In today’s competitive manufacturing landscape, finding the right hot forging aluminum supplier can be the difference between project success and costly setbacks. MAIKONG stands as your premier partner in precision aluminum forging, delivering exceptional quality, competitive pricing, and comprehensive manufacturing solutions. Our expertise in hot forging aluminum components enables your business to achieve superior product performance while optimizing costs and production timelines.

Comprehensive Hot Forging Aluminum Supplier Services

At MAIKONG, we deliver end-to-end aluminum forging solutions backed by extensive manufacturing capabilities. With 60+ CNC machines and 100+ tons of monthly metal processing capacity, we provide precision fabrication for both standard and custom components across diverse industries.

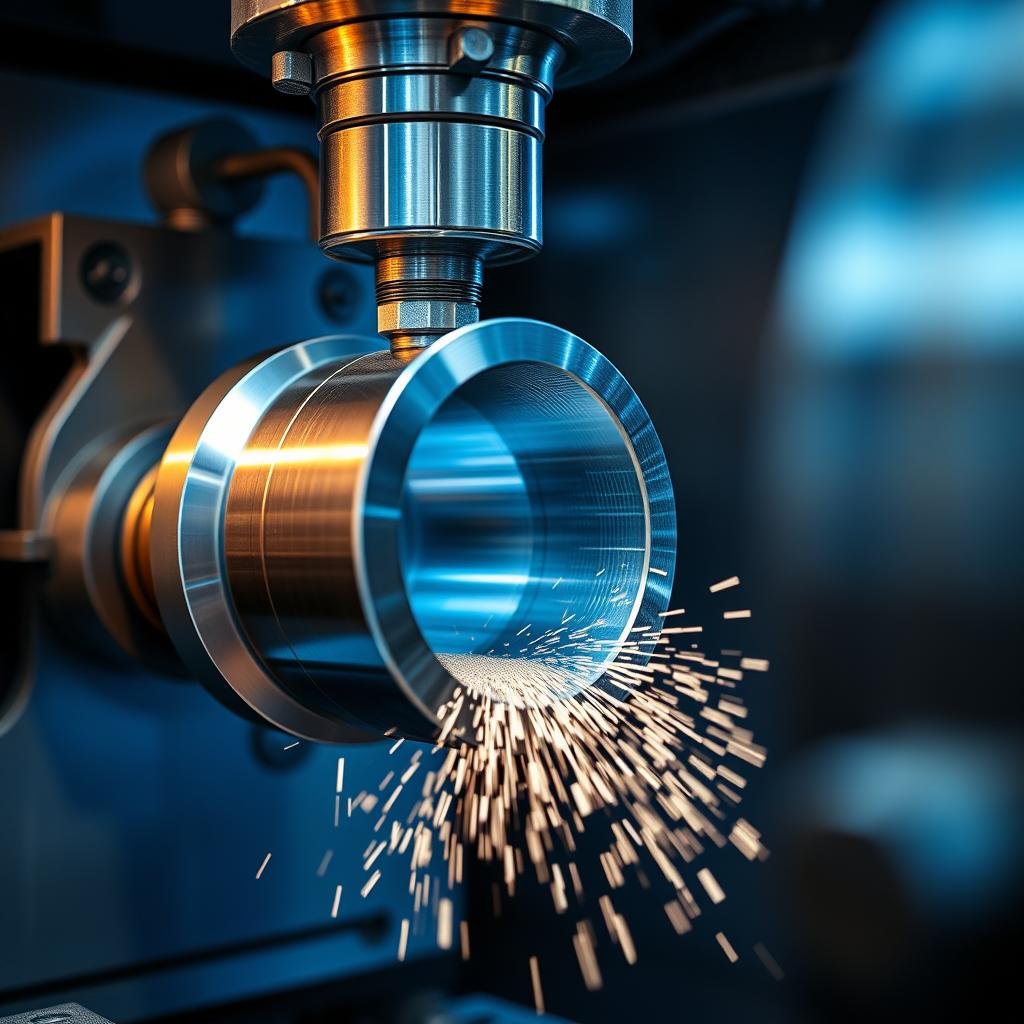

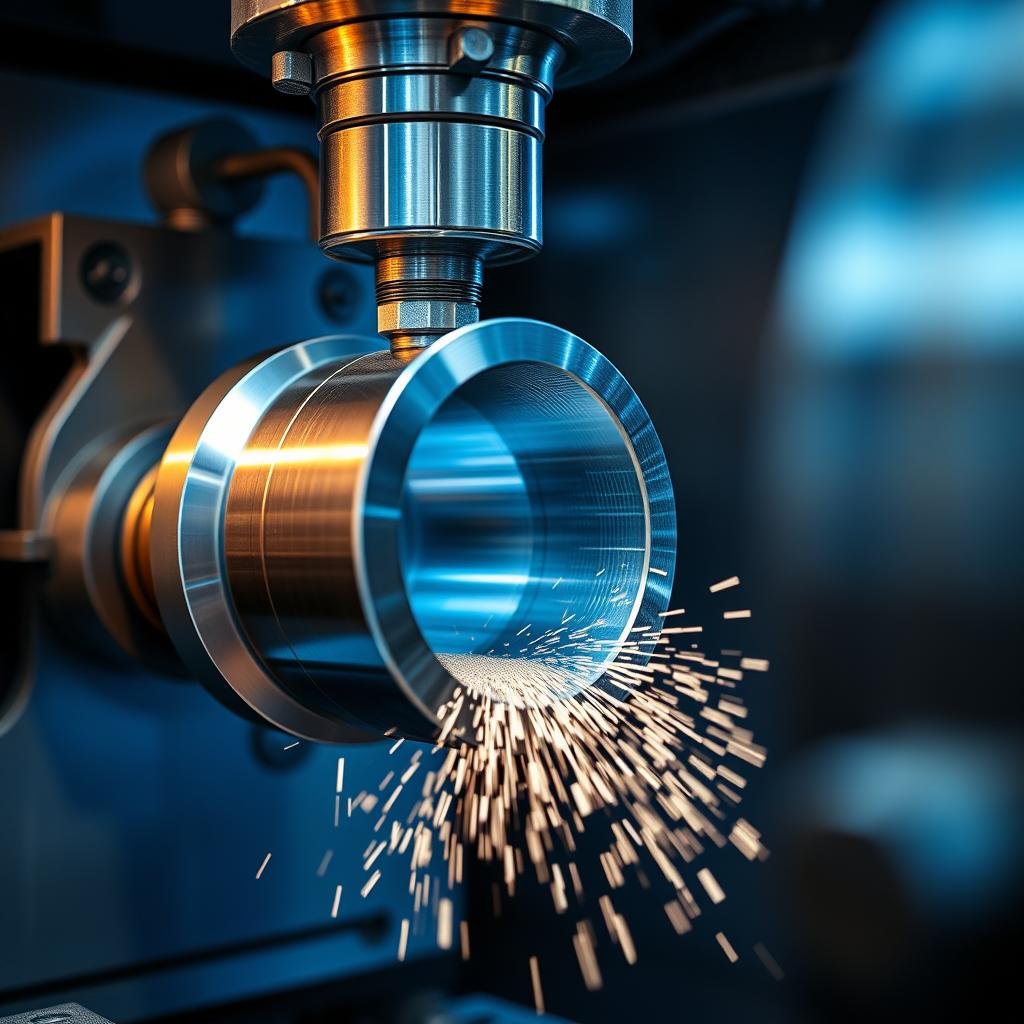

CNC Turning Services

Our CNC turning capabilities deliver superior surface finishes for cylindrical shapes, deep holes, and machined threads in aluminum forgings. Ideal for components requiring precise dimensions and exceptional surface quality.

