In the world of metal manufacturing, forging procedures stand as one of the most reliable and time-tested methods for creating high-strength, durable components. At MAIKONG, we’ve mastered these techniques to deliver superior custom metal parts that meet the most demanding specifications. Our comprehensive approach combines traditional forging wisdom with cutting-edge technology to produce components with exceptional mechanical properties, refined grain structures, and outstanding performance characteristics.

Understanding Forging Procedures and Their Importance

State-of-the-art forging operations at MAIKONG’s GD, SZ facility

State-of-the-art forging operations at MAIKONG’s GD, SZ facility

Forging is a manufacturing process that shapes metal using localized compressive forces. These forces are delivered with specialized equipment like power hammers or presses. What sets forging apart from other metalworking processes is its ability to enhance the internal structure of metals, creating parts with superior strength and toughness.

The basic principle of forging involves heating metal to a temperature where it becomes malleable, then applying pressure to shape it into the desired form. This process aligns the grain structure of the metal with the part’s shape, significantly improving its mechanical properties compared to casting or machining from stock.

The Evolution of Forging Procedures Through History

Forging dates back to ancient civilizations, with evidence of forged tools and weapons from as early as 4000 BC. What began as simple hammering by early blacksmiths has evolved into sophisticated industrial processes. Today, MAIKONG combines these time-honored techniques with advanced technology to create precision components for various industries.

Modern forging procedures utilize computer-controlled equipment, precise temperature management, and advanced die designs to achieve unprecedented levels of accuracy and consistency. This evolution has expanded forging’s applications across automotive, aerospace, oil and gas, and many other sectors requiring high-performance metal components.

Classification of Forging Procedures

At MAIKONG, we classify forging procedures based on several key parameters to ensure we select the optimal process for each custom metal part. Understanding these classifications helps our clients appreciate the technical considerations behind our manufacturing recommendations.

Classification by Temperature

Hot forging operation at MAIKONG’s advanced manufacturing facility

Temperature plays a crucial role in determining the characteristics and applications of different forging methods:

Hot Forging

Performed at temperatures above the metal’s recrystallization point (typically 1,550°F to 2,250°F for steel). This makes the metal highly malleable, requiring less force to shape while allowing for significant deformation. MAIKONG’s hot forging capabilities produce components with excellent grain structure and mechanical properties.

Warm Forging

Conducted at temperatures between cold and hot forging (typically 800°F to 1,500°F for steel). This intermediate approach combines some benefits of both methods, offering better precision than hot forging while requiring less force than cold forging. Our warm forging processes deliver excellent dimensional control with good strength characteristics.

Cold Forging

Performed at room temperature or slightly elevated temperatures below the recrystallization point. Cold forging produces parts with excellent dimensional accuracy and surface finish. MAIKONG’s cold forging capabilities are ideal for high-precision components that require minimal post-processing.

Classification by Equipment and Tooling

Different forging equipment produces varying results and is suitable for different applications:

| Equipment Type |

Characteristics |

Ideal Applications |

| Hammer Forging |

Uses impact force; excellent for directional grain flow |

Complex shapes, aerospace components |

| Press Forging |

Uses continuous pressure; better internal deformation |

Precision components, automotive parts |

| Roll Forging |

Uses rotating dies; creates elongated parts |

Shafts, axles, leaf springs |

| Upset Forging |

Increases cross-section by compressing length |

Fasteners, bolts, valve bodies |

Advanced Forging Procedures at MAIKONG

MAIKONG employs a comprehensive range of forging methods to address diverse manufacturing requirements. Each technique offers distinct advantages for specific applications and materials.

MAIKONG’s state-of-the-art forging equipment in our GD, SZ facility

Open Die Forging

In open die forging, metal is shaped between flat or simply shaped dies that don’t completely constrain the metal. This versatile process is ideal for large or unique parts with simple geometries. MAIKONG’s open die forging capabilities handle components weighing from a few pounds to several tons, with applications in power generation, oil and gas, and heavy machinery.

