Metal forging stands as one of humanity’s oldest and most reliable manufacturing methods, transforming raw metal into precision components through controlled pressure and heat. At MAIKONG, we’ve perfected the art and science of forge metal processes, delivering superior strength, durability, and performance in every custom component we produce. Whether you need aluminum forging services, steel forging solutions, or precision CNC machining, our state-of-the-art facilities in GD, SZ provide world-class metal forging capabilities to clients across the globe.

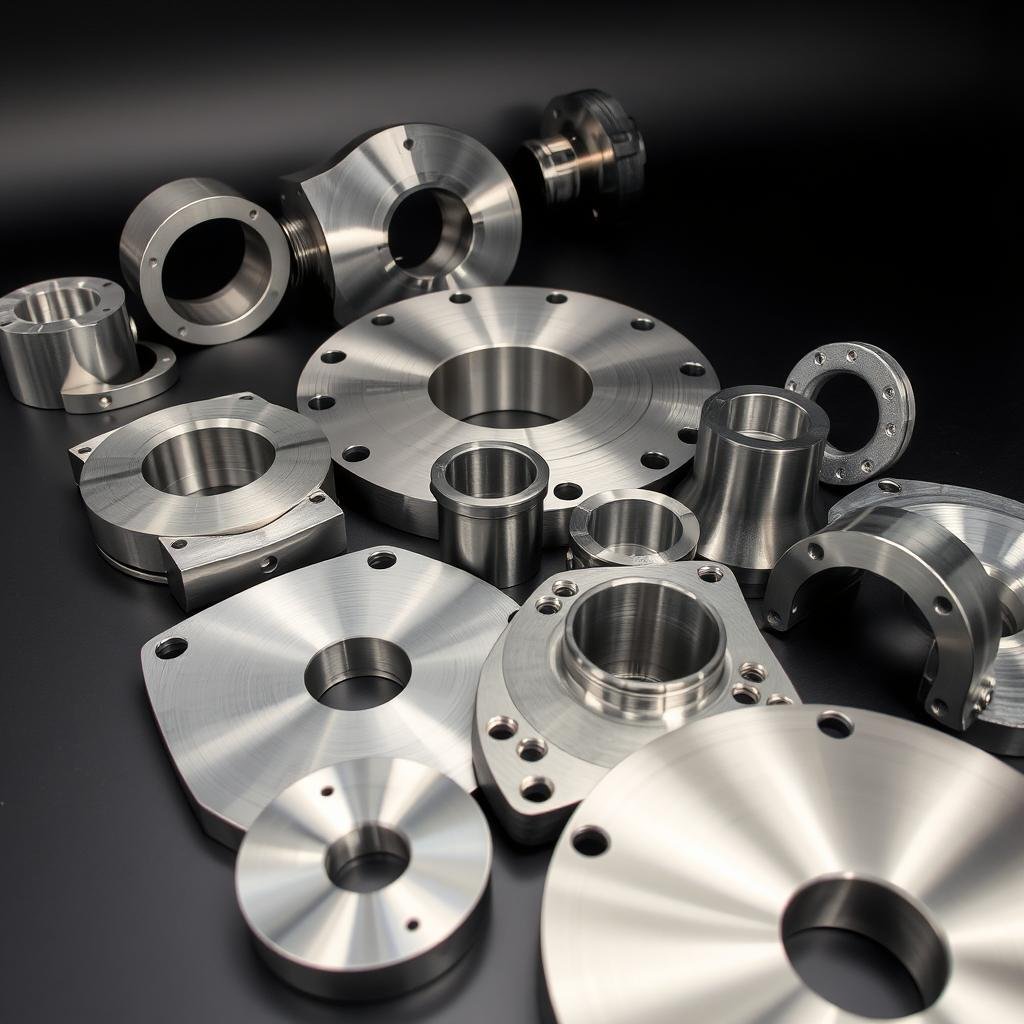

CNC Machining for Forged Metal Components

Precision CNC machining of forged components at MAIKONG

MAIKONG combines forging expertise with advanced CNC machining capabilities to deliver fully finished components that meet precise dimensional requirements. Our integrated approach ensures seamless transition from forging to final machining, optimizing both quality and cost-effectiveness.

Our CNC Machining Services

CNC Turning

Our CNC turning services are ideal for creating precise cylindrical shapes, deep holes, and machined threads. We specialize in turning forged components to achieve superior surface finishes and tight tolerances.

CNC Milling

MAIKONG’s multi-axis CNC milling capabilities allow us to create complex prismatic shapes and flat surfaces with exceptional accuracy. Our advanced equipment requires no fixed tooling, offering flexibility and precision.

Swiss-Type Machining

For precision small parts and long shaft components, our Swiss-type machining services offer unmatched accuracy. With dual spindles and multi-axis capabilities, we provide one-stop solutions for the most demanding applications.

