In today’s demanding manufacturing landscape, the structural integrity of metal components can make or break product performance. Forging presses stand at the forefront of metal forming technology, delivering unmatched strength, durability, and precision that alternative methods simply cannot achieve. At MAIKONG, we’ve perfected the art and science of metal forging to provide American manufacturers with components that withstand the most challenging conditions while maintaining optimal weight-to-strength ratios.

MAIKONG’s state-of-the-art

forging press facility in GD, SZ

The Critical Advantages of Forging Press Technology

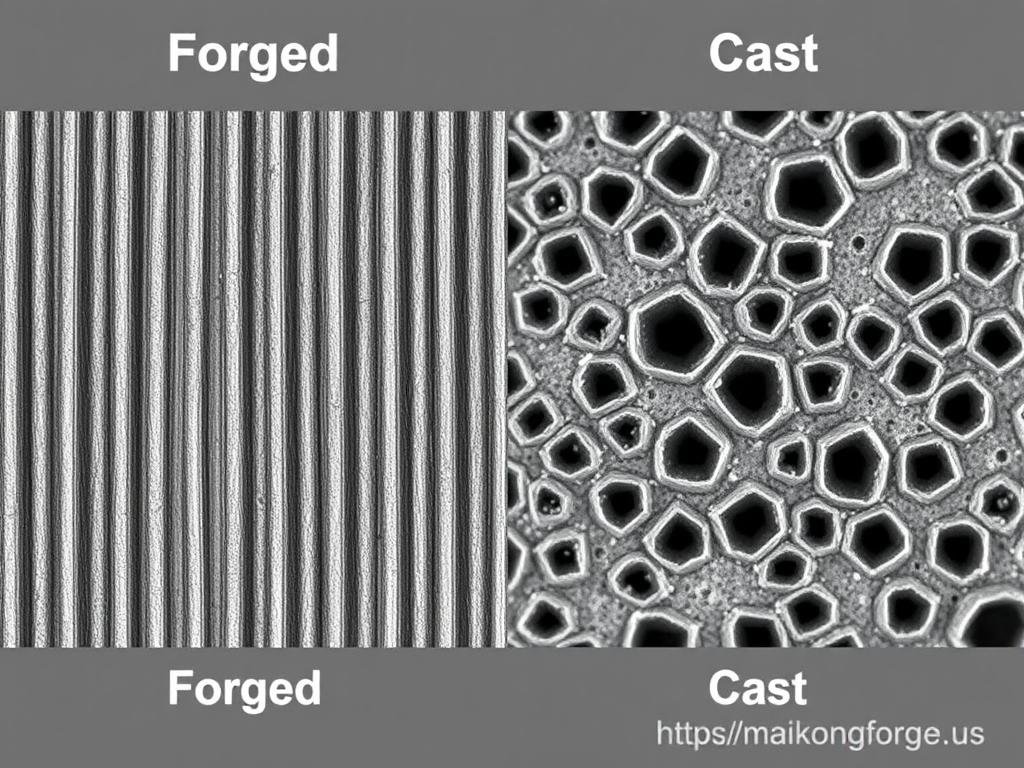

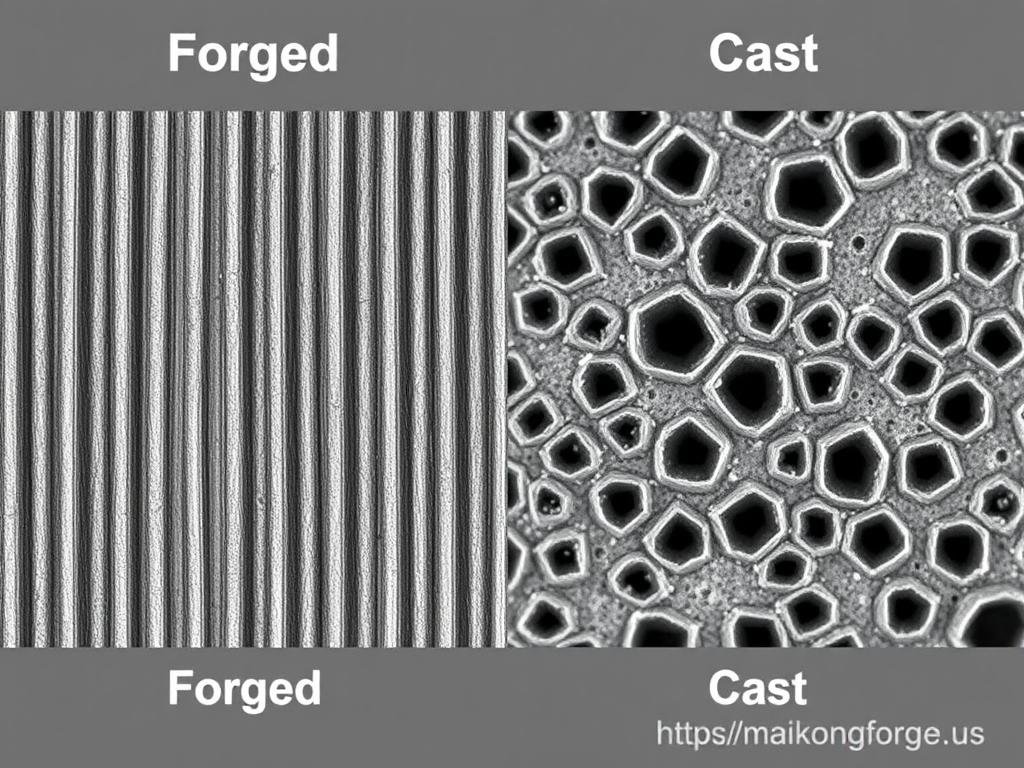

When performance matters, forging press technology delivers superior results through controlled deformation of metal. Unlike casting or machining alone, forging aligns the grain structure of metals, dramatically enhancing strength, durability, and fatigue resistance.

Enhanced Structural Integrity

The forging press process creates components with up to 26% higher tensile strength compared to cast parts. This translates to longer service life and improved safety margins for critical applications in aerospace, automotive, and industrial equipment.

Superior Grain Structure

Our hydraulic forging presses precisely control the metal flow, creating an optimized grain structure that follows the component’s shape. This directional strength is impossible to achieve with casting methods.

Ready to Enhance Your Metal Components?

Discover how MAIKONG’s forging technology can improve your product performance.

Get a Quick Quote

Forging vs. Casting: Why Forging Presses Deliver Superior Results

Understanding the fundamental differences between forging and casting is essential for making informed manufacturing decisions. Our forging press technology offers significant advantages over traditional casting methods.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Weight-to-Strength Ratio |

✅ High strength-to-weight ratio |

Bulkier parts may be needed |

| Critical Applications |

