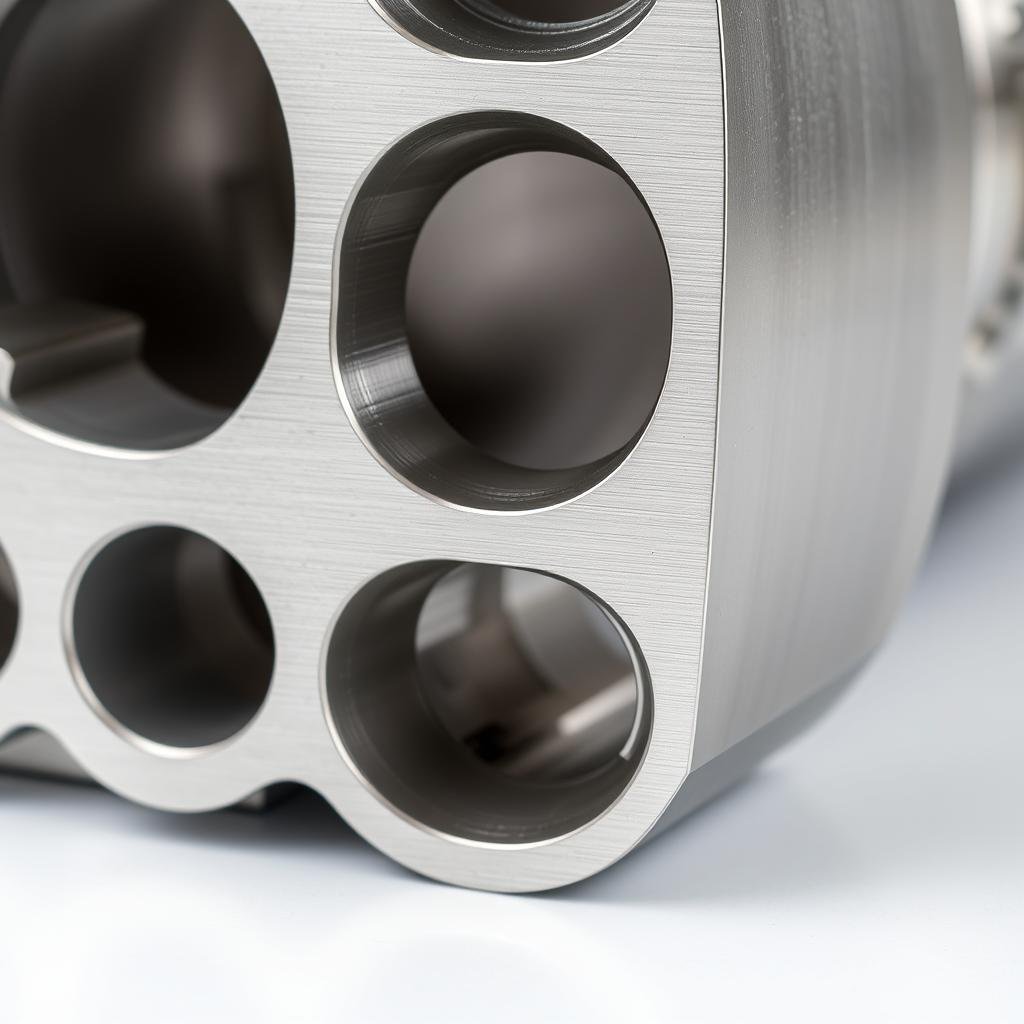

Mechanical testing of MAIKONG metal forge components

The unique manufacturing process of metal forge components creates distinct mechanical advantages that directly impact performance in demanding applications. Understanding these benefits helps engineers make informed decisions when specifying components for critical systems.

Enhanced Strength

Forged components exhibit 25-30% higher tensile strength compared to cast or machined alternatives. This strength enhancement comes from the refined grain structure and elimination of internal voids during the forging process.

Superior Fatigue Resistance

The aligned grain structure of metal forge components provides exceptional resistance to cyclic loading, extending service life by up to 40% in high-stress applications where fatigue failure is a concern.

Optimal Weight Distribution

MAIKONG’s precision metal forge processes allow for strategic material placement, creating components with optimized weight distribution that maintain strength while reducing overall mass.

