The forging procedure stands as one of manufacturing’s oldest and most reliable metal-shaping techniques, dating back thousands of years yet remaining crucial for modern industries. For US businesses seeking high-quality metal components with superior strength and durability, understanding this transformative process is essential. At MAIKONG, we’ve perfected the art and science of metal forging, delivering exceptional custom components to businesses across America with unmatched precision and competitive pricing.

Understanding the Forging Procedure: Fundamentals and Benefits

The forging procedure is a manufacturing process that shapes metal using compressive forces. Unlike casting, which melts metal into molds, forging manipulates solid metal through controlled pressure, resulting in components with superior mechanical properties. This ancient metalworking technique has evolved into a sophisticated manufacturing process critical for industries where component reliability is non-negotiable.

The forging procedure reshapes metal’s internal grain structure for superior strength

Why the Forging Procedure Creates Superior Metal Components

The forging procedure stands apart from other metal-forming methods because it fundamentally alters the internal grain structure of the metal. When properly executed, forging aligns the grain flow with the part’s geometry, significantly enhancing:

- Structural strength and integrity

- Impact and fatigue resistance

- Uniformity throughout the component

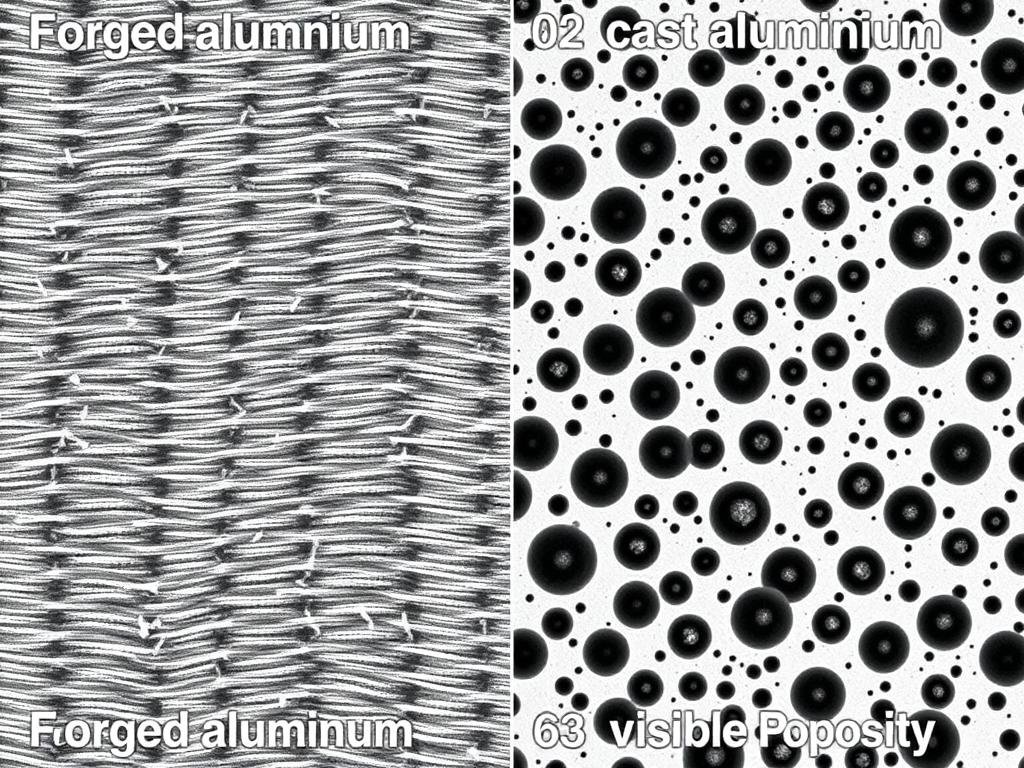

- Elimination of internal voids and porosity

- Enhanced mechanical properties

- Superior performance under stress

At MAIKONG, our advanced forging procedures ensure each component meets the most demanding specifications while maintaining competitive pricing for US businesses.