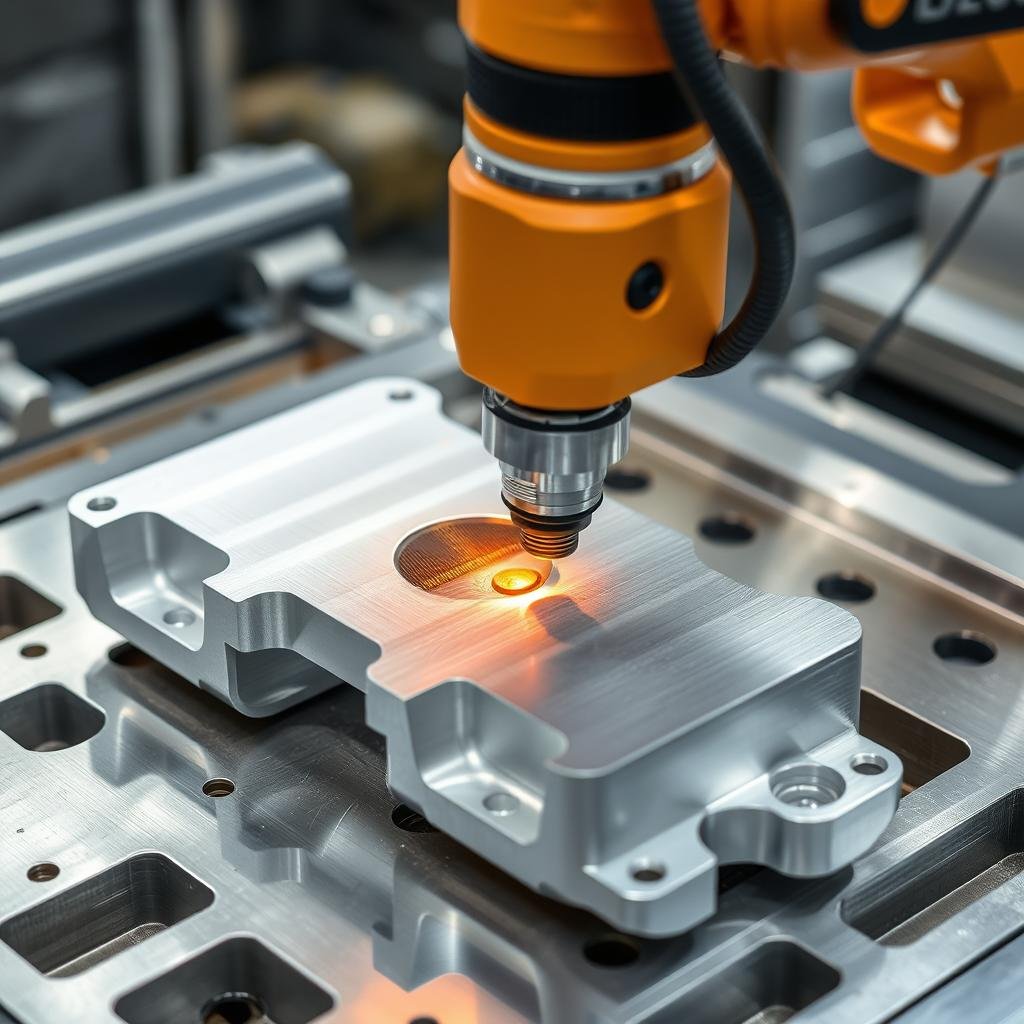

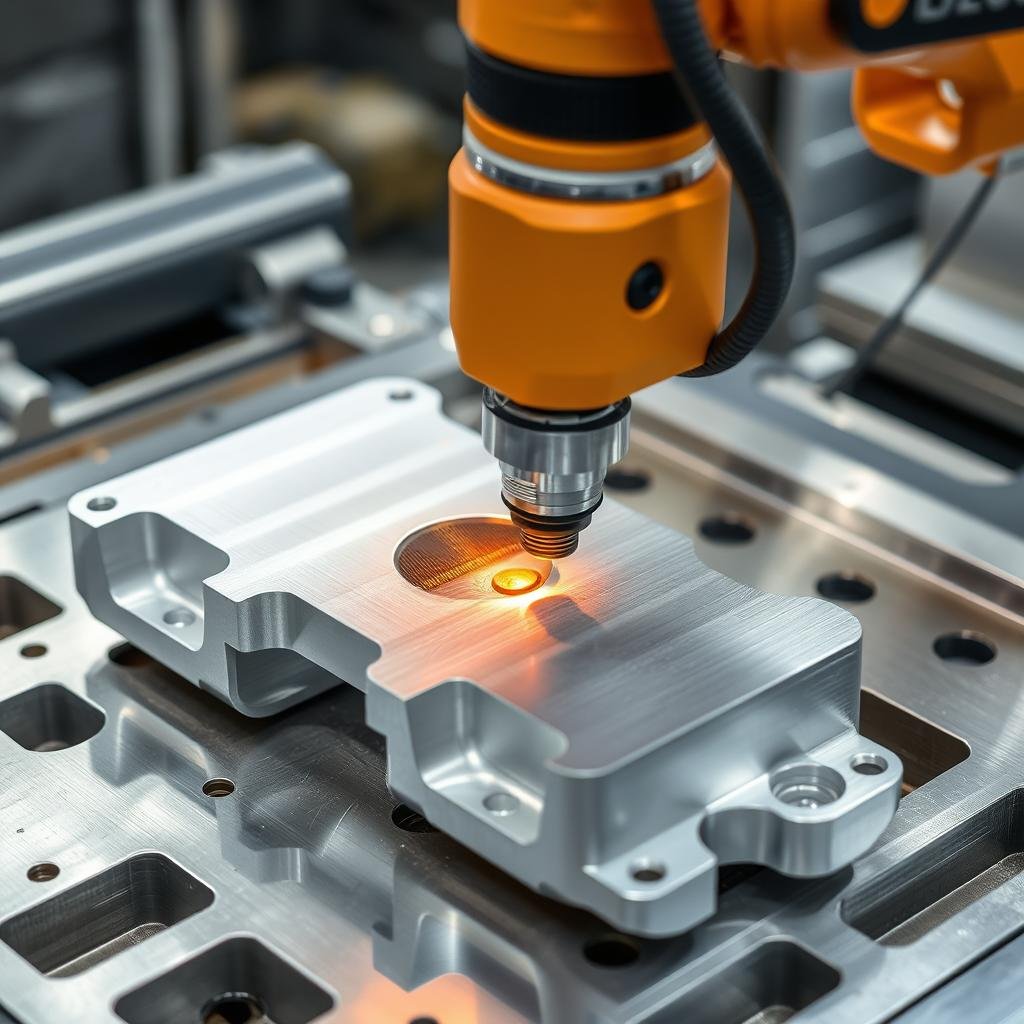

CNC Milling Services

Our multi-axis CNC milling creates complex prismatic shapes and flat surfaces with exceptional accuracy. This tooling-free approach offers flexibility and precision for your most demanding aluminum components.

CNC SWISS Type Machining

Specializing in small precision parts and long shaft components, our Swiss-type machining features dual spindles and multi-axis capabilities for one-stop manufacturing solutions with unmatched accuracy.

Why Choose MAIKONG as Your Hot Forging Aluminum Supplier

As both producer and consumer of our customers’ products, we understand the critical importance of consistency, strength, and weight in each forged aluminum component. Our dedicated focus on crafting superior forged parts enables us to meet your exact requirements for heat treating, machining, and testing.

Material Excellence

Our material laboratory plays a vital role in our production process, enabling us to achieve the precise results you demand. Our team possesses a profound understanding of aluminum alloys, their properties, and their interactions, ensuring our products consistently meet the highest standards of quality and performance.

One of our greatest strengths lies in the diverse solutions we offer, encompassing a range of additional services that provide comprehensive support for the end application of precision aluminum forgings, allowing us to maintain competitiveness while delivering exceptional value.

Become a US Distributor

We’re actively seeking US distributors and agents for our high-quality, competitively priced aluminum forging solutions.

Contact for Distribution

Full-Service Aluminum Forging Center

