The art of forged metal manufacturing has been refined over centuries, evolving into a sophisticated process that transforms various metals into strong, durable components. At MAIKONG, we’ve mastered this ancient craft while incorporating modern precision engineering to deliver superior forged metal parts that meet the most demanding specifications across industries.

Comprehensive Forged Metal Processes

At MAIKONG, we’ve mastered multiple forging techniques to deliver the ideal solution for any application. Our comprehensive approach ensures optimal results regardless of complexity, volume, or material requirements.

Open Die Forging

In open die forging, metal is shaped between flat or simply shaped dies that don’t completely enclose the material. This process is ideal for larger components and allows for greater flexibility in creating custom shapes. MAIKONG’s open die forging capabilities can accommodate components ranging from a few pounds to several tons.

Closed Die Forging

Closed die forging (impression die forging) uses custom-designed dies to create precise, complex shapes with tight tolerances. This method is ideal for high-volume production and components requiring consistent dimensions. Our advanced closed die forging capabilities deliver superior grain flow and mechanical properties.

Cold, Warm and Hot Forging

MAIKONG offers complete temperature-based forging solutions. Cold forging provides excellent dimensional accuracy and surface finish. Warm forging balances formability with precision. Hot forging allows for complex deformation with minimal force. Our metallurgical expertise ensures we select the optimal temperature process for your specific application requirements.

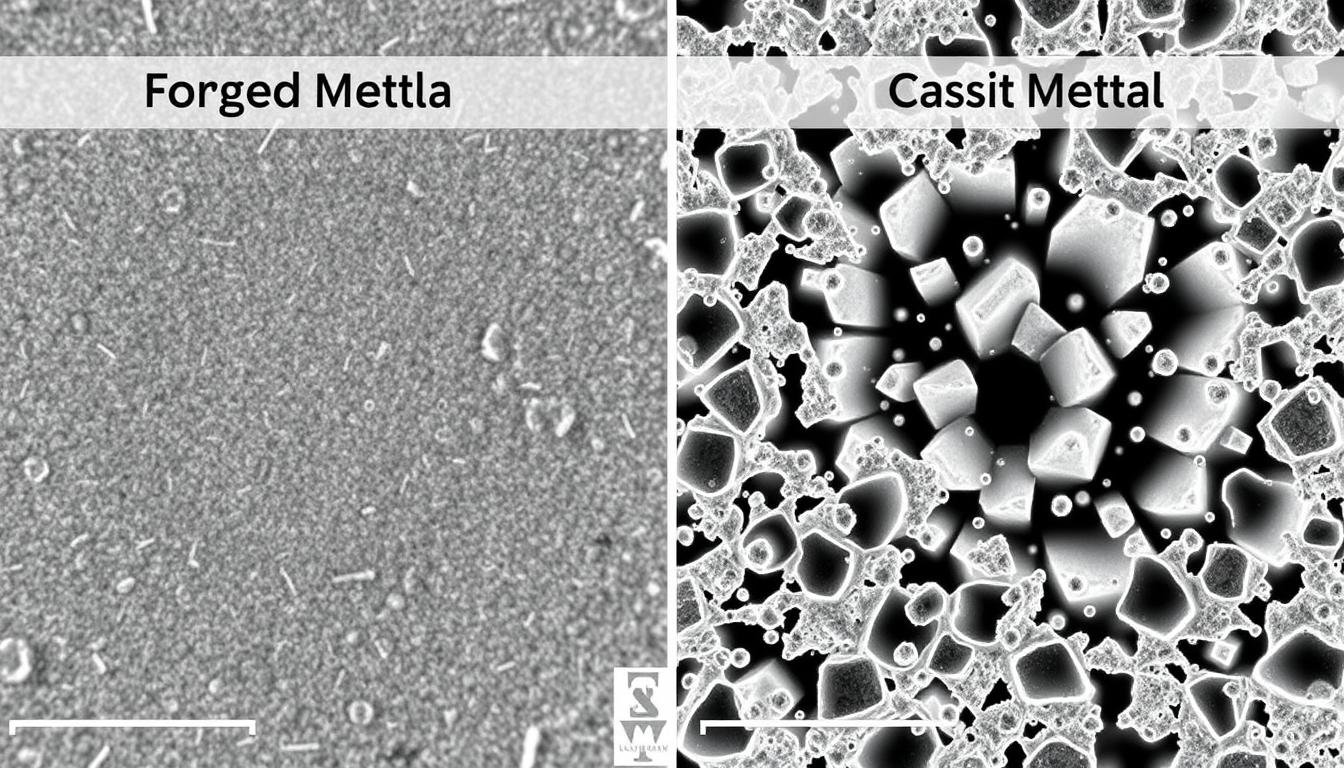

Forged Metal vs. Casting: Understanding the Difference

When selecting a manufacturing process for metal components, understanding the differences between forging and casting is crucial for making the right choice for your application.

| Comparison Categories |

Forged Metal |

Cast Metal |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

Can achieve complex shapes in one session |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Ideal Applications |

Structural components, high-stress applications, safety-critical parts |

Complex geometries, lower-stress applications, decorative components |

Not Sure Which Process Is Right For Your Project?