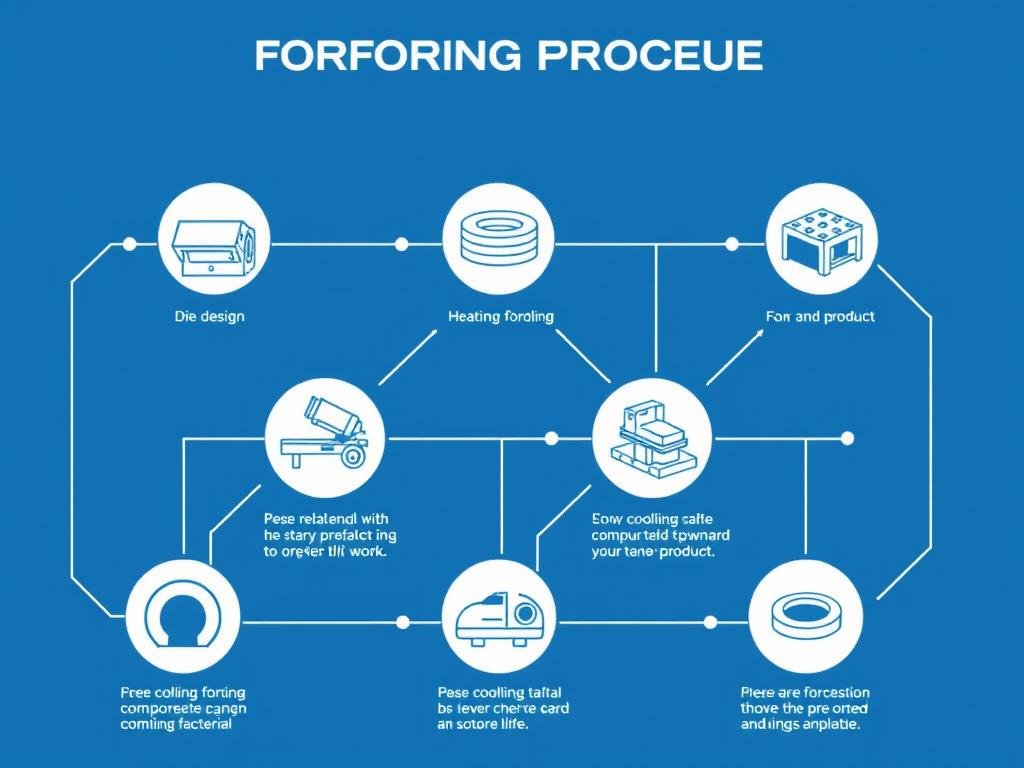

The Essential Steps in the Metal Forging Procedure

The forging procedure follows a systematic approach that transforms raw metal into precision-engineered components. Each step requires expertise and precision to ensure optimal results. At MAIKONG, we’ve refined these processes to deliver exceptional quality across all our forging services.

Step 1: Die Design and Engineering in the Forging Procedure

The forging procedure begins with precise die design. Our engineering team at MAIKONG uses advanced CAD/CAM technology to create dies that will shape the metal into the exact specifications required. This critical first step determines the quality and precision of the final product.

Step 2: Material Selection and Preparation

Selecting the appropriate metal is crucial to the forging procedure. At MAIKONG, we work with a wide range of materials including carbon steel, alloy steel, stainless steel, aluminum, brass, and more. The selected material is cut to the required dimensions and prepared for the heating process.

Step 3: Heating the Metal

In the forging procedure, heating the metal to the correct temperature is essential for achieving optimal malleability. Different metals require specific temperature ranges:

| Metal Type |

Forging Temperature Range |

Characteristics |

| Carbon Steel |

2100-2300°F (1150-1260°C) |

Excellent strength, good malleability when heated |

| Alloy Steel |

2000-2200°F (1090-1200°C) |

Enhanced properties for specific applications |

| Stainless Steel |

2100-2350°F (1150-1290°C) |

Corrosion resistance, high strength |

| Aluminum |

750-950°F (400-510°C) |

Lightweight, excellent strength-to-weight ratio |

| Brass |

1300-1650°F (700-900°C) |

Good corrosion resistance, excellent machinability |

Step 4: The Actual Forging Procedure

The core of the forging procedure involves applying controlled pressure to shape the heated metal. At MAIKONG, we employ several forging methods depending on the component requirements:

Open Die Forging

Metal is compressed between flat or simply shaped dies, allowing for greater material movement and ideal for larger components or simpler shapes.

Closed Die Forging

Metal is shaped within impression dies that contain the exact negative of the desired part shape, creating more complex and precise components.