Closed Die Forging

Also known as impression die forging, this method shapes metal within two dies containing the negative impression of the desired part. The metal flows to fill the die cavity under extreme pressure. MAIKONG’s closed die forging delivers complex geometries with excellent mechanical properties, making it ideal for critical components in automotive, aerospace, and defense applications.

Precision Forging

Precision forging creates near-net-shape components with minimal need for secondary machining. MAIKONG’s precision forging capabilities achieve tight tolerances and excellent surface finishes, reducing production costs while maintaining superior mechanical properties. This approach is particularly valuable for high-volume production of complex components.

Need Custom Forged Components?

MAIKONG offers comprehensive forging solutions tailored to your specific requirements. Our engineering team can help select the optimal forging procedure for your application.

Get A Quick Quote

Roll Forging

Roll forging uses rotating dies to gradually shape metal, creating parts with excellent grain flow and reduced material waste. MAIKONG’s roll forging processes are ideal for elongated components like shafts, axles, and connecting rods, offering superior strength-to-weight ratios compared to machined parts.

Upset Forging

Upset forging increases the diameter of a workpiece by compressing its length. MAIKONG employs this technique for manufacturing fasteners, valve bodies, and similar components with varying cross-sections. The process creates excellent grain flow and mechanical properties in the enlarged areas.

The Superior Benefits of Forged Metal Parts

Microstructure comparison: Forged metal (left) vs. cast metal (right)

Forging vs. Casting: Why Choose Forged Components

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Critical Applications |

Structural members and load-bearing components |

Limited suitability for critical applications |

Key Advantages of MAIKONG’s Forging Processes

- Enhanced mechanical properties through optimized grain structure

- Superior strength-to-weight ratio, especially in aluminum forgings

- Excellent fatigue resistance for critical components

- Improved impact toughness and fracture resistance

- Consistent material properties throughout the component

- Absence of internal defects like porosity or shrinkage cavities

- Cost-effective production for medium to high volumes

Materials Compatible with MAIKONG’s Forging Procedures

MAIKONG’s advanced forging capabilities accommodate a wide range of metals and alloys, each offering unique properties for specific applications.

