In the demanding world of metal fabrication, the forging press stands as the cornerstone of precision manufacturing. At MAIKONG, we’ve dedicated ourselves to mastering this essential technology, delivering superior quality presses that combine power, precision, and reliability. Our expertise spans across hydraulic and mechanical forging press systems, providing American manufacturers with the tools they need to excel in today’s competitive market.Whether you’re seeking robust hydraulic presses for heavy-duty applications or specialized mechanical systems for precision work, our comprehensive range of forging press solutions offers unmatched performance at competitive prices. Join the growing network of satisfied MAIKONG customers across the USA who trust our technology to power their manufacturing excellence.

Understanding Forging Press Technology: Types and Applications

The forging press industry has evolved significantly, with various technologies designed to meet specific manufacturing needs. Understanding these different press types is crucial for selecting the right equipment for your operation. MAIKONG offers comprehensive solutions across all major categories.

Hydraulic Forging Press Systems

Hydraulic presses utilize fluid pressure to generate force, offering precise control and consistent pressure throughout the stroke. These systems excel in applications requiring controlled deformation and are ideal for materials that demand slower squeezing operations.

- Adjustable force and speed settings

- Excellent for open die forge applications

- Ideal for isothermal forging processes

- Available in capacities from 17 to 40 tons

- Lower die contact time for extended tool life

Mechanical Forging Press Technology

Mechanical presses employ a motor-driven system with an eccentric crankshaft that delivers a constant stroke length. These presses achieve maximum force near the bottom of the stroke, making them perfect for precision forging operations.

- Higher production rates (up to 70 strokes per minute)

- Best suited for low-profile forgings

- Automatic ejection capabilities

- Reduced draft requirements

- Less operator skill required compared to hammers

Find Your Ideal Forging Press Solution

Not sure which press technology best suits your manufacturing needs? Our engineering team is ready to analyze your requirements and recommend the perfect solution.

Get Expert Recommendation

Screw Press Technology: Precision and Power Combined

The screw press represents a remarkable balance of power and precision in the forging press family. These systems convert angular kinetic energy into linear force through a flywheel and screw assembly, delivering controlled and powerful strokes ideal for precision forging operations.

Key Advantages of MAIKONG Screw Presses

- Programmable blow control for both stroke and force

- Reduced die contact time for extended tool life

- Consistent and repeatable blow force

- Reduced draft angles to minimize waste material

- Simplified die setting procedures

- Energy-efficient operation

Drive System Options

- Friction drive systems for traditional applications

- Direct electric drive for enhanced control

- Gear drive with slipping clutch for larger capacity machines

- Hydraulic clutch drive for fastest cycling times

- Available in various tonnage ratings

Featured Product: MAIKONG SP-3000 Screw Press

Our flagship screw press combines advanced hydraulic clutch technology with precision control systems, delivering unmatched performance for demanding applications. With programmable stroke and force settings, the SP-3000 maximizes efficiency while minimizing energy consumption.

| Specification |

Value |

| Maximum Force |

3000 kN |

| Stroke Length |

300-500 mm (adjustable) |

| Drive System |

Hydraulic Clutch |

| Control System |

Digital PLC with touchscreen |

| Energy Efficiency |

Class A+ rating |

Upset Forging Technology: Specialized Shaping Solutions

Upset forging, sometimes called heading, is performed on horizontal forging machines known as upsetters. This specialized forging press technology excels at enlarging and reshaping specific sections of bars or tubes, creating complex profiles with exceptional material properties.

The Upset Forging Process

In its simplest form, hot upset forging holds heated stock between two half dies while applying pressure to the end of the stock in the direction of its axis. This pressure causes the metal to upset (spread) through controlled displacement. Modern upset forging machines employ multiple pass tooling to produce complex shapes with remarkable accuracy and consistency.

Applications of Upset Forging

- Shaft-type parts production

- Headed bolts and fasteners

- Flanged shafts and components

- Cluster gears manufacturing

- Wrench sockets requiring simultaneous upsetting and piercing

- Center or offset deformation requirements

MAIKONG Upsetter Advantages

- Multi-pass tooling capabilities

- Precise die alignment systems

- Automated material handling

- Programmable force control

- Quick-change die systems

- Enhanced operator safety features

Explore Our Upset Forging Solutions

MAIKONG offers comprehensive upset forging systems designed for efficiency, precision, and reliability. Contact our team to discuss your specific requirements.

