Forging metal is one of the oldest and most reliable manufacturing processes, dating back thousands of years. This transformative technique shapes metal through compressive forces, creating components with superior strength, durability, and structural integrity. At MAIKONG, we’ve perfected the art and science of metal forging, combining traditional craftsmanship with cutting-edge technology to deliver exceptional custom components for industries worldwide.Whether you’re seeking aluminum forgings with an optimal strength-to-weight ratio, precision steel components, or custom brass parts, this comprehensive guide will walk you through everything you need to know about the forging metal process and how MAIKONG can meet your manufacturing needs with unparalleled quality and cost-effectiveness.

Understanding Forging Metal: The Fundamentals

Forging metal is a manufacturing process that shapes metal using compressive forces delivered through hammering, pressing, or rolling. Unlike casting, which involves pouring molten metal into molds, forging works with solid metal that has been heated to increase its malleability. This fundamental difference results in stronger components with refined grain structures and fewer defects.

MAIKONG’s advanced forging facility in action, shaping heated metal with precision hydraulic presses

The Origins and Evolution of Forging Metal

The practice of forging metal has deep historical roots, with evidence dating back to 4000 BC in Mesopotamia. Early humans discovered that heating metals made them easier to shape, leading to the development of basic hammering techniques. Over centuries, this rudimentary process evolved into sophisticated methods that now power modern manufacturing.

From simple hand tools to advanced hydraulic presses, the evolution of forging technology has dramatically increased production capabilities while maintaining the core principles that make forged components superior. Today, MAIKONG continues this tradition with state-of-the-art equipment and processes that deliver precision-forged components to clients across the globe.

Key Benefits of Forging Metal Components

- Enhanced strength through refined grain structure

- Superior mechanical properties and performance

- Improved resistance to impact and fatigue

- Greater structural integrity with fewer defects

- Excellent weight-to-strength ratio, especially in aluminum forgings

- Consistent quality and reliability in critical applications

- Versatility across various metals and alloys

Classification of Forging Metal Processes

The forging metal industry employs various methods, each with distinct advantages for specific applications. Understanding these classifications helps in selecting the optimal process for your manufacturing needs.

Classification by Temperature

Cold Forging

Performed at room temperature or slightly elevated temperatures below the recrystallization point. Offers excellent dimensional accuracy, superior surface finish, and enhanced mechanical properties. Ideal for precision components with tight tolerances.

Warm Forging

Conducted at temperatures above room temperature but below the metal’s recrystallization point. Combines benefits of both cold and hot forging, offering good dimensional control with moderate force requirements. Perfect for complex geometries with moderate precision needs.

Hot Forging

Performed at temperatures above the metal’s recrystallization point. Requires less force, allows for significant deformation, and is suitable for creating complex shapes. Ideal for large components and difficult-to-form metals.

Visual comparison of cold, warm, and hot forged components produced at MAIKONG’s facility

Classification by Tooling and Equipment

Open Die Forging

Metal is shaped between flat or simply shaped dies that don’t completely enclose the workpiece. The material flows outward, requiring skilled operators to manipulate the workpiece. Suitable for large, simple shapes and low-volume production.

Closed Die Forging

Also known as impression die forging, this method shapes metal within two dies containing a pre-cut cavity. The metal fills the die completely, creating complex shapes with excellent dimensional accuracy. Ideal for medium to high-volume production.

Roll Forging

Metal is passed between two rotating rolls with shaped cavities, gradually forming the desired cross-section. This continuous process is efficient for elongated parts with varying cross-sections, such as axles, shafts, and blades.

Advanced Forging Metal Methods at MAIKONG

At MAIKONG, we employ a variety of specialized forging metal techniques to meet diverse manufacturing requirements. Our expertise spans traditional methods and cutting-edge processes that deliver exceptional results for even the most demanding applications.

MAIKONG’s state-of-the-art forging facility combines traditional expertise with advanced technology

Precision Forging

Precision forging, also known as net-shape or near-net-shape forging, creates components with minimal need for secondary operations. At MAIKONG, our precision forging capabilities deliver components with tight tolerances, reducing machining requirements and material waste while maintaining exceptional structural integrity.

