In the world of metal manufacturing, a Well-Defined Forging Procedure stands as the foundation for producing high-quality, reliable components. At MAIKONG, we’ve perfected these procedures through decades of experience, enabling us to deliver superior forged parts that meet the most demanding specifications. Whether you’re in aerospace, automotive, or industrial manufacturing, the right forging process can dramatically improve your product’s performance while reducing costs. This comprehensive guide explores how precision-engineered forging procedures transform raw metal into exceptional components that outperform those made through alternative manufacturing methods.

What is a Well-Defined Forging Procedure?

A Well-Defined Forging Procedure is a meticulously engineered manufacturing process that shapes metal using compressive forces. Unlike haphazard approaches, a properly defined procedure accounts for every variable: material selection, heating parameters, die design, compression force, cooling rates, and post-forging treatments. At MAIKONG, our forging procedures represent decades of metallurgical expertise and continuous refinement.

Forging is one of the oldest metalworking processes, dating back thousands of years, but modern Well-Defined Forging Procedures incorporate advanced technologies and precise controls that ancient blacksmiths could never imagine. Today’s forging combines traditional principles with computer modeling, automated controls, and sophisticated metallurgical science.

Core Elements of a Well-Defined Forging Procedure

- Precise material selection based on application requirements

- Optimized heating parameters for ideal metal plasticity

- Computer-designed dies that ensure proper grain flow

- Controlled application of compressive force

- Carefully managed cooling rates to develop desired microstructure

- Comprehensive quality control at each production stage

- Documented process parameters for consistency and repeatability

When these elements work in harmony, the result is a forged component with superior mechanical properties, consistent quality, and exceptional performance in demanding applications.

Types of Forging Processes in a Comprehensive Procedure

A Well-Defined Forging Procedure may incorporate various forging methods, each selected based on the specific requirements of the final component. At MAIKONG, we’ve mastered multiple forging techniques to deliver optimal results for every project.

Classification by Temperature

Hot Forging

Performed above the metal’s recrystallization temperature (typically 950-1260°C for steel), hot forging offers excellent metal plasticity and formability with lower forming force requirements. This process is ideal for creating large components and rough forming of high-strength alloys.

Warm Forging

Operating below recrystallization temperature but above cold forging range (650-950°C for steel), warm forging delivers better surface finish than hot forging with moderate forming forces. It’s perfect for medium-to-small precision parts requiring good surface quality.

Cold Forging

Conducted at room temperature or slightly above, cold forging produces components with exceptional dimensional accuracy (±0.3mm tolerance) and superior surface finish. This process is ideal for precision fasteners and small structural components where tight tolerances are critical.

Classification by Die Constraint

Open-Die Forging

In open-die forging, the metal workpiece is compressed between dies that don’t completely constrain metal flow. This technique is ideal for large or simple-shaped components and allows for precise grain flow orientation to enhance strength in critical directions.

Closed-Die Forging

Closed-die forging (also called impression-die forging) uses dies that completely enclose the workpiece, forcing the metal to conform precisely to the die cavity shape. This method delivers complex geometries with excellent dimensional accuracy and is ideal for high-volume production of critical components.

Need Help Selecting the Right Forging Process?

Our engineering team can analyze your component requirements and recommend the optimal forging procedure for your specific application.

Get Expert Recommendations

Key Steps in a Well-Defined Forging Procedure

A truly effective forging operation follows a carefully orchestrated sequence of steps, each critical to the final product’s quality. At MAIKONG, we’ve refined each stage of our forging procedures to ensure optimal results.

1. Material Selection and Preparation

The foundation of any Well-Defined Forging Procedure begins with selecting the appropriate metal alloy. Different applications require specific material properties, and at MAIKONG, we carefully analyze requirements for strength, ductility, corrosion resistance, and temperature performance before selecting the optimal alloy.

