The forging process stands as one of manufacturing’s oldest and most reliable metal shaping techniques, transforming raw materials into high-strength components through controlled deformation. At MAIKONG, we’ve refined this ancient craft with modern precision, combining traditional principles with cutting-edge technology to deliver superior metal components. Whether you’re seeking aluminum forging services, steel components, or custom metal parts, understanding the fundamental elements that define an effective forging process is essential for achieving optimal mechanical properties and performance in your finished products.This comprehensive guide explores the critical factors that influence forging quality, from material selection and die design to temperature control and finishing operations. We’ll examine how these elements work together to create components with exceptional strength-to-weight ratios, refined grain structures, and superior mechanical properties for applications across automotive, aerospace, industrial, and consumer sectors.

Understanding the Fundamentals of the Forging Process

The forging process involves reshaping metal through compressive forces, typically delivered via hammering, pressing, or rolling. Unlike casting, where metal is melted and poured into molds, forging works with solid metal that’s heated to increase malleability before being shaped. This fundamental difference results in components with superior grain structure and mechanical properties.

At its core, forging process techniques can be categorized by temperature: hot forging (performed above the metal’s recrystallization temperature), warm forging (below recrystallization but above room temperature), and cold forging (at or near room temperature). Each approach offers distinct advantages depending on the material, component design, and performance requirements.

Need Custom Forged Components?

MAIKONG offers comprehensive forging and machining services with 60+ CNC machines and 100+ tons monthly capacity. Contact us for a consultation on your specific requirements.

Get a Quick Quote

The Historical Evolution of Forging Process Techniques

The forging process dates back thousands of years, with origins in ancient Mesopotamia around 4000 BC. Early blacksmiths discovered that heating metal made it easier to shape, leading to the development of rudimentary forging techniques. Over centuries, the process evolved from simple hammering to sophisticated industrial operations.

Today’s modern forging process incorporates advanced technologies like computer-controlled hydraulic presses, precision die design through CAD/CAM systems, and automated handling equipment. At MAIKONG, we’ve embraced these technological advancements while maintaining the core principles that make forging superior to other manufacturing methods for high-performance components.

Classification of Forging Process Methods

Understanding the different classifications of forging process techniques is essential for selecting the optimal approach for your specific application. These classifications are typically based on temperature, equipment used, and die configuration.