Today’s manufacturing demands require aluminum and its alloys across numerous industries due to their exceptional mechanical properties—high modulus of elasticity, tensile strength, and yield strength. From automotive and aerospace to construction and electronics, aluminum forgings deliver reliable performance in critical applications.

Through proper deformation and grain flow, combined with material homogeneity, our forging process maximizes impact toughness, fracture toughness, and fatigue strength while ensuring consistent performance and quality in every component.

CAD/CAM Design

Our advanced analysis software facilitates early-stage issue identification and mitigation, optimizing your component design before production begins.

Material Selection

We thoroughly evaluate mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness of each aluminum alloy for your specific application.

Tooling Design

Our expert tooling design ensures initial quality, while regular maintenance preserves consistency—both critical for producing high-quality aluminum forgings.

Forging Process

Our forging workshop is equipped to accommodate diverse aluminum forging specifications, from small precision components to large structural parts.

Heat Treatment

We conduct comprehensive statistical analysis and documentation for our in-house heat treatment, ensuring consistent mechanical properties across all components.

Surface Finishing

Our automated grinding with specialized robots removes parting lines and achieves precise surface finishes for optimal component performance and appearance.

Why Choose Hot Forging for Aluminum Components?

Aluminum forging delivers an optimal strength-to-weight ratio—a fundamental engineering principle balancing material strength and weight. This consideration is essential in industries prioritizing performance, efficiency, and safety.