- Comprehensive material analysis and certification

- Precise cutting of billets to optimal dimensions

- Pre-forging cleaning to remove contaminants

- Documentation of material properties for quality assurance

2. Die Design and Manufacturing

Superior forged components begin with expertly designed dies. Using advanced CAD/CAM systems, our engineers create dies that ensure proper metal flow, optimal grain structure, and precise final dimensions.

- Computer simulation of metal flow during forging

- Precision CNC machining of die components

- Heat treatment of dies for durability and dimensional stability

- Regular die maintenance and inspection protocols

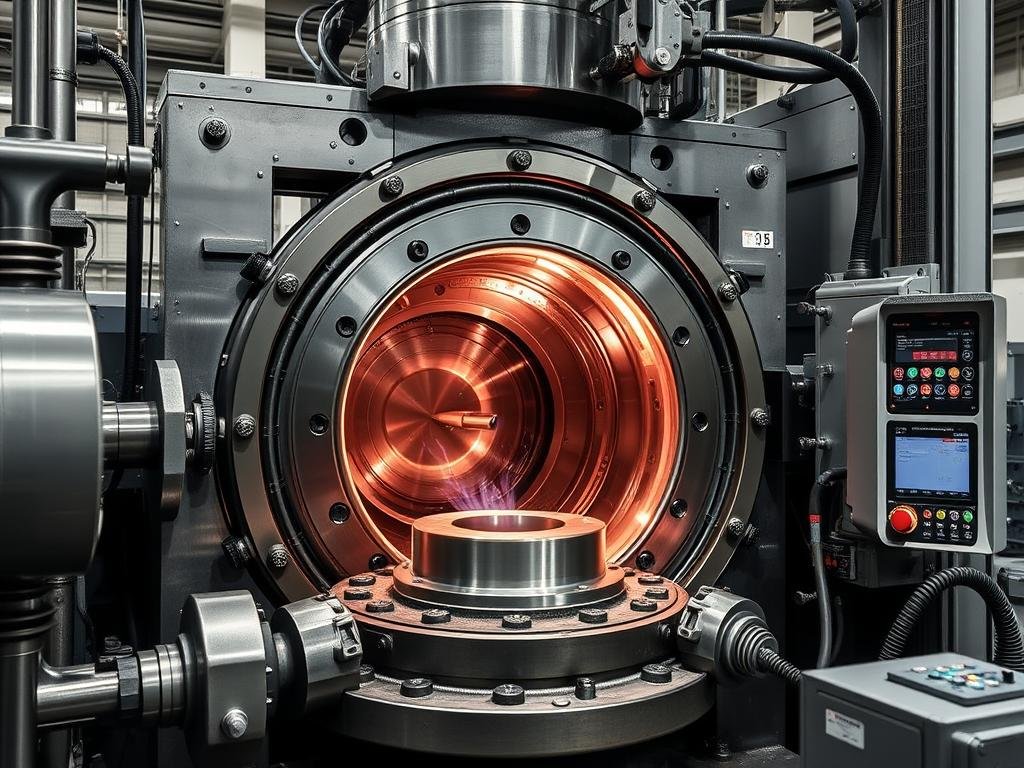

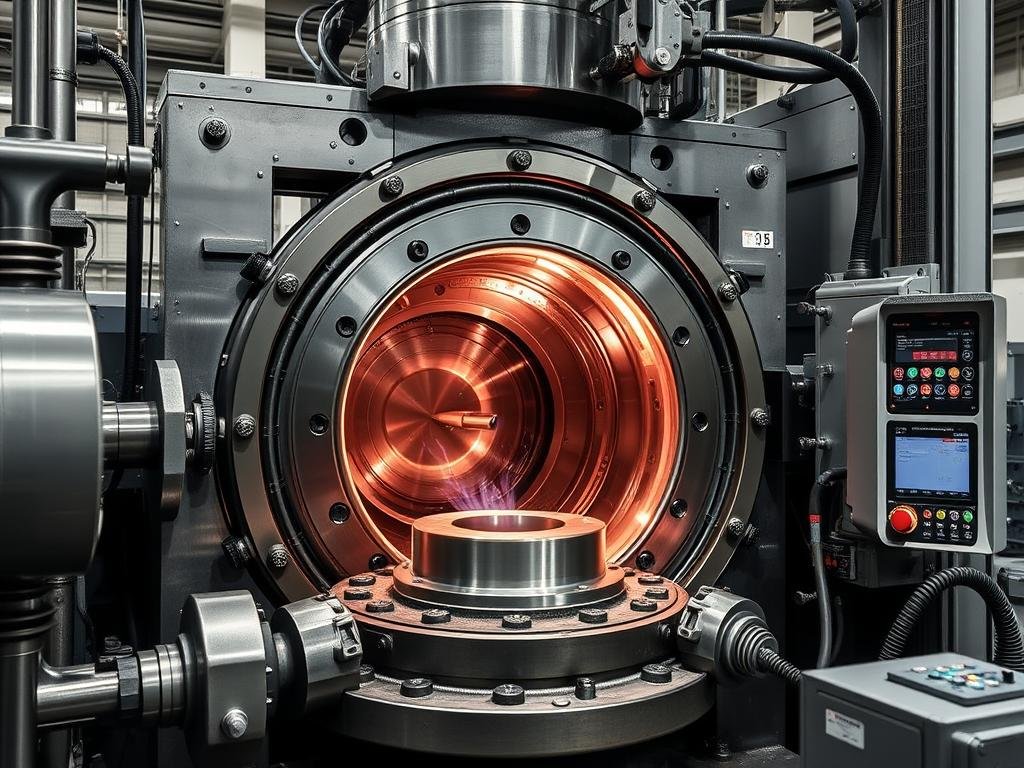

3. Heating Process

Proper heating is critical to achieving ideal metal plasticity for forging. Our Well-Defined Forging Procedure includes precise temperature control based on material type and component requirements.

- Computer-controlled heating to exact temperature specifications

- Uniform heating throughout the workpiece

- Temperature verification using calibrated pyrometers

- Minimized scale formation through controlled atmosphere

4. Forging Operation

The actual forging operation applies carefully calculated compressive forces to shape the heated metal. Our state-of-the-art equipment ensures precise control over every forging parameter.

- Hydraulic presses with force monitoring and control

- Multi-stage forging for complex geometries

- Automated handling for consistency and safety

- Real-time process monitoring and adjustment

5. Heat Treatment

Post-forging heat treatment is essential for developing the desired mechanical properties in the forged component. Our comprehensive heat treatment capabilities include:

- Solution heat treatment for aluminum alloys

- Quenching with precise temperature control

- Aging treatments to develop peak strength

- Stress relief treatments to enhance dimensional stability

- Annealing for improved machinability when required

6. Finishing Operations

The final steps in our Well-Defined Forging Procedure include precision machining and surface treatments to complete the component to exact specifications.

- CNC machining to achieve final dimensions

- Surface grinding for improved finish

- Shot blasting to remove scale

- Surface treatments such as anodizing or painting

- Final inspection and quality verification

Benefits of Implementing a Well-Defined Forging Procedure

Companies that partner with MAIKONG gain significant advantages from our meticulously developed forging procedures. These benefits translate directly to improved product performance and reduced total costs.

Enhanced Mechanical Properties

A Well-Defined Forging Procedure creates components with superior strength, improved fatigue resistance, and enhanced impact toughness. The controlled deformation process refines grain structure and eliminates internal defects, resulting in parts that outperform those made through casting or machining.

Optimized Material Utilization

Our precision forging procedures produce near-net-shape components that require minimal machining. This approach significantly reduces material waste, lowers processing costs, and decreases energy consumption compared to conventional manufacturing methods.

Consistent Quality

By following documented procedures with strict process controls, MAIKONG delivers forged components with exceptional consistency. This translates to reliable performance, predictable service life, and reduced warranty claims for our customers.