Various metal alloys processed at MAIKONG’s forging facility

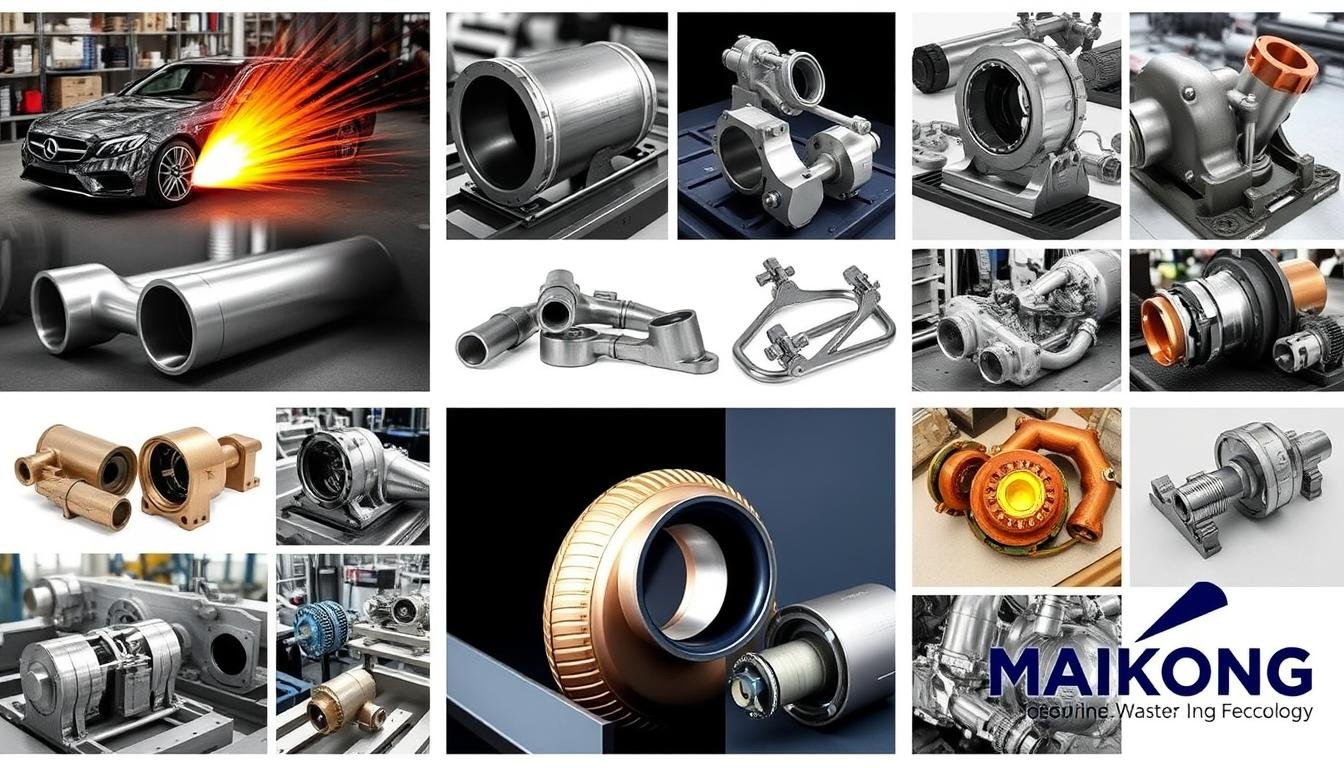

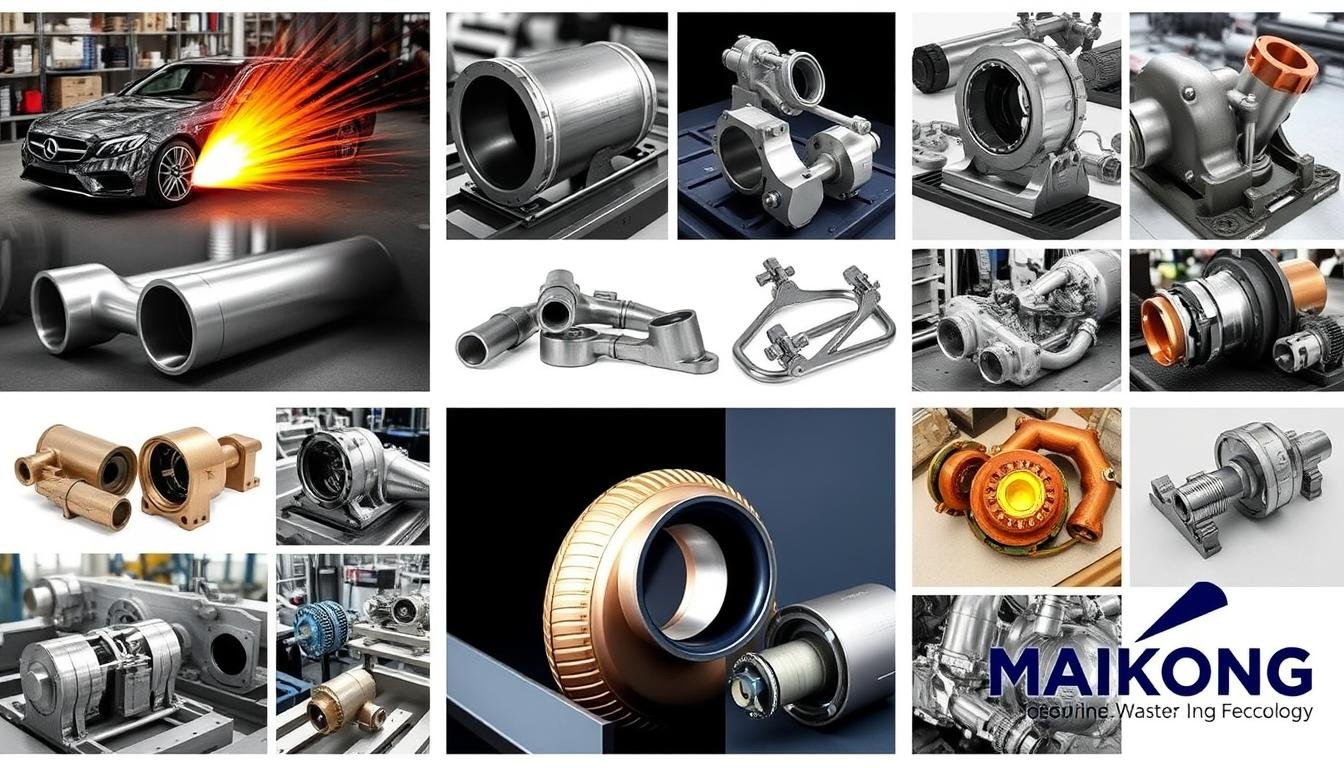

Aluminum Alloys

MAIKONG specializes in aluminum forging, working with series 2xxx, 6xxx, and 7xxx alloys. These lightweight materials offer excellent strength-to-weight ratios, making them ideal for aerospace, automotive, and sporting goods applications. Our aluminum forging processes create components with superior grain structure and mechanical properties.

Steel Alloys

As a leading steel forging company, MAIKONG processes carbon steels, alloy steels, and tool steels. These materials provide exceptional strength, hardness, and wear resistance for applications in heavy machinery, oil and gas, and industrial equipment. Our steel forging capabilities handle components from small precision parts to large industrial elements.

Specialty Metals

MAIKONG’s advanced forging procedures extend to specialty metals including brass, copper alloys, and titanium. These materials offer unique combinations of properties such as corrosion resistance, electrical conductivity, and biocompatibility for specialized applications in marine, electrical, and medical industries.

The MAIKONG Forging Process: From Design to Delivery

At MAIKONG, we’ve developed a comprehensive approach to forging that ensures quality at every stage. Our process combines technical expertise with rigorous quality control to deliver superior custom metal parts.

MAIKONG’s end-to-end forging process workflow

Our Comprehensive Forging Workflow