Temperature-Based Forging Process Classification

| Forging Type |

Temperature Range |

Advantages |

Typical Applications |

| Hot Forging |

Above recrystallization (850-1150°C for steel) |

Higher ductility, lower forming forces, complex shapes |

Large components, complex geometries, automotive parts |

| Warm Forging |

Below recrystallization but above room temperature |

Better precision than hot forging, less energy than cold |

Medium-sized components, moderate complexity |

| Cold Forging |

Room temperature or slightly above |

Superior surface finish, tight tolerances, no oxidation |

Fasteners, small precision components, high-volume parts |

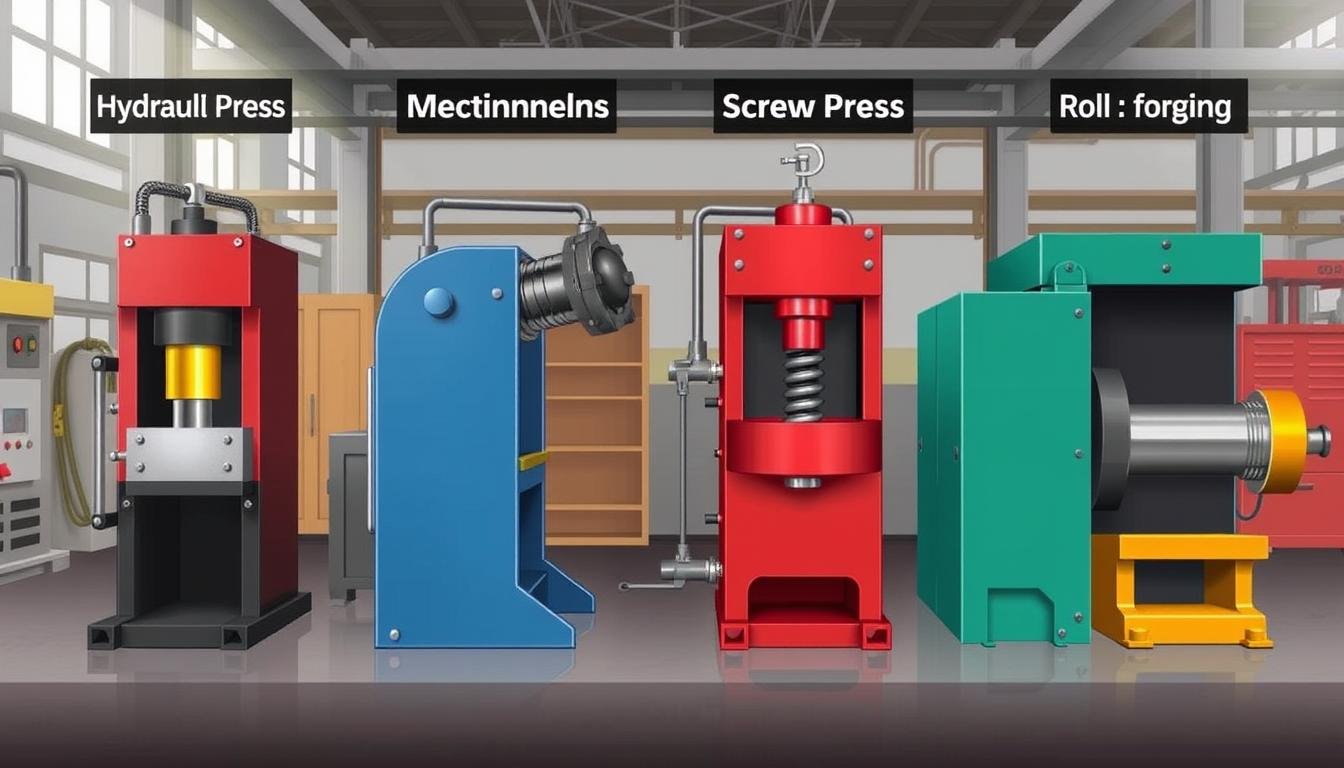

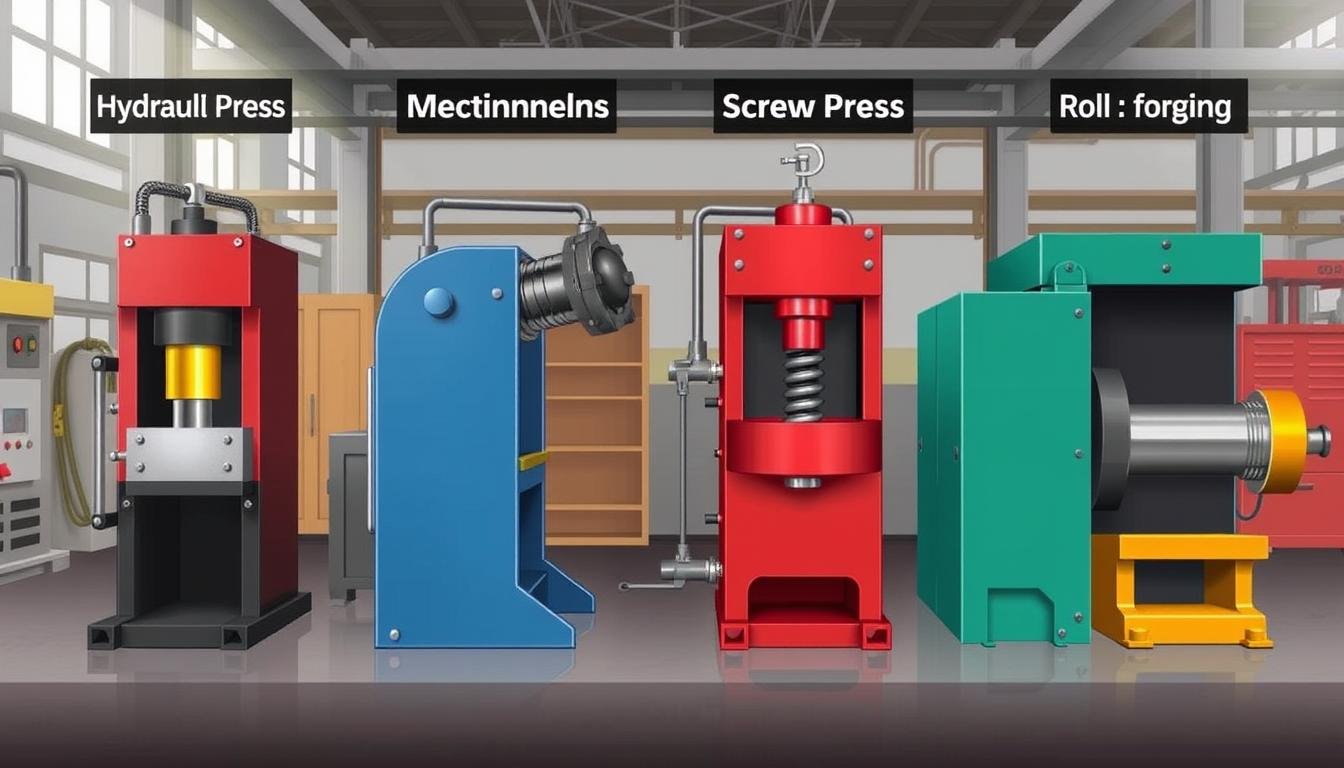

Equipment and Die-Based Forging Process Classification

Open Die Forging

In open die forging, the metal workpiece is never completely confined in the dies. The material is placed between two flat or simply shaped dies that hammer or press the material into the desired shape. This process requires skilled operators to manipulate the workpiece between strikes. Open die forging is ideal for large components and low-volume production.

Closed Die Forging

Closed die forging (also called impression die forging) uses two dies with impressions that create a complete enclosure around the workpiece. When force is applied, the metal flows to fill the die cavities. This method produces more complex shapes with tighter tolerances than open die forging and is suitable for medium to high-volume production.

Roll Forging

Roll forging uses cylindrical or semi-cylindrical rolls to progressively shape a heated bar as it passes through. This process reduces thickness while increasing length and is particularly effective for producing parts with varying cross-sections like axles, leaf springs, and hand tools.

Upset Forging

Upset forging increases the diameter of a workpiece by compressing its length. This technique is commonly used for creating heads on bolts, rivets, and screws. The process can be performed hot or cold depending on the material and size of the component.

