Forged metal components represent the pinnacle of manufacturing strength and durability. When exceptional performance is non-negotiable, forging delivers unmatched structural integrity by aligning metal grain structure and eliminating internal defects. This comprehensive guide explores the science, methods, and applications of metal forging while showcasing how MAIKONG’s expertise can transform your manufacturing challenges into precision-engineered solutions.

Essential Metal Forging Methods and Processes

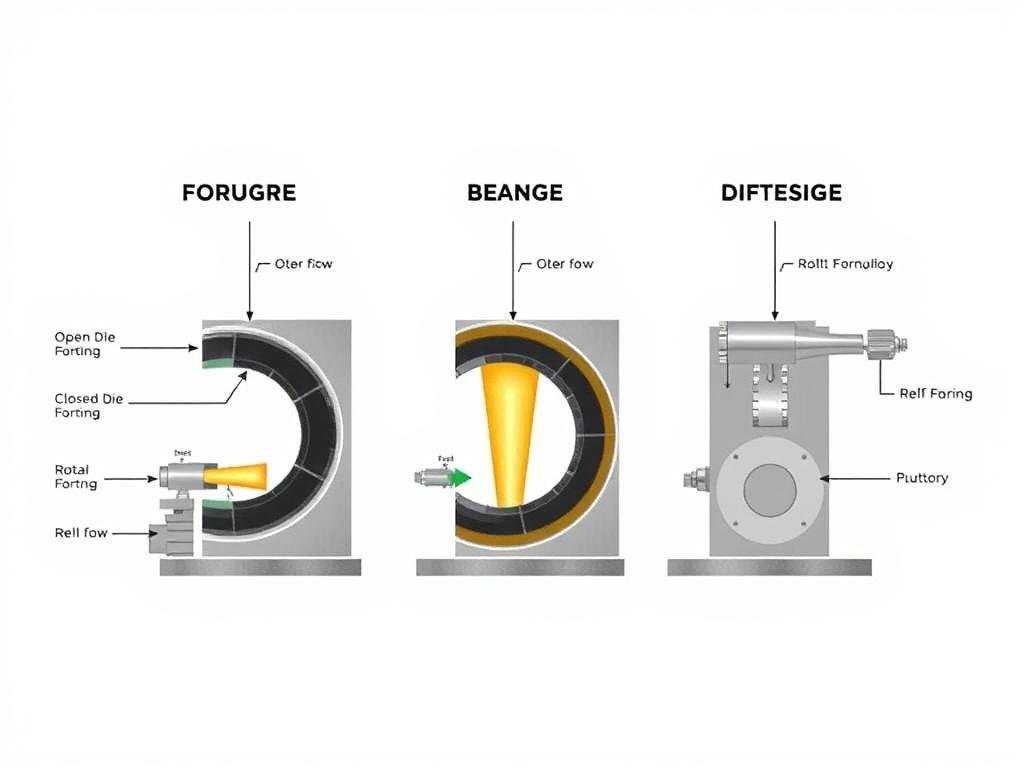

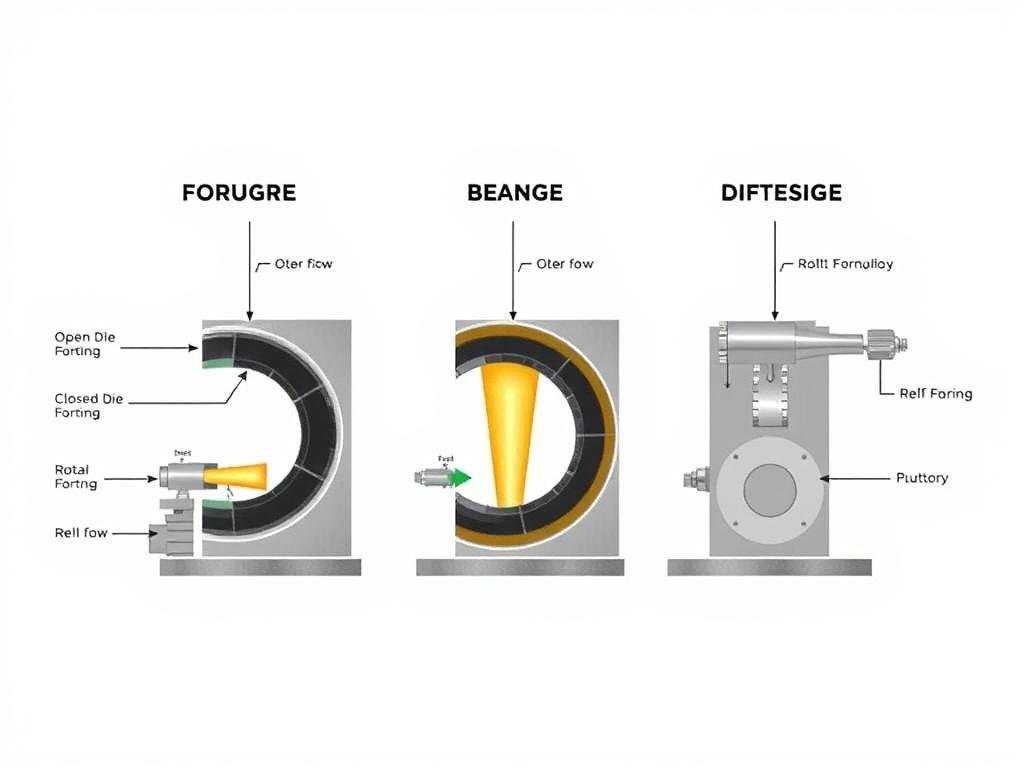

Comparison of primary forging methods used at MAIKONG

The forging industry employs several distinct methods, each with specific advantages for different applications. At MAIKONG, we utilize multiple forging techniques to deliver optimal results based on your component requirements.

Open Die Forging

In open die forging, metal is shaped between two dies that don’t completely enclose the workpiece. This method:

- Is ideal for larger, simpler components and low-volume production

- Allows for greater flexibility in producing custom shapes

- Typically operates at temperatures between 500°F and 2400°F

- Creates components like bars, rings, shafts, and discs

Closed Die Forging

Also known as impression die forging, this method completely encloses the metal within specially designed die cavities:

- Produces complex, precise components with tighter tolerances

- Ideal for medium to high-volume production runs

- Creates near-net-shape parts that require minimal machining

- Can manufacture components ranging from a few ounces to 60,000 lbs

Roll Forging

Roll forging uses cylindrical or semi-cylindrical rolls with shaped grooves to progressively form metal:

- Efficiently produces elongated parts with varying cross-sections

- Excellent for high-volume production of items like hand tools and blades

- Creates components with superior mechanical properties

- Reduces material waste compared to other manufacturing methods

Additional Forging Techniques

Cold Forging

Performed at or near room temperature, cold forging offers excellent dimensional precision and surface finish, though it’s limited to less complex shapes and more malleable metals.

Hot Forging

Conducted above the metal’s recrystallization temperature, hot forging allows for significant deformation and complex shapes but may require additional finishing operations.