Impression Die Forging

A type of closed die forging that creates precise, complex shapes with excellent dimensional accuracy and surface finish.

Roll Forging

Metal is passed between cylindrical or contoured rolls to gradually form the desired shape, ideal for elongated parts with varying cross-sections.

Step 5: Trimming and Finishing

After the primary forging procedure, excess material (flash) is removed through trimming operations. This step ensures the component meets dimensional specifications and prepares it for subsequent processing.

Step 6: Heat Treatment

Heat treatment is often an essential part of the forging procedure, enhancing the mechanical properties of the forged component. Processes may include:

- Normalizing to refine grain structure

- Annealing to increase ductility

- Quenching and tempering to optimize hardness and strength

- Solution treatment for specific alloys

Step 7: Final Machining and Inspection

The forging procedure often requires final machining to achieve precise dimensions and surface finishes. At MAIKONG, our comprehensive CNC machining capabilities ensure that forged components meet exact specifications. Every component undergoes rigorous inspection to verify dimensional accuracy and material integrity.

Need Expert Guidance on Your Forging Project?

Our engineering team can help you determine the optimal forging procedure for your specific application. Contact us today for a consultation.

Contact Our Engineering Team

Types of Forging Procedures and Their Applications

The forging procedure can be classified based on temperature, equipment used, and the specific technique employed. Each type offers distinct advantages for different applications and materials.

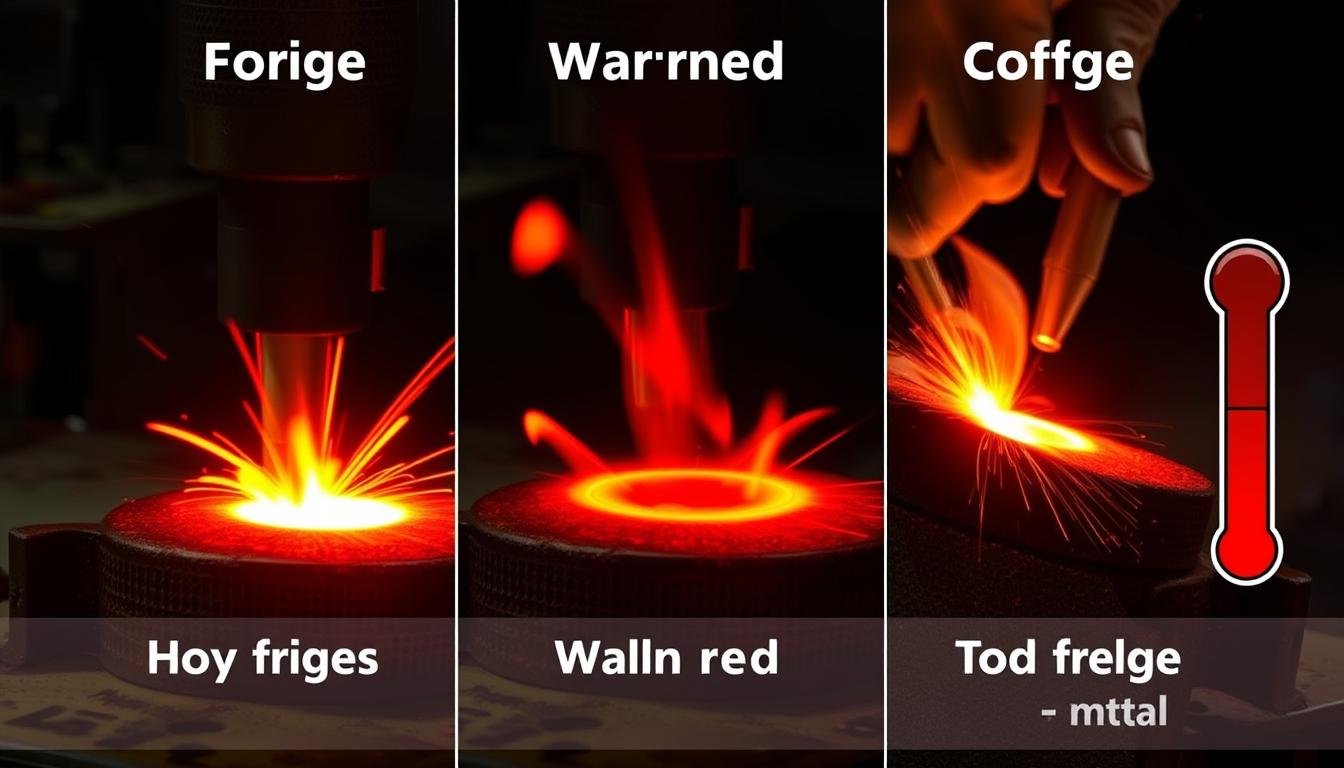

Classification by Temperature in the Forging Procedure

Hot Forging

Performed above the metal’s recrystallization temperature, typically between 0.6-0.75 of the melting point. Offers excellent malleability and lower force requirements.