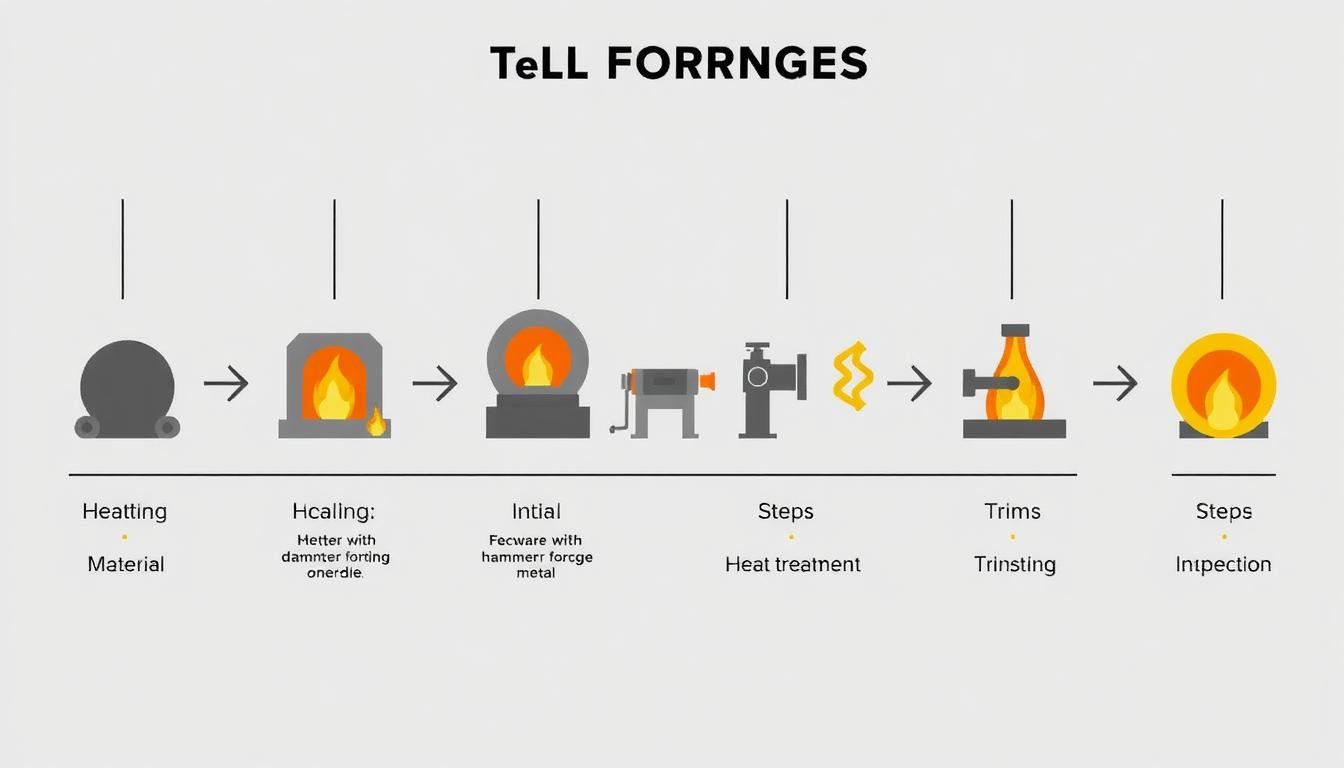

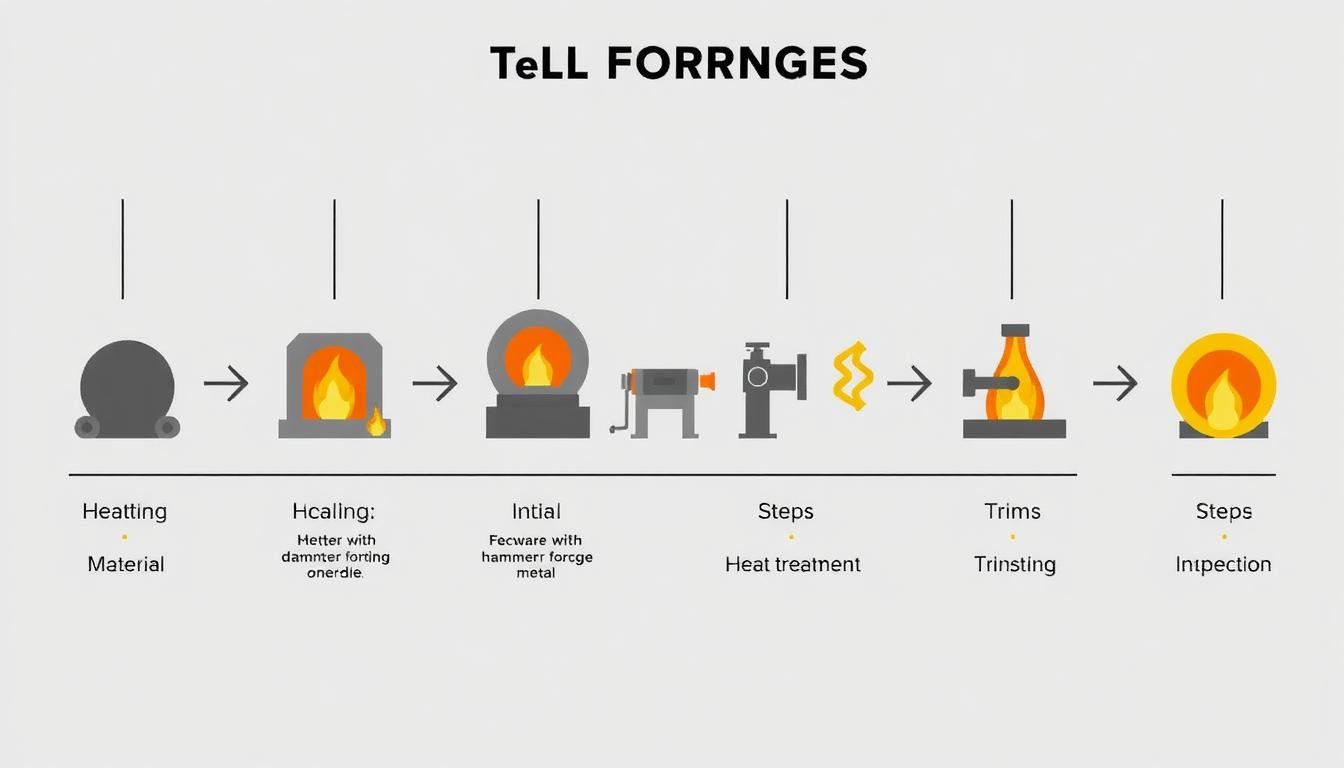

Critical Steps in the Forging Process

A successful forging process involves several carefully controlled steps, each contributing to the quality and performance of the final component. At MAIKONG, we’ve optimized each phase to ensure consistent, high-quality results.

Material Selection and Preparation

The forging process begins with careful material selection. Nearly all metals can be forged, including carbon steel, alloy steel, stainless steel, aluminum, titanium, brass, and copper. The choice depends on the component’s requirements for strength, weight, corrosion resistance, and other properties.

At MAIKONG, our material laboratory plays a crucial role in ensuring we select the optimal material for each application. We conduct comprehensive testing to verify material properties before beginning the forging process, ensuring consistent quality in the finished components.

Die Design and Manufacturing

Die design is a critical element of the forging process that directly impacts component quality, material flow, and production efficiency. Using advanced CAD/CAM systems, our engineers design dies that optimize grain flow while minimizing material waste.

For complex components, we employ finite element analysis (FEA) to simulate the forging process and predict potential issues before production begins. This approach allows us to refine die designs for optimal performance and longevity.

Heating and Temperature Control

Precise temperature control is essential for an effective forging process. Different metals require specific temperature ranges to achieve optimal formability without degrading material properties. For example, steel is typically forged between 850°C and 1150°C, while aluminum is forged at temperatures up to 500°C.

MAIKONG utilizes advanced heating systems with precise temperature monitoring to ensure consistent heating throughout the workpiece. This attention to detail prevents issues like overheating, which can lead to grain growth and reduced mechanical properties.

Expert Forging Services at MAIKONG

With our comprehensive in-house capabilities from material selection to finishing, we deliver superior forged components with exceptional mechanical properties and precision.

