In today’s global manufacturing landscape, understanding the nuances of the forging process is crucial for procurement professionals seeking high-quality metal components. This comprehensive guide demystifies forging terminology, techniques, and quality considerations to help US procurement teams make informed sourcing decisions. Whether you’re evaluating suppliers for automotive parts, aerospace components, or industrial equipment, mastering these concepts will empower you to communicate effectively with manufacturers and secure components that meet your exact specifications.

What Is The Forging Process?

Modern forging operation at MAIKONG’s GD, SZ facility

Modern forging operation at MAIKONG’s GD, SZ facility

The forging process is a manufacturing method that shapes metal using compressive forces. When metal is heated to elevated temperatures, it becomes malleable, allowing manufacturers to employ manual force, hydraulic presses, and specialized equipment to shape it with precision. Unlike casting, which involves pouring molten metal into molds, forging works by applying pressure to solid metal, resulting in superior mechanical properties.

Most forged products today are manufactured using electrically powered presses, though certain specialty items still employ traditional manual methods. The process creates components with refined grain structure, higher fatigue resistance, and superior strength compared to other manufacturing methods.

Metals Commonly Used in the Forging Process

- Alloy steel

- Aluminum and aluminum alloys

- Brass and copper

- Carbon steel

- Duplex steel

- Nickel alloys

- Stainless steel

- Titanium

- Tool steel

Generally, metals that aren’t highly brittle can undergo forging. Materials like cast iron, certain high-carbon steels, and other brittle alloys are unsuitable due to their inability to withstand impact loads during the forging operation.

How to Classify Forging Processes

To better understand the various types of forging processes, we can classify them using two primary methods: by temperature and by tooling/equipment used.

Classification by Temperature

Temperature ranges for different forging classifications

Hot Forging

Hot forging is the original forging procedure where metal is heated above its recrystallization temperature, typically between 0.3 to 0.4 times the melting point for pure metals and approximately halfway for alloys. At MAIKONG, we typically work with steel at temperatures ranging from 850 to 1150 degrees Celsius, while aluminum is forged at temperatures up to 500 degrees Celsius.

Advantages of hot forging include:

- Lower required compressive force

- Enhanced material plasticity

- Ability to work with harder materials

- Improved grain structure

- Elimination of work hardening

- Greater material deformation possible

- Reduced energy requirements

- Suitable for complex geometries

However, hot forging has several disadvantages, including lower precision, rougher surface finish, and susceptibility to defects such as oxidation, decarburization, and burn damage.

Warm Forging

In warm forging, metal is heated above room temperature while remaining significantly below the recrystallization temperature. This makes the metal more pliable while providing better precision than hot forging. Compared to hot forging, warm forging results in smoother surfaces and greater dimensional accuracy, but requires higher deformation forces to shape the metal.

Cold Forging

Cold forging occurs at room temperature without heating the metal. Instead, compressive forces are applied to shape the material directly. This technique yields superior surface finishes, high dimensional accuracy, and parts that are ready for immediate use. Additionally, cold forging is one of the simplest processes to automate.

The main challenges with cold forging include the requirement for high-tonnage presses (as significant compressive forces are necessary) and the increased risk of cracking due to low plasticity at lower temperatures.

Expert Forging Solutions from MAIKONG

With over 20 years of experience in precision forging, MAIKONG offers comprehensive manufacturing solutions for your custom metal components. Our state-of-the-art facility in GD, SZ specializes in aluminum, steel, and brass forging with superior quality control.

Get A Quick Quote

Classification by Tooling and Equipment

Traditionally, blacksmiths used rudimentary equipment such as hammers and anvils for forging. The Industrial Revolution introduced mechanical and hydraulic-powered presses and upsetters, using dies to produce more complex shapes. Today’s advanced forging operations employ sophisticated equipment for precision and efficiency.

Types of Forging Methods

The forging process branches into various methods depending on factors such as process layout, types of parts produced, level of automation, and equipment used. Here are some of the most popular forging processes used today:

Drop Forging

Drop forging operation at MAIKONG’s production facility

Drop forging is a manufacturing process in which a drop hammer is released onto a workpiece from a specific height. The workpiece is positioned on a stationary anvil, and the forces generated by multiple impacts gradually compress it into the desired shape.

Drop forging can be categorized into two types:

Open Die Forging

In open die forging, there is no die positioned above the workpiece; instead, the hammer makes direct contact with the surface. A variation called “cogging” secures the material using metal claws while manipulators approach from multiple directions to alter its shape.

Closed Die Forging

Also known as impression-die forging, closed-die forging encapsulates the workpiece within the die. The desired final shape is cast into one or both dies (top and bottom). As the hammer strikes the top die, it forces the metal to fill the die cavity.

The counterblow process is a variation that uses high-pressure air or oil to accelerate forging die cavities toward one another, allowing the metal stock to conform to the shape of the dies.

Press Forging

Press forging uses a principle similar to drop forging; however, instead of relying on impact, it applies a continuous force that lasts longer—a controlled squeezing rather than a sudden impact.