Ideal for: Complex shapes, larger components, and most industrial applications

Warm Forging

Conducted at temperatures between cold and hot forging ranges. Balances the benefits of both methods with moderate energy requirements.

Ideal for: Precision components with moderate complexity and good surface finish

Cold Forging

Performed at or near room temperature. Delivers excellent dimensional accuracy and surface finish but requires greater force.

Ideal for: High-precision small to medium components with superior surface finish

Equipment Used in the Forging Procedure

The equipment used significantly influences the forging procedure and the characteristics of the final product:

Hammers

Deliver impact force through repeated blows. Types include:

- Drop hammers (gravity-driven)

- Power hammers (mechanically assisted)

- Counterblow hammers (opposing hammers)

Presses

Apply continuous pressure rather than impact. Types include:

- Mechanical presses (crank or eccentric drives)

- Hydraulic presses (fluid pressure systems)

- Screw presses (screw-driven mechanisms)

At MAIKONG, our state-of-the-art facility in GD, SZ is equipped with advanced forging equipment to handle diverse forging procedures for any application.

Explore Our Comprehensive Forging Capabilities

From aluminum forging to steel and brass, MAIKONG delivers precision-forged components with superior quality and competitive pricing.

Discover Our Capabilities

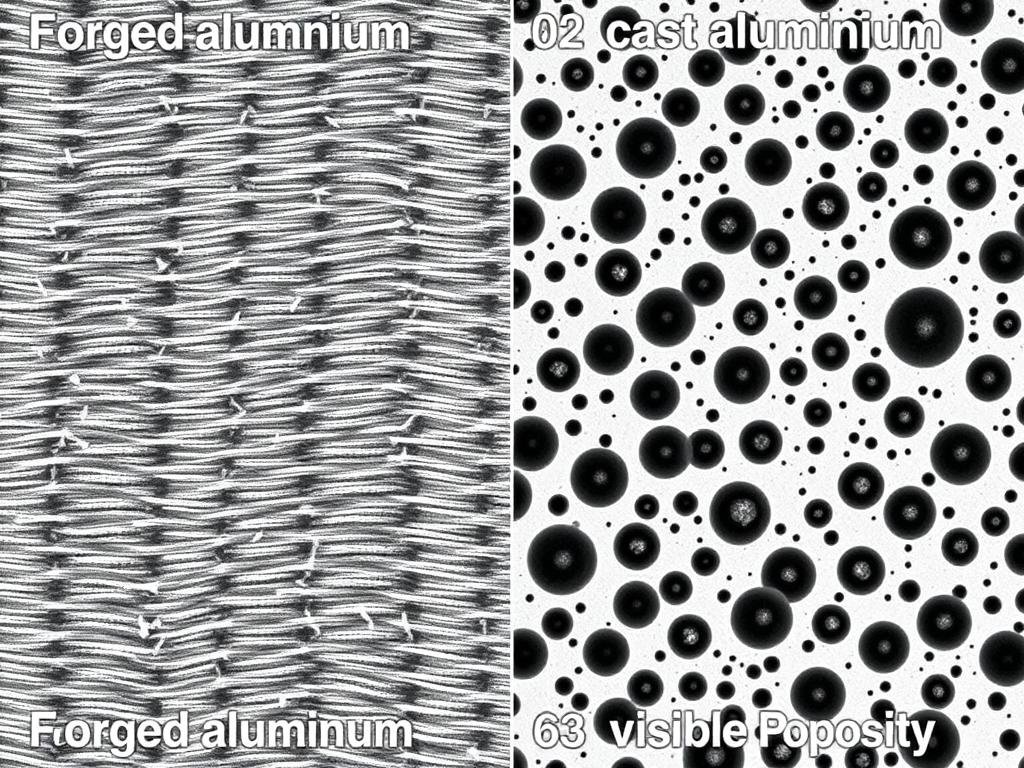

Aluminum Forging vs. Casting: Why the Forging Procedure Delivers Superior Results

When considering manufacturing methods for metal components, understanding the differences between forging and casting is crucial. The forging procedure offers significant advantages for applications where strength, reliability, and performance are critical.