Contact via WhatsApp

Forging Operations

The core forging process involves applying compressive force to shape the heated workpiece. Depending on the component complexity and production volume, this may involve multiple stages:

- Edging (or fullering) – Initial shaping to distribute material

- Blocking – Intermediate forming to approach final shape

- Finishing – Final forming to achieve precise dimensions

- Trimming – Removing excess material (flash)

MAIKONG’s forging workshop is equipped with state-of-the-art equipment to handle diverse specifications and volumes, from prototype development to high-volume production runs.

Heat Treatment

Post-forging heat treatment is often essential to achieve the desired mechanical properties in the finished component. Common heat treatment processes include:

- Annealing – Reduces hardness and increases ductility

- Normalizing – Refines grain structure for improved toughness

- Quenching and tempering – Increases strength and hardness

- Solution treatment – Prepares aluminum alloys for aging

Our in-house heat treatment facilities allow for comprehensive statistical analysis and documentation, ensuring consistent results that meet or exceed industry standards.

Finishing Operations

The final steps in the forging process involve various finishing operations to achieve the required dimensions, surface finish, and appearance:

- Machining – Achieving precise dimensions and features

- Grinding – Removing parting lines and improving surface finish

- Surface treatments – Enhancing appearance and corrosion resistance

- Inspection – Verifying dimensional accuracy and material properties

MAIKONG’s comprehensive capabilities include CNC machining with 60+ machines, automated grinding with specialized robots, and various surface treatment options to deliver components ready for immediate use or assembly.

Advantages of the Forging Process Over Other Manufacturing Methods

The forging process offers several significant advantages over alternative manufacturing methods like casting, machining from solid, or powder metallurgy. These benefits make forging the preferred choice for components where performance and reliability are critical.