Comparative Advantages of Forging vs. Other Manufacturing Methods

| Performance Criteria |

Forging with MAIKONG |

Casting |

Machining from Stock |

| Mechanical Strength |

Superior – Refined grain structure with directional properties |

Moderate – Potential for porosity and inclusions |

Good – But interrupted grain flow at machined surfaces |

| Fatigue Resistance |

Excellent – Continuous grain flow follows component contours |

Fair – Internal defects can initiate fatigue cracks |

Good – But cut grains create potential failure points |

| Material Utilization |

High – Near-net-shape with minimal machining |

High – Near-net-shape but with higher rejection rates |

Poor – Significant material removed as chips |

| Internal Integrity |

Excellent – Consolidated structure free of voids |

Variable – Potential for shrinkage cavities and gas porosity |

Good – But limited by starting material quality |

| Production Efficiency |

High – Rapid forming with minimal secondary operations |

Moderate – Complex setup but good for intricate shapes |

Low – Time-consuming material removal |

Ready to Experience Superior Forged Components?

MAIKONG’s well-defined forging procedures deliver components with exceptional performance and consistency.

Request a Quote Today

Materials Optimized for Well-Defined Forging Procedures

At MAIKONG, we’ve developed specialized forging procedures for a wide range of metals and alloys. Each material requires specific process parameters to achieve optimal results.

Aluminum Alloys

Our aluminum forging expertise includes specialized procedures for 2xxx, 6xxx, and 7xxx series alloys. These lightweight, corrosion-resistant components are ideal for aerospace, automotive, and sporting goods applications where weight reduction is critical.

Carbon and Alloy Steels

MAIKONG’s steel forging procedures produce exceptionally strong components for applications requiring maximum durability and wear resistance. Our expertise includes low, medium, and high-carbon steels as well as specialty alloy steels.

Brass and Copper Alloys

Our specialized procedures for brass and copper alloys create components with excellent electrical conductivity, corrosion resistance, and aesthetic appeal. These materials are ideal for electrical components, decorative hardware, and marine applications.

Aluminum Forging vs. Casting: The MAIKONG Advantage

For many applications, properly forged aluminum components offer significant advantages over cast alternatives. MAIKONG’s Well-Defined Forging Procedure for aluminum maximizes these benefits.