The continuous pressure in press forging results in plastic deformation throughout the entire volume of the part, unlike drop forging, which primarily affects the surface layer. Forging presses can use either cold or hot forging processes.

Upset Forging

Upset forging, also known as heading, uses a series of dies to deform or upset one end of a workpiece. This process is commonly used to increase the cross-section of round bars at one end to form articles such as nails, bolts, and screws.

The round bar is secured using gripping dies, while another die advances toward the exposed end, compresses it, and alters its shape.

Automatic Hot Forging

Automatic hot forging provides a quick and efficient means of mass-producing blanks or finished products from steel bars. Steel bars with specified lengths are fed into the machine, induction-heated, descaled, cut, and forged into finished products within seconds.

The parts may undergo several forming stages inside the machine, and the output is sometimes sent for cold or precision forging to obtain additional benefits in the finished product.

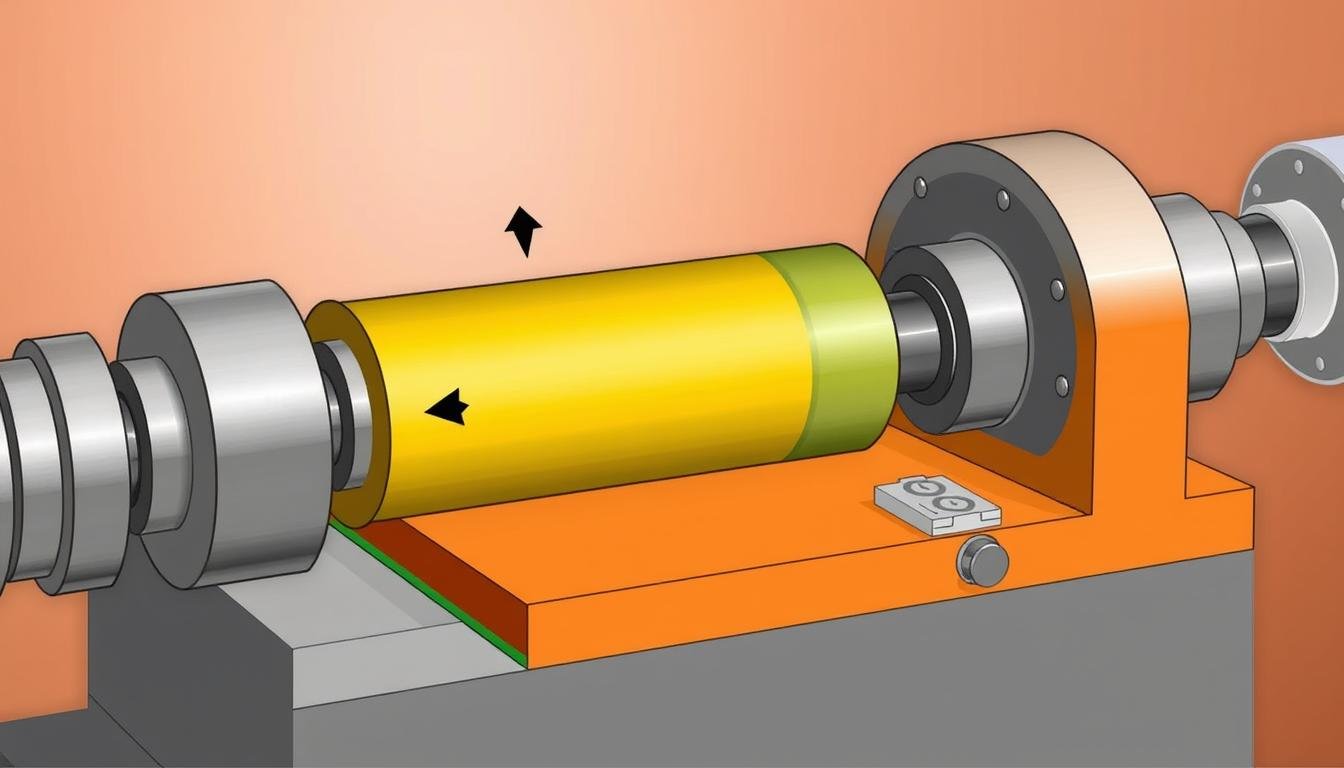

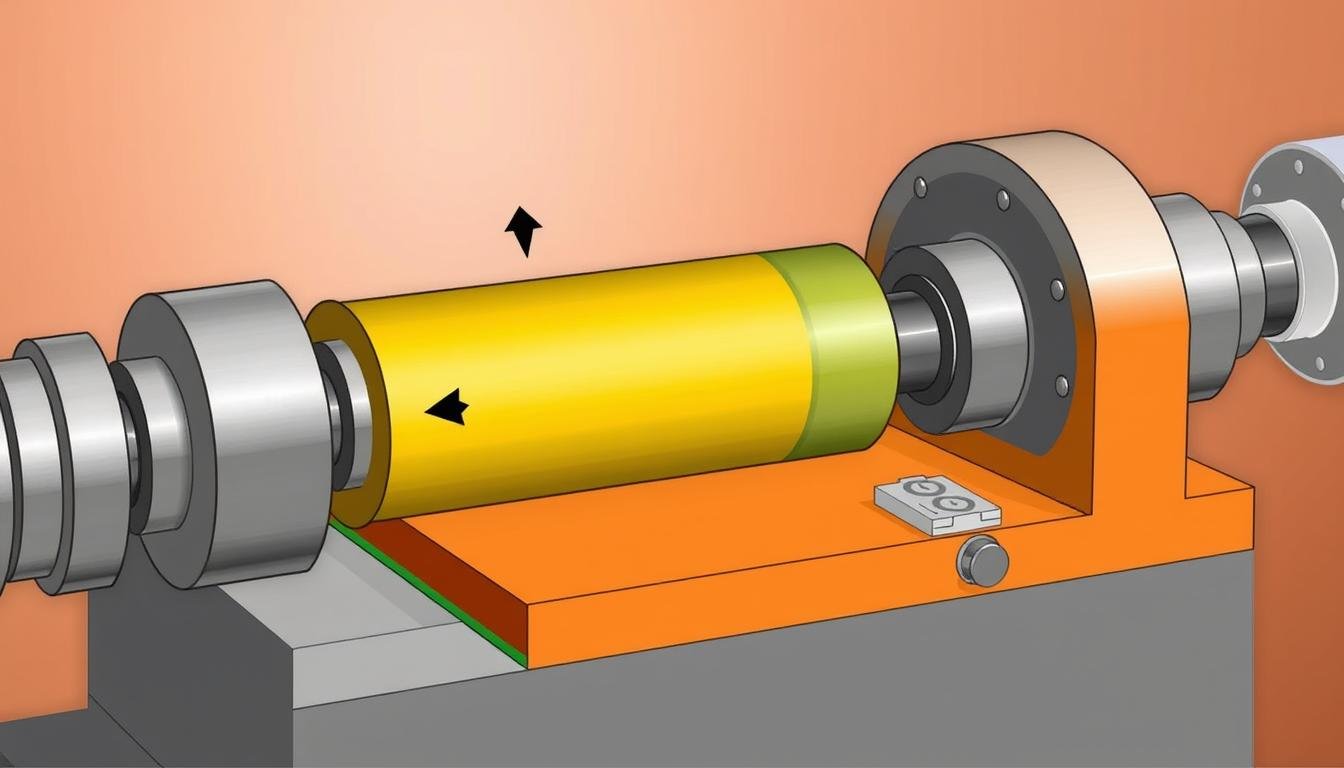

Roll Forging

Roll forging process diagram

Roll forging is a specialized process that can produce parts with unique cross-sections at a large scale. It involves two opposing rolls that receive long bars with either flat or round cross-sections. As the bar passes through the gap between the rolls, it’s compressed, resulting in reduced thickness and increased length.

The part may be reversed and passed again through the same or different rollers if the final product requires multiple stages. Roll forging can be hot or cold, with hot forging requiring lighter compressive forces while providing excellent grain structure.

Rolled Ring Forging

The rolled ring forging process produces seamless metal rings. The process begins by piercing a cylindrical stock from the center to create a donut shape, with an idler roller positioned in this hollow center. The workpiece is rotated and manipulated using two different sets of rollers.

This process is typically used for critical components such as gears, clutches, and bearings, which require seamless parts for both functional and safety purposes.

Precision Forging

Precision forging, also known as net-shape or near-net shape forging, is conducted at significantly lower temperatures than hot forging, allowing for enhanced precision. For steel, the temperature range is typically between 750 and 950 degrees Celsius.

This is primarily a finishing process rather than a standalone operation. Components produced from other forging methods are sent for precision forging before being put to use or undergoing additional manufacturing processes.

Cold Forging for Precision

Precision forging can also be performed at near-ambient temperatures, commonly referred to as cold forging. This method yields highly accurate final dimensions and typically eliminates the need for additional finishing operations. However, it’s not suitable for all types of metals, and lubrication plays a crucial role in preserving the mating surfaces of the dies.