Upset Forging

This specialized technique increases the cross-section of material by compressing its length. MAIKONG utilizes upset forging to produce components like bolts, rivets, and valve stems, where a portion of the part requires a larger diameter than the original stock.

Rolled Ring Forging

MAIKONG excels in producing seamless rings through our advanced rolled ring forging process. By punching a hole in a round metal billet and then rolling and shaping it, we create rings with superior grain structure for applications in aerospace, energy, and industrial equipment.

Need Custom Forged Components?

MAIKONG specializes in precision metal forging for critical applications. Our team of experts will help you select the optimal forging process for your specific requirements.

Get A Quick Quote

Materials Used in Forging Metal Processes

The choice of material significantly impacts the forging process and the final component’s properties. At MAIKONG, we work with a wide range of metals and alloys to meet diverse application requirements.

Steel Forgings

Carbon, alloy, and stainless steels offer exceptional strength, durability, and heat resistance. MAIKONG’s steel forgings are ideal for high-stress applications in automotive, industrial, and construction equipment.

Aluminum Forgings

Lightweight with excellent strength-to-weight ratios, aluminum forgings provide corrosion resistance and good thermal conductivity. Perfect for aerospace, automotive, and consumer products requiring weight reduction.

Brass Forgings

Offering excellent machinability, corrosion resistance, and attractive appearance, brass forgings are ideal for plumbing components, electrical connectors, and decorative hardware.

MAIKONG works with various metals including steel, aluminum, and brass to create custom forged components

Aluminum Forging vs. Casting: A Comparative Analysis

When considering manufacturing methods for aluminum components, understanding the differences between forging and casting is crucial for selecting the optimal process.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Lower due to potential air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Requires multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Weight-to-Strength Ratio |