✅ Structural members and load-bearing capabilities |

Limited suitability for critical applications |

Microscopic comparison: Forged metal (left) shows aligned grain structure while cast metal (right) shows random grain pattern with potential voids

MAIKONG’s Advanced Forging Press Capabilities

With over 60 CNC machines and a monthly metal processing capacity exceeding 100 tons, MAIKONG stands as a leader in precision metal forging and machining. Our comprehensive capabilities ensure we can meet your most demanding requirements.

Metal Forging

Our hydraulic forging presses range from 500 to 2500 tons, capable of producing components from aluminum, steel, brass, and other alloys with exceptional precision.

CNC Machining

Complementing our forging press operations, our CNC machining services include turning, milling, swiss machining, and multi-axis machining for complete component finishing.

Quality Assurance

Our ISO 9001:2015 certified quality management system ensures every component produced on our forging presses meets the highest standards through rigorous testing and verification.

Experience MAIKONG Quality

Join the growing number of US manufacturers who trust MAIKONG for critical components.

Contact Us on WhatsApp

Industries Benefiting from MAIKONG Forging Press Technology

Our advanced forging press technology delivers critical advantages across multiple industries where performance, reliability, and safety are paramount.

Aerospace

Our forging press produces critical components where weight reduction and structural integrity are essential for safety and fuel efficiency. From landing gear components to structural elements, we deliver precision and reliability.

Automotive

From engine components to drivetrain parts, our forging press technology creates automotive components that withstand extreme stress, temperature variations, and continuous operation.

Industrial Machinery

Heavy equipment and industrial machinery rely on our forging press components to deliver consistent performance under extreme loads and harsh operating conditions.