| Performance Factor |

MAIKONG Forged Aluminum |

Cast Aluminum |

| Tensile Strength |

Superior – Up to 30% stronger than casting |

Lower – Limited by porosity and coarse grain structure |

| Fatigue Resistance |

Excellent – Refined grain structure resists crack initiation |

Fair – Internal defects can lead to premature failure |

| Ductility |

High – Allows for energy absorption in impact situations |

Limited – More brittle behavior under load |

| Dimensional Accuracy |

Excellent – Precision forging with minimal variation |

Variable – Shrinkage and warpage can affect dimensions |

| Weight Optimization |

Superior – Higher strength allows for thinner sections |

Limited – Requires thicker sections for equivalent strength |

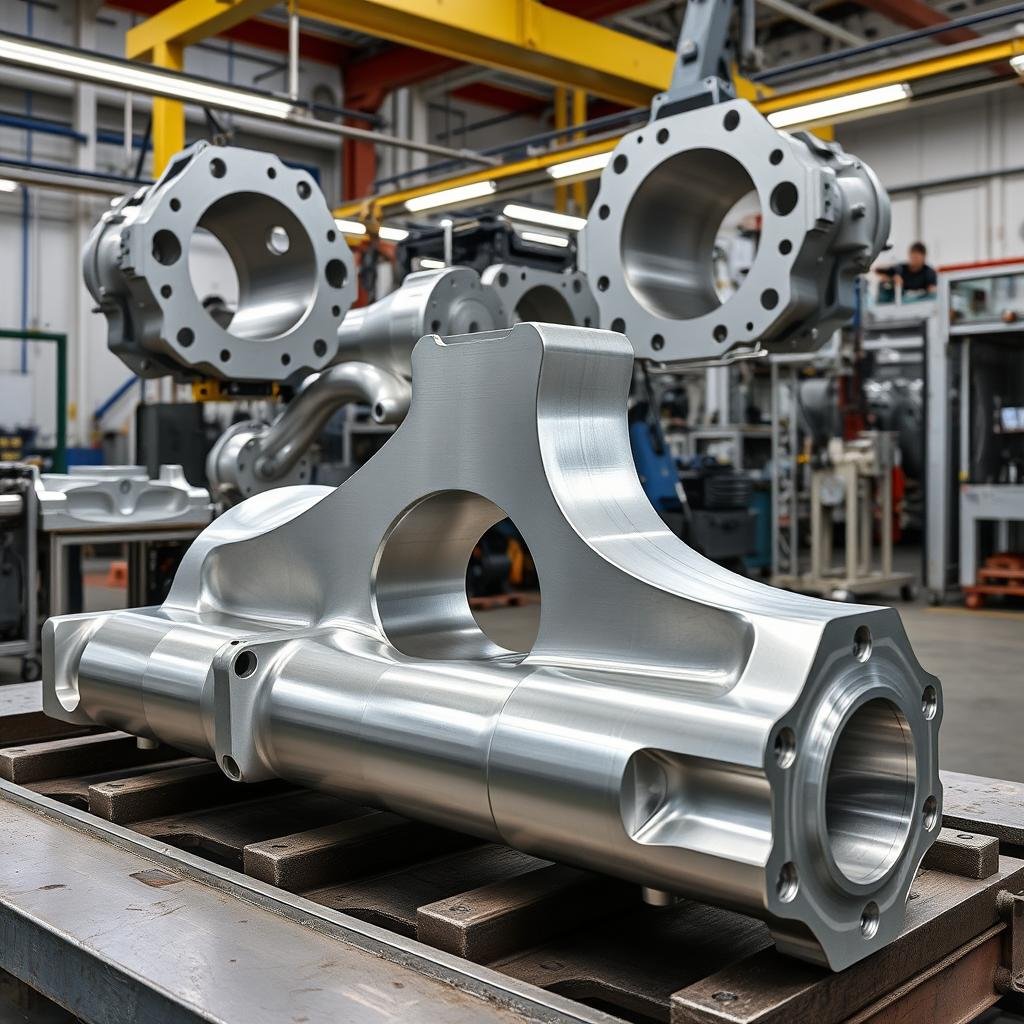

Applications of Well-Defined Forging Procedures Across Industries

MAIKONG’s precision forging capabilities serve diverse industries with components that meet the most demanding performance requirements.