Strength-to-Weight Excellence

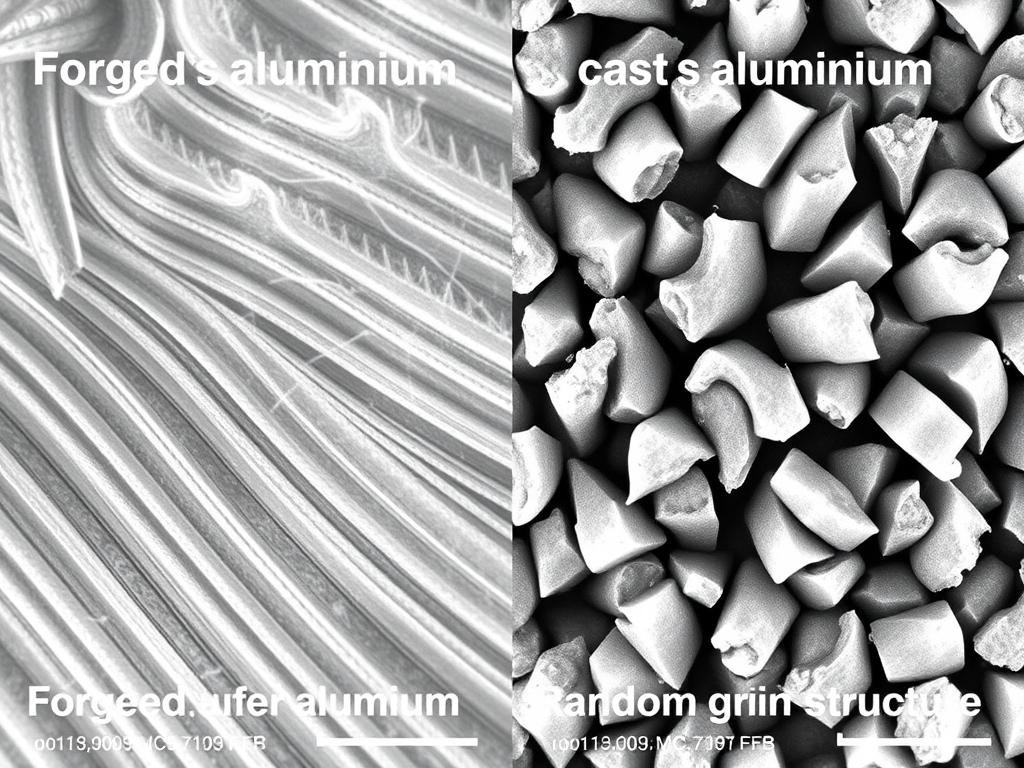

Aluminum, recognized for its lightweight properties and robust mechanical characteristics, is enhanced through our forging process. This refines its internal grain structure for improved resilience and strength, making aluminum forgings the optimal choice for withstanding both static and dynamic loads.

Our forging process aligns the grain structure of aluminum, creating a directional flow that significantly enhances mechanical properties compared to cast or machined components.

Aluminum Forging vs. Casting: A Comprehensive Comparison

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

Can achieve complex shapes in one session |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Heat Treatment Response |

Responsive for controlled material properties |

Less predictable response |

| Weight-to-Strength Ratio |

High strength-to-weight ratio |

Bulkier parts may be needed |

| Critical Applications |

Structural members and load-bearing components |

Limited suitability for critical applications |

Need Expert Guidance?

Our engineering team can help determine the optimal manufacturing process for your specific component requirements.

Request Technical Consultation

Quality Assurance from Your Hot Forging Aluminum Supplier

At MAIKONG, quality isn’t just a department—it’s our foundation. Our comprehensive quality management system ensures every component meets or exceeds your specifications.

Certified Excellence

We proudly maintain ISO 9001:2015 certification, demonstrating our commitment to quality management systems that ensure consistent, high-quality outputs. Our quality engineering staff monitors the production process at all stages—from raw material selection through forging, heat treatment, CNC milling, and surface treatment.

The advantages of our in-house production allow us to maintain strict quality control at every step, ensuring consistency and excellence in every component we deliver.

Material Testing

Our comprehensive material testing includes chemical composition analysis, mechanical property verification, and microstructure examination to ensure every component meets specification.

Dimensional Inspection

Using advanced coordinate measuring machines (CMM) and precision gauges, we verify all critical dimensions to ensure your components meet exact specifications.

Non-Destructive Testing

Our NDT capabilities include ultrasonic, penetrant, and other advanced inspection methods to verify internal integrity without compromising your components.

State-of-the-Art Manufacturing Facility

MAIKONG’s manufacturing facility, located in GD, SZ, houses a comprehensive range of well-maintained forging equipment. Our strategic location presents logistical advantages, facilitating efficient receipt of raw materials and prompt dispatch of finished components to our partners worldwide.

Our suite of machinery, encompassing hydraulic forging presses, uniform heat treatment furnaces, and precision-driven CNC machines, assures both the quality and volume of our production. The factory layout is engineered for optimal efficiency, with production lines designed to minimize waste and expedite the manufacturing process.

Forging Equipment

Our hydraulic presses range from 500 to 3000 tons, providing the capability to forge aluminum components from small precision parts to large structural elements.

Heat Treatment

Our precision-controlled heat treatment furnaces ensure uniform temperature distribution and precise cycle control for consistent mechanical properties.