✅ High strength-to-weight ratio |

Bulkier parts may be needed for equivalent strength |

| Ideal Applications |

Aerospace, automotive, critical structural components |

Consumer goods, decorative items, complex housings |

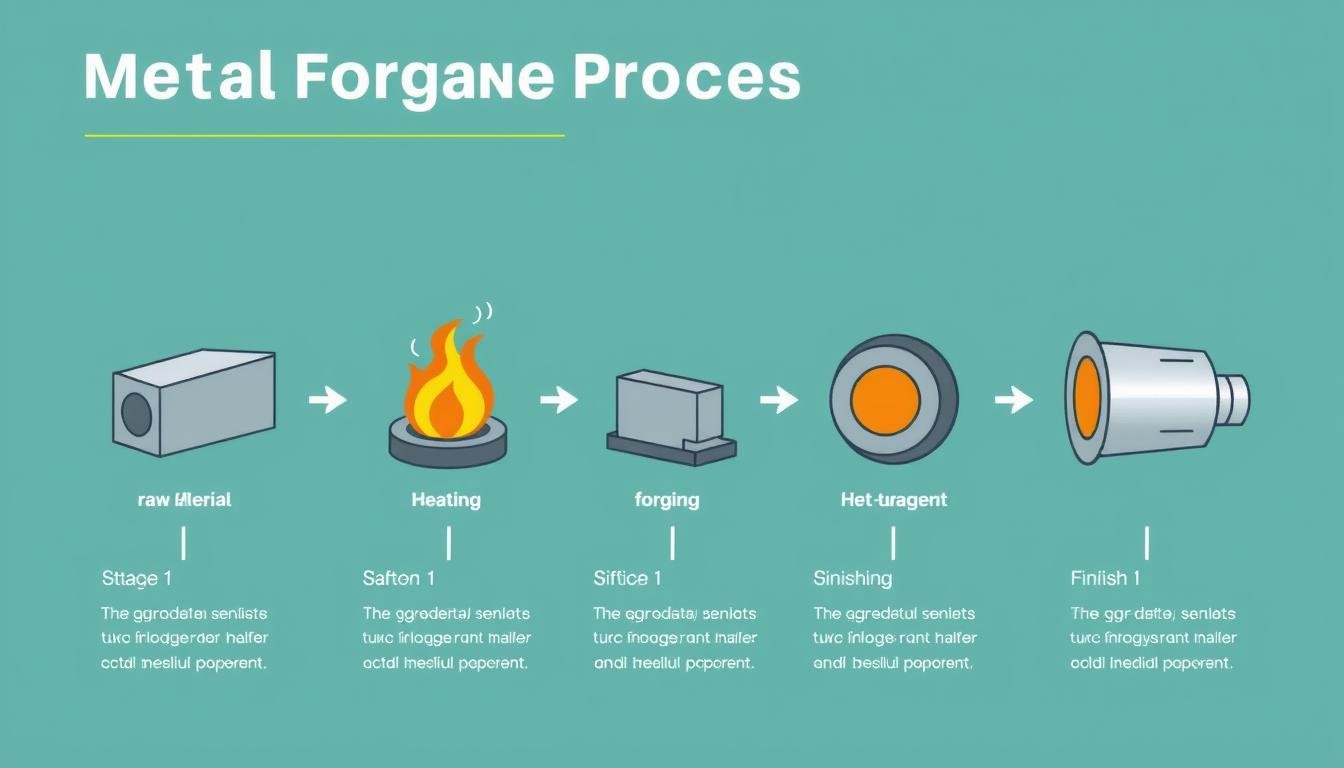

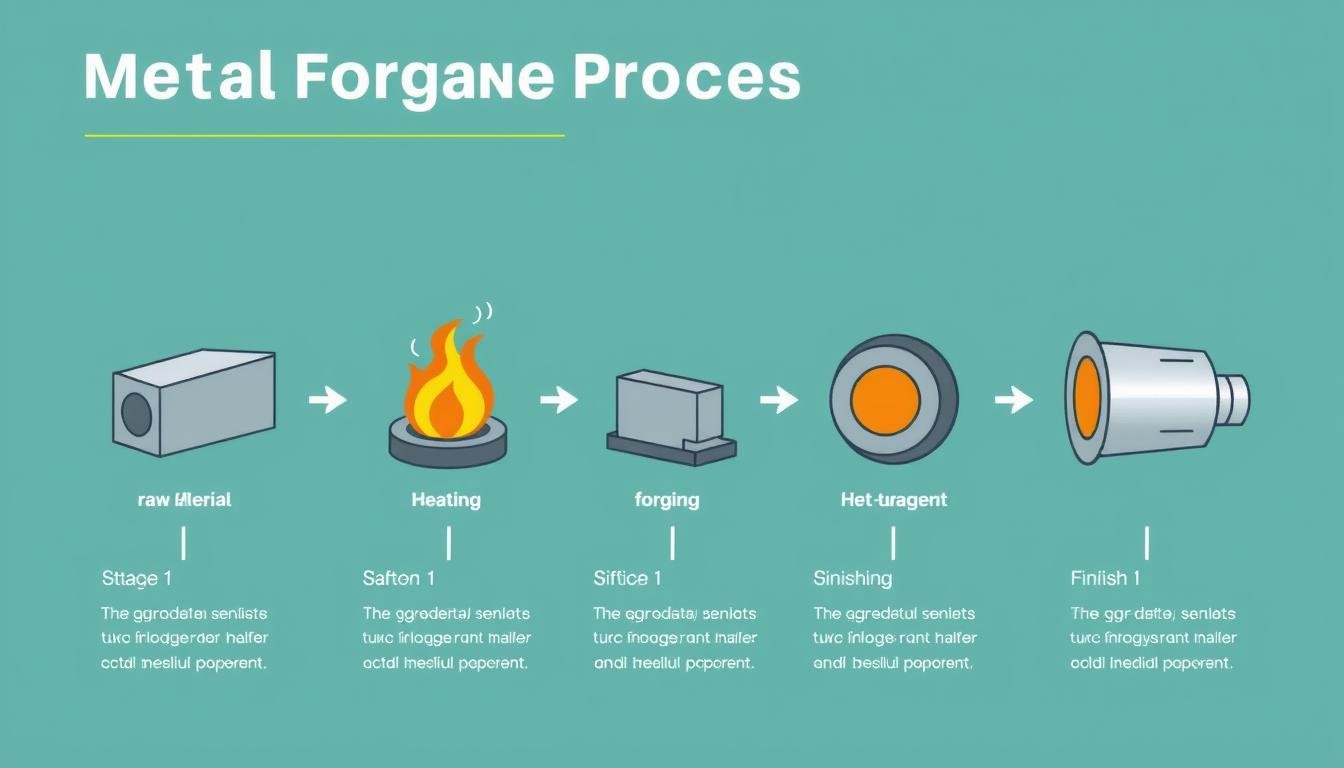

The Forging Metal Process: Step by Step

Understanding the complete forging metal process helps appreciate the craftsmanship and precision that goes into creating high-quality forged components. At MAIKONG, we follow a comprehensive workflow to ensure exceptional results.

- Design and Engineering: Our team works closely with clients to understand requirements and develop optimal designs using advanced CAD/CAM software and simulation tools.

- Material Selection: We select the appropriate metal or alloy based on the component’s application, performance requirements, and cost considerations.

- Die Design and Manufacturing: Custom dies are designed and precision-machined to create the desired component geometry with optimal material flow.

- Billet Preparation: Raw material is cut to the required dimensions and prepared for the forging process.

- Heating: The material is heated to the appropriate temperature in controlled furnaces to achieve optimal malleability.

- Forging: The heated material is shaped using specialized equipment, applying precise pressure to form the component according to design specifications.

- Trimming and Cleaning: Excess material (flash) is removed, and the component is cleaned of scale and other surface contaminants.

- Heat Treatment: Components undergo controlled heating and cooling to enhance mechanical properties and relieve internal stresses.

- Finishing Operations: Secondary processes such as machining, grinding, and surface treatments are applied as required.

- Quality Inspection: Rigorous testing and inspection ensure the component meets all specifications and quality standards.

MAIKONG’s comprehensive forging process ensures quality at every stage from design to final inspection

Equipment Used in Forging Metal Manufacturing

The quality of forged components depends significantly on the equipment used in their production. MAIKONG has invested in advanced machinery to ensure precision, consistency, and efficiency in our forging operations.