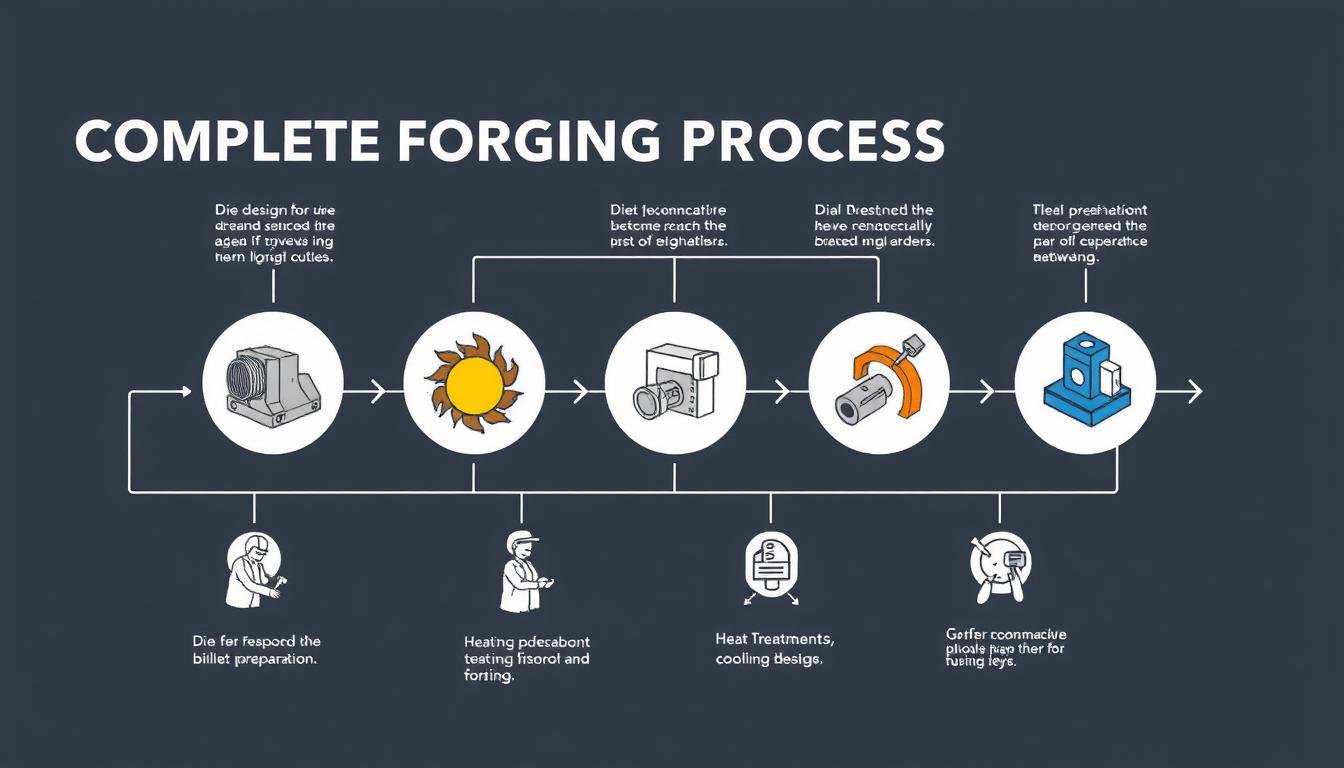

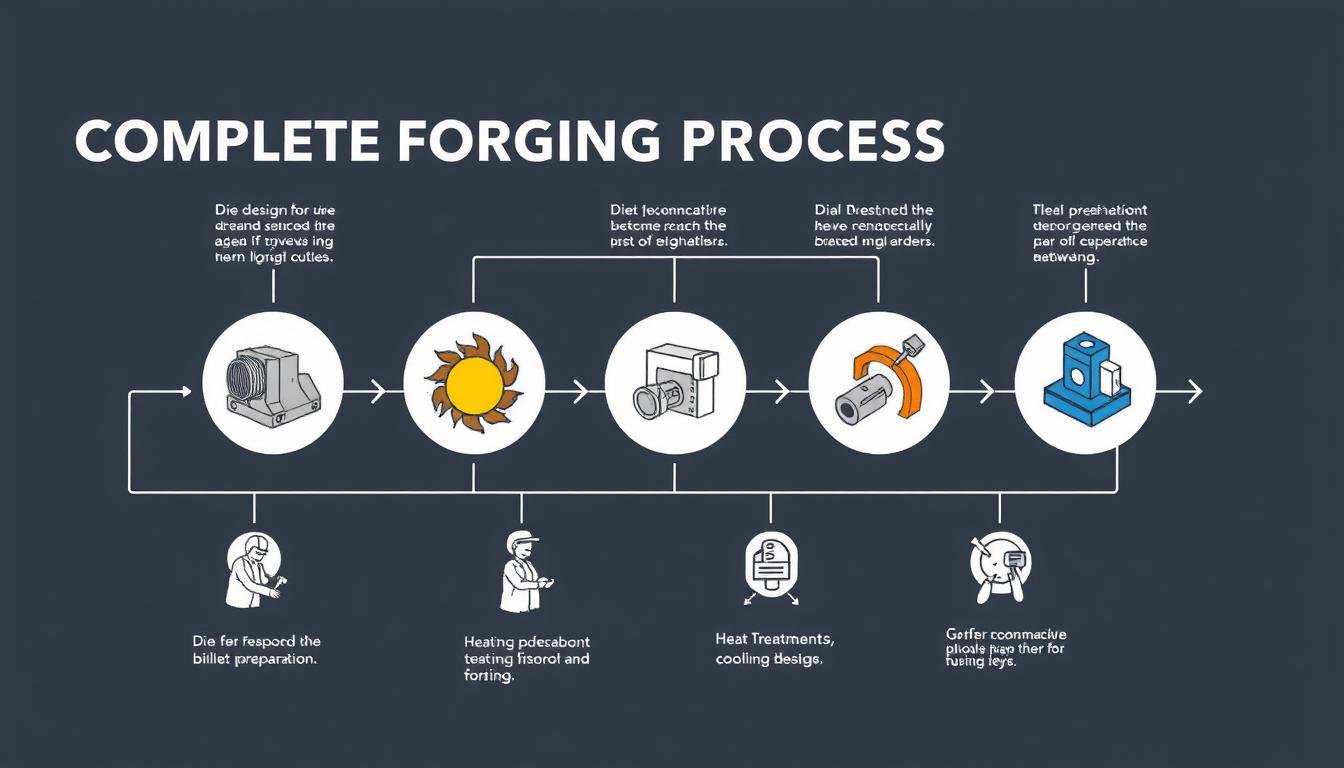

Essential Steps in the Forging Process

Complete forging process workflow at MAIKONG

Heat and high pressure soften most metals, allowing forging to be effective with a wide range of materials. However, because the properties of different metals vary, the forging process must be adapted accordingly. Here’s a typical forging process workflow:

Die Design and Manufacturing

Modern forging processes use dies to enhance accuracy, precision, and production speed. Die design and manufacturing is the first step in the forging process. A good die provides advantages such as better grain flow, good surface finish, less wastage, improved dimensional accuracy, and consistent production quality.

Billet/Ingot Preparation

Billets or ingots with varying cross-sections serve as raw materials for the forging process. Depending on product specifications, the required lengths of appropriate cross-sections are cut and incorporated into the production line.

Heating

In this step, the metal is heated, typically in a furnace, to its forging temperature. The forging temperature for steel ranges from 850 to 1150 degrees Celsius, while the ideal forging temperature for aluminum is up to 500 degrees Celsius. The specific heating and soaking temperatures are determined based on the type of metal being used.

Forging Operation

The heated metal is moved to the die, where it’s pressed into shape. Multiple passes through various dies may be necessary to achieve the final form. Additionally, the part may require reheating between presses to maintain optimal formability.

Heat Treatment

Most components undergo heat treatment following forging to enhance specific mechanical properties, including strength and hardness. Common heat treatment processes include annealing, tempering, quenching, normalizing, solution treatment, and case hardening.

Cooling

Cooling presents an excellent opportunity to enhance properties such as strength and grain structure. By employing various cooling mechanisms and rates, desirable characteristics in forged components can be promoted.

Finishing

The component may require finishing operations such as machining, trimming, and surface treatment before it’s fit for use. Properties like corrosion resistance and aesthetic appeal can be enhanced by applying specific coatings during this stage.