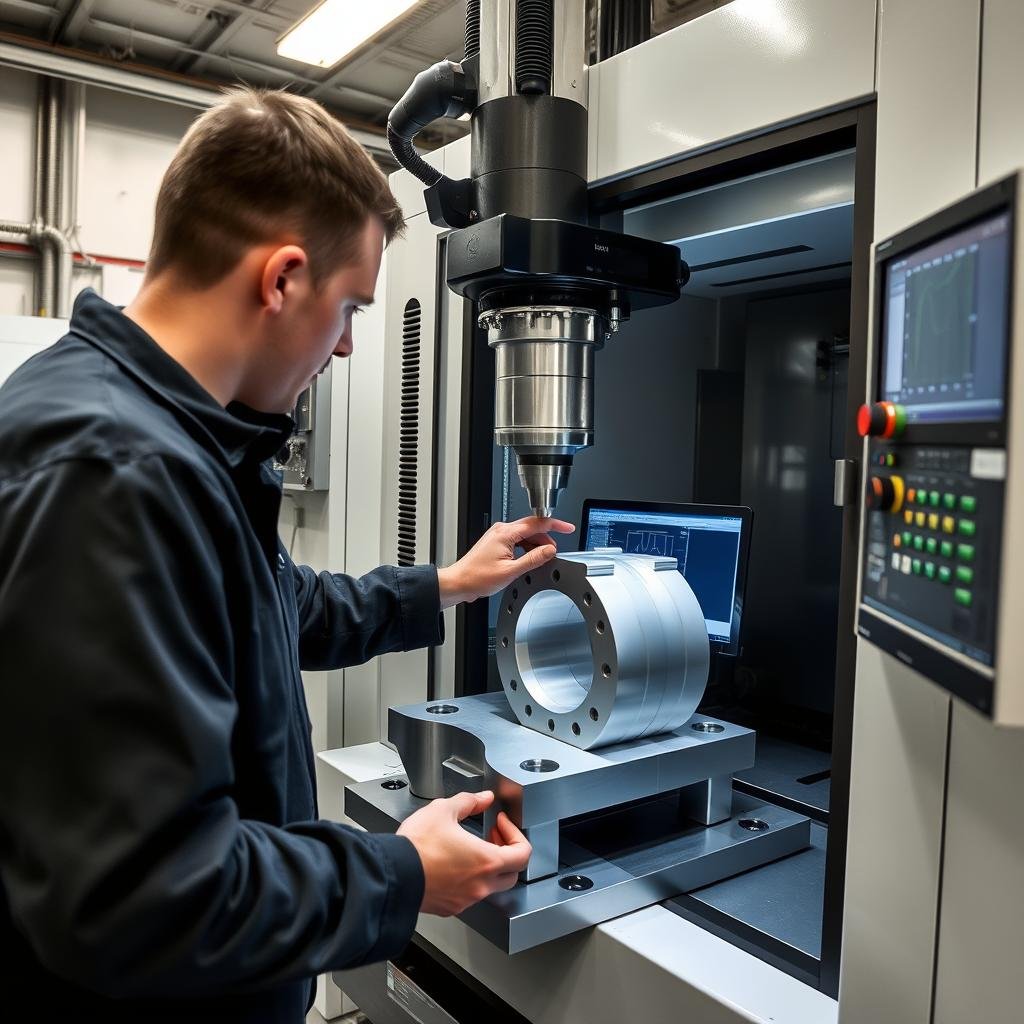

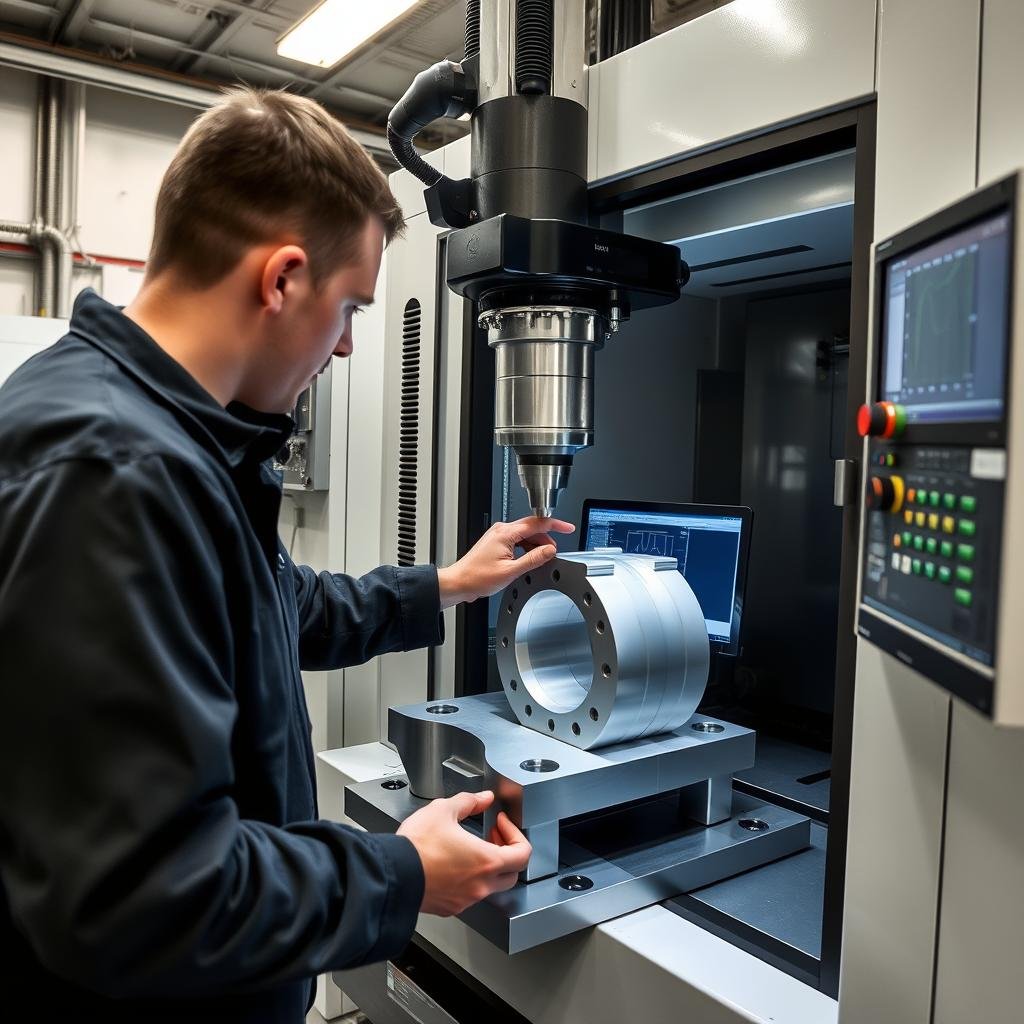

CNC Machining

With 60+ CNC machines, including multi-axis machining centers, we provide precision secondary operations for your forged aluminum components.

Advanced Design and Manufacturing Process

Our comprehensive design and manufacturing process ensures your components are optimized for performance, manufacturability, and cost-effectiveness.

CAD/CAM Integration

CAD/CAM refers to the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM). Our powerful computing systems enable our designers and engineers to create optimal component designs and manufacturing processes.

Our team of engineers collaborates to design a customized forging process that aligns with your specific requirements. This includes the creation of tailored die designs utilizing advanced computer-aided design (CAD) tools. These designs are then scrutinized through finite element analysis (FEA), which simulates the forging process and predicts the performance of the end product.

Specialized Heat Treatment Services

At MAIKONG, we specialize in aluminum forging, meticulously shaping aluminum into precise forms using compressive forces. Our dedicated team handles every step of the aluminum forging process, from design to final finishing.

Precision Heat Treatment

Our heat treatment capabilities enhance the mechanical properties of your aluminum components, making them not just fit for purpose but also long-lasting. We ensure material selection is of the highest quality, and the forging process itself is conducted with precision and care.