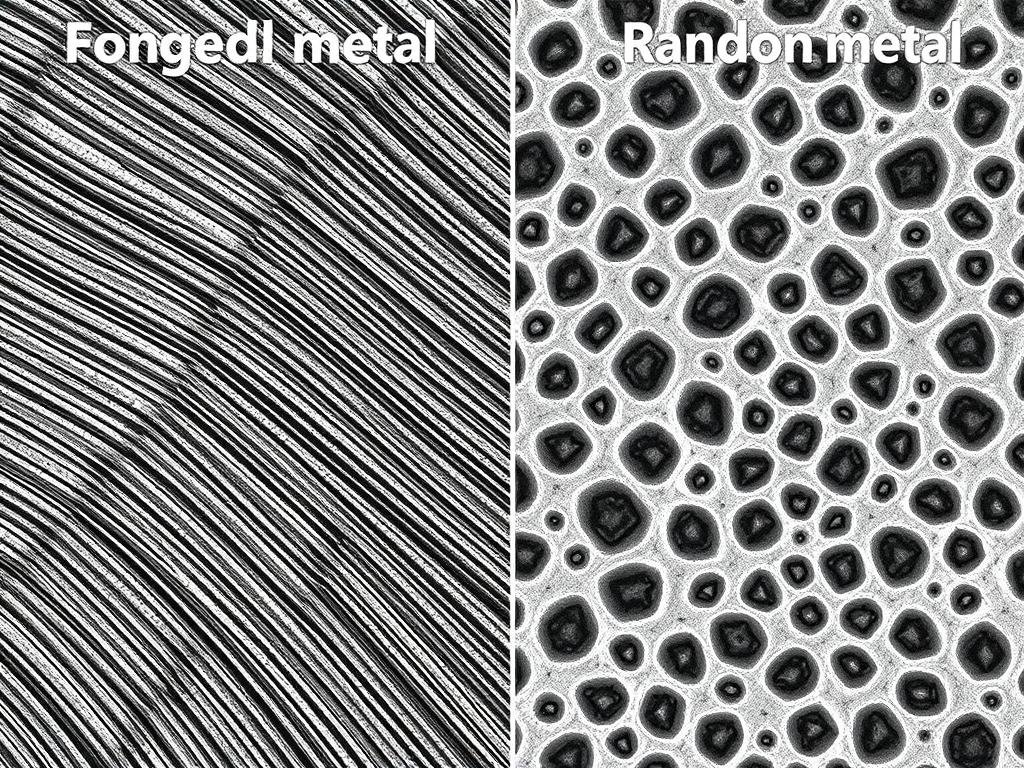

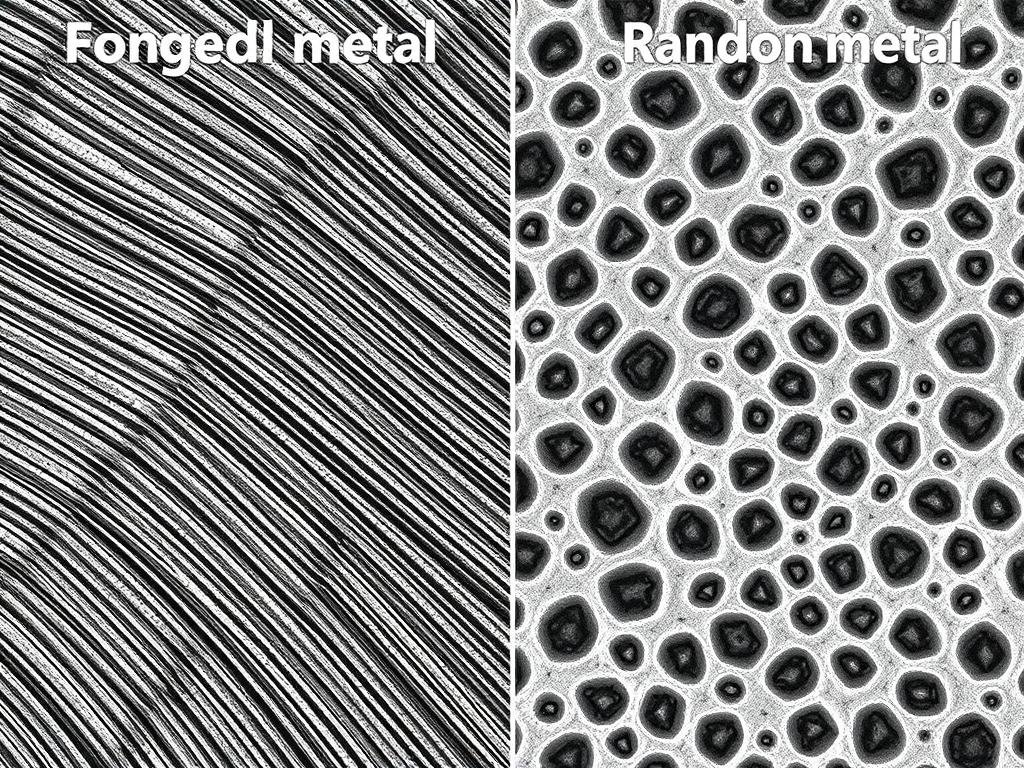

Superior Mechanical Properties

Forging’s primary advantage is the enhancement of mechanical properties through controlled deformation. The forging process refines grain structure and creates directional grain flow that follows the component’s geometry, resulting in:

- Higher tensile strength

- Improved fatigue resistance

- Enhanced impact toughness

- Better fracture toughness

- Greater ductility

- Reduced internal voids

- Elimination of porosity

- Consistent performance

Optimal Strength-to-Weight Ratio

The forging process creates components with exceptional strength-to-weight ratios, particularly important in industries like aerospace and automotive where weight reduction without compromising strength is critical. Aluminum forging exemplifies this advantage, delivering components that combine lightweight properties with robust mechanical characteristics.

| Comparison Categories |

Aluminum Forging |

Cast Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Weight-to-Strength Ratio |

High strength-to-weight ratio |

Bulkier parts may be needed |

Cost-Effectiveness in Production

While the initial tooling costs for forging process equipment can be higher than some alternatives, the long-term economic benefits often make forging more cost-effective, particularly for medium to high-volume production:

- Reduced material waste compared to machining from solid

- Lower rejection rates due to consistent quality

- Reduced need for secondary operations

- Longer component service life reducing replacement costs

- Improved production efficiency with automated processes

At MAIKONG, our optimized forging process and comprehensive in-house capabilities from raw material to finishing operations allow us to offer competitive pricing while maintaining exceptional quality.

