The manufacturing industry relies on precision equipment to create durable metal components. At the heart of metal forming technology stands the Forging Press – a powerful machine that shapes metal through controlled force application. For US industrial buyers seeking reliable metal forming solutions, understanding the capabilities, types, and applications of forging presses is essential for making informed purchasing decisions.This comprehensive guide explores everything you need to know about forging press technology, from basic principles to advanced applications. We’ll examine how MAIKONG’s precision engineering delivers exceptional value through superior craftsmanship, competitive pricing, and comprehensive support for US manufacturers.

Understanding Forging Press Technology

A forging press is a machine tool designed to shape metal through the application of pressure. Unlike hammering methods that use impact force, presses apply slow, controlled pressure to achieve precise deformation of metal workpieces. This controlled process results in superior grain structure alignment, enhancing the mechanical properties of the finished components.

The primary advantage of forging press technology is the ability to produce parts with exceptional strength-to-weight ratios and consistent internal structures. This makes pressed components ideal for applications where reliability and performance are critical.

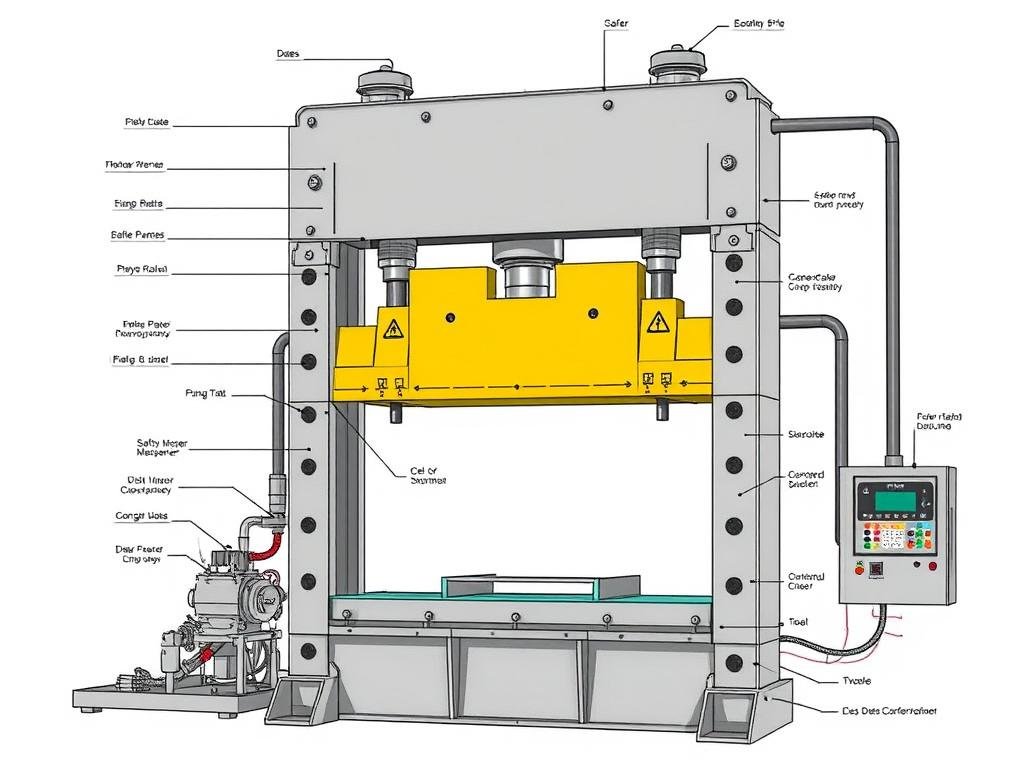

Key Components of a Forging Press

- Frame structure (provides rigidity and support)

- Power system (hydraulic, mechanical, or servo-electric)

- Die sets (tooling that shapes the metal)

- Control systems (manual or automated operation)

- Safety mechanisms (guards, emergency stops)

Types of Forging Presses for Industrial Applications

Industrial buyers should understand the different types of forging presses available to select the most appropriate equipment for their specific manufacturing needs. Each type offers distinct advantages for particular applications.

Hydraulic Forging Presses

Hydraulic forging presses utilize fluid pressure to generate force, offering precise control and consistent pressure throughout the stroke. These machines excel in applications requiring controlled deformation and are available in capacities ranging from small 10-ton shop models to massive 50,000-ton industrial units.

Advantages:

- Full pressure available throughout the entire stroke

- Adjustable pressure and speed settings

- Lower noise levels compared to mechanical presses

- Excellent for precision forming operations

Mechanical Forging Presses

Mechanical presses use a flywheel, clutch, and eccentric drive to generate force. They deliver high production rates and are ideal for high-volume manufacturing operations where consistent part geometry is required.

Advantages:

- Higher production speeds than hydraulic presses

- Greater energy efficiency for repetitive operations

- Lower maintenance requirements

- Excellent for high-volume production runs

Screw Presses for Specialized Applications

Screw presses utilize a vertical screw mechanism to generate force. These machines are particularly well-suited for precision forging operations and applications requiring controlled energy transfer.