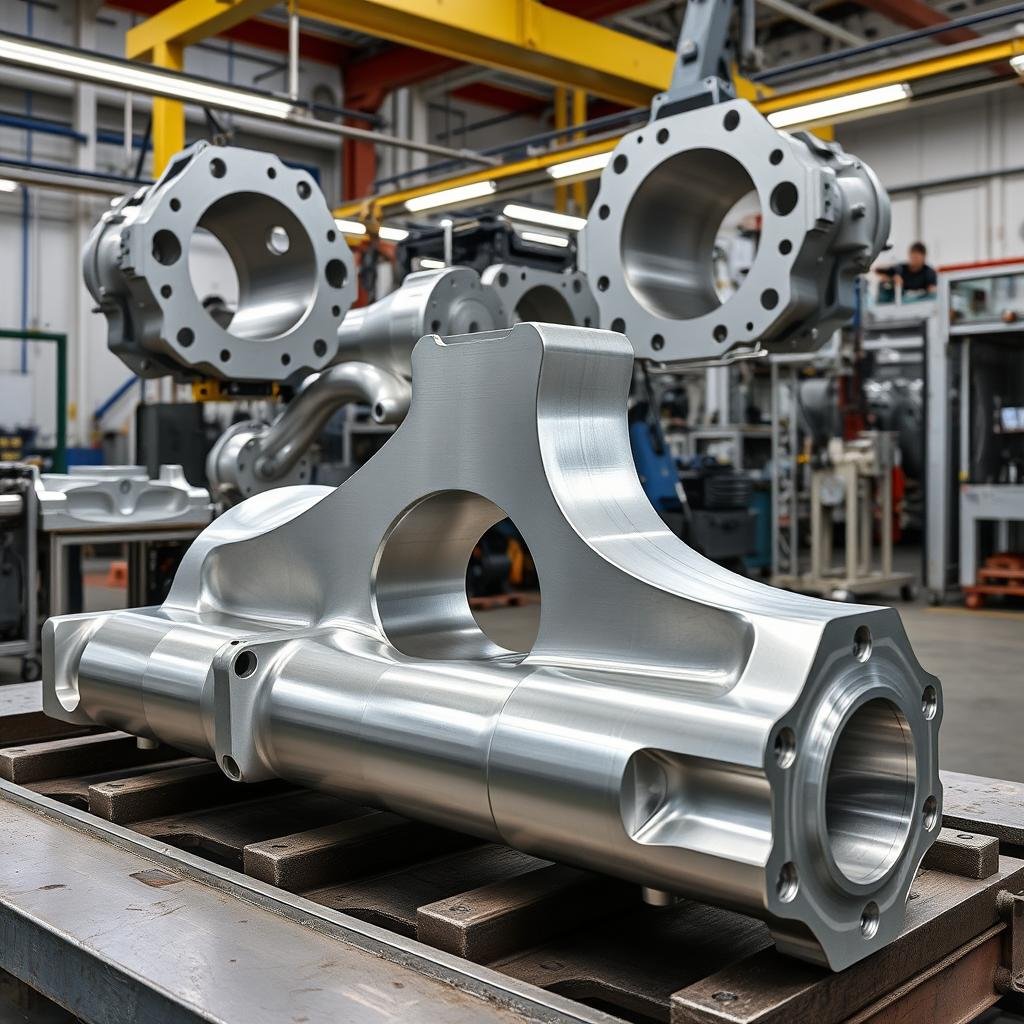

Aerospace

Our aerospace forging procedures create lightweight, high-strength components for critical applications where failure is not an option. From structural elements to landing gear components, MAIKONG delivers parts that meet rigorous aerospace standards.