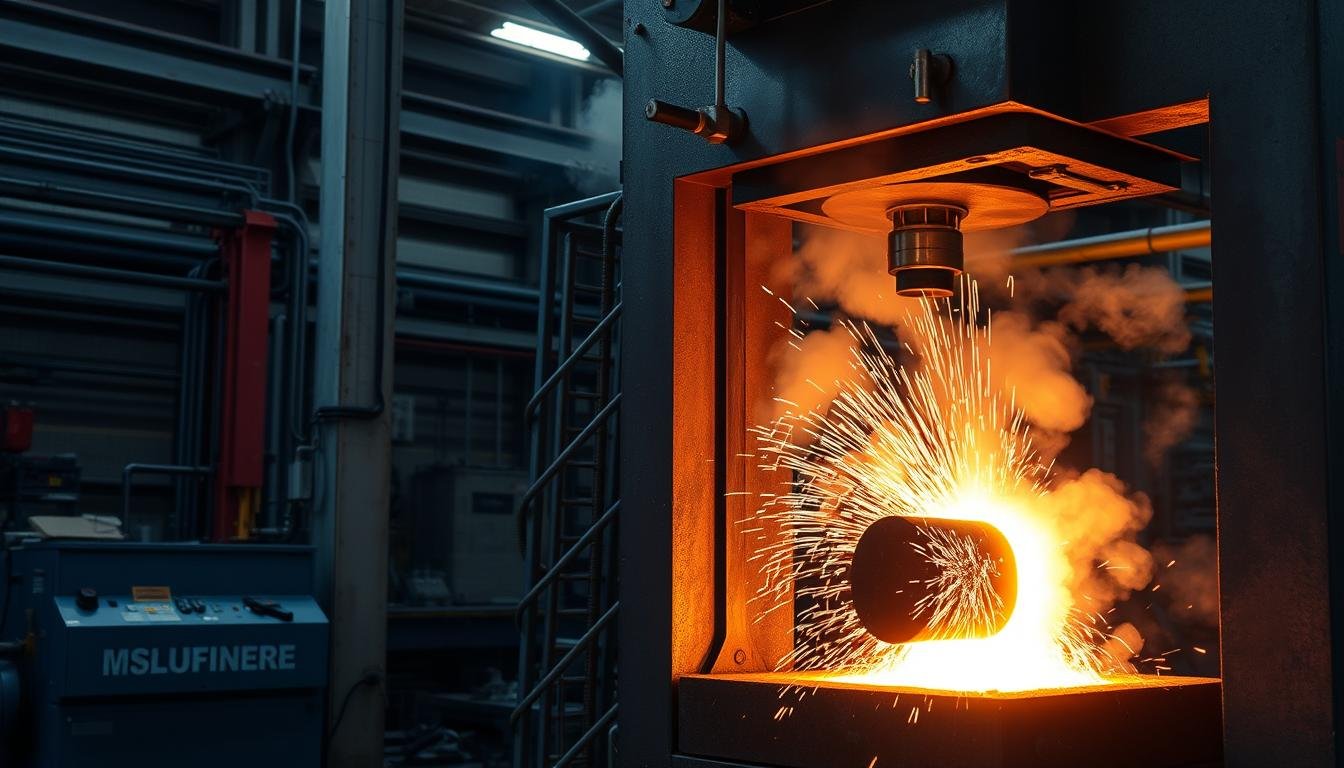

Standard Forging Equipment and Technology

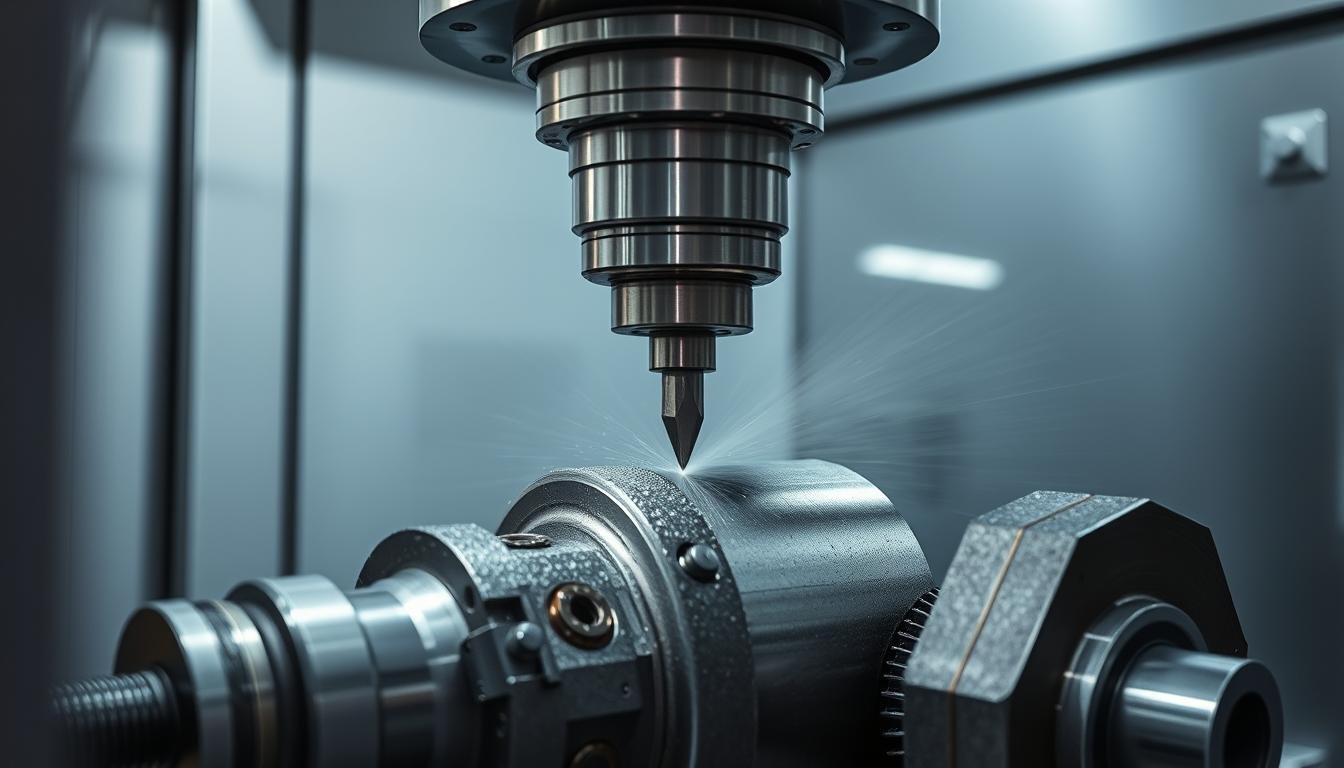

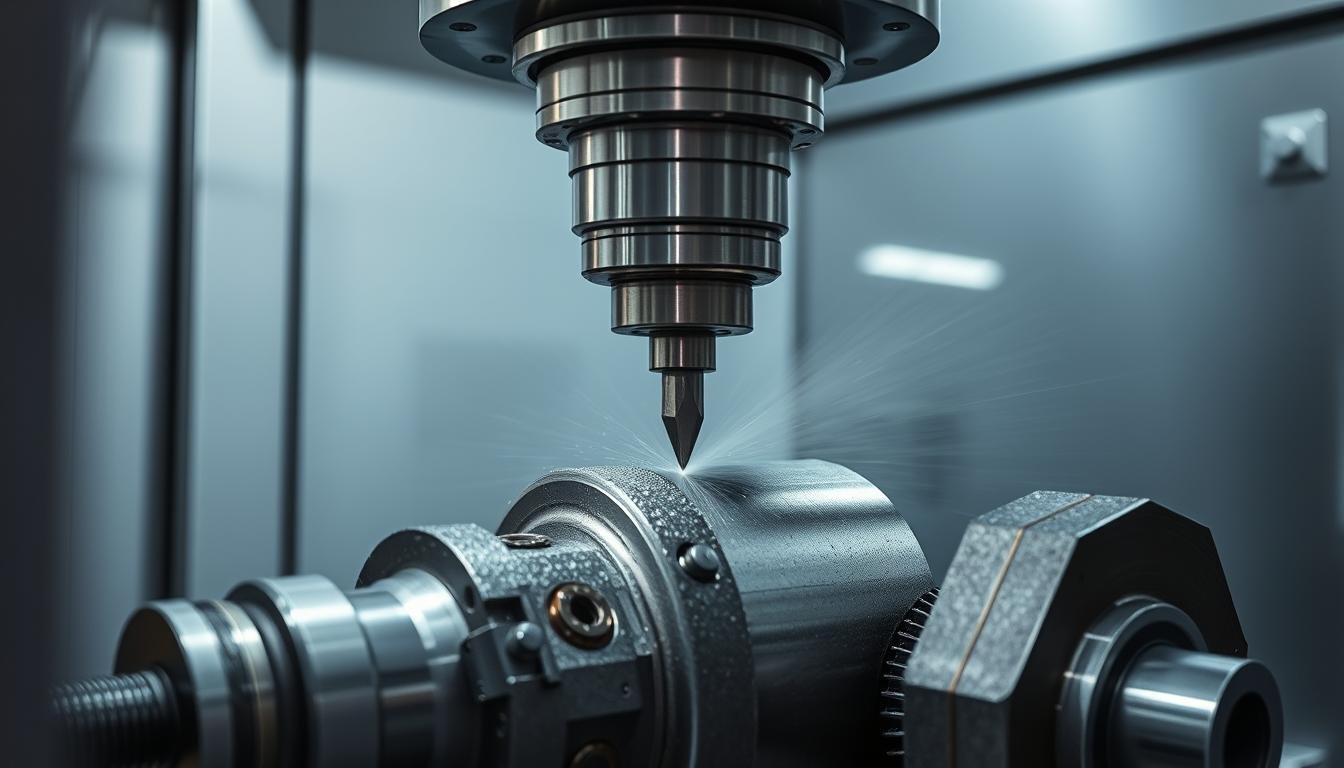

State-of-the-art hydraulic forging press at MAIKONG’s GD facility

The quality of forged components depends significantly on the equipment used in their production. MAIKONG has invested in advanced forging machinery to ensure consistent, high-quality results.

Forging Hammers

Deliver high-impact force to shape metal through repeated blows. Our power hammers provide up to 50,000 lbs of driving force for optimal metal deformation and grain refinement.

Hydraulic Presses

Apply continuous, controlled pressure to form metal with precision. MAIKONG’s hydraulic presses deliver up to 50,000 tons of force for exceptional component quality.

Specialized Equipment

Including ring rollers for seamless circular components, upsetters for horizontal forging applications, and precision heating furnaces for optimal metal workability.