Microstructure comparison: Forged aluminum (left) shows aligned grain flow; cast aluminum (right) shows random structure with potential porosity

| Comparison Categories |

MAIKONG Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Heat Treatment Response |

✅ Responsive for controlled material properties |

Less predictable response |

| Grain Structure |

✅ Directional grain flow for improved properties |

No directional grain structure |

| Weight-to-Strength Ratio |

✅ High strength-to-weight ratio |

Bulkier parts may be needed |

| Critical Applications |

✅ Ideal for structural members and load-bearing components |

Limited suitability for critical applications |

The superior properties achieved through MAIKONG’s forging procedure make it the preferred choice for applications where component failure is not an option.

Industries Benefiting from MAIKONG’s Forging Procedure

The exceptional strength, reliability, and performance of components produced through our forging procedure make them ideal for numerous industries with demanding applications.

Aerospace

Our forging procedure creates critical components where failure is not an option:

- Landing gear components

- Engine mounts and brackets

- Structural airframe components

- Turbine and compressor parts

Automotive

MAIKONG’s forged components deliver reliability in demanding automotive applications:

- Connecting rods and crankshafts

- Transmission components

- Steering and suspension parts

- Drivetrain components

Medical

Precision and reliability are paramount in medical applications:

- Surgical instruments

- Implant components

- Medical device structures

- Equipment frameworks

Oil & Gas

Our forging procedure creates components that withstand extreme conditions:

- Valve bodies and components

- Wellhead equipment

- Pressure vessel components

- Drilling equipment parts

Heavy Machinery

Forged components deliver reliability in demanding industrial applications:

- Gears and shafts

- Hydraulic components

- Structural elements

- High-stress mechanical parts

Defense

Mission-critical components where performance is essential:

- Weapons systems components

- Vehicle structural elements

- Naval equipment parts

- Specialized hardware

Serving Your Industry with Precision Forged Components

Whatever your industry, MAIKONG delivers forged components that meet your exact specifications with competitive pricing and exceptional quality.

Discuss Your Industry Requirements

The MAIKONG Advantage: Our Complete Forging Procedure Solution

At MAIKONG, we offer a comprehensive approach to metal forging that encompasses every aspect of the forging procedure from initial design to final delivery. Our integrated services ensure consistent quality, competitive pricing, and exceptional results for US businesses.