Discuss Your Project on WhatsApp

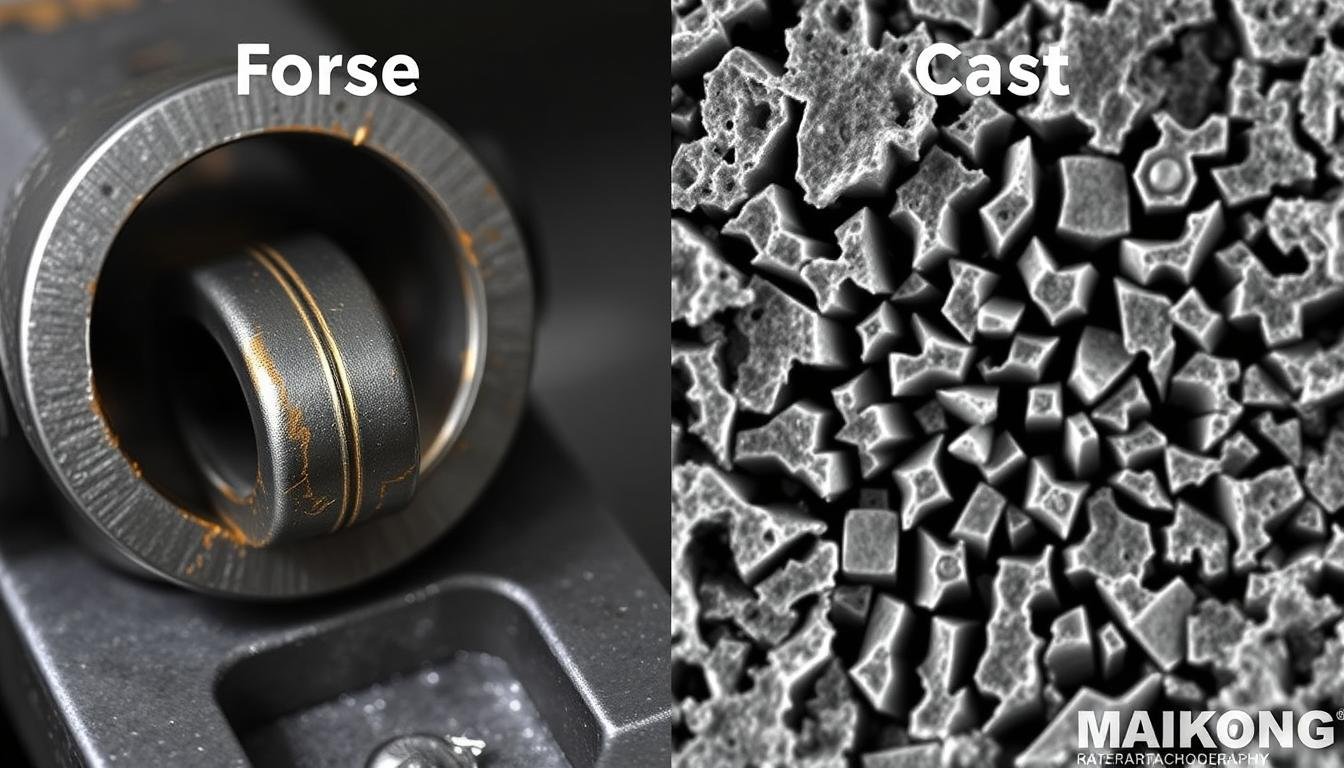

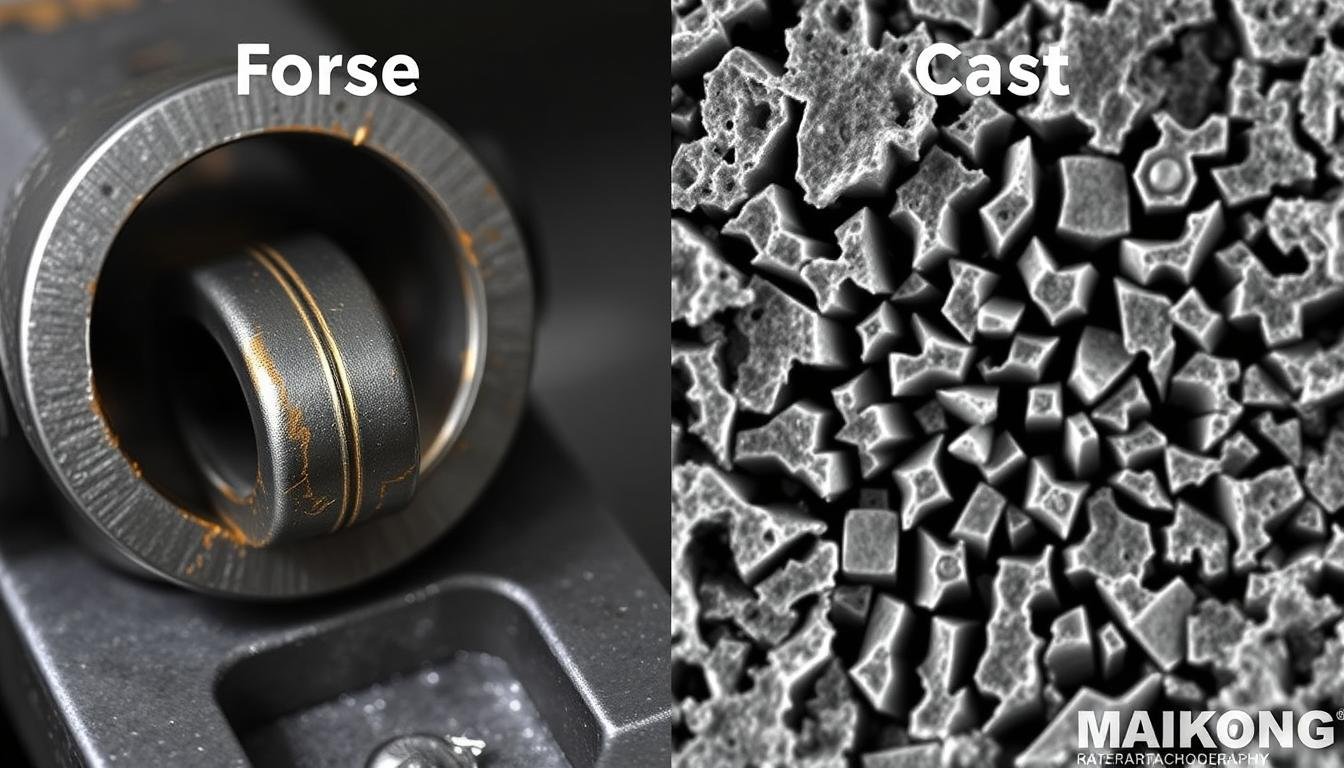

Why Choose Forging Press Technology Over Casting?

When considering manufacturing methods for metal components, the choice between forging and casting significantly impacts the final product’s performance. Forging press technology offers distinct advantages that make it the preferred choice for applications where strength, durability, and reliability are paramount.

| Comparison Categories |

Forging Process |

Casting Process |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Grain Structure |

Directional grain flow for improved properties |

No directional grain structure |

| Weight-to-Strength Ratio |

High strength-to-weight ratio |

Bulkier parts may be needed |

The MAIKONG Advantage in Forging Press Technology

At MAIKONG, we’ve perfected the art and science of forging through advanced press technology and precision engineering. Our forging processes ensure optimal grain flow alignment, maximizing the mechanical properties of each component we produce. This results in parts that consistently outperform cast alternatives in critical applications where failure is not an option.

Experience the Forging Difference

Ready to upgrade your components from cast to forged? Contact our engineering team to discuss how MAIKONG’s forging technology can enhance your product’s performance.

Email Our Engineering Team

MAIKONG’s Advanced Forging Press Manufacturing Capabilities

Located in the heart of GD, SZ, MAIKONG’s manufacturing facility represents the pinnacle of forging press technology and precision engineering. Our strategic location and comprehensive equipment suite enable us to deliver exceptional quality and volume while maintaining competitive pricing for our American partners.

Forging Equipment

- Hydraulic forging presses (17-40 ton capacity)

- Mechanical forging systems

- Screw presses with digital controls

- Upset forging machines

- Custom die manufacturing capabilities

CNC Machining

- 60+ CNC machines

- Multi-axis machining centers

- Swiss-type precision machining

- CNC turning and milling

- Surface grinding and finishing

Quality Control

- Advanced material testing laboratory

- Dimensional inspection equipment

- Non-destructive testing capabilities

- ISO 9001:2015 certified processes

- Comprehensive documentation

Our Complete Service Offering

MAIKONG delivers a comprehensive suite of services beyond basic forging press operations. Our integrated approach ensures seamless production from concept to completion, with every step managed under one roof for optimal quality control.