Forged Metal vs. Cast Aluminum: A Comprehensive Comparison

Microstructural and visual comparison between forged and cast components

When selecting a manufacturing method for metal components, understanding the differences between forging and casting is crucial for making informed decisions that impact performance, longevity, and cost-effectiveness.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Weight-to-Strength Ratio |

✅ High strength-to-weight ratio |

Bulkier parts may be needed for equivalent strength |

| Critical Applications |

✅ Ideal for structural members and load-bearing components |

Limited suitability for critical applications |

While casting offers advantages for complex geometries and lower initial tooling costs, forged metal components deliver superior performance in applications where strength, durability, and reliability are paramount.

MAIKONG’s Comprehensive Forging Capabilities

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

At MAIKONG, we offer a complete suite of metal forging and precision machining services. Our integrated approach ensures quality at every stage—from initial design to final inspection.

Design & Engineering

Our engineering team utilizes advanced CAD/CAM software to optimize component design for manufacturability, performance, and cost-effectiveness. We identify potential issues early in the development process, saving time and resources.

Material Selection

We work with a wide range of metals including aluminum alloys, carbon and alloy steels, stainless steel, titanium, brass, and copper. Our materials lab ensures every batch meets stringent quality standards.

Tooling Design

Precision-engineered dies and tooling are critical for quality forged components. Our in-house tooling capabilities ensure optimal die design, regular maintenance, and consistent production quality.