Our engineering team can help determine the optimal manufacturing approach based on your specific requirements.

Consult Our Experts on WhatsApp

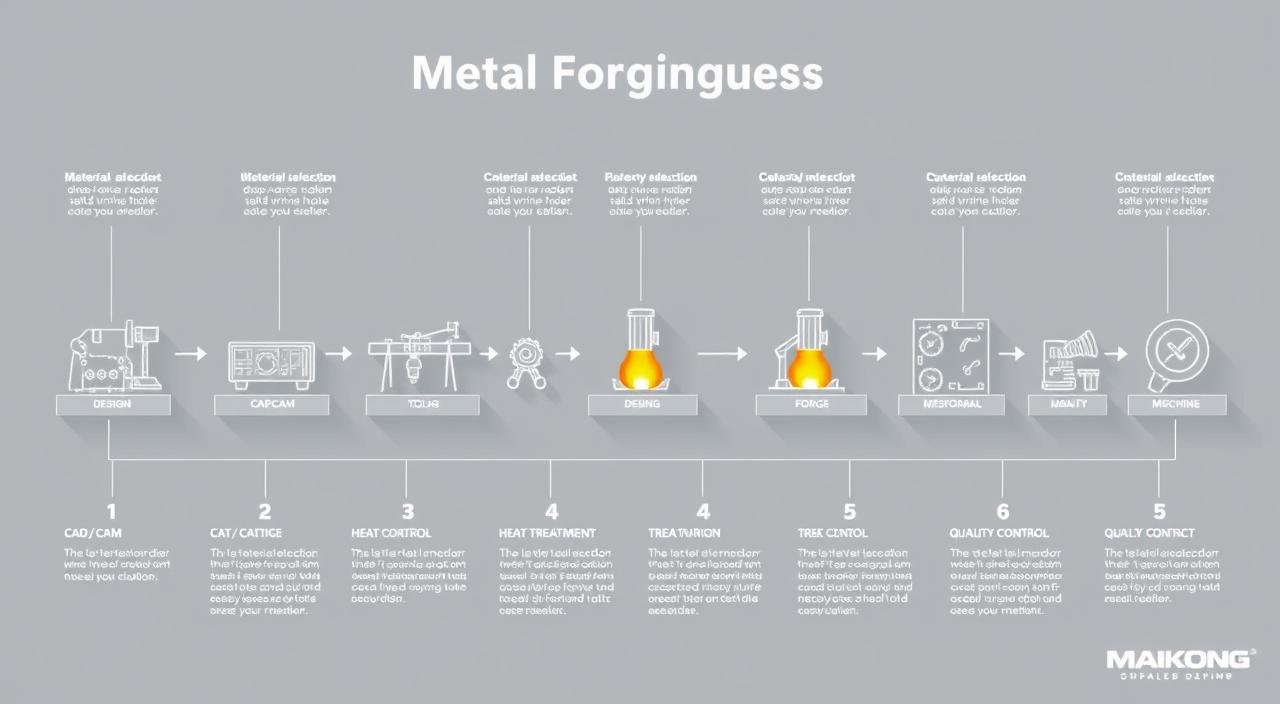

The MAIKONG Forged Metal Process

At MAIKONG, we’ve developed a comprehensive forging process that ensures consistent quality and optimal performance for every component we manufacture. Our integrated approach combines traditional forging expertise with modern technology and rigorous quality control.

Design & Engineering

- Advanced CAD/CAM systems for precision design

- Finite element analysis for performance optimization

- Material selection expertise for optimal properties

- Design for manufacturability consultation

- Prototype development and testing

Manufacturing Excellence

- Custom tooling design and fabrication

- Multiple forging methods (open die, closed die)

- Temperature-controlled processes (hot, warm, cold)

- Precision heat treatment for optimal properties

- Advanced CNC machining capabilities

Quality Assurance

- ISO 9001:2015 certified quality system

- In-house material testing laboratory

- Non-destructive testing capabilities

- Dimensional verification with advanced equipment

- Comprehensive documentation and traceability

Premium Materials for Forged Metal Components

The quality of raw materials directly impacts the performance of forged components. At MAIKONG, we source only premium materials and verify their properties in our in-house testing laboratory before production.