Hydraulic Presses

Our hydraulic presses deliver controlled, consistent pressure for precision forging. With capacities ranging from 500 to 8,000 tons, these machines handle components of various sizes with exceptional accuracy.

Mechanical Presses

MAIKONG’s mechanical presses offer high production rates for medium to large volume orders. These machines provide excellent repeatability for consistent component quality across production runs.

Ring Rolling Mills

Specialized equipment for producing seamless rings with precise dimensions and superior grain structure. Our advanced ring rolling capabilities serve aerospace, energy, and industrial applications.

MAIKONG’s high-capacity hydraulic press delivering precise, controlled force for optimal forging results

Explore Our Manufacturing Capabilities

MAIKONG’s state-of-the-art equipment and experienced team ensure exceptional quality for your forged components. Contact us to discuss your specific requirements.

Contact Our Experts

MAIKONG’s Comprehensive Forging Metal Services

At MAIKONG, we offer a complete range of metal forging and related services to meet all your manufacturing needs. Our integrated approach ensures quality, consistency, and cost-effectiveness throughout the production process.

CNC Machining Services

Our advanced CNC machining capabilities complement our forging operations, allowing us to deliver precision-finished components. With 60+ CNC machines and 100+ tons of monthly processing capacity, we handle turning, milling, Swiss machining, multi-axis machining, and more.

Custom Metal Forging

MAIKONG specializes in custom forging solutions for aluminum, steel, and brass components. Our expertise spans open die, closed die, and roll forging processes, delivering components with superior strength and durability for critical applications.

Heat Treatment & Surface Finishing

Our comprehensive in-house heat treatment and surface finishing capabilities ensure your components achieve optimal mechanical properties and aesthetic qualities. Services include anodizing, painting, laser engraving, and sand blasting.