Through controlled heating and cooling cycles, we can achieve specific mechanical properties tailored to your application requirements, including:

- Increased strength and hardness

- Improved ductility and toughness

- Enhanced fatigue resistance

- Stress relief for dimensional stability

- Optimized machinability

Advanced Surface Treatment Options

At MAIKONG, we take a proactive approach to maintaining the quality of our surface treatments, which encompass anodizing, painting, laser engraving, and sand blasting.

Anodizing

Our anodizing process creates a durable, corrosion-resistant surface layer while allowing for decorative coloring options to enhance your component’s appearance and performance.

Painting

Our precision painting capabilities include both powder coating and wet painting options, providing excellent adhesion, durability, and aesthetic appeal for your components.

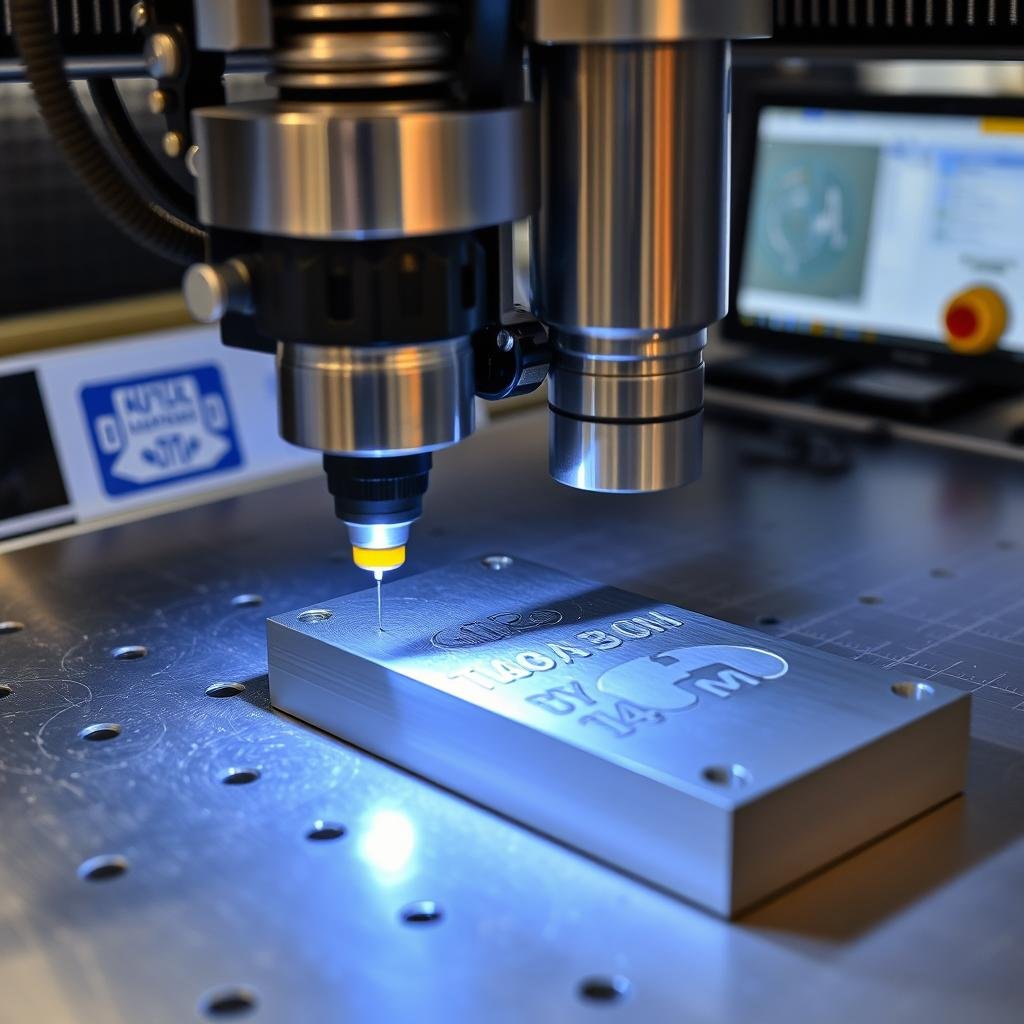

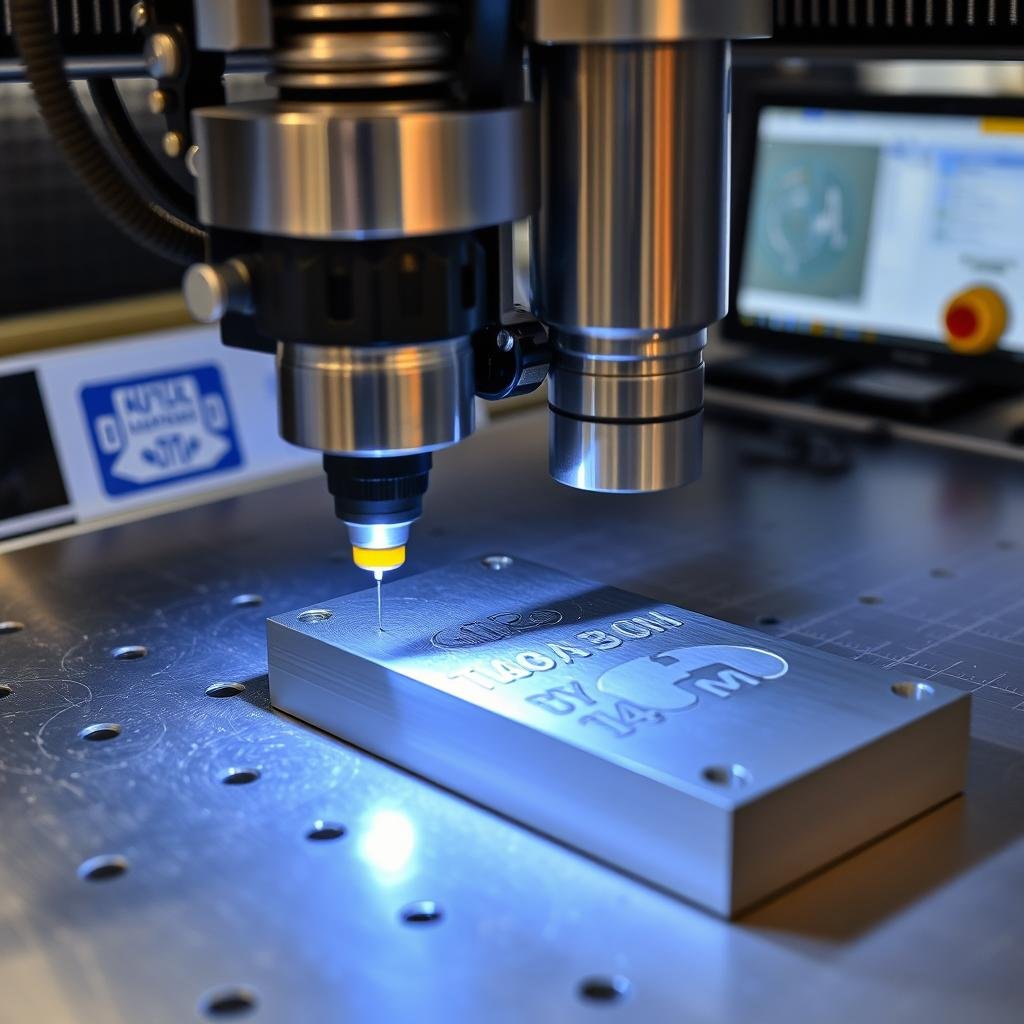

Laser Engraving

Our advanced laser engraving systems provide permanent, precise marking for part identification, branding, or functional requirements with exceptional detail and durability.

By leveraging advanced tools like spectrophotometers for color and gloss measurement, adhesion testers to assess coating bonds, precisely configured laser engraving settings, and meticulously controlled sand blasting parameters, we manage to mitigate potential issues and ensure consistent, high-quality surface finishes.

Industry Applications for Hot Forging Aluminum Supplier Products

MAIKONG’s aluminum forgings serve diverse industries with components that meet the most demanding performance requirements.