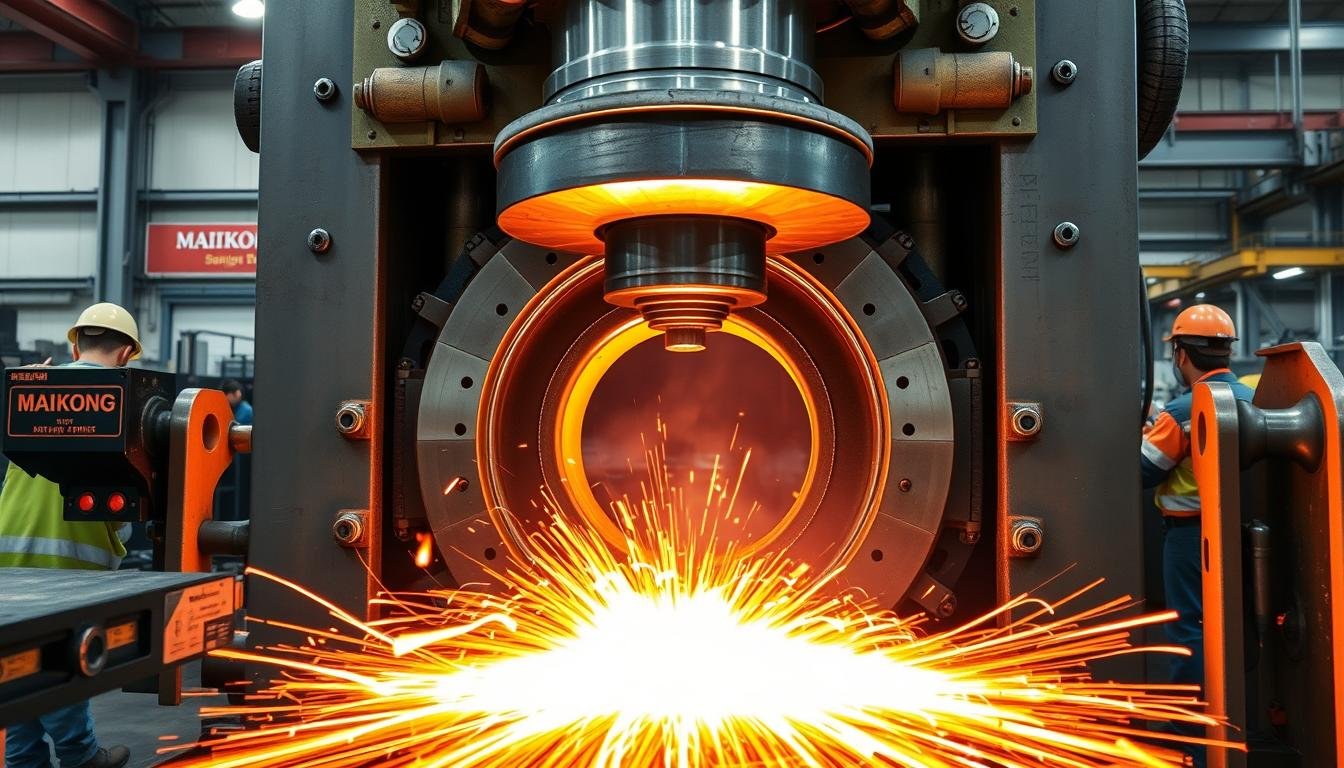

MAIKONG’s state-of-the-art forging facility in GD, SZ

Our Comprehensive Forging Procedure Services

Design & Engineering

Our engineering team utilizes advanced CAD/CAM technology to optimize component design for the forging procedure, ensuring optimal performance and manufacturability.

Material Selection

We provide expert guidance on material selection, considering mechanical properties, machinability, heat treatment characteristics, and cost-effectiveness.

Tooling Design

Our precision tooling design ensures consistent quality throughout the forging procedure, with regular maintenance to preserve dimensional accuracy.

Forging Operations

Our forging workshop accommodates diverse specifications with advanced equipment for hot, warm, and cold forging procedures.

Heat Treatment

In-house heat treatment with comprehensive statistical analysis ensures optimal mechanical properties for every component.

Precision Machining

State-of-the-art CNC machines provide precise secondary operations to achieve exact dimensional specifications.

Surface Treatment

We offer comprehensive surface finishing options including anodizing, painting, laser engraving, and sand blasting to enhance appearance and performance.

Quality Assurance

Rigorous quality control procedures ensure every component meets stringent standards, with ISO 9001:2015 certification guaranteeing consistent quality.

Logistics Support

We manage the entire supply chain from raw material to final delivery, ensuring timely shipment to US businesses.

Why US Businesses Choose MAIKONG for Their Forging Procedure Needs

- Comprehensive one-stop solution from design to delivery

- Superior quality with ISO 9001:2015 certification

- Competitive pricing with excellent value

- Advanced equipment and technology

- Experienced engineering and production teams

- Rigorous quality control at every stage

- Flexible production capabilities

- Responsive customer service

- Fast turnaround times

- Comprehensive material expertise

Conclusion: Elevate Your Products with MAIKONG’s Forging Procedure

The forging procedure remains one of the most reliable manufacturing methods for creating components with superior strength, durability, and performance. At MAIKONG, we’ve perfected this ancient craft with modern technology and expertise to deliver exceptional forged components to US businesses across diverse industries.

Our comprehensive approach encompasses every aspect of the forging procedure from initial design to final delivery, ensuring consistent quality, competitive pricing, and exceptional results. Whether you need aluminum forging services, steel forging components, or custom metal parts, MAIKONG delivers solutions that meet your exact specifications.

Contact us today to discover how our forging procedure expertise can enhance your products and streamline your supply chain. With MAIKONG as your manufacturing partner, you gain access to world-class forging capabilities with the reliability and quality your business demands.

Begin Your Partnership with MAIKONG Today

Experience the difference that superior forging solutions can make for your business.

Get Started Now