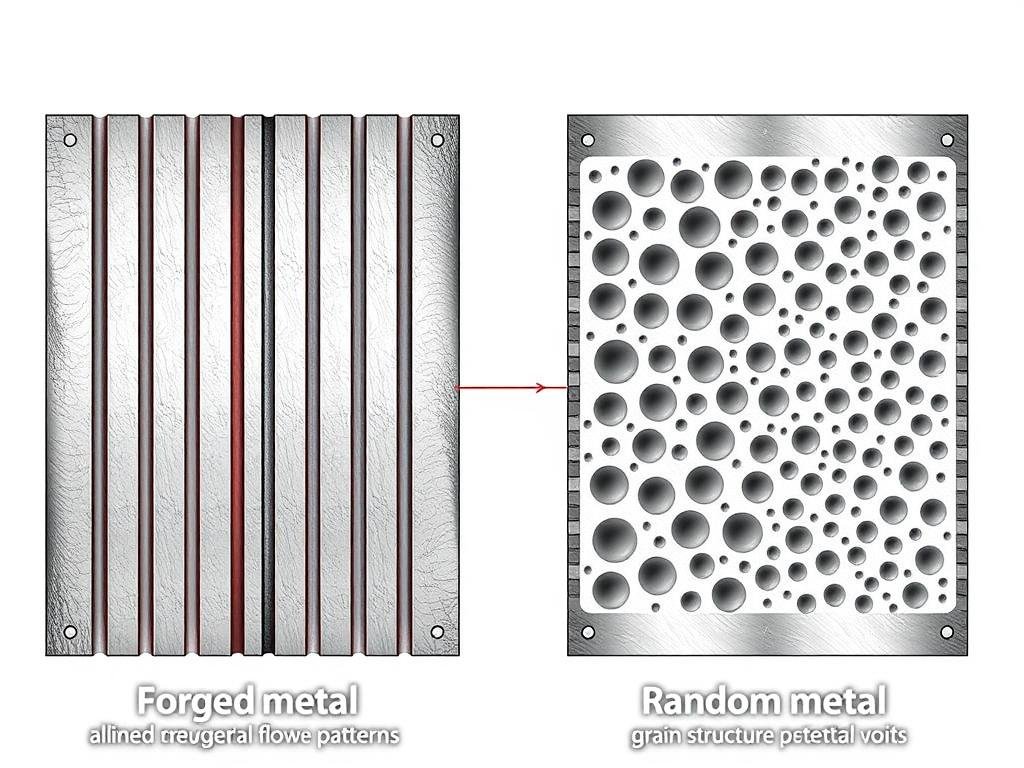

Comparative Mechanical Properties: Metal Forge vs. Alternative Manufacturing

| Property |

Metal Forge |

Casting |

Machining |

Advantage |

| Tensile Strength |

Excellent |

Good |

Very Good |

20-30% stronger than cast |

| Impact Resistance |

Excellent |

Fair |

Good |

Up to 50% higher impact resistance |

| Fatigue Resistance |

Excellent |

Fair |

Good |

2-3x longer fatigue life |

| Structural Integrity |

Excellent |

Good |

Very Good |

No internal voids or porosity |

| Grain Structure |

Directional, refined |

Random |

Interrupted |

Optimized for load paths |

Request Mechanical Testing Data

Get detailed mechanical property reports for MAIKONG’s metal forge components relevant to your application.