Design & Engineering

- CAD/CAM design services

- Finite element analysis

- Material selection consultation

- Process optimization

- Tooling design and development

Post-Processing Services

- Heat treatment

- Surface finishing

- Precision machining

- Assembly services

- Custom packaging and shipping

Tour Our Virtual Facility

Want to see our capabilities in action? Schedule a virtual tour of our manufacturing facility and witness firsthand how MAIKONG’s technology can benefit your business.

Schedule Virtual Tour

Industry Applications for Forging Press Technology

MAIKONG’s forging press technology powers critical components across numerous industries where performance, reliability, and precision are non-negotiable. Our specialized forging processes deliver superior parts that consistently outperform alternatives in the most demanding applications.

Aerospace

Our aerospace components meet rigorous standards for strength-to-weight ratio and fatigue resistance, critical for safety and performance in flight applications.

- Engine components

- Landing gear parts

- Structural elements

- Control system components

Automotive

MAIKONG forged components deliver the durability and precision required in modern automotive applications, from performance vehicles to commercial transport.

- Crankshafts and connecting rods

- Transmission components

- Steering and suspension parts

- Drivetrain elements

Industrial Machinery

Our industrial components withstand extreme conditions while maintaining precise tolerances, ensuring reliable operation in demanding environments.

- Heavy equipment components

- Power generation parts

- Mining and construction equipment

- Manufacturing machinery elements

Discover Industry-Specific Solutions

MAIKONG’s engineering team specializes in developing custom forging solutions for specific industry challenges. Contact us to discuss your unique requirements.

Explore Industry Solutions

Quality Assurance in Forging Press Manufacturing

At MAIKONG, quality isn’t just a department—it’s a core philosophy that permeates every aspect of our forging press operations. Our comprehensive quality management system ensures that every component we produce meets or exceeds the most stringent industry standards and customer specifications.

Our Quality Control Process

From raw material verification to final inspection, our quality control procedures are designed to identify and prevent potential issues at every stage of production. This systematic approach ensures consistent quality and reliability across all our forged components.

Material Testing

- Chemical composition analysis

- Mechanical property verification

- Microstructure examination

- Hardness testing

- Grain flow analysis

Production Monitoring

- Statistical process control

- In-process inspection points

- Automated dimensional verification

- Temperature and force monitoring

- Tool wear tracking

Certifications and Standards

MAIKONG maintains rigorous quality management systems certified to international standards, ensuring consistent quality and continuous improvement in our forging press operations.

- ISO 9001:2015 Quality Management System

- IATF 16949 Automotive Quality Management

- Compliance with ASTM and SAE material standards

- Adherence to industry-specific requirements

“Quality expresses a component’s capacity for fully satisfying the customer’s needs and expectations. At MAIKONG, we let the numbers speak for themselves.”

– MAIKONG Quality Philosophy

Request Quality Documentation

Interested in learning more about our quality assurance processes? Contact us to request detailed information about our certifications and quality control procedures.

Request Quality Documentation

Become a MAIKONG Forging Press Distributor in the USA

MAIKONG is actively expanding our distribution network across the United States, seeking qualified partners to represent our premium forging press technology and custom manufacturing services. As a MAIKONG distributor, you’ll gain exclusive access to our comprehensive product line, competitive pricing, and dedicated support.

Why Partner with MAIKONG?

Competitive Advantages

- Industry-leading quality at competitive prices

- Comprehensive product range

- Custom manufacturing capabilities

- Dedicated technical support

- Flexible minimum order quantities

Distributor Benefits

- Exclusive territorial rights

- Competitive commission structure

- Marketing and sales support

- Technical training programs

- Regular product updates

Distributor Qualification Requirements

MAIKONG seeks partners with established presence in industrial manufacturing, metalworking, or related industries. Ideal candidates will have:

- Existing customer base in relevant industries

- Technical understanding of forging and machining processes

- Sales and marketing capabilities

- Commitment to quality and customer service

- Financial stability and growth orientation