The MAIKONG Advantage in CNC Machining

- 60+ CNC machines with 100+ tons monthly capacity

- Multi-axis machining capabilities for complex geometries

- Precision turning, milling, and Swiss machining

- Surface grinding and laser engraving services

- Material testing and verification laboratory

- Comprehensive quality control systems

- Cost-effective solutions for any production volume

Our Comprehensive Forge Metal Process

MAIKONG’s integrated forging process workflow

At MAIKONG, we’ve developed a comprehensive approach to metal forging that ensures quality at every stage. Our integrated process combines traditional forging expertise with cutting-edge technology to deliver superior components with optimal efficiency.

CAD/CAM Integration

Our process begins with advanced CAD/CAM systems that enable precise design and simulation. This allows us to identify potential issues early and optimize the forging process before production begins, saving time and resources.

Material Selection

We carefully select materials based on mechanical properties, machinability, heat treatment characteristics, and cost-effectiveness. Our material laboratory ensures that all raw materials meet exact specifications.

Tooling Design

Our expert engineers design custom tooling that ensures initial quality and consistency throughout production. Regular maintenance preserves die integrity, which is critical for producing high-quality forgings.

Forging Process

Our forging workshop is equipped to handle diverse specifications and volumes. We utilize hydraulic presses and specialized equipment to shape metal with precision and consistency.

Heat Treatment

In-house heat treatment facilities allow us to precisely control material properties. We conduct comprehensive statistical analysis and documentation to ensure consistent results.

Surface Treatment

We offer various surface treatments including anodizing, painting, laser engraving, and sand blasting. Advanced tools like spectrophotometers and adhesion testers ensure quality and consistency.

Ready to Start Your Metal Forging Project?

MAIKONG offers end-to-end solutions from design to finished components. Our expert team is ready to help you bring your project to life with precision and efficiency.

Request a Consultation

Quality Assurance in Forge Metal Production

Rigorous quality control inspection at MAIKONG’s testing laboratory

Quality is at the heart of everything we do at MAIKONG. Our ISO 9001:2015 certified quality management system ensures that every component we produce meets or exceeds customer specifications and industry standards.

Our Quality Control Procedures

Material Verification

Our in-house laboratory conducts comprehensive testing of raw materials to verify chemical composition and mechanical properties. This ensures that only materials meeting our strict standards enter the production process.

In-Process Inspection

Throughout the forging and machining processes, our quality technicians perform regular inspections to catch any deviations early. This proactive approach minimizes defects and ensures consistent quality.

Non-Destructive Testing

We employ various non-destructive testing methods including ultrasonic testing, magnetic particle inspection, and radiography to identify any internal defects that might compromise component integrity.

Dimensional Verification

Using precision measuring equipment, we verify that all dimensions meet specified tolerances. Our coordinate measuring machines (CMMs) provide accurate 3D measurements of complex geometries.