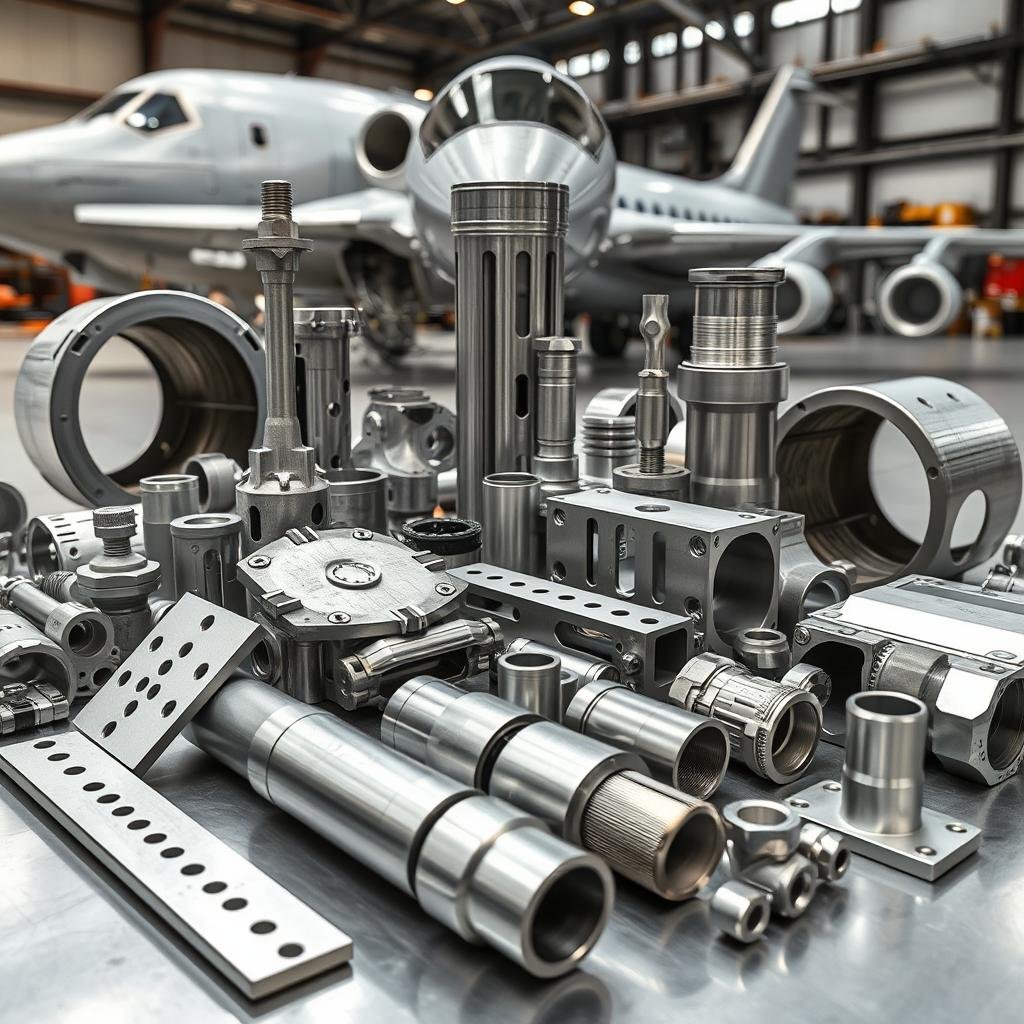

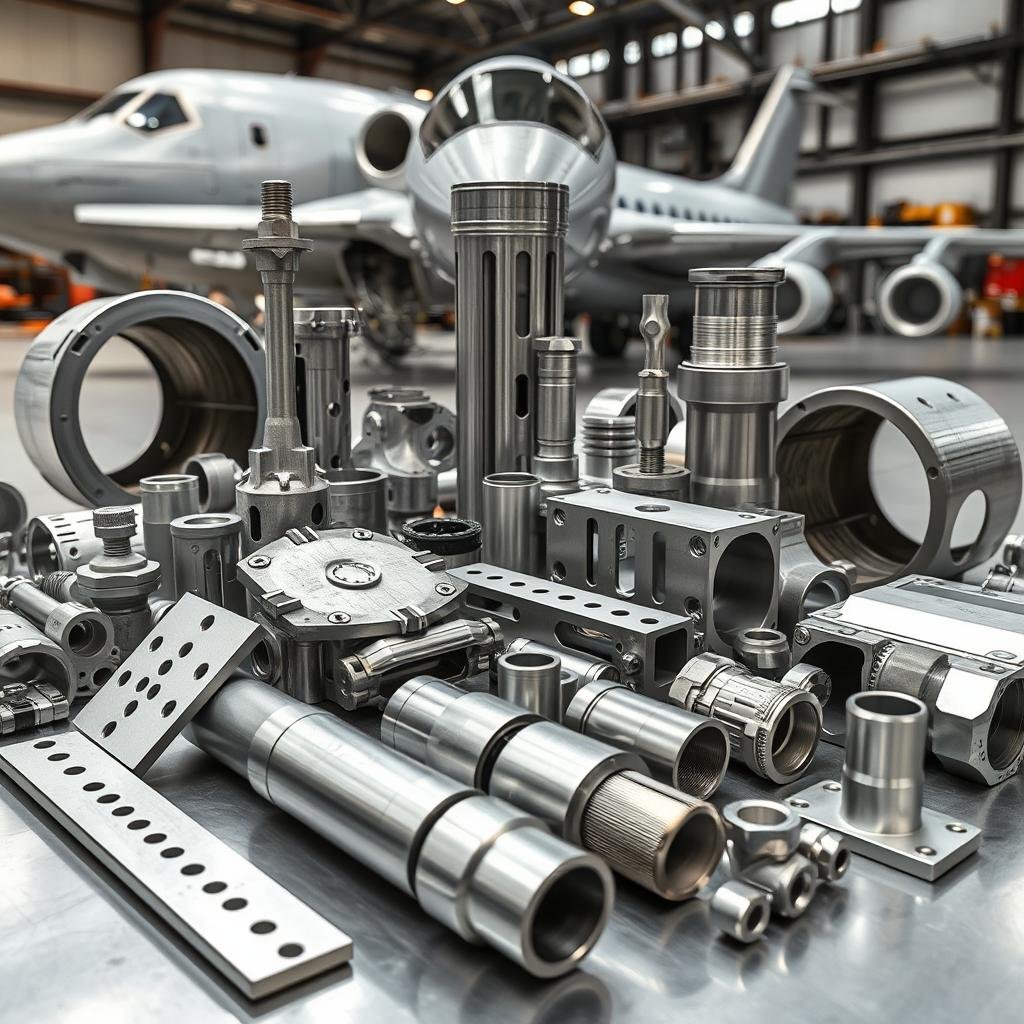

Aerospace

Our aerospace-grade aluminum forgings include structural components, engine parts, landing gear components, and mounting brackets that meet rigorous industry standards for performance and reliability.