Aluminum Alloys

Our aluminum forging capabilities include series 2XXX, 6XXX, and 7XXX alloys, offering exceptional strength-to-weight ratios and excellent corrosion resistance. These alloys are ideal for aerospace, automotive, and sporting goods applications.

Steel Varieties

We work with carbon, alloy, and stainless steels to meet diverse application requirements. From high-strength low-alloy steels for structural components to corrosion-resistant stainless steels for marine applications, we have the expertise to forge the ideal solution.

Specialty Metals

Beyond aluminum and steel, MAIKONG offers forging services for brass, copper, and specialty alloys. These materials provide unique properties like electrical conductivity, antimicrobial characteristics, and decorative appeal for specialized applications.

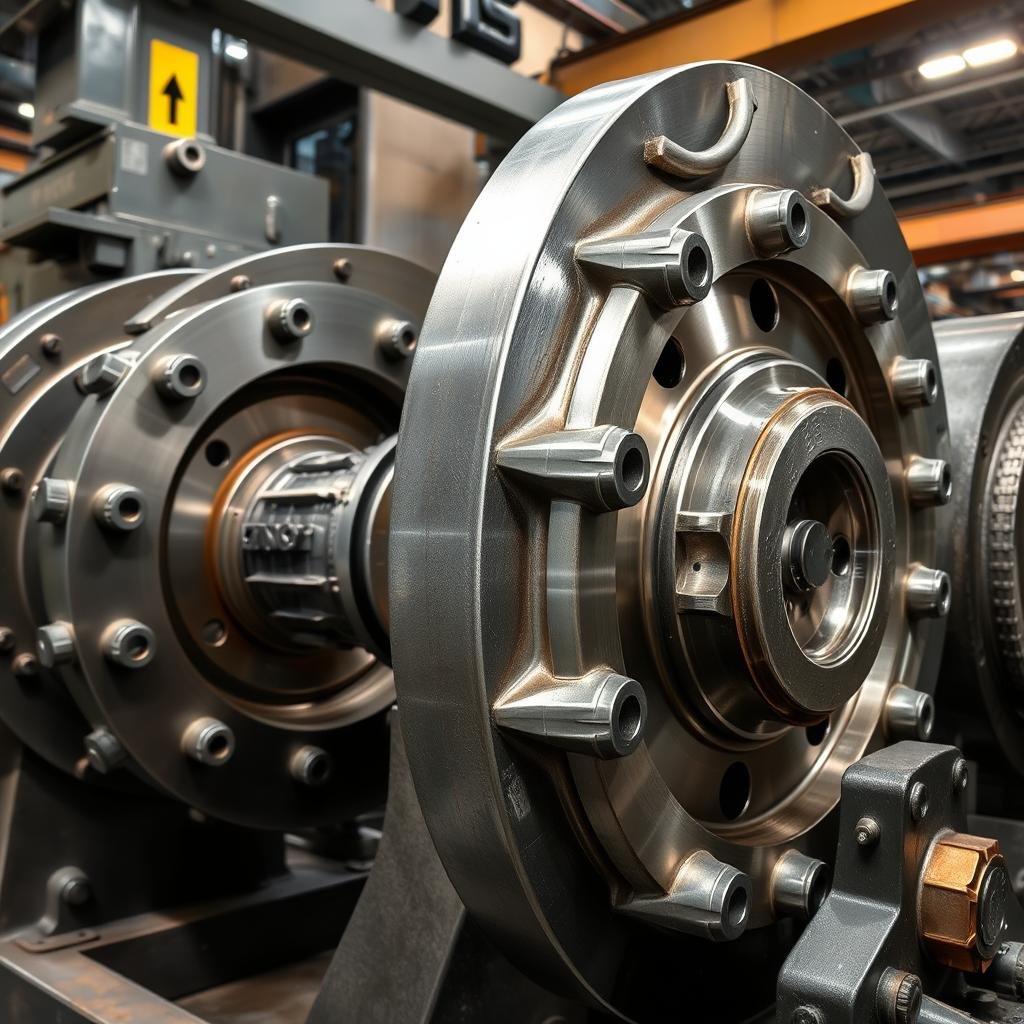

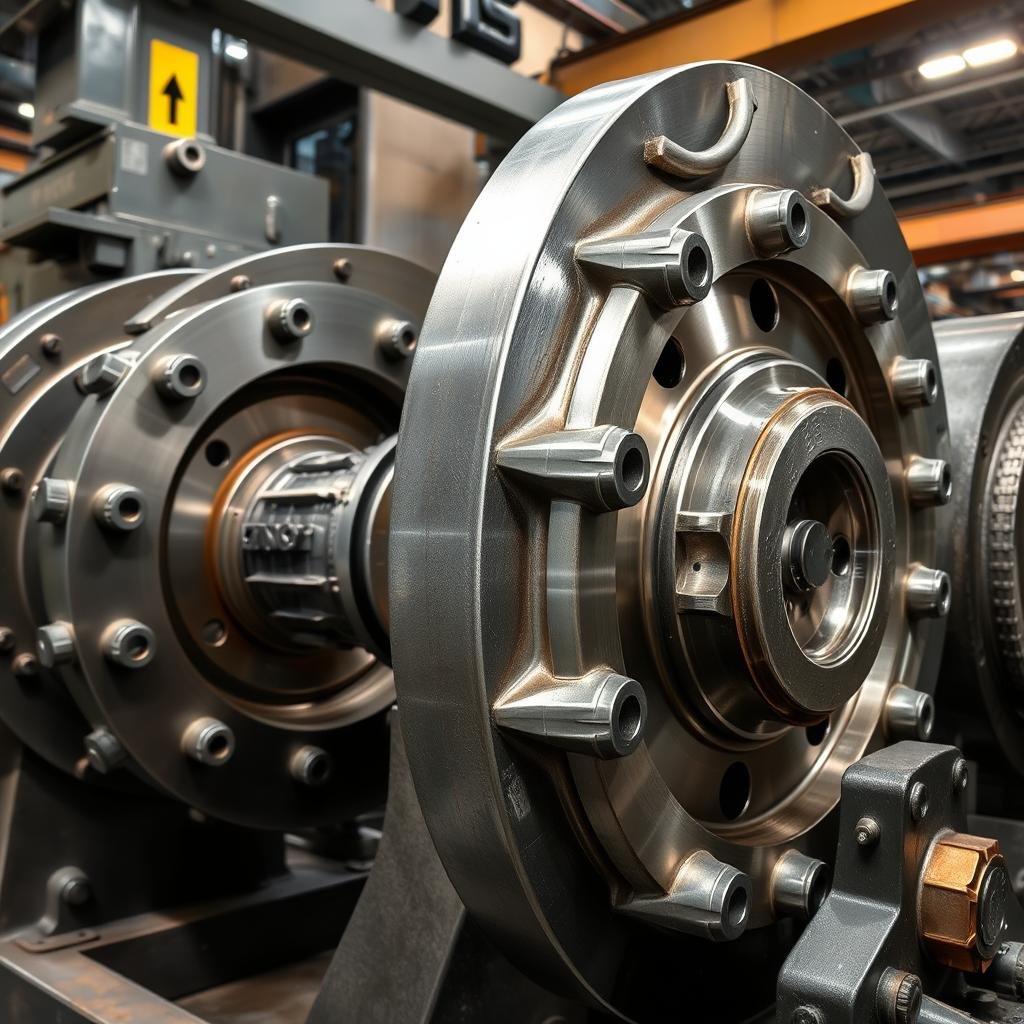

Industries Served by MAIKONG Forged Metal Solutions

Our premium forged components deliver exceptional performance across diverse industries where reliability, strength, and precision are non-negotiable requirements.

Aerospace

Automotive

Industrial Machinery

Additional Industries We Serve:

- Oil & Gas: Pressure-resistant components for extreme environments

- Power Generation: Critical components for turbines and generators

- Marine: Corrosion-resistant parts for maritime applications

- Construction: High-strength structural components

- Agriculture: Durable equipment parts for demanding conditions

- Defense: Precision components meeting military specifications

Quality Assurance for Forged Metal Components