Forging Press vs. Casting: Understanding the Differences

When considering metal forming methods, industrial buyers often compare forging and casting processes. Understanding these differences is crucial for selecting the appropriate manufacturing method for your specific requirements.

| Comparison Criteria |

Forging Process |

Casting Process |

| Internal Structure |

Dense, aligned grain structure |

Potential for porosity and inclusions |

| Mechanical Strength |

Superior strength and durability |

Lower tensile strength |

| Fatigue Resistance |

Excellent resistance to fatigue failure |

More susceptible to fatigue |

| Geometric Complexity |

Limited to simpler geometries |

Can achieve complex shapes |

| Dimensional Accuracy |

High precision with proper tooling |

Potential for inconsistencies |

| Material Wastage |

Minimal material waste |

Higher material loss |

| Production Volume |

Ideal for medium to high volumes |

Suitable for all production volumes |

Need Expert Guidance on Forging Solutions?

Our engineering team can help determine the optimal forging process for your specific application requirements.

Get Expert Consultation

MAIKONG’s Advanced Forging Press Capabilities

With over two decades of experience in precision metal forming, MAIKONG has established itself as a leading provider of high-quality forging solutions. Our state-of-the-art manufacturing facility in GD, SZ is equipped with advanced forging press technology and comprehensive quality control systems.

Our Comprehensive Metal Forming Services

CNC Machining Services

Our advanced CNC machining capabilities complement our forging operations, allowing for precise finishing of forged components. We offer turning, milling, and multi-axis machining services.

Precision Metal Forging

MAIKONG specializes in precision forging of various metals including aluminum, steel, and brass. Our forging presses range from 10 to 4,000 tons of capacity.

Custom Metal Parts

From concept to completion, we provide comprehensive custom metal part manufacturing services tailored to your specific requirements and industry standards.

Material Expertise

Aluminum Forging

Our aluminum forging services deliver components with exceptional strength-to-weight ratios, ideal for aerospace and automotive applications.

Steel Forging

We specialize in carbon and alloy steel forging for applications requiring maximum strength and durability in demanding environments.

Brass Forging

Our brass forging capabilities produce corrosion-resistant components with excellent electrical conductivity for specialized applications.

Quality Assurance in Forging Press Manufacturing

At MAIKONG, quality is built into every step of our manufacturing process. Our comprehensive quality management system ensures that all forged components meet or exceed industry standards and customer specifications.

Our Quality Control Process

- Material verification and testing before processing

- Die design validation using advanced simulation software

- In-process monitoring during forging operations

- Dimensional inspection using precision measuring equipment

- Mechanical property testing of finished components

- Surface quality inspection and non-destructive testing

Certifications and Standards

MAIKONG maintains rigorous quality management systems certified to international standards. Our commitment to quality ensures that every component produced on our forging presses meets the highest standards of performance and reliability.

Industrial Applications of Forging Press Technology

Forging press technology plays a critical role across numerous industries where high-strength, reliable metal components are essential. MAIKONG’s forging capabilities serve diverse sectors with customized solutions.

Automotive Industry

Forged components for engine parts, transmission systems, steering mechanisms, and suspension components where strength and durability are paramount.

Aerospace Applications

Precision forged parts for aircraft engines, landing gear components, and structural elements requiring exceptional reliability and performance.

Industrial Equipment

Heavy-duty forged components for manufacturing equipment, power generation systems, and industrial machinery operating in demanding environments.

Ready to Discuss Your Specific Application?

Our engineering team can help develop custom forging solutions tailored to your industry requirements.

Contact Our Engineers

US Distribution Opportunities for MAIKONG Forging Press Products

MAIKONG is actively seeking distribution partners throughout the United States to represent our high-quality forging products and services. We offer competitive terms, comprehensive support, and exceptional product quality to help our partners succeed in the US market.

Benefits of Partnership

- Exclusive territorial rights

- Competitive pricing structure

- Technical training and support

- Marketing materials and assistance

- Reliable supply chain and logistics

- Comprehensive product warranty

Become a MAIKONG Distribution Partner

Join our growing network of successful distributors and bring MAIKONG’s premium forging solutions to your market.

Explore Distribution Opportunities

Why Choose MAIKONG for Your Forging Press Needs

MAIKONG combines decades of forging expertise with state-of-the-art manufacturing capabilities to deliver exceptional value to US industrial buyers. Our commitment to quality, competitive pricing, and comprehensive customer support makes us the ideal partner for your metal forming requirements.

The MAIKONG Advantage

- Superior product quality and consistency

- Competitive pricing and excellent value

- Comprehensive technical support

- Flexible manufacturing capabilities

- Reliable delivery and logistics

- Extensive material expertise

Ready to Transform Your Metal Forming Capabilities?

Contact MAIKONG today to discuss how our forging press solutions can enhance your manufacturing operations.

Visit Our Website