Forging Operations

With multiple forging methods available, we select the optimal process for your specific requirements. Our workshop accommodates diverse specifications from small precision components to larger structural parts.

Heat Treatment

In-house heat treatment capabilities allow us to precisely control material properties. We conduct comprehensive statistical analysis and documentation to ensure consistent results.

CNC Machining

Our machining workshop features 60+ advanced CNC machines with 100+ tons monthly capacity. We specialize in turning, milling, Swiss machining, multi-axis machining, and surface grinding for precision finishing of forged components.

Surface Treatment

Comprehensive finishing options including anodizing, painting, laser engraving, and sand blasting. We use advanced measurement tools like spectrophotometers and adhesion testers to ensure consistent quality.

Quality Assurance

Rigorous inspection protocols including dimensional verification, material testing, and non-destructive evaluation ensure every component meets or exceeds specifications. Our ISO 9001:2015 certification demonstrates our commitment to quality.

Logistics & Support

Efficient shipping worldwide with comprehensive documentation. Our customer support team provides regular updates and responsive communication throughout your project.

Experience MAIKONG’s Manufacturing Excellence

Discover how our integrated forging and machining capabilities can deliver superior components for your most demanding applications.

Request a Consultation

Industries and Applications for Forged Metal Components

Custom forged components manufactured by MAIKONG for diverse industrial applications

The exceptional strength, durability, and reliability of forged metal components make them ideal for critical applications across numerous industries. MAIKONG serves diverse sectors with precision-engineered forged parts.

Automotive

Forged components are essential in automotive manufacturing, providing the strength and durability needed for:

- Crankshafts and connecting rods

- Transmission gears and shafts

- Steering and suspension components

- Engine blocks and cylinder heads

Aerospace

The aerospace industry relies on forged parts where failure is not an option:

- Landing gear components

- Turbine discs and blades

- Structural airframe components

- Engine mounts and brackets

Industrial Equipment

Heavy machinery and industrial applications benefit from forged components in:

- Hydraulic cylinders and pistons

- Gears and power transmission parts

- Valves and fittings for high-pressure systems

- Structural components for heavy equipment

Oil & Gas

The demanding environments of oil and gas extraction require exceptionally durable components:

- Drill bits and drilling equipment

- Valves and pressure vessels

- Flanges and fittings

- Pump components and impellers

Construction

Building and infrastructure projects utilize forged components for:

- Structural connectors and fasteners

- Heavy equipment components

- Crane hooks and lifting equipment

- Specialized tools and attachments

Consumer Products

Even everyday items benefit from the strength of forging:

- High-quality hand tools

- Sporting equipment components

- Bicycle and motorcycle parts

- Hardware and fasteners

Need Custom Forged Components for Your Industry?

MAIKONG specializes in manufacturing precision forged parts for demanding applications across all industries. Contact our engineering team to discuss your specific requirements.

Or reach us on WhatsApp

Complementary CNC Machining Services

Precision CNC machining of forged components at MAIKONG

MAIKONG offers comprehensive CNC machining services that perfectly complement our forging capabilities. With 60+ CNC machines providing over 100 tons of monthly processing capacity, we deliver precision-finished components that meet the most exacting specifications.

CNC Turning Services

Our CNC turning capabilities are ideal for creating precise cylindrical shapes with superior surface finishes. This process excels at producing:

- Deep holes with exceptional straightness

- Precisely machined threads

- Complex cylindrical profiles

- Components requiring tight dimensional tolerances

When combined with our forging expertise, CNC turning delivers components with both the internal strength of forged metal and the precise dimensions and finishes required for critical applications.

CNC Milling Services

For complex prismatic shapes and flat surfaces, our multi-axis CNC milling services provide unmatched versatility and precision. This process is perfect for:

- Complex 3D contours and surfaces

- Precise pocket and slot features

- Intricate patterns and textures

- Components requiring tight geometric tolerances

Our advanced CNC milling capabilities require no fixed tooling, offering exceptional flexibility for both prototype and production runs while maintaining extremely high accuracy.