Request Test Data

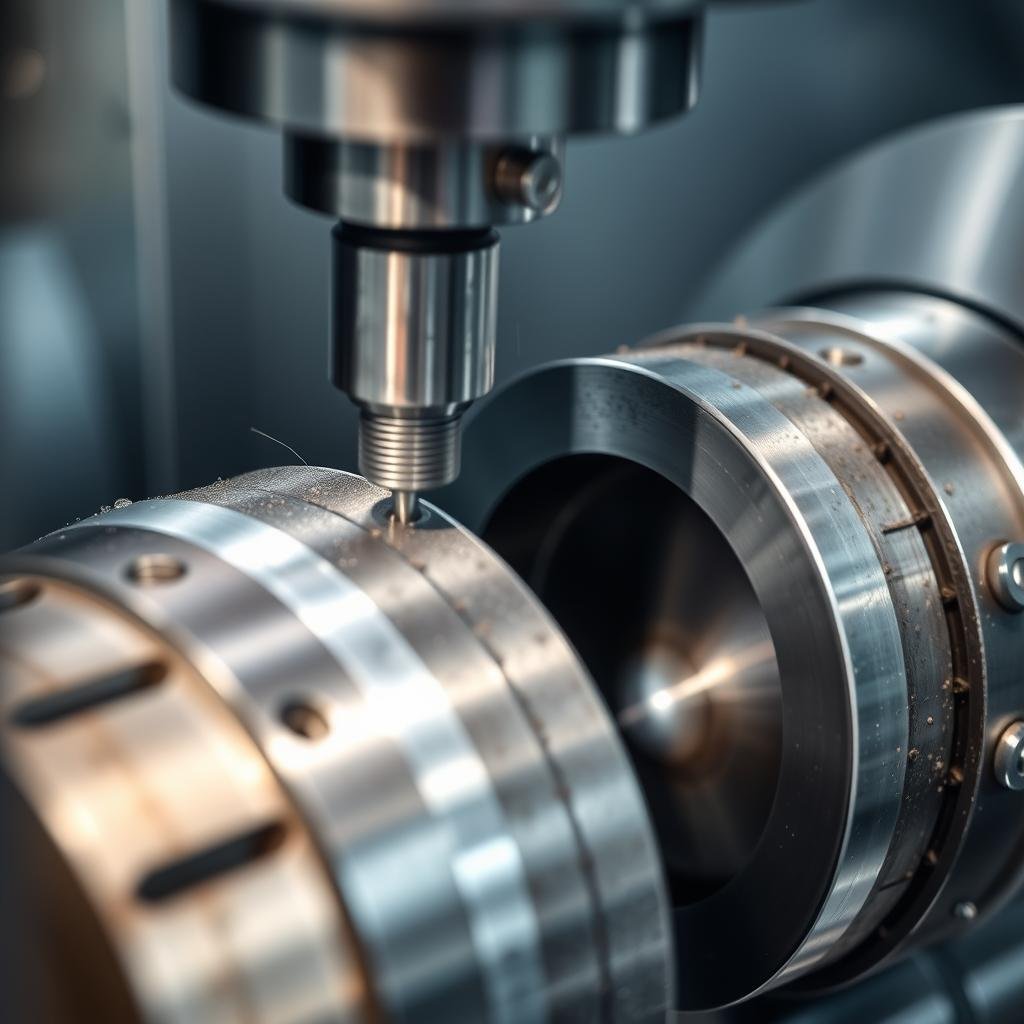

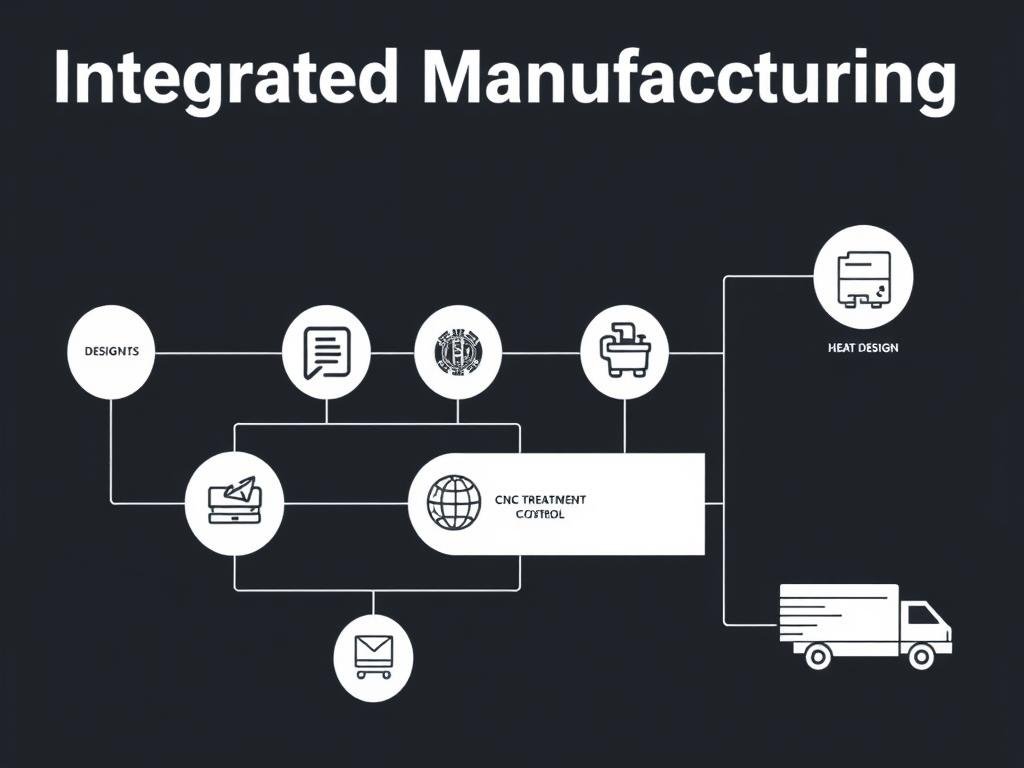

MAIKONG’s Metal Forge Capabilities and Manufacturing Excellence

MAIKONG’s state-of-the-art metal forge facility in GD, SZ

With over 60 CNC machines and 100+ tons of monthly metal processing capacity, MAIKONG delivers precision metal forge components with exceptional quality and consistency. Our comprehensive manufacturing capabilities integrate forging with advanced machining and finishing processes to provide complete component solutions.

Our Manufacturing Process

- Design Optimization: CAD/CAM analysis to identify and mitigate potential issues early in the design phase