Industrial Applications of the Forging Process

The versatility and performance advantages of the forging process make it essential across numerous industries where component reliability and strength are critical. MAIKONG serves diverse sectors with custom forged components tailored to specific application requirements.

Automotive and Transportation

The automotive industry relies heavily on forged components for critical applications where safety and performance are paramount:

- Engine components (crankshafts, connecting rods, camshafts)

- Transmission parts (gears, shafts, synchronizers)

- Steering and suspension components (knuckles, control arms)

- Wheel hubs and axle components

- Drivetrain components (differential gears, CV joints)

The forging process delivers the strength, durability, and fatigue resistance necessary for these components to withstand the rigors of automotive applications.

Aerospace and Defense

Aerospace applications demand the highest levels of performance and reliability, making the forging process essential for critical components:

- Structural airframe components

- Landing gear parts

- Jet engine disks and shafts

- Turbine blades and compressor components

- Missile and rocket components

The superior strength-to-weight ratio and reliability of forged components are particularly valuable in aerospace applications where weight reduction and safety are critical considerations.

US Distributors Wanted

MAIKONG is seeking US distributors for our high-quality, cost-effective forged components and CNC machining services. Join our growing network of partners.

Contact for Distribution Opportunities

Industrial Equipment and Machinery

Heavy industrial equipment relies on forged components to withstand extreme loads, impacts, and operating conditions:

- Construction equipment components (bucket teeth, track links)

- Mining machinery parts (crusher components, drill bits)

- Agricultural equipment (tractor components, implement parts)

- Oil and gas equipment (valves, flanges, fittings)

- Power generation components (turbine parts, generator components)

The forging process creates components with the durability and impact resistance needed for these demanding applications.

Consumer and Sporting Goods

Beyond industrial applications, the forging process is also used for consumer products where strength and durability are important:

- Hand tools (wrenches, hammers, pliers)

- Bicycle components (cranks, stems, forks)

- Golf club heads

- Knife blades

- Firearm components

These applications benefit from forging’s ability to create components with excellent strength, wear resistance, and long service life.

MAIKONG’s Advanced Forging Process Capabilities

At MAIKONG, we’ve developed comprehensive forging process capabilities that combine traditional expertise with cutting-edge technology. Our facilities in GD, SZ are equipped with state-of-the-art equipment and staffed by experienced professionals dedicated to delivering exceptional quality and value.

Comprehensive In-House Capabilities

Our full-service approach encompasses every aspect of the forging process from initial design to finished components:

Design & Engineering

- Advanced CAD/CAM systems

- Finite element analysis

- Process simulation

- Die design optimization

Material Processing

- Material testing laboratory

- Precision heating systems

- Multiple forging methods

- In-house heat treatment

Finishing Operations

- 60+ CNC machines

- Automated grinding

- Surface treatments

- Quality inspection

Quality Assurance in the Forging Process

Quality is integral to every aspect of our forging process. MAIKONG maintains ISO 9001:2015 certification and implements rigorous quality control procedures throughout production:

- Comprehensive material testing and verification

- In-process inspections at critical stages

- Advanced non-destructive testing methods

- Dimensional verification using precision measurement equipment

- Mechanical property testing of finished components

- Statistical process control for continuous improvement

Our commitment to quality ensures that every component we produce meets or exceeds customer specifications and industry standards.

+8613-51090-74-01Contact us directly for immediate assistance with your forging requirements

Custom Solutions for Diverse Requirements

MAIKONG specializes in developing custom forging process solutions tailored to specific application requirements. Our expertise spans a wide range of materials and component types:

Materials Expertise

- Carbon and alloy steels

- Stainless steels

- Aluminum alloys

- Titanium

- Brass and copper

- Specialty alloys

Component Specialization

- Automotive components

- Industrial equipment parts

- Aerospace components

- Consumer product parts

- Custom engineered solutions

- Prototype to production

Our engineering team works closely with customers to develop optimal forging process parameters for each application, ensuring the best combination of performance, cost-effectiveness, and manufacturability.

Advanced Forging Process Techniques and Innovations

The forging process continues to evolve with technological advancements and innovative approaches. At MAIKONG, we stay at the forefront of these developments to offer our customers the most advanced forging solutions.

Precision and Near-Net Shape Forging

Precision forging represents a significant advancement in the forging process, producing components with minimal need for secondary machining operations. This approach offers several advantages:

- Reduced material waste and machining costs

- Preservation of optimal grain flow throughout the component

- Improved production efficiency and shorter lead times

- Enhanced mechanical properties in the finished component

MAIKONG has invested in precision forging capabilities to deliver components that require minimal finishing while maintaining the superior mechanical properties inherent to the forging process.