CNC Swiss-Type Machining Services

For exceptional precision in small parts and long shaft components, MAIKONG’s Swiss-type machining services offer unmatched capabilities. Our equipment features:

- Dual spindles for continuous operation

- 3-axis, 4-axis, and 5-axis configurations

- Complete one-stop manufacturing solution

- Highest level of accuracy without additional equipment

Precision Machining for Your Forged Components

Combine MAIKONG’s forging and CNC machining capabilities for complete component manufacturing—from raw material to finished part.

Email Our Engineering Team

Quality Assurance and Certification

Rigorous quality inspection of forged components at MAIKONG

At MAIKONG, quality is not just a department—it’s a fundamental aspect of our entire operation. We implement comprehensive quality management systems to ensure every component meets or exceeds specifications.

Our Quality Commitment

We understand that in critical applications, component quality directly impacts safety, performance, and reliability. Our quality assurance program includes:

Material Verification

Our in-house materials laboratory conducts thorough testing to verify chemical composition, mechanical properties, and microstructure of all raw materials before production begins.

In-Process Inspection

Regular checks throughout the manufacturing process ensure dimensional accuracy, surface quality, and conformance to specifications at every stage.

Non-Destructive Testing

Advanced NDT methods including ultrasonic testing, magnetic particle inspection, and radiography detect any internal defects that could compromise component integrity.

Final Inspection

Comprehensive evaluation of finished components using precision measurement equipment ensures complete conformance to all specifications before shipment.

Certifications and Standards

MAIKONG maintains ISO 9001:2015 certification, demonstrating our commitment to consistent quality management practices. We also adhere to industry-specific standards relevant to your application, ensuring components meet all regulatory requirements.

Quality Philosophy: At MAIKONG, we believe quality expresses a component’s capacity to fully satisfy customer needs and expectations. Our integrated approach—from raw material selection through forging, heat treatment, CNC milling, and surface treatment—allows our quality engineering staff to monitor production and quality at all times, ensuring consistency and excellence in every component we produce.

Why Choose MAIKONG for Your Forged Metal Components

MAIKONG’s expert team delivering manufacturing excellence

The MAIKONG Advantage

- Integrated Manufacturing: Complete in-house capabilities from design through finishing

- Technical Expertise: Specialized knowledge in forging processes and metallurgy

- Quality Assurance: Rigorous testing and inspection at every production stage

- Competitive Pricing: Excellent value without compromising quality

- Production Capacity: 60+ CNC machines with 100+ tons monthly capacity

- Material Versatility: Experience with aluminum, steel, brass, and specialty alloys

- Global Shipping: Efficient logistics and worldwide delivery capabilities

US Distributor and Agent Opportunities

MAIKONG is actively seeking distribution partners and sales agents throughout the United States. If you serve manufacturing clients who need high-quality forged components at competitive prices, we offer attractive partnership opportunities.

Become a MAIKONG Distribution Partner

Join our growing network of US representatives and provide your customers with premium forged metal components at competitive prices.

Inquire About Partnership

Excellence in Forged Metal Manufacturing

MAIKONG combines traditional forging expertise with modern precision machining to deliver superior metal components for the most demanding applications. Our comprehensive capabilities, quality focus, and competitive pricing make us the ideal manufacturing partner for businesses that require exceptional performance and reliability from their components.

Whether you need aluminum forgings, steel components, brass parts, or custom CNC machining services, our team is ready to exceed your expectations. Contact us today to experience the MAIKONG difference in forged metal excellence.

Start Your Next Manufacturing Project with MAIKONG

From concept to completion, we deliver precision-engineered forged components that perform when it matters most.

Contact Us Today

Industrial metal forging process at MAIKONG’s state-of-the-art facility in GD, SZ

Industrial metal forging process at MAIKONG’s state-of-the-art facility in GD, SZ