- Material Selection: Comprehensive consideration of mechanical properties, machinability, and cost-effectiveness

- Tooling Design: Precision die creation ensuring initial quality and consistent production

- Forging Process: Advanced hydraulic presses accommodating diverse specifications

- Heat Treatment: In-house heat treatment with comprehensive statistical analysis and documentation

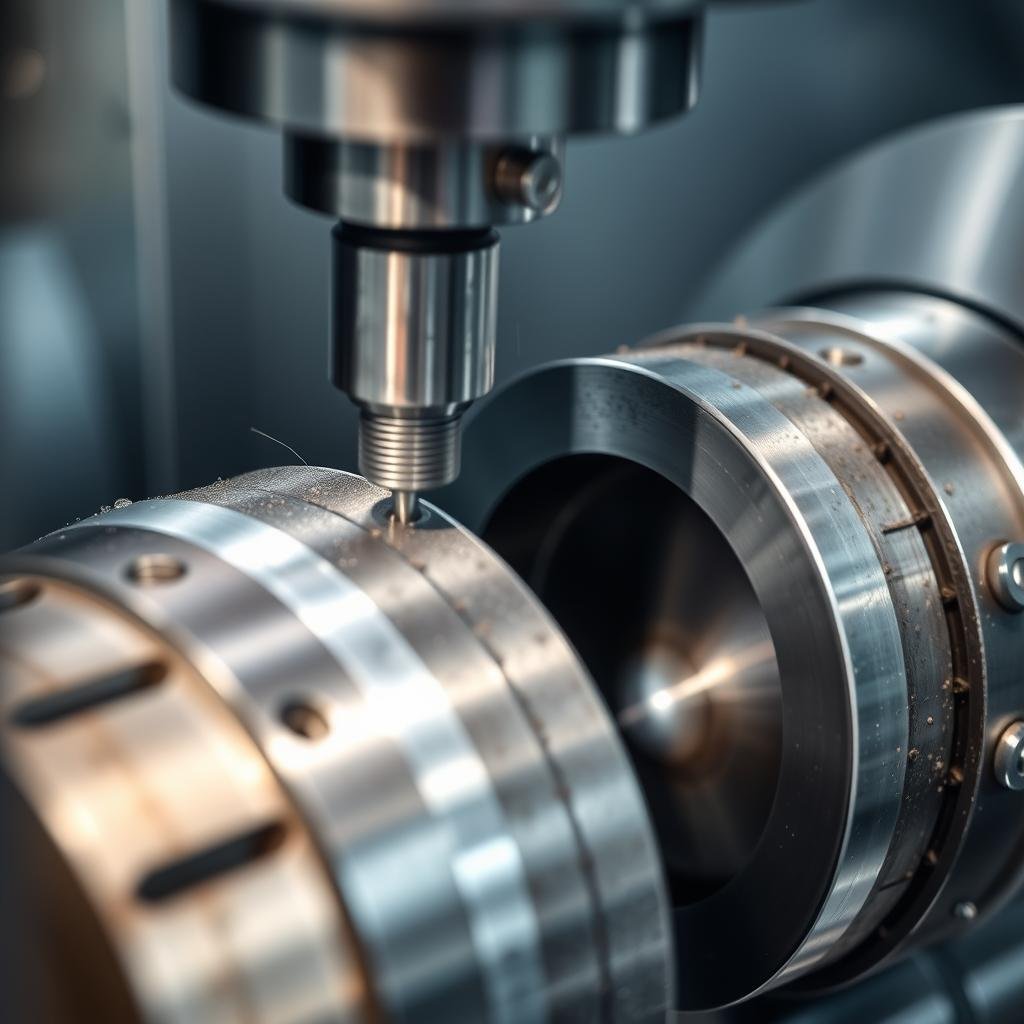

- Precision Machining: State-of-the-art CNC equipment for intricate operations

- Surface Treatment: Enhanced appearance and performance through specialized finishing