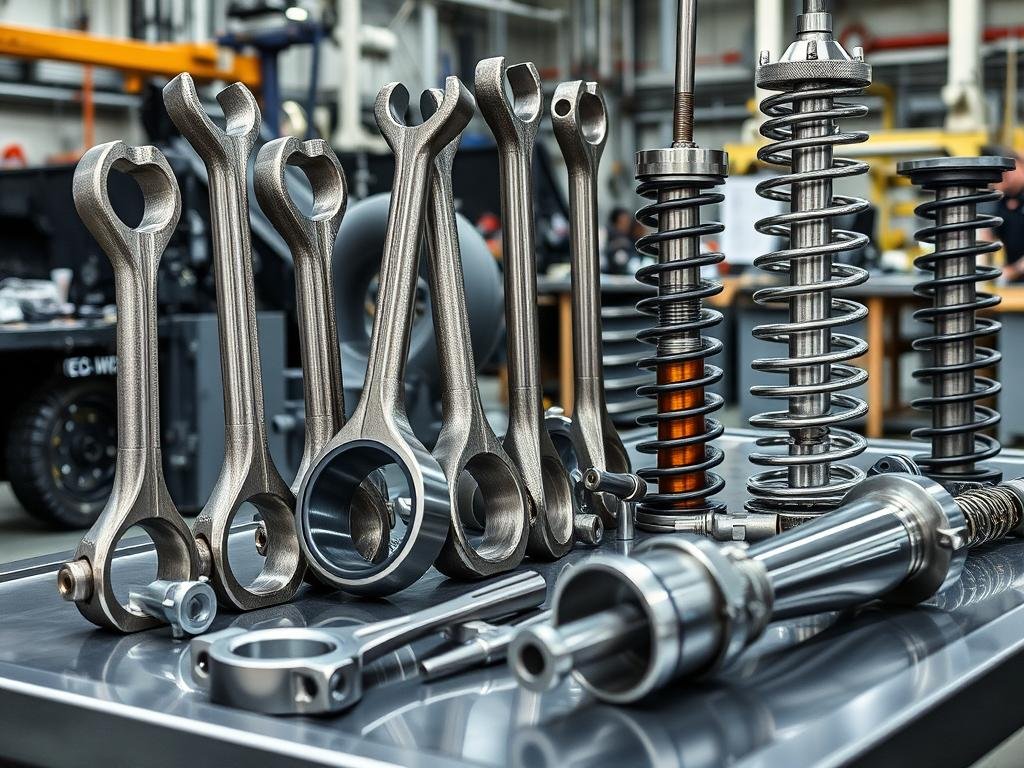

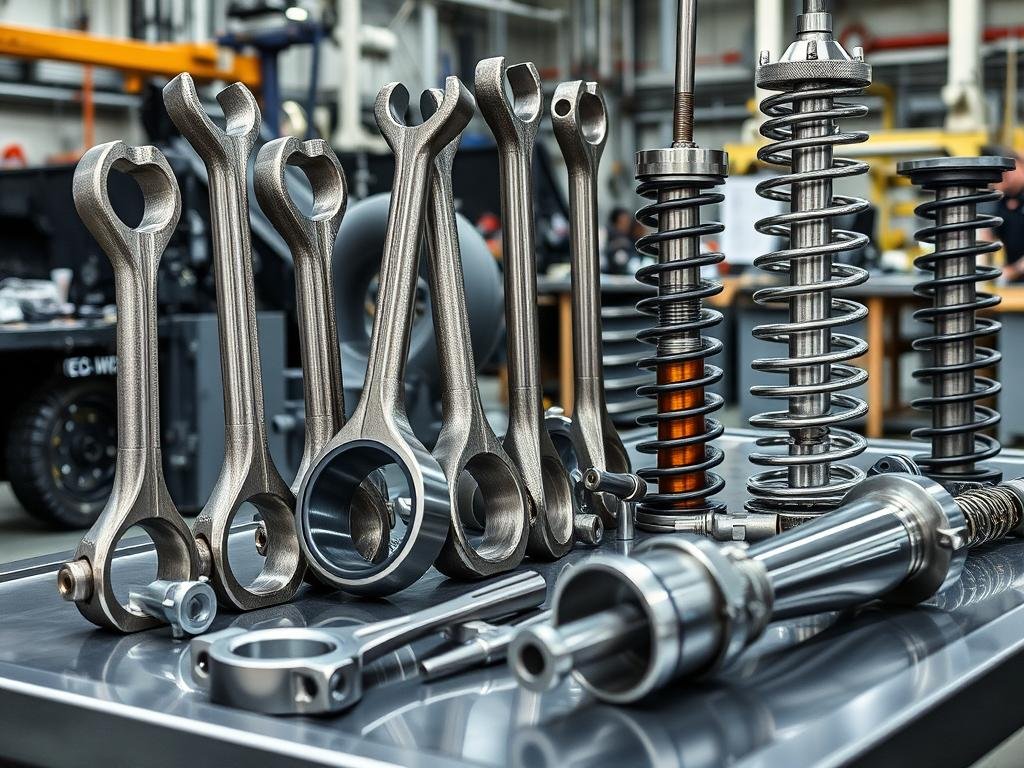

Automotive

MAIKONG’s automotive forging procedures produce connecting rods, crankshafts, steering components, and suspension parts that deliver superior performance and durability. Our components help manufacturers reduce weight while improving reliability.

Industrial Equipment

For industrial machinery and equipment, our forging procedures create components that withstand extreme loads, harsh environments, and continuous operation. From gears and shafts to hydraulic components, MAIKONG delivers reliability.