Automotive

From suspension components and engine parts to structural elements, our automotive aluminum forgings deliver the perfect balance of strength, weight reduction, and durability.

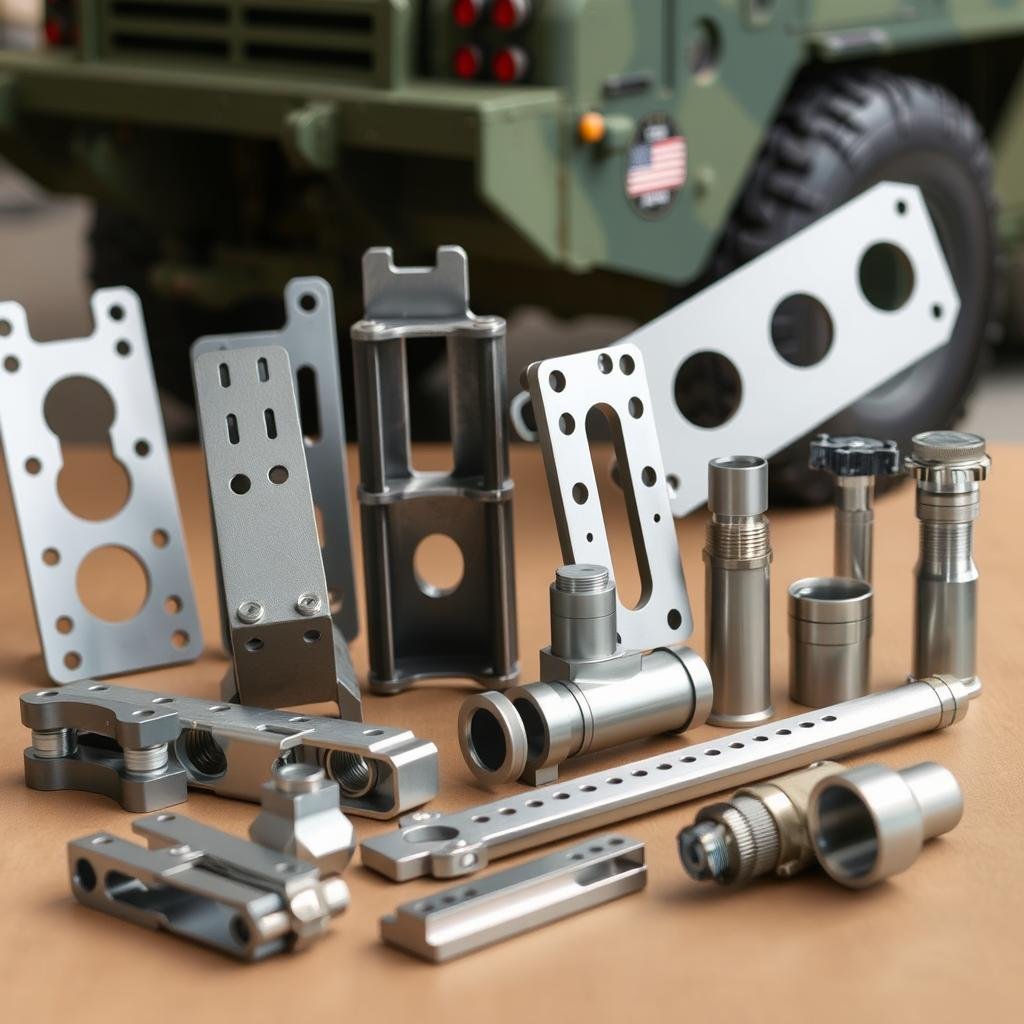