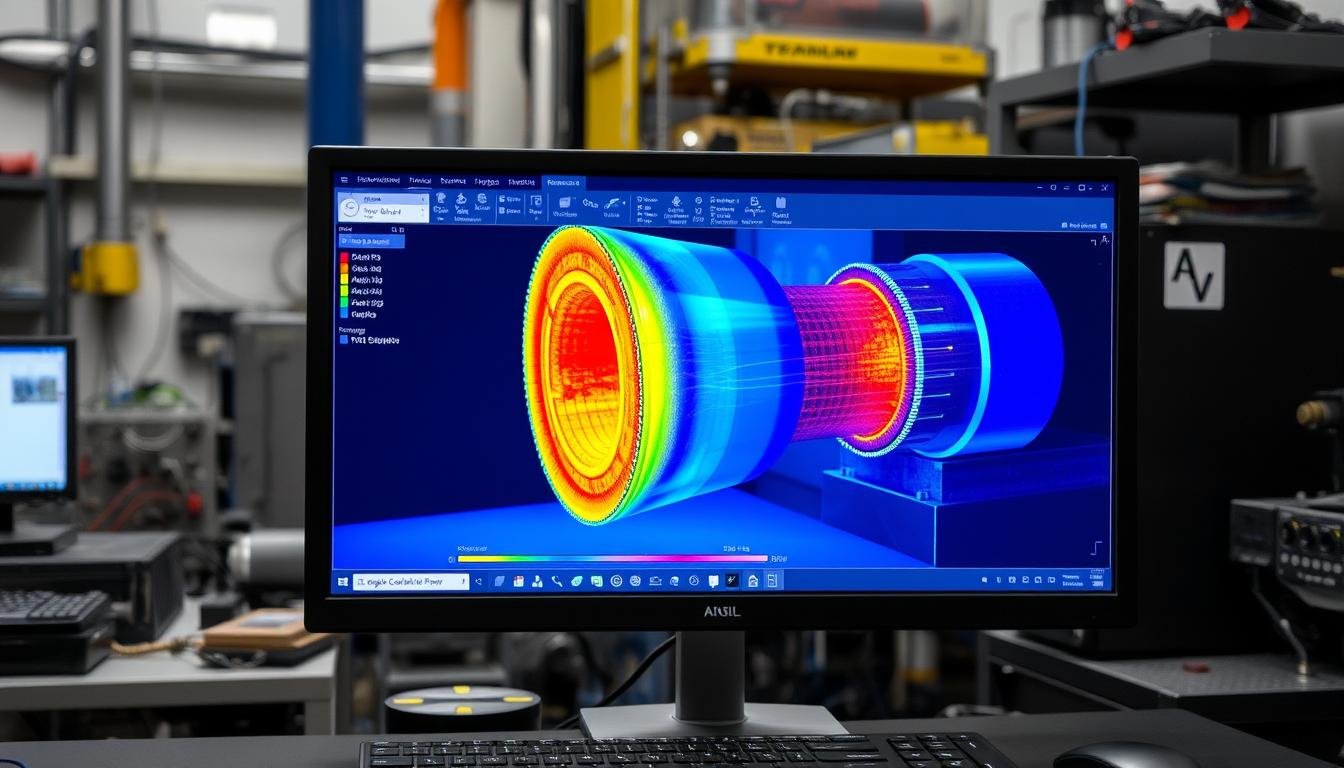

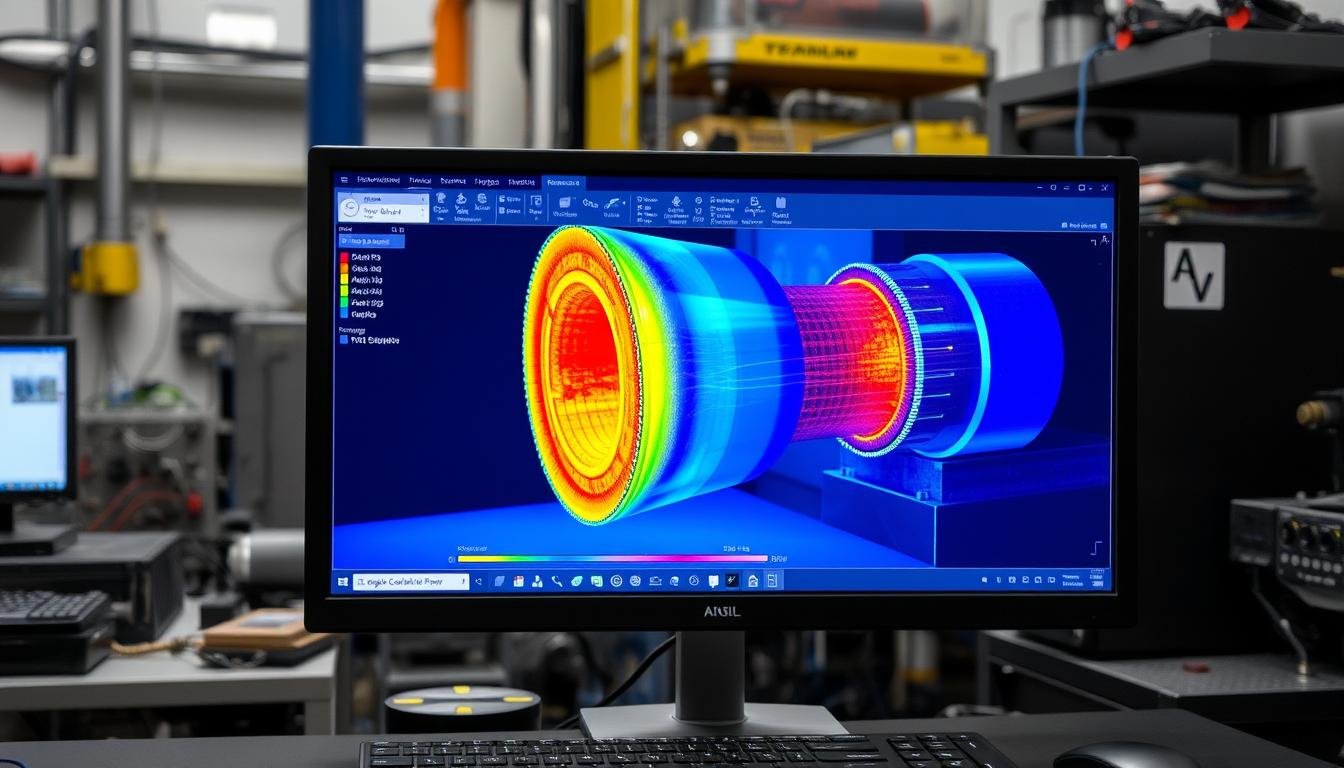

Computer Simulation and Process Optimization

Advanced computer simulation has revolutionized the forging process by allowing engineers to predict and optimize material flow, die filling, and stress distribution before physical production begins:

- Finite element analysis (FEA) for die design optimization

- Material flow simulation to prevent defects

- Thermal analysis to optimize heating and cooling parameters

- Stress analysis to predict and prevent die failure

These simulation capabilities enable MAIKONG to develop optimized forging process parameters that ensure consistent quality while minimizing development time and costs.

Integrated Manufacturing Systems

Modern forging process operations increasingly incorporate integrated manufacturing systems that combine forging with other processes for enhanced efficiency:

- Automated material handling and transfer systems

- Integrated heating, forging, and cooling operations

- In-line inspection and quality control

- Seamless integration with machining and finishing operations

MAIKONG’s manufacturing facility in GD, SZ features integrated production lines that streamline the entire process from raw material to finished component, ensuring consistent quality and efficient production.

Experience MAIKONG’s Advanced Forging Capabilities

From prototype development to high-volume production, our comprehensive capabilities deliver superior components with exceptional value.

Request a Consultation

Material Selection for Optimal Forging Process Results

The selection of appropriate materials is a critical factor in achieving optimal results from the forging process. Different materials exhibit varying characteristics during forging and in the finished component, making material selection a key consideration in component design.

Commonly Forged Materials and Their Characteristics

| Material |

Forging Temperature |

Key Properties |

Typical Applications |

| Carbon Steel |

1100-1250°C |

Good strength, ductility, and cost-effectiveness |

Automotive components, hand tools, industrial parts |

| Alloy Steel |

1050-1200°C |

Enhanced strength, toughness, and wear resistance |

Gears, shafts, heavy machinery components |

| Stainless Steel |

1100-1250°C |

Corrosion resistance, good strength, and appearance |

Food processing equipment, marine components |

| Aluminum Alloys |

350-500°C |

Lightweight, good strength-to-weight ratio |

Aerospace components, automotive parts |

| Titanium |

870-980°C |

Exceptional strength-to-weight ratio, corrosion resistance |

Aerospace, medical implants, chemical processing |

| Brass |

700-800°C |

Good corrosion resistance, electrical conductivity |

Plumbing fittings, electrical components |

Material Testing and Verification

At MAIKONG, our material laboratory conducts comprehensive testing to ensure that all materials used in our forging process meet the required specifications:

- Chemical composition analysis

- Mechanical property testing

- Microstructure examination

- Hardness testing

- Grain size analysis

This rigorous testing ensures that the starting material has the appropriate characteristics for the forging process and will deliver the required properties in the finished component.

Quality Control in the Forging Process

Maintaining consistent quality throughout the forging process is essential for producing reliable, high-performance components. MAIKONG implements comprehensive quality control procedures at every stage of production.

Common Defects and Prevention Strategies

Understanding potential defects in the forging process and implementing strategies to prevent them is a key aspect of quality control:

Potential Defects

- Laps and folds from improper material flow

- Underfilling of die cavities

- Surface cracks from improper heating or cooling

- Internal cracks from excessive deformation

- Improper grain flow orientation

Prevention Strategies

- Optimized die design through simulation

- Precise temperature control during heating

- Proper lubrication during forging

- Controlled deformation rates

- Regular die maintenance and inspection

Inspection Methods and Quality Standards

MAIKONG employs a range of inspection methods to verify the quality of forged components:

- Visual inspection for surface defects

- Dimensional inspection using coordinate measuring machines (CMM)

- Non-destructive testing (ultrasonic, magnetic particle, dye penetrant)

- Destructive testing of sample components

- Microstructure examination

- Mechanical property testing

Our quality management system is certified to ISO 9001:2015 standards, ensuring consistent adherence to established procedures and continuous improvement in our forging process.

Conclusion: Mastering the Forging Process for Superior Components

The forging process remains one of the most effective methods for producing high-strength, reliable metal components across a wide range of industries. By understanding and optimizing the key elements that define an effective forging process—from material selection and die design to temperature control and finishing operations—manufacturers can achieve superior results that meet the most demanding performance requirements.

At MAIKONG, we’ve combined traditional forging expertise with modern technology and comprehensive in-house capabilities to deliver exceptional value to our customers. Our facilities in GD, SZ feature 60+ CNC machines with a monthly capacity exceeding 100 tons, allowing us to serve diverse industries with custom forged components that meet the highest standards of quality and performance.

Whether you’re seeking aluminum forging services, steel components, or custom metal parts, MAIKONG offers the expertise, capabilities, and commitment to quality needed to ensure your components perform as required. We invite you to contact us to discuss your specific requirements and discover how our comprehensive forging and machining services can benefit your applications.

Partner with MAIKONG for Your Forging Needs

From design assistance to finished components, our team is ready to support your manufacturing requirements with cost-effective, high-quality solutions.