At MAIKONG, quality isn’t just a department—it’s a core value embedded throughout our organization. Our comprehensive quality management system ensures that every component we produce meets or exceeds the most demanding specifications.

Our Quality Commitment

MAIKONG’s quality management system is certified to ISO 9001:2015 standards, providing a framework for consistent quality and continuous improvement. Our in-house testing laboratory enables comprehensive material verification and performance validation at every stage of production.

Testing Capabilities:

- Chemical composition analysis

- Mechanical property testing (tensile, hardness, impact)

- Dimensional verification with precision equipment

- Non-destructive testing (ultrasonic, magnetic particle)

- Metallographic examination

“Quality means doing it right when no one is looking. At MAIKONG, we maintain the highest standards at every step of the forging process to ensure components that perform flawlessly in the most demanding applications.”

– MAIKONG Quality Director

Experience the MAIKONG Forged Metal Advantage

With decades of experience in forged metal manufacturing, MAIKONG combines traditional craftsmanship with cutting-edge technology to deliver components that exceed expectations. Our comprehensive capabilities, from design assistance through final inspection, ensure a seamless experience and superior results for your most demanding applications.

Whether you need high-volume production or specialized custom components, MAIKONG has the expertise, equipment, and commitment to quality to be your trusted manufacturing partner. Contact us today to discover how our forged metal solutions can enhance your products and streamline your supply chain.