- Quality Control: Rigorous inspection ensuring components meet stringent standards

Key Metal Forge Services

Aluminum Forging Services

Aluminum Forging Services

Steel Forging Components

Steel Forging Components

Brass Forged Precision Parts

Brass Forged Precision Parts

CNC Machining Services

CNC Machining Services

Explore Our Manufacturing Capabilities

Discover how MAIKONG’s integrated metal forge and precision machining capabilities can deliver superior components for your applications.

View Capabilities

Industry Applications for Metal Forge Components

MAIKONG metal forge components across diverse industries

The superior mechanical properties of metal forge components make them ideal for critical applications across numerous industries. MAIKONG’s precision manufacturing capabilities deliver components that meet the most demanding requirements in these sectors.

Aerospace

Aerospace applications demand the highest standards of reliability and performance. MAIKONG’s metal forge components deliver exceptional strength-to-weight ratios critical for fuel efficiency while maintaining structural integrity under extreme conditions.

Automotive

From engine components to chassis systems, automotive applications benefit from the enhanced fatigue resistance and durability of forged parts. Our precision metal forge processes ensure consistent performance in safety-critical systems.

Industrial Machinery

Industrial equipment operates under demanding conditions where component failure can cause costly downtime. MAIKONG’s metal forge components provide the reliability and longevity needed for continuous operation.

Case Study: Optimizing Performance Through Metal Forge Design

A leading equipment manufacturer approached MAIKONG to redesign a critical load-bearing component that was experiencing premature failure. By converting from a cast design to a precision metal forge approach, our engineering team:

- Reduced component weight by 22% while increasing strength by 35%

- Extended service life from 2,000 hours to over 5,000 hours

- Eliminated catastrophic failures that were causing costly downtime

- Maintained dimensional accuracy for seamless integration

The redesigned component not only resolved the immediate failure issues but also improved overall system performance and reduced maintenance requirements.

Discuss Your Application Requirements

Our engineering team can help identify opportunities to enhance performance through metal forge component design.

Contact Our Engineers

Quality Assurance in Metal Forge Manufacturing

Rigorous quality control of MAIKONG metal forge components

At MAIKONG, quality is not just an inspection process—it’s integrated throughout our manufacturing operations. Our comprehensive quality management system ensures that every metal forge component meets or exceeds specifications and performs reliably in the field.

Our Quality Approach

MAIKONG’s quality management system is certified to ISO 9001:2015 standards, reflecting our commitment to consistent quality and continuous improvement. Our in-house material laboratory plays a crucial role in achieving precise results through comprehensive understanding of material properties and interactions.

Quality control procedures include:

- Material verification and certification

- In-process dimensional inspection

- Non-destructive testing (ultrasonic, magnetic particle)

- Mechanical property testing

- Surface finish inspection

- Final dimensional verification

Request Our Quality Certifications

Learn more about MAIKONG’s quality management system and certifications for metal forge manufacturing.

Email for Certification Details

Elevate Your Designs with MAIKONG Metal Forge Components

The mechanical advantages of specifying metal forge components in your designs are clear: superior strength, enhanced fatigue resistance, optimized weight distribution, and exceptional reliability. MAIKONG’s comprehensive manufacturing capabilities deliver these benefits through precision forging processes integrated with advanced machining and quality control.

Whether you’re designing aerospace components, automotive systems, industrial machinery, or other demanding applications, MAIKONG’s metal forge solutions provide the performance and reliability your products require. Contact us today to discuss your specific requirements or explore opportunities to represent our high-quality components in the US market.

Start Your Partnership with MAIKONG Today

Take the first step toward superior metal forge components for your designs or distribution portfolio.

Contact MAIKONG Now

Aluminum Forging Services

Aluminum Forging Services Steel Forging Components

Steel Forging Components Brass Forged Precision Parts

Brass Forged Precision Parts CNC Machining Services

CNC Machining Services