MAIKONG’s precision CNC machining center providing secondary operations for forged components

Quality Assurance and Certification

Quality is at the heart of everything we do at MAIKONG. Our comprehensive quality management system ensures that every component meets or exceeds the required specifications and industry standards.

- ISO 9001:2015 certified quality management system

- Comprehensive material testing laboratory

- Advanced inspection equipment including CMM and spectrographic analysis

- 100% component inspection for critical applications

- Statistical process control for consistent quality

- Detailed documentation and traceability

MAIKONG’s rigorous quality control ensures every component meets exact specifications

Applications of Forging Metal Components

Forged components play critical roles across numerous industries, providing the strength, durability, and reliability required for demanding applications. MAIKONG serves diverse sectors with custom forging solutions.

Automotive Industry

Forged components are essential in automotive applications, including crankshafts, connecting rods, transmission gears, steering knuckles, and suspension components. These parts require the superior strength and fatigue resistance that only forging can provide.

Aerospace and Aviation

The aerospace industry relies on forged components for critical applications where failure is not an option. Landing gear components, engine mounts, structural fittings, and turbine discs benefit from the exceptional strength-to-weight ratio of forged parts.

Industrial Equipment

Heavy machinery and industrial equipment depend on forged components to withstand extreme loads and harsh operating conditions. Gears, shafts, flanges, valves, and hydraulic components benefit from the superior mechanical properties of forged metal.

MAIKONG produces a wide range of forged components for diverse industrial applications

Additional Industry Applications

Oil & Gas

Valves, flanges, fittings, and structural components for drilling equipment must withstand extreme pressures and harsh environments, making forged components the ideal choice.

Power Generation

Turbine blades, rotors, shafts, and structural components in power plants benefit from the superior mechanical properties and reliability of forged metal parts.

Medical Equipment

Surgical instruments, implant components, and medical device structures require the precision, strength, and biocompatibility that forged components can provide.

Why Choose MAIKONG for Your Forging Metal Needs

MAIKONG stands apart as a premier provider of metal forging and machining services, offering exceptional quality, competitive pricing, and comprehensive capabilities to meet diverse manufacturing requirements.

The MAIKONG Advantage

- Comprehensive in-house capabilities from design to finishing

- State-of-the-art equipment for optimal quality and efficiency

- 60+ CNC machines with 100+ tons monthly processing capacity

- ISO 9001:2015 certified quality management system

- Competitive pricing without compromising quality

- Experienced engineering team for technical support

- Flexible production volumes from prototypes to high-volume manufacturing

- Global shipping capabilities with logistics expertise

MAIKONG’s integrated manufacturing facility in GD, SZ combines forging, machining, and finishing capabilities

Partner with MAIKONG for Superior Forged Components

Experience the MAIKONG difference with our comprehensive metal forging and machining services. Contact us today to discuss your project requirements and discover how we can deliver exceptional quality at competitive prices.

Become a MAIKONG Distributor in the United States

MAIKONG is actively seeking distribution partners across the United States to represent our premium metal forging and machining services. As a MAIKONG distributor, you’ll have access to our comprehensive manufacturing capabilities, competitive pricing, and exceptional quality to serve clients in various industries.

- Exclusive territorial rights in your region

- Comprehensive product and technical training

- Marketing and sales support materials

- Competitive commission structure

- Direct access to our engineering team

- Regular product updates and innovations

Interested in Distribution Opportunities?

Contact our partnership team to learn more about becoming a MAIKONG distributor in the United States.

Email: Lucy@maikongforge.us

Conclusion: Excellence in Forging Metal Manufacturing

MAIKONG combines traditional craftsmanship with cutting-edge technology to deliver exceptional forged metal components for diverse applications. Our comprehensive capabilities, from design and forging to machining and finishing, ensure superior quality, consistency, and cost-effectiveness for your manufacturing needs.

Whether you require aluminum forgings with optimal strength-to-weight ratios, precision steel components, or custom brass parts, MAIKONG has the expertise, equipment, and experience to exceed your expectations. Contact us today to discuss your project requirements and discover the MAIKONG difference in metal forging excellence.