| Process Step |

Key Considerations |

Quality Impact |

MAIKONG Capabilities |

| Die Design |

Material flow, draft angles, parting line |

Dimensional accuracy, surface finish |

Advanced CAD/CAM software, simulation tools |

| Billet Preparation |

Material selection, size calculation |

Material utilization, grain structure |

Precision cutting, material testing |

| Heating |

Temperature control, heating rate |

Formability, grain size |

Computer-controlled furnaces, temperature monitoring |

| Forging |

Press force, deformation rate |

Grain flow, mechanical properties |

Hydraulic presses, automation systems |

| Heat Treatment |

Temperature cycles, cooling rates |

Hardness, strength, ductility |

In-house heat treatment, statistical process control |

| Cooling |

Cooling method, cooling rate |

Residual stress, dimensional stability |

Controlled cooling systems, monitoring equipment |

| Finishing |

Surface requirements, tolerances |

Final appearance, performance |

CNC machining, grinding, surface treatments |

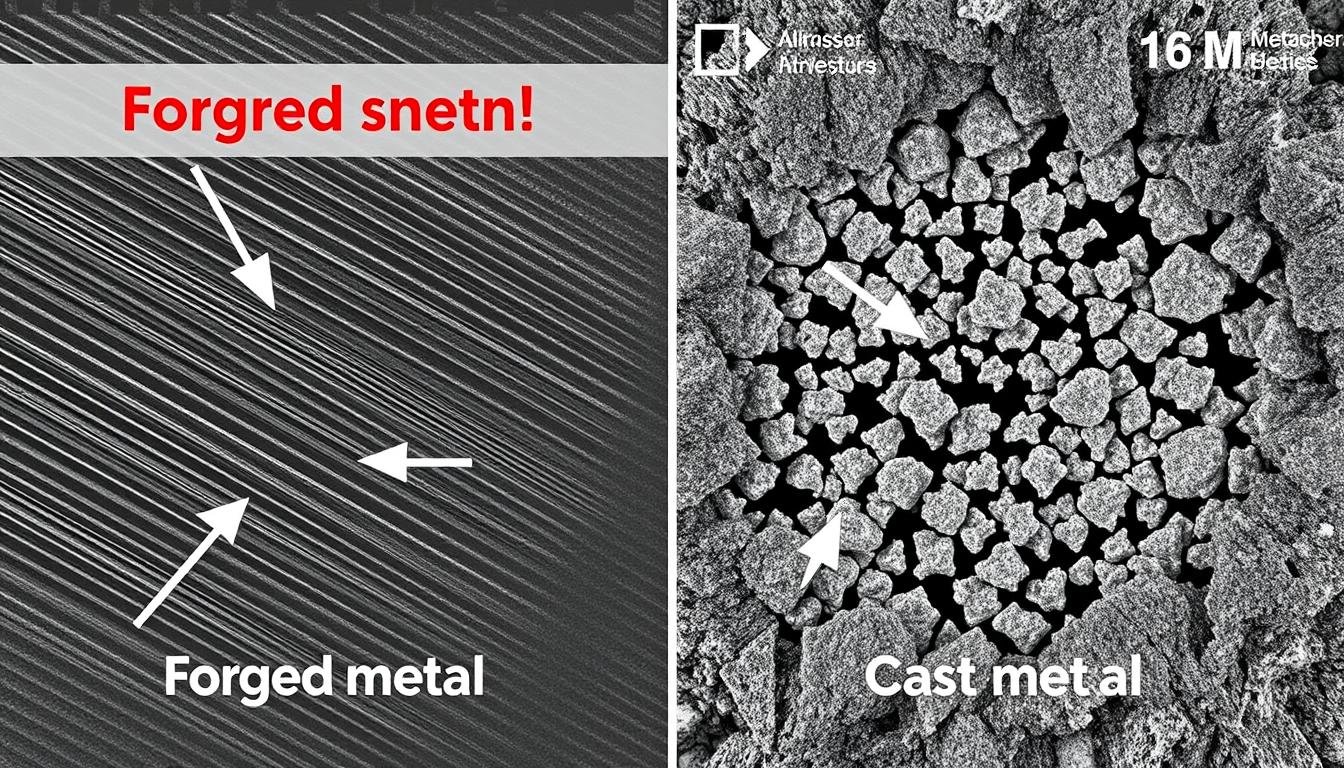

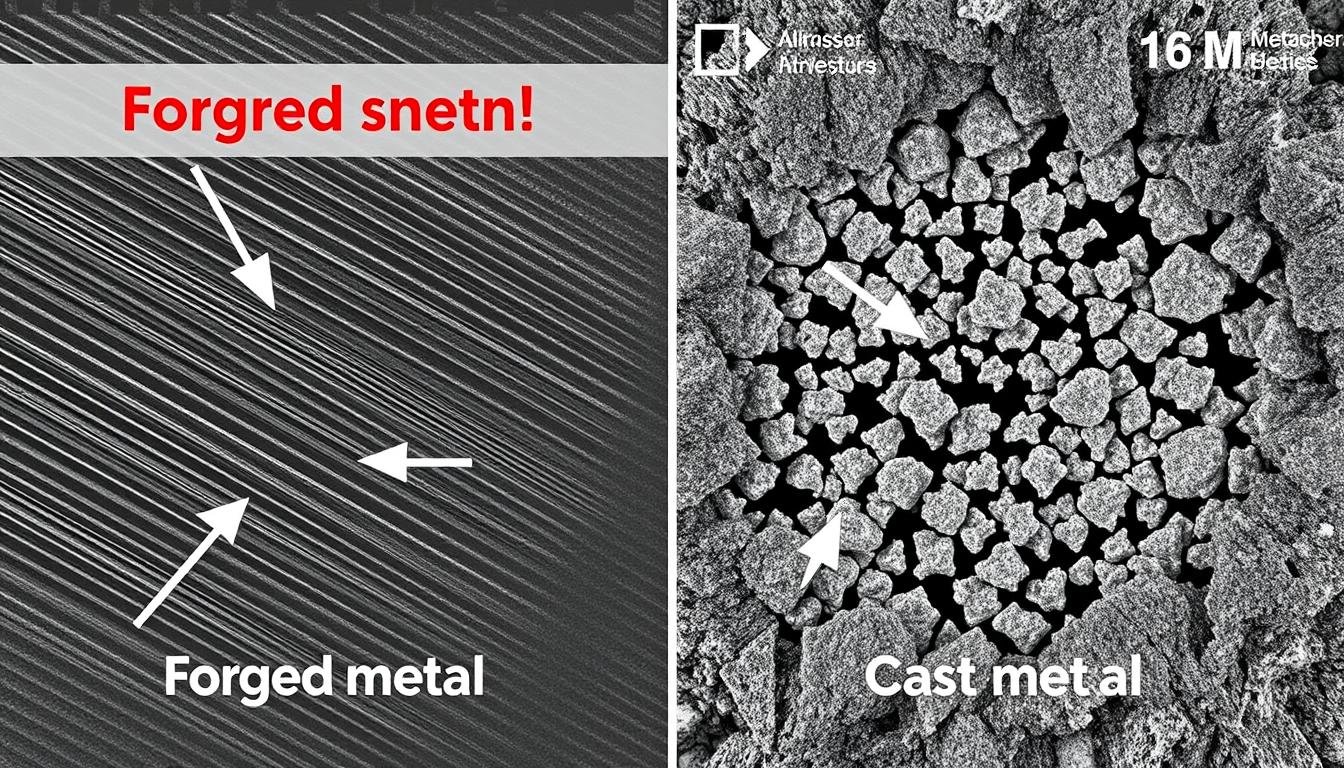

Why Choose Forging Process for Critical Components?