Common Defects in Forging and How We Prevent Them

| Defect Type |

Description |

MAIKONG’s Prevention Method |

| Voids |

Unfilled sections in the metal caused by trapped gas or air |

Optimized die design and proper heating techniques |

| Cracks |

Surface cracks due to low temperatures or excessive stress |

Precise temperature control and stress management |

| Laps |

Metal folds over itself, creating a weak seam |

Improved material flow and optimized die design |

| Cold shuts |

Weak seams caused by improper material flow |

Adequate heating and controlled material flow |

| Excess flash |

Material that flows out of die cavities |

Precision die design and controlled pressure |

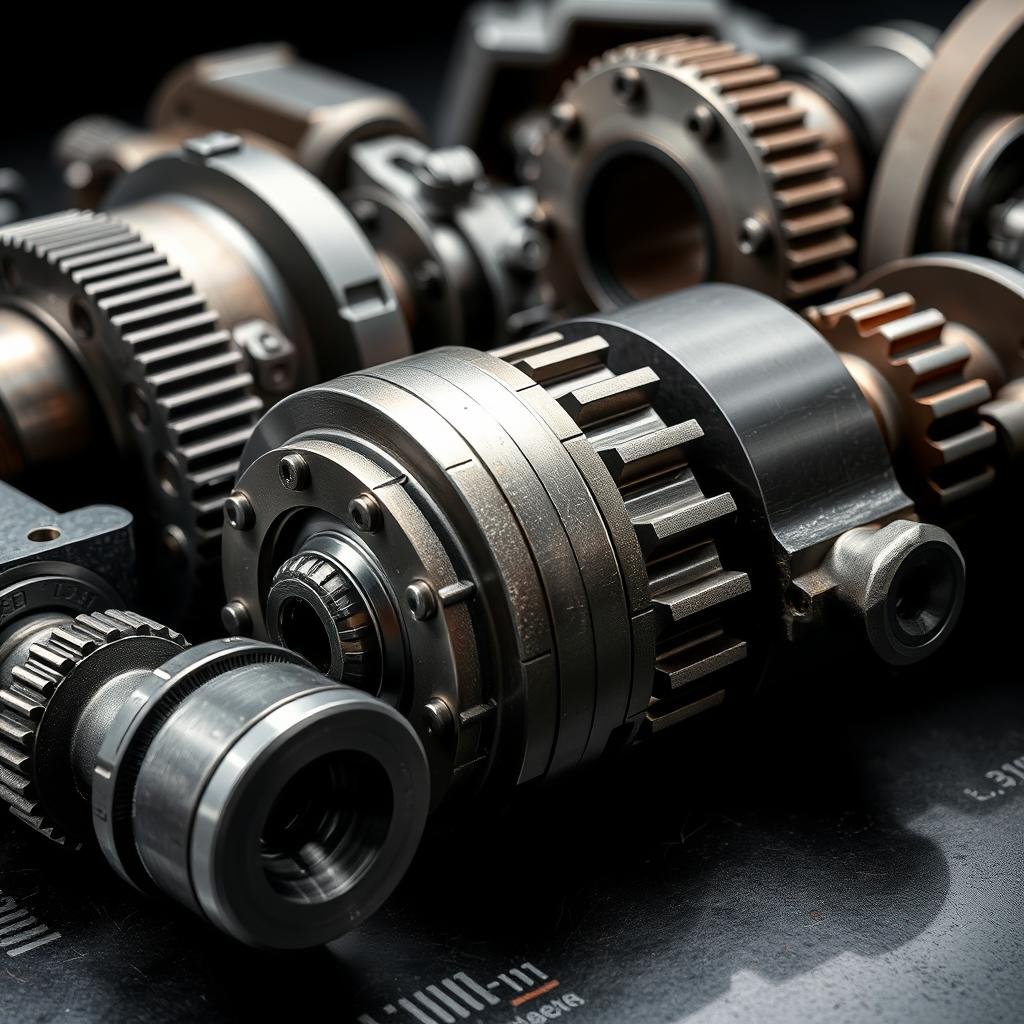

Industries Served by MAIKONG Forge Metal Solutions

MAIKONG forged components serving diverse industries

MAIKONG’s forge metal solutions serve a wide range of industries that demand high-performance, reliable components. Our expertise in forging and precision machining allows us to meet the specific requirements of each sector, from automotive to aerospace and beyond.

Automotive

We produce critical forged components for the automotive industry, including connecting rods, crankshafts, steering knuckles, and suspension components. Our parts meet strict quality and safety standards while offering weight reduction and improved performance.

Aerospace

Our aerospace forged components meet the industry’s demanding requirements for lightweight strength and reliability. We produce structural components, landing gear parts, and engine mounts that withstand extreme conditions while minimizing weight.

Industrial Equipment

For industrial machinery and equipment, we forge components that deliver exceptional durability and performance under harsh conditions. Our products include gears, shafts, flanges, and structural components for various industrial applications.

Additional Industries We Serve

Oil & Gas

Our forged components for the oil and gas industry withstand extreme pressures, temperatures, and corrosive environments. We produce valve bodies, flanges, fittings, and structural components that ensure safety and reliability in critical applications.

Construction

The construction industry relies on our forged components for strength and durability. We produce structural connectors, fasteners, and equipment components that meet rigorous building standards and withstand environmental challenges.

Agricultural

For agricultural equipment, we forge components that endure constant use in demanding conditions. Our products include tractor parts, implement components, and attachments that combine strength with wear resistance for extended service life.

Find the Right Forging Solution for Your Industry

MAIKONG’s experts understand the unique requirements of your industry. Contact us to discuss how our forging capabilities can address your specific challenges.

Get Industry-Specific Solutions

Why Choose MAIKONG for Your Forge Metal Needs

MAIKONG’s dedicated team of forging experts

When you partner with MAIKONG for your forge metal requirements, you gain access to a world-class manufacturer committed to quality, innovation, and customer satisfaction. Our comprehensive capabilities and customer-focused approach set us apart from the competition.

The MAIKONG Advantage

- 60+ CNC machines with 100+ tons monthly capacity

- ISO 9001:2015 certified quality management system

- Complete in-house production from raw material to finished product

- Advanced material testing and verification laboratory

- Comprehensive forging and machining capabilities

- Cost-effective solutions with competitive pricing

- Experienced engineering team for technical support

- Flexible production volumes from prototypes to high-volume runs

Our Commitment to Excellence

“At MAIKONG, we recognize the crucial importance of consistency, strength, and weight in each forged part for the final product. With a dedicated focus on crafting superior forged parts, we fulfill your requirements for heat treating, machining, and testing to deliver optimal outcomes with a profound understanding of materials and their properties.”

– MAIKONG Leadership Team

Ready to Experience the MAIKONG Difference?

Contact us today to discuss your metal forging needs or to become a distributor in the United States. Our team is ready to provide the solutions you need.

Get A Quick Quote

Contact on WhatsApp

Experience Superior Forge Metal Solutions with MAIKONG

From aluminum forging services to steel forging solutions and precision CNC machining, MAIKONG delivers exceptional quality and value across all our metal forging capabilities. Our commitment to excellence, combined with our comprehensive in-house production facilities, ensures that your components meet the highest standards of performance and reliability.

Whether you need custom forged parts for automotive, aerospace, industrial, or other applications, our team has the expertise and resources to bring your project to life. Contact MAIKONG today to discover how our metal forging solutions can help you achieve your manufacturing goals with confidence.

Start Your Metal Forging Project Today

Contact MAIKONG for expert guidance and competitive quotes on your metal forging requirements.

Get A Quick Quote