- CAD/CAM Engineering: Our process begins with advanced computer-aided design and manufacturing. MAIKONG’s engineering team uses sophisticated simulation tools to optimize part design for forging, identifying potential issues before production begins.

- Material Selection: We carefully select the optimal material based on mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness for your specific application.

- Tooling Design: MAIKONG’s tooling experts design and manufacture precision dies that ensure consistent quality and optimal grain flow in the finished parts.

- Forging Operation: Using our state-of-the-art equipment, we execute the selected forging procedure with precise control of temperature, pressure, and timing to achieve optimal results.

- Heat Treatment: In-house heat treatment capabilities allow us to enhance mechanical properties through carefully controlled heating and cooling cycles.

- Precision Machining: MAIKONG’s CNC machining services provide secondary operations to achieve final dimensions and features with tight tolerances.

- Surface Treatment: We offer various finishing options including anodizing, painting, and plating to enhance appearance, corrosion resistance, and performance.

- Quality Inspection: Rigorous testing and inspection ensure every part meets or exceeds specifications before shipment.

Ready to Start Your Forging Project?

Contact MAIKONG today to discuss your custom metal part requirements. Our engineering team will help you select the optimal forging procedure for your application.

Contact via WhatsApp

Email Us

Industry Applications for MAIKONG’s Forged Components

MAIKONG’s custom forged parts serve critical functions across numerous industries, where their superior strength, durability, and reliability are essential.