Microstructure comparison: Forged metal (left) vs. Cast metal (right)

Forging offers distinct advantages in metalworking. It’s a cost-effective and versatile method for producing high-strength, reliable products suitable for critical applications. The refined grain structure resulting from forging imparts exceptional directional strength and structural integrity.

Aluminum Forging and Optimal Strength-to-Weight Ratio

Strength-to-weight ratio is a fundamental engineering principle that addresses the balance between material strength and weight—an essential consideration in industries prioritizing performance, efficiency, and safety. Aluminum, recognized for its lightweight properties and robust mechanical characteristics, is enhanced through forging, refining its internal grain structure for enhanced resilience and strength.

This makes aluminum forgings the optimal choice for withstanding static and dynamic loads. With optimal strength-to-weight ratio showcasing engineering excellence, a combination of material science, metallurgy, and precision manufacturing is achieved. It embodies efficiency and performance, reshaping possibilities across industries.

The Advantage of Aluminum Forging over Casting

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Heat Treatment Response |

✅ Responsive for controlled material properties |

Less predictable response |

| Grain Structure |

✅ Directional grain flow for improved properties |

No directional grain structure |

| Weight-to-Strength Ratio |

✅ High strength-to-weight ratio |

Bulkier parts may be needed |

| Resistance to Corrosion |

✅ Improved due to denser structure |

Naturally forming oxide layer for resistance |

Need Custom Forged Components?

MAIKONG specializes in high-quality custom forging for critical applications. Our team can help you select the optimal forging process for your specific requirements.

Request a Consultation

MAIKONG’s Comprehensive Forging Process Capabilities

MAIKONG’s state-of-the-art forging facility in GD, SZ

At MAIKONG, we don’t just supply forged components; we consider how to best support the end application at each step of our one-stop forging process. We’ve established a comprehensive service center for metal forgings, providing technical support and solutions to our customers worldwide.

Full-Service Supply Center for Metal Forgings

Today, aluminum and its alloys are widely used in various industries due to their high mechanical properties such as high modulus of elasticity, tensile strength, and yield strength. These materials are essential in automotive manufacturing, aerospace, construction, and electronics industries.

Through proper deformation and grain flow, combined with material homogeneity, our forging process maximizes impact toughness, fracture toughness, and fatigue strength while ensuring consistent performance and quality of metal forgings.

Our Comprehensive Forging Services

CAD/CAM Design

Our engineering team utilizes advanced analysis software to facilitate early-stage issue identification and mitigation. This ensures optimal die design and process parameters before production begins.

Material Selection

We thoroughly consider the mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness of each alloy to ensure the optimal material for your application.

Tooling Design

Our tooling design ensures initial quality, while regular maintenance preserves consistency—both critical for producing high-quality forgings that meet precise specifications.

Forging Operations

Our forging workshop is equipped to accommodate diverse metal forging specifications, from small precision components to larger structural parts across various industries.

Heat Treatment

We conduct comprehensive statistical analysis and documentation for our in-house heat treatment processes, ensuring consistent mechanical properties across all components.

Surface Finishing

From automated grinding with specialized robots to remove parting lines to various surface treatments that enhance appearance and performance, we provide complete finishing solutions.

CNC Machining

Our machining workshop is equipped with state-of-the-art CNC machines capable of precise and intricate forging machining operations for complete component finishing.

Surface Treatment

We offer comprehensive surface treatments including anodizing, painting, laser engraving, and sand blasting to enhance both appearance and performance of forged components.

Quality Control

Our rigorous quality control procedures ensure that forged components meet stringent standards through comprehensive testing and inspection at every stage of production.

Quality Assurance and Testing

Quality inspection at MAIKONG’s material testing laboratory

As both a producer and consumer of our customers’ products, we recognize the crucial importance of consistency, strength, and weight in each forged part for the final product. With a dedicated focus on crafting superior forged parts, we can fulfill your requirements for heat treating, machining, and testing.

Our material laboratory plays a vital role in our production process, enabling us to achieve the precise results you demand. Our team is committed to delivering optimal outcomes by possessing a profound understanding of materials, their properties, and their interactions. We are devoted to ensuring that our products consistently meet the highest standards of quality and performance.

Since 2015, MAIKONG has held the ISO 9001:2015 certification, demonstrating our commitment to quality management systems and continuous improvement.

Advanced Manufacturing Facility

MAIKONG’s manufacturing facility, located in GD, SZ, houses a range of well-maintained forging equipment. Our strategic location presents us with logistical advantages, facilitating efficient receipt of raw materials and prompt dispatch of finished parts to our partners worldwide.

