Comprehensive Guide to Metal Forging Procedures

Forging is one of the oldest and most reliable metalworking techniques, producing components with superior strength and structural integrity. At MAIKONG, we’ve perfected our forging procedure through years of expertise and investment in advanced equipment. This comprehensive guide explores the intricacies of metal forging, from traditional techniques to modern innovations that we implement at our Shenzhen manufacturing facility to deliver exceptional quality components to our global B2B clients.

MAIKONG: Your Premier Forging Partner

Based in Shenzhen, China, MAIKONG has established itself as a leading manufacturer specializing in CNC machining, metal forging, and custom metal parts production. Our state-of-the-art facility combines traditional forging expertise with cutting-edge technology to deliver components that meet the most demanding specifications across industries.

Our Manufacturing Capabilities

- Advanced production equipment for precision forging

- Comprehensive CNC machining services

- Expert metal forging across multiple materials

- Custom metal parts manufacturing

- Specialized aluminum forging services

- Professional steel forging processes

- Precision brass component production

Why Choose MAIKONG

- Access to China’s premium supply chain resources

- Industry-leading production equipment

- Superior quality at competitive prices

- Customization capabilities across all services

- Dedicated technical support via WhatsApp

- Streamlined communication channels

- Reliable delivery and logistics management

Ready to Discuss Your Forging Requirements?

Our engineering team is available to provide technical consultation and address your specific manufacturing needs.

Contact Our Engineering Team

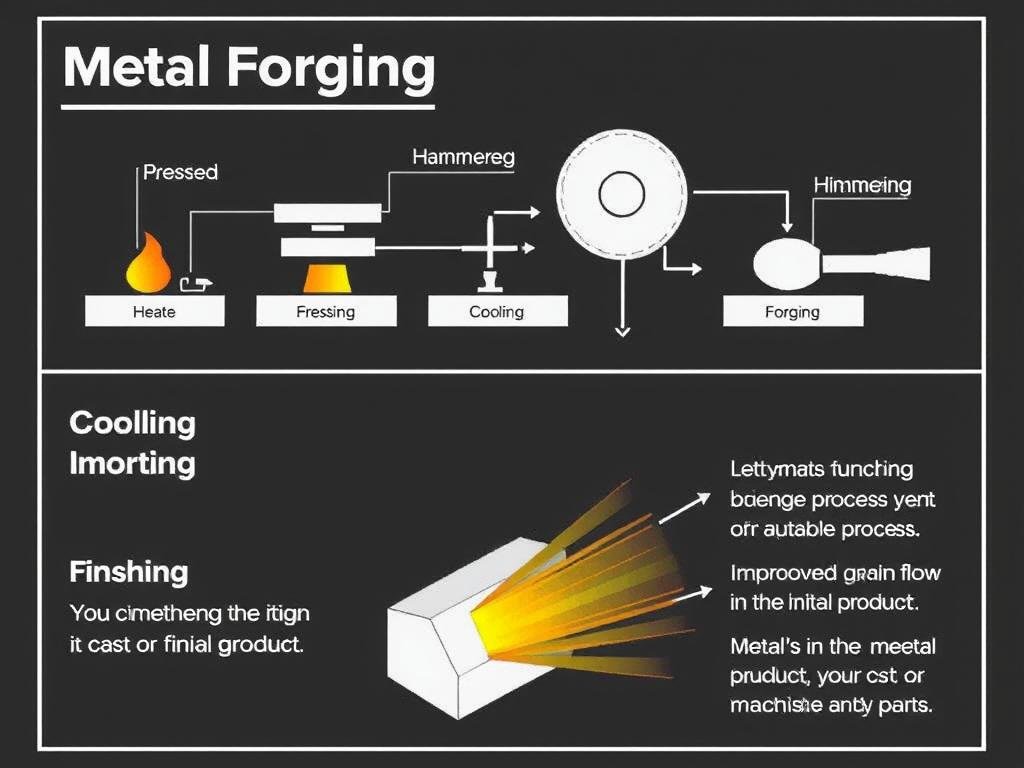

Understanding the Forging Procedure

The forging procedure involves shaping metal using localized compressive forces, delivered through specialized equipment like power hammers or hydraulic presses. Unlike other metalworking methods, forging creates a refined grain structure that follows the shape of the component, resulting in superior strength, durability, and performance under stress.