MAIKONG forged components in various industry applications

Automotive

MAIKONG’s forged components are widely used in automotive applications including crankshafts, connecting rods, transmission gears, and suspension components. Our forging procedures create parts with the strength and durability to withstand the demanding conditions of modern vehicles.

Aerospace

The aerospace industry relies on MAIKONG’s precision forged parts for critical applications where failure is not an option. Our components meet stringent industry standards for structural integrity, weight optimization, and reliability in extreme conditions.

Industrial Machinery

MAIKONG supplies forged components for industrial equipment including gears, shafts, flanges, and structural elements. These parts deliver the strength and wear resistance needed for continuous operation in demanding industrial environments.

Oil & Gas

The oil and gas sector uses MAIKONG’s forged components in valves, fittings, and structural elements that must withstand high pressures, extreme temperatures, and corrosive environments.

Medical Equipment

MAIKONG’s precision forging capabilities produce components for medical devices and equipment where reliability and biocompatibility are essential considerations.

Sporting Goods

Our aluminum forging services create lightweight, high-strength components for bicycles, golf clubs, and other sporting equipment where performance is paramount.

MAIKONG’s Comprehensive Manufacturing Capabilities

Beyond our core forging expertise, MAIKONG offers a complete range of manufacturing services to meet all your custom metal part needs.

MAIKONG’s advanced CNC machining center

CNC Machining Services

MAIKONG’s state-of-the-art CNC machining center complements our forging capabilities, providing precision secondary operations for forged components. With over 60 CNC machines and 100+ tons of monthly processing capacity, we offer:

CNC Turning Services

Ideal for creating precise cylindrical shapes, deep holes, and machined threads with superior surface finishes. MAIKONG’s CNC turning capabilities deliver fast turnaround on precision manufactured parts.

CNC Milling Services

Our multi-axis CNC milling equipment creates complex prismatic shapes and flat surfaces with high accuracy. These flexible machines require no fixed tooling while maintaining extreme precision.

CNC SWISS Type Machining

Specialized in precision small parts and long shaft components, our Swiss-type machining equipment features dual spindles and multi-axis capabilities for one-stop manufacturing solutions.

Precision CNC Machining

MAIKONG’s precision machining services achieve tight tolerances and excellent surface finishes for critical components across various industries.

Quality inspection of forged components at MAIKONG

Quality Assurance

At MAIKONG, quality is built into every step of our manufacturing process. Our comprehensive quality management system includes:

- ISO 9001:2015 certified quality management system

- Advanced material testing laboratory for precise material verification

- Dimensional inspection using state-of-the-art measuring equipment

- Non-destructive testing capabilities for critical components

- Statistical process control for consistent quality

- Comprehensive documentation and traceability

Partner with MAIKONG for Superior Custom Metal Parts

MAIKONG combines decades of forging expertise with cutting-edge technology to deliver custom metal parts that exceed expectations. Our comprehensive capabilities, from design engineering to final inspection, ensure quality at every stage of production.

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

With our cost-effective manufacturing solutions and commitment to customer satisfaction, MAIKONG is the ideal partner for your custom forging and machining needs. We’re actively seeking agents throughout the United States to represent our quality products and services.

Contact MAIKONG Today

Ready to discuss your custom metal part requirements? Our engineering team is standing by to help you select the optimal forging procedure for your application.

Email: Lucy@maikongforge.us | Website: https://maikongforge.us

Become a MAIKONG Agent in the US

MAIKONG is seeking representatives throughout the United States to promote our high-quality forging and machining services. If you’re interested in becoming an agent for our cost-effective manufacturing solutions, contact us today to discuss partnership opportunities.

State-of-the-art forging operations at MAIKONG’s GD, SZ facility

State-of-the-art forging operations at MAIKONG’s GD, SZ facility