Our suite of machinery, encompassing hydraulic forging presses, uniform heat treatment furnaces, and precision-driven CNC machines, assures both the quality and volume of our production. The factory layout is planned to foster optimal efficiency. Our production lines have been engineered to minimize waste and expedite the manufacturing process.

This strategic arrangement ensures a smooth and uninterrupted flow of materials, right from the moment raw material enters our premises to the point where completed parts are prepared for dispatch.

Industrial Applications of the Forging Process

Sample forged components manufactured by MAIKONG

The forging process is incredibly versatile and can be applied to anything from small parts measured in inches to components that weigh up to 700,000 lbs. Forged products are used as structural components in numerous industries:

Automotive Components

The automotive industry relies heavily on forged components for critical parts that require high strength and durability. Common forged automotive parts include:

- Crankshafts and connecting rods

- Transmission gears and shafts

- Steering knuckles and control arms

- Wheel hubs and axle components

- Engine valves and valve stems

Aerospace Applications

The aerospace industry demands components with exceptional reliability and performance under extreme conditions. Forged aerospace components include:

- Landing gear components

- Turbine discs and blades

- Structural airframe components

- Engine mounts and brackets

- Control system components

Industrial Equipment

Heavy industrial equipment benefits from the superior strength and durability of forged components, particularly in high-stress applications:

- Gears and gear blanks

- Shafts and spindles

- Hooks, pins, and couplings

- Valves and fittings for high-pressure systems

- Heavy machinery components

Oil and Gas Industry

The oil and gas sector requires components that can withstand extreme pressures, temperatures, and corrosive environments:

- Valve bodies and bonnets

- Wellhead components

- Flanges and fittings

- Drill bits and drilling equipment

- Pressure vessel components

CNC machining of forged components at MAIKONG

MAIKONG’s Specialized Services

At MAIKONG, we offer a comprehensive range of metal manufacturing services to meet diverse industry needs:

- CNC Machining

- Metal Forging

- Precision Machining

- Custom Metal Parts

- Aluminum Forging Services

- Steel Forging

- Brass Forging

- CNC Milling Services

- CNC Turning Services

- Contract Manufacturing CNC

- CNC Prototyping

- Custom Metal Fabrication

Partnering with MAIKONG for Your Forging Process Needs

MAIKONG’s engineering team collaborating with clients

When you choose MAIKONG as your forging partner, you benefit from our comprehensive approach to metal component manufacturing. Our team collaborates with you from initial design through final production to ensure your components meet exact specifications and performance requirements.

Our Collaborative Process

- Requirement Analysis: Our team works with you to understand your specific needs, including material requirements, mechanical properties, dimensional tolerances, and production volumes.

- Design Optimization: Using advanced CAD/CAM tools, we optimize component design for the forging process, ensuring manufacturability while maintaining functional requirements.

- Material Selection: We help select the optimal material based on performance requirements, cost considerations, and availability.

- Process Planning: Our engineers develop a comprehensive forging process plan, including die design, heating parameters, and post-forging operations.

- Prototype Development: For new designs, we can produce prototype components for testing and validation before full production.

- Production: Once approved, we move to full-scale production with rigorous quality control at every stage.

- Secondary Operations: We provide complete finishing services including heat treatment, machining, and surface treatments.

- Quality Assurance: Every component undergoes comprehensive inspection and testing to ensure it meets all specifications.

Why US Procurement Teams Choose MAIKONG

MAIKONG Advantages

- Comprehensive one-stop manufacturing solution

- ISO 9001:2015 certified quality management system

- Advanced material testing laboratory

- Competitive pricing with high-quality results

- Experienced engineering team for technical support

- Flexible production capabilities for various volumes

- Complete secondary processing capabilities

- Streamlined communication with US clients

Ready to Discuss Your Forging Requirements?

Contact MAIKONG today to speak with our engineering team about your custom forging and machining needs. We’re seeking distribution partners and agents throughout the United States.

Email: Lucy@maikongforge.us

Get A Quick Quote

Conclusion: Mastering Forging Process Terminology for Procurement Success

Understanding the nuances of forging processes is essential for procurement professionals seeking high-quality metal components. By mastering the terminology and concepts outlined in this guide, you can communicate more effectively with manufacturers and make informed decisions when sourcing forged parts.

Forging continues to be a preferred manufacturing method for critical components due to its ability to produce parts with superior strength, durability, and performance characteristics. As forging technology advances, it becomes increasingly accurate and refined through the use of advanced materials and simulation techniques.

At MAIKONG, we combine traditional forging expertise with modern manufacturing capabilities to deliver exceptional quality and value. Our comprehensive services—from design and material selection through forging, heat treatment, machining, and finishing—provide a complete solution for your metal component needs.

Contact us today to discuss how our forging expertise can benefit your next project.

Modern forging operation at MAIKONG’s GD, SZ facility

Modern forging operation at MAIKONG’s GD, SZ facility