The Science Behind Metal Forging

During the forging process, the metal’s internal grain structure deforms to follow the general shape of the part. This continuous grain flow throughout the component leads to exceptional strength characteristics and reliability at high stress points. This is why forged components are preferred for critical “cannot fail” applications in aerospace, automotive, oil and gas, and other demanding industries.

Forging produces parts with superior strength-to-weight ratios compared to casting or machining, making it the preferred manufacturing method for safety-critical components.

Key Benefits of Forged Components

Enhanced Strength

Forged parts exhibit approximately 20% higher strength-to-weight ratio compared to machined or cast parts of the same material, making them ideal for high-stress applications.

Improved Grain Structure

The forging process creates a refined, continuous grain flow that follows the component’s shape, significantly enhancing fatigue resistance and structural integrity.

Superior Reliability

Forging eliminates internal defects like porosity and voids that can occur in casting, resulting in more reliable performance under demanding conditions.

Types of Forging Processes at MAIKONG

At MAIKONG, we employ various forging techniques based on your specific requirements, material properties, and the desired characteristics of the final component. Our expertise spans the complete spectrum of forging processes:

Classification by Temperature

Hot Forging

Performed at temperatures above the metal’s recrystallization point (typically 0.6 times the melting temperature), hot forging allows for significant deformation with relatively lower forces. This process is ideal for creating complex shapes and large components.

Warm Forging

Conducted at temperatures between hot and cold forging ranges, warm forging offers a balance between formability and precision. This technique requires moderate force and produces components with good dimensional accuracy and surface finish.

Cold Forging

Cold forging is performed at room temperature or slightly elevated temperatures below the recrystallization point. This process delivers excellent dimensional accuracy, superior surface finish, and enhanced mechanical properties, though it requires greater force and is typically used for smaller components.

Classification by Technique

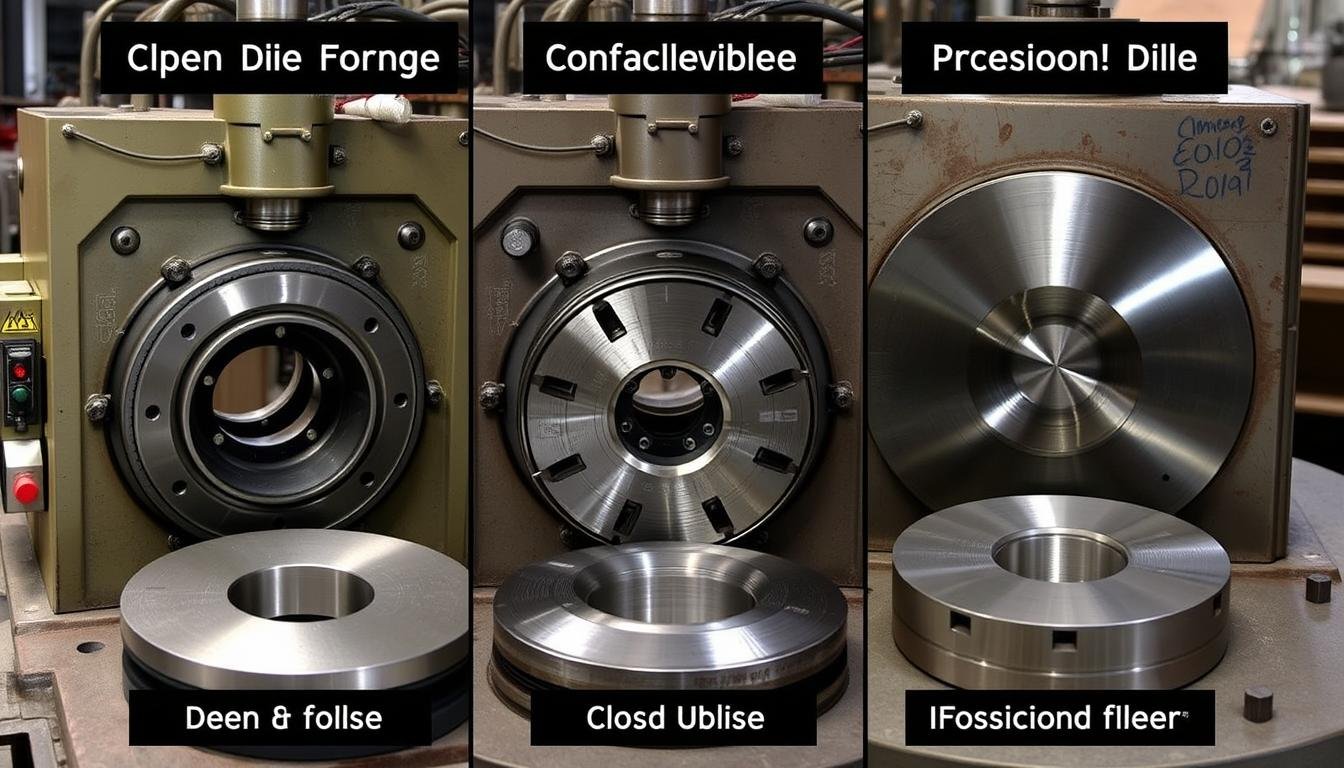

Open Die Forging

Open die forging involves shaping metal between multiple strikes of a hammer or press without fully enclosing the workpiece. This versatile technique is ideal for large or unique components and allows for excellent grain flow development. At MAIKONG, we utilize advanced open die forging for producing large structural components with superior mechanical properties.

Closed Die Forging

Also known as impression die forging, this process shapes metal within two or more dies that contain a pre-cut profile of the desired part. The metal flows and fills the die cavity under extreme pressure, creating complex shapes with excellent dimensional accuracy. Our closed die forging capabilities deliver precision components for automotive, aerospace, and industrial applications.

Impression Die Forging

This specialized form of closed die forging creates precise, complex shapes by forcing heated metal into die cavities. The process typically involves multiple stages including edging, blocking, and finishing to achieve the final geometry. MAIKONG’s impression die forging delivers components with superior grain flow and mechanical properties.

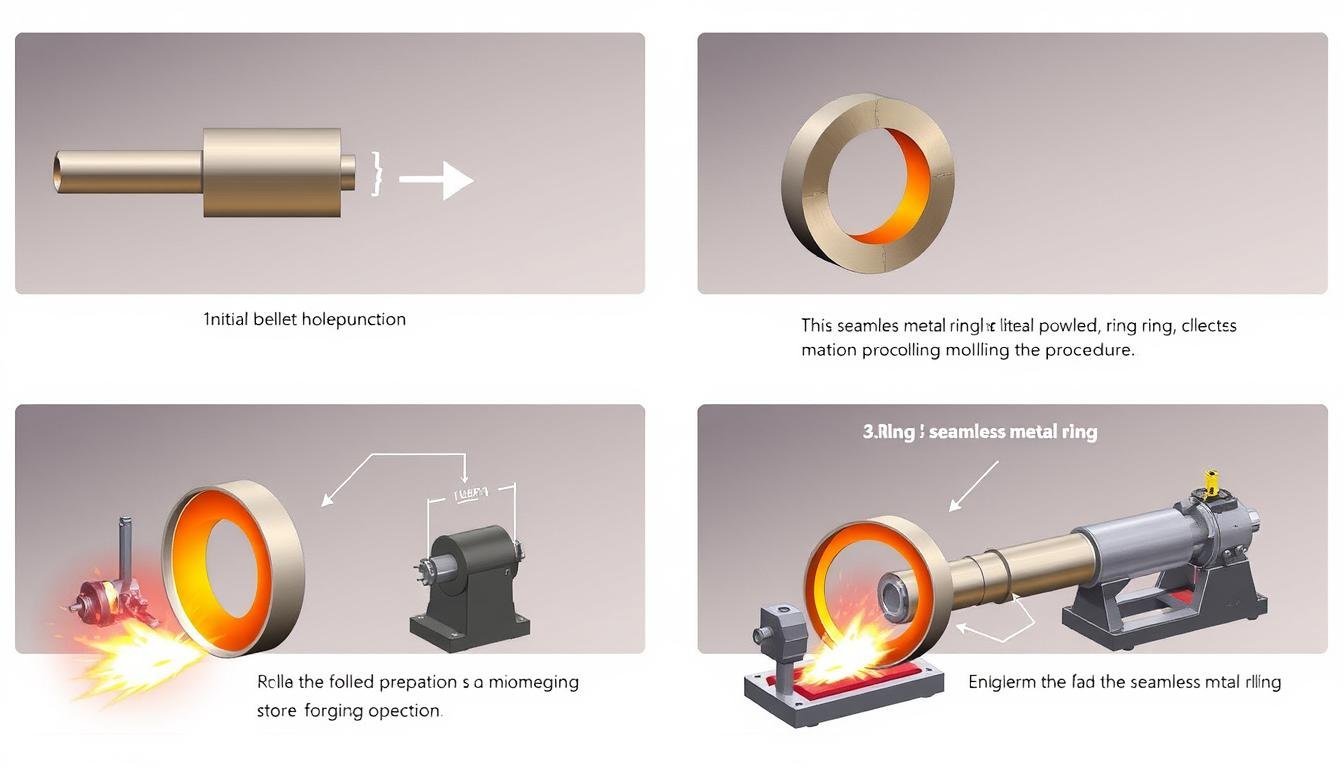

Rolled Ring Forging

Rolled ring forging creates seamless rings by punching a hole in a round metal stock and then rolling and shaping it to the desired dimensions. This specialized process is ideal for producing bearings, flanges, and rings for industrial machinery, with excellent circumferential grain flow that enhances performance under stress.

The Complete Forging Procedure at MAIKONG

Our comprehensive forging procedure follows a systematic approach to ensure consistent quality and superior mechanical properties in every component we produce. Each step is carefully controlled and monitored by our experienced team:

-

Design and Engineering

Our process begins with thorough analysis of your requirements and collaborative engineering to optimize the component design for the forging process. This includes material selection, die design, and process planning to ensure manufacturability and performance.

-

Material Selection and Preparation

We select appropriate high-quality raw materials based on the component requirements. The material is then cut to the required size and inspected for quality before proceeding to the heating stage.

-

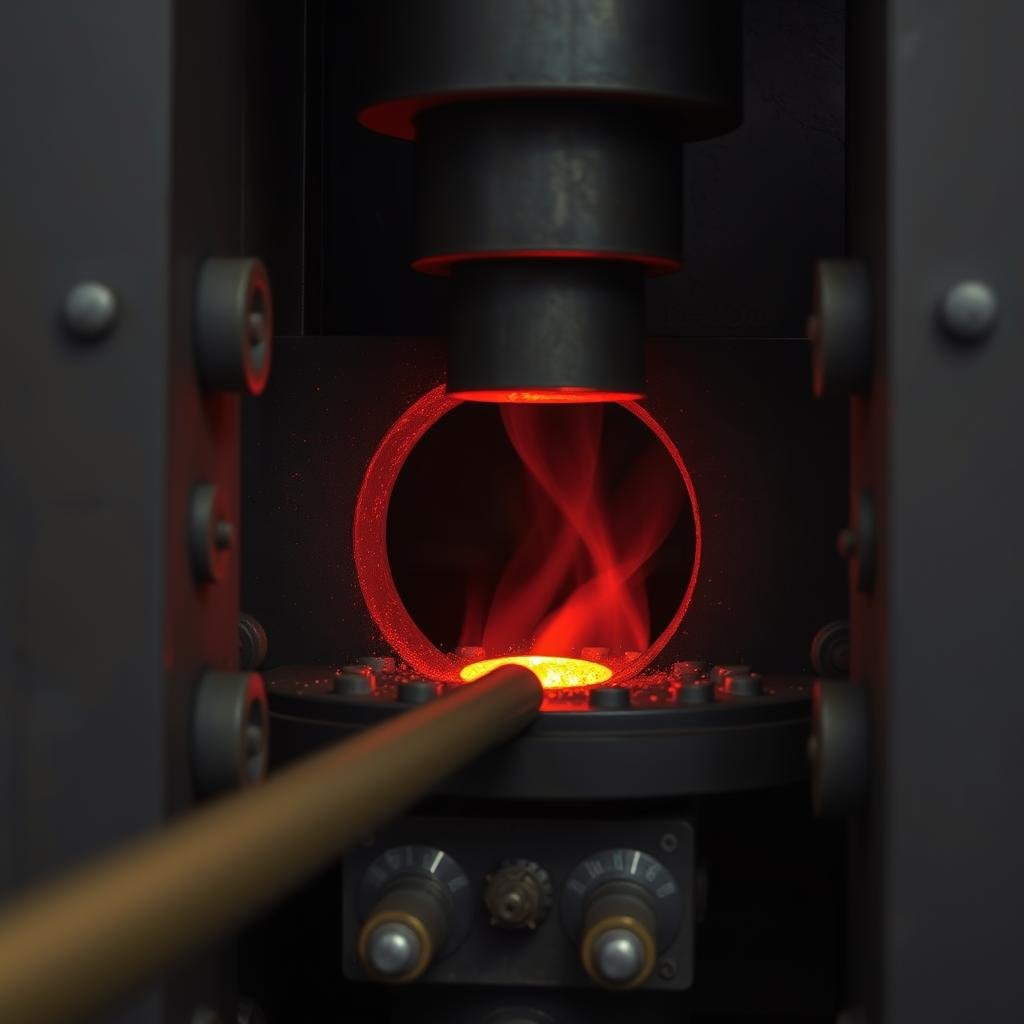

Heating

The metal is heated to its optimal forging temperature in precision-controlled furnaces. For steel, this typically ranges from 850°C to 1150°C, while aluminum is forged at temperatures up to 500°C. Precise temperature control is critical for achieving the desired formability and grain structure.

-

Preforming

For complex components, we implement a preforming stage where the heated material is shaped into a rough approximation of the final form. This step distributes the material efficiently and prepares it for the final forging operation.

-

Forging

The preheated and preformed material is placed in the forging die and subjected to controlled pressure using our advanced hydraulic presses or mechanical hammers. For complex components, multiple forging steps may be required to achieve the final shape.

-

Trimming and Punching

After forging, excess material (flash) is removed through precision trimming operations. Any required holes or cavities are created through punching or secondary operations.

-

Heat Treatment

To enhance specific mechanical properties such as hardness, strength, or ductility, the forged components undergo carefully controlled heat treatment processes including annealing, normalizing, quenching, or tempering as required by the specification.

-

Finishing Operations

Depending on the requirements, components may undergo additional finishing operations such as machining, grinding, or surface treatments to achieve the final dimensions, tolerances, and surface characteristics.

-

Quality Inspection

Every component undergoes rigorous inspection using advanced measurement equipment, non-destructive testing, and where required, destructive testing of samples to verify mechanical properties and internal integrity.

Material Expertise in Forging

At MAIKONG, we have extensive experience forging a wide range of metals and alloys to meet diverse application requirements. Our material expertise includes:

Aluminum Forging

Our specialized aluminum forged approach delivers lightweight yet strong components with excellent corrosion resistance. We work with various aluminum alloys including 2XXX, 6XXX, and 7XXX series for aerospace, automotive, and consumer applications.

Steel Forging

Our steel forging capabilities span carbon steels, alloy steels, tool steels, and stainless steels. We produce high-strength components for demanding applications in industrial machinery, oil and gas, and heavy equipment sectors.

Brass and Copper Alloys

We specialize in forging brass and copper alloys for applications requiring excellent electrical conductivity, corrosion resistance, and non-sparking properties. These components are widely used in electrical, marine, and safety-critical applications.

Our aluminum forged applications extend to specialized industries in locations like Santa Ana and throughout North America, where we’ve delivered custom components for aerospace, defense, and high-performance automotive applications. The aluminum forged approach we implement ensures optimal grain flow and mechanical properties for these demanding applications.

| Material |

Common Alloys |

Forging Temperature Range |

Key Properties |

Typical Applications |

| Aluminum |

2024, 6061, 7075 |

350°C – 500°C |

Lightweight, corrosion resistant, good strength-to-weight ratio |

Aerospace components, automotive parts, structural elements |

| Carbon Steel |

1045, 1060, 4140 |

900°C – 1250°C |

High strength, durability, heat treatable |

Gears, shafts, industrial machinery components |

| Stainless Steel |

304, 316, 410 |

1100°C – 1250°C |

Corrosion resistance, high temperature strength |

Valve components, marine applications, food processing equipment |

| Brass |

C36000, C38500 |

650°C – 800°C |

Excellent machinability, corrosion resistance, non-sparking |

Valves, fittings, electrical components |

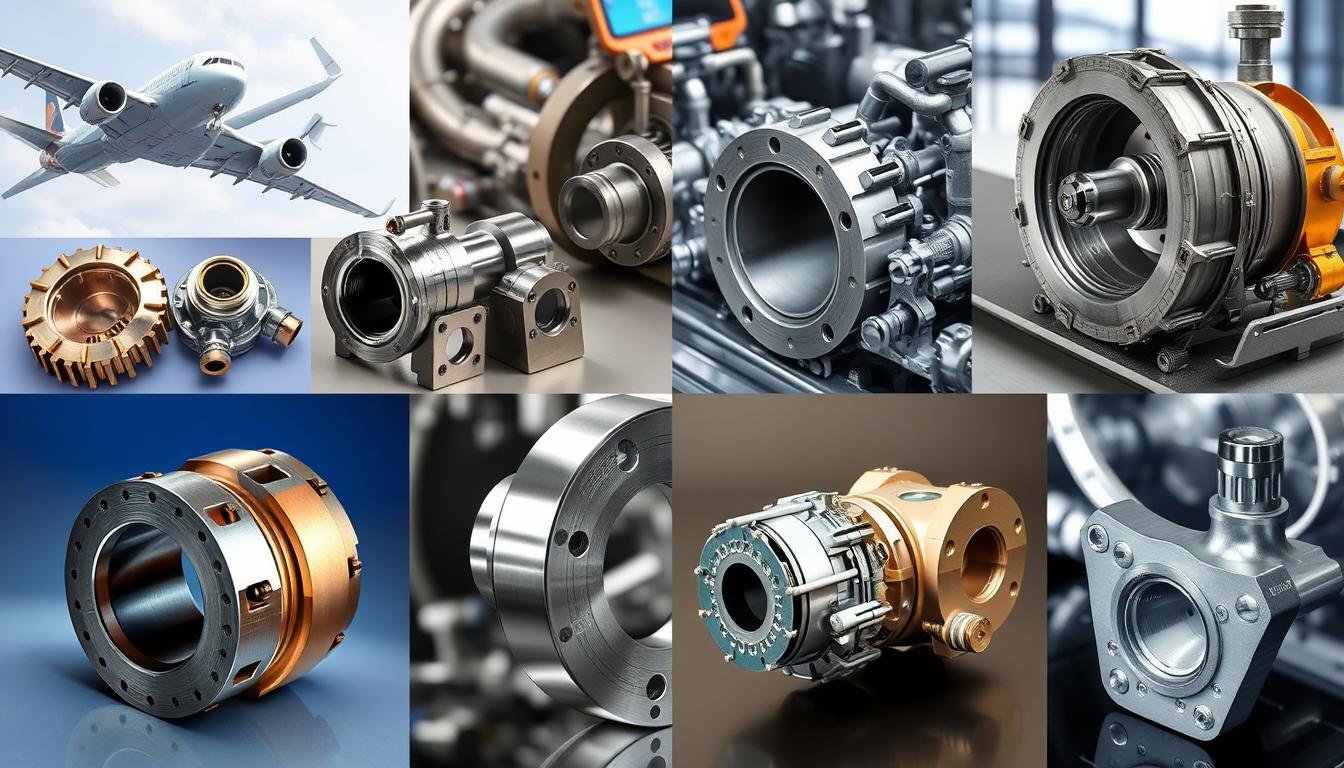

Industry Applications for Forged Components

The superior strength, reliability, and performance of forged components make them essential across numerous industries. At MAIKONG, we serve diverse sectors with specialized forging solutions:

Aerospace and Defense

- Structural components

- Landing gear parts

- Engine components

- Fastening systems

- Control system elements

Automotive and Transportation

- Crankshafts and connecting rods

- Transmission components

- Steering and suspension parts

- Wheel hubs and axles

- Engine mounting brackets

Oil and Gas

- Valve bodies and components

- Flanges and fittings

- Pressure vessel components

- Drilling equipment parts

- Subsea components

Industrial Machinery

- Gears and gear blanks

- Shafts and spindles

- Bearing components

- Hydraulic system parts

- Heavy equipment components

Medical and Surgical

- Orthopedic implants

- Surgical instrument components

- Medical device housings

- Dental equipment parts

- Diagnostic equipment components

Power Generation

- Turbine components

- Generator parts

- Valve bodies and stems

- Pressure containment components

- Structural supports

Quality Assurance in the Forging Procedure

At MAIKONG, quality is integrated into every step of our forging procedure. Our comprehensive quality management system ensures that each component meets or exceeds the specified requirements:

Quality Control Measures

- Raw material certification and verification

- In-process inspection at critical stages

- Dimensional verification using advanced measurement equipment

- Non-destructive testing including ultrasonic, magnetic particle, and dye penetrant inspection

- Destructive testing of samples for mechanical property verification

- Surface quality inspection and defect analysis

- Final inspection and documentation

Testing Capabilities

- Chemical composition analysis

- Mechanical property testing (tensile, yield, elongation)

- Hardness testing (Rockwell, Brinell, Vickers)

- Microstructure analysis

- Corrosion resistance testing

- Fatigue and impact testing

- Dimensional accuracy verification

Our commitment to quality ensures that every forged component leaving our facility meets the highest standards of performance, reliability, and durability.

The MAIKONG Advantage in Metal Forging

Choosing MAIKONG as your forging partner provides numerous advantages that enhance your product quality, reduce costs, and streamline your supply chain:

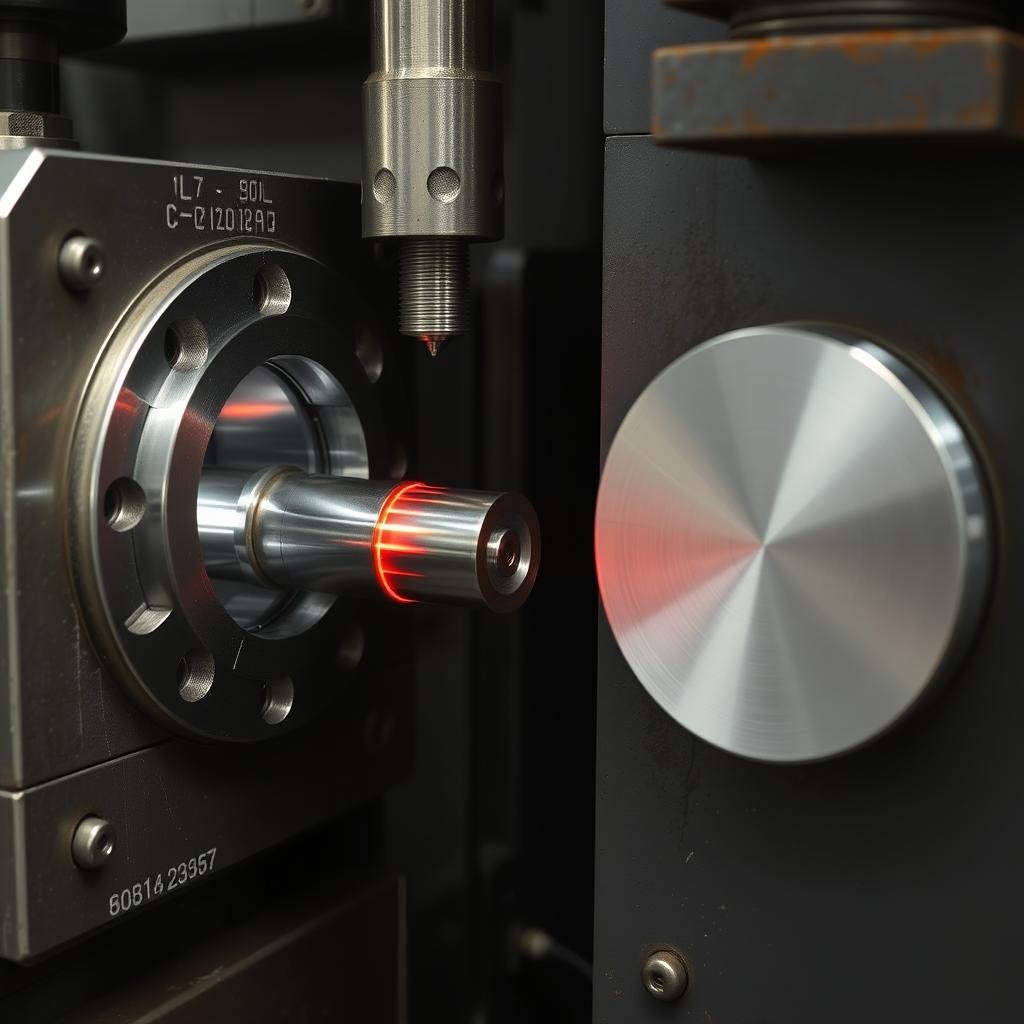

Advanced Technology

Our state-of-the-art forging equipment includes precision-controlled hydraulic presses, mechanical hammers, and specialized tooling that enables us to produce complex components with exceptional accuracy and consistency.

Material Expertise

With extensive experience working with diverse metals and alloys, our metallurgists and engineers can recommend the optimal material and process parameters for your specific application requirements.

Cost-Effective Solutions

Our strategic location in Shenzhen provides access to China’s premier supply chain resources, allowing us to offer competitive pricing without compromising on quality or performance.

Customization Capabilities

We specialize in custom forging solutions tailored to your unique requirements, from material selection to process optimization and finishing operations.

Technical Support

Our engineering team provides comprehensive technical support throughout the project lifecycle, from design optimization to production troubleshooting and quality verification.

Reliable Delivery

Our efficient production planning and logistics management ensure on-time delivery of your components, helping you maintain your production schedules and market commitments.

Excellence in Every Forged Component

At MAIKONG, we combine traditional forging expertise with modern technology to deliver superior metal components that meet the most demanding requirements. Our comprehensive forging procedure ensures optimal grain flow, mechanical properties, and dimensional accuracy in every part we produce.

From our facility in Shenzhen, we serve global clients with high-quality forged components, competitive pricing, and responsive technical support. Whether you’re in Santa Ana or anywhere across North America, our aluminum forged applications and other metal forging capabilities are ready to support your manufacturing needs.

Contact us today to discover how MAIKONG can become your trusted partner for precision forged components that deliver exceptional performance and reliability.