Medical Devices

The biocompatibility and structural integrity of our forging press components make them ideal for medical implants, surgical instruments, and diagnostic equipment.

Our Comprehensive Forging Press Manufacturing Process

MAIKONG’s integrated approach ensures quality at every stage, from initial design through final inspection. Our forging press operations are supported by advanced CAD/CAM systems and rigorous quality control.

Design & Engineering

- Advanced CAD/CAM integration

- Finite Element Analysis (FEA)

- Material optimization

- Process simulation

Forging & Heat Treatment

- Precision die design

- Controlled forging press operations

- Customized heat treatment

- Grain structure optimization

Finishing & Quality Control

- Precision CNC machining

- Surface treatment options

- Dimensional verification

- Material property testing

Quality Assurance for Forging Press Components

At MAIKONG, quality isn’t just a department—it’s a core value embedded in every aspect of our forging press operations. Our comprehensive quality management system ensures consistent excellence.

Material Verification

Our in-house laboratory conducts comprehensive material testing to ensure every component produced on our forging presses meets exact specifications for chemical composition and mechanical properties.

Dimensional Inspection

Advanced coordinate measuring machines (CMMs) verify that all forging press components meet precise dimensional requirements, ensuring perfect fit and function in your assemblies.

ISO 9001:2015 Certified

MAIKONG maintains rigorous quality management systems certified to international standards, ensuring consistent quality across all our forging press operations.

Frequently Asked Questions About Forging Press Technology

What materials can be processed using MAIKONG’s forging presses?

MAIKONG’s advanced forging press technology can process a wide range of materials including aluminum alloys, carbon steel, stainless steel, titanium, brass, and specialty alloys. Our metallurgical expertise ensures optimal processing parameters for each material type.

What are the size limitations for components produced on your forging presses?

Our forging press capabilities range from small precision components weighing just a few ounces to large industrial components up to 50 pounds. The specific dimensional limitations depend on the complexity of the part and material type. Contact our engineering team for an assessment of your specific requirements.

How does MAIKONG ensure consistent quality across forging press production runs?

We implement a comprehensive quality management system that includes statistical process control, regular die maintenance, material verification, and both in-process and final inspections. Our ISO 9001:2015 certification ensures all forging press operations follow rigorous quality protocols.

What advantages do hydraulic forging presses offer over mechanical presses?

Hydraulic forging presses provide more precise control over force application, allowing for more complex geometries and better material flow. They also offer greater flexibility in terms of stroke length and dwell time, resulting in improved part quality and consistency, especially for complex components.

Have More Questions?

Our technical team is ready to address your specific inquiries about our forging capabilities.

Email Our Technical Team

Become a MAIKONG Forging Press Agent in the US

MAIKONG is actively recruiting agents across the United States to represent our premium forging press components and machining services. As a MAIKONG agent, you’ll gain access to our comprehensive range of high-quality metal components at competitive prices, backed by our technical expertise and reliable delivery.

Agent Benefits

- Exclusive territorial rights

- Competitive commission structure

- Technical training and support

- Marketing materials and samples

- Dedicated account manager

Ideal Agent Profile

- Established relationships with manufacturers

- Technical understanding of metal components

- Sales experience in industrial markets

- Commitment to customer service

- Drive to grow market share

Join the MAIKONG Agent Network

Expand your product portfolio with our premium forging and machining capabilities.

Apply to Become an Agent

Why Choose MAIKONG for Your Forging Press Components

MAIKONG combines advanced forging press technology with precision machining capabilities to deliver superior metal components that meet the most demanding requirements. Our commitment to quality, competitive pricing, and customer satisfaction has made us a trusted partner for manufacturers across industries.

From material selection through final inspection, our comprehensive approach ensures that every component leaving our facility meets the highest standards of quality and performance. Experience the MAIKONG difference today and discover why leading manufacturers trust our forging press expertise for their most critical applications.

Ready to Get Started?

Contact us today to discuss your specific requirements and discover how MAIKONG can enhance your product performance.

Get a Quick Quote

MAIKONG’s state-of-the-art forging press facility in GD, SZ

MAIKONG’s state-of-the-art forging press facility in GD, SZ