Case Study: Optimized Forging Procedure for Critical Components

“MAIKONG’s well-defined forging procedure transformed our manufacturing process. Their precision-forged components have improved our product performance while reducing assembly time and warranty claims. The consistent quality and competitive pricing make them an ideal partner.”

– Engineering Director, Leading Automotive Manufacturer

A major equipment manufacturer approached MAIKONG with a challenging requirement: redesign a critical component that was experiencing premature failure when produced through conventional manufacturing methods. Our engineering team analyzed the application requirements and developed a custom forging procedure that:

- Optimized grain flow to align with primary stress directions

- Eliminated internal defects that were initiating fatigue cracks

- Reduced weight by 15% while increasing strength by 22%

- Improved dimensional consistency for better assembly fit

- Reduced total manufacturing cost through near-net-shape forging

The result was a component with significantly improved service life that helped our customer enhance their product’s reputation for reliability.

Have a Challenging Component That Needs Improvement?

Our engineering team can develop a custom forging procedure to solve your most difficult manufacturing challenges.

Discuss Your Project

MAIKONG’s Comprehensive Forging and Machining Capabilities

As both a producer and consumer of precision components, MAIKONG understands the critical importance of consistency, strength, and dimensional accuracy in every forged part. Our integrated manufacturing capabilities ensure superior results from raw material to finished component.

Forging Equipment and Capacity

Our manufacturing facility in GD, SZ houses state-of-the-art forging equipment that enables us to handle projects of any scale:

- Multiple hydraulic forging presses ranging from 500 to 3,000 tons

- Precision-controlled heating furnaces with temperature uniformity ±5°C

- Automated handling systems for consistent production

- Monthly production capacity exceeding 100 tons of forged components

- Capability to forge components from 0.1 kg to 50 kg

CNC Machining Services

MAIKONG operates over 60 CNC machines that provide 100+ tons of metal processing capacity per month. Our comprehensive machining services include:

CNC Turning Services

Our CNC turning capabilities create precise cylindrical shapes with superior surface finishes. Ideal for deep holes, machined threads, and components requiring exceptional concentricity and dimensional accuracy.

CNC Milling Services

MAIKONG’s multi-axis CNC milling services produce complex prismatic shapes and flat surfaces with exceptional precision. Our advanced machines require no fixed tooling, offering flexibility and accuracy for diverse components.

CNC Swiss-Type Machining

Specializing in precision small parts and long shaft components, our Swiss-type machining features dual spindles and multi-axis capabilities. This provides a one-stop solution with the highest level of accuracy for intricate components.

Quality Assurance

MAIKONG’s commitment to quality is reflected in our comprehensive testing and verification capabilities:

- ISO 9001:2015 certified quality management system

- State-of-the-art material testing laboratory

- Dimensional inspection using coordinate measuring machines (CMM)

- Non-destructive testing including ultrasonic and magnetic particle inspection

- Mechanical property testing for tensile strength, hardness, and impact resistance

- 100% inspection of critical dimensions and features

Experience MAIKONG’s Manufacturing Excellence

From forging to final machining, our integrated capabilities deliver superior components with competitive pricing.

Request Manufacturing Services

Partnering with MAIKONG for Superior Forged Components

A Well-Defined Forging Procedure is the foundation for producing components with exceptional performance, consistency, and value. At MAIKONG, we’ve refined our procedures through decades of experience to deliver forged parts that exceed expectations.

Our comprehensive capabilities—from material selection and forging to heat treatment and precision machining—enable us to serve as your complete manufacturing partner. Whether you need aluminum, steel, or brass components, our team has the expertise to deliver superior results.

As we expand our presence in the United States, we’re actively seeking distributors who share our commitment to quality and customer satisfaction. Join us in bringing world-class forging and machining capabilities to manufacturers across America.

Contact MAIKONG Today

Discover how our well-defined forging procedures can improve your product performance and reduce manufacturing costs.

Request a Quote

Complete our simple form for a detailed quote on your forging and machining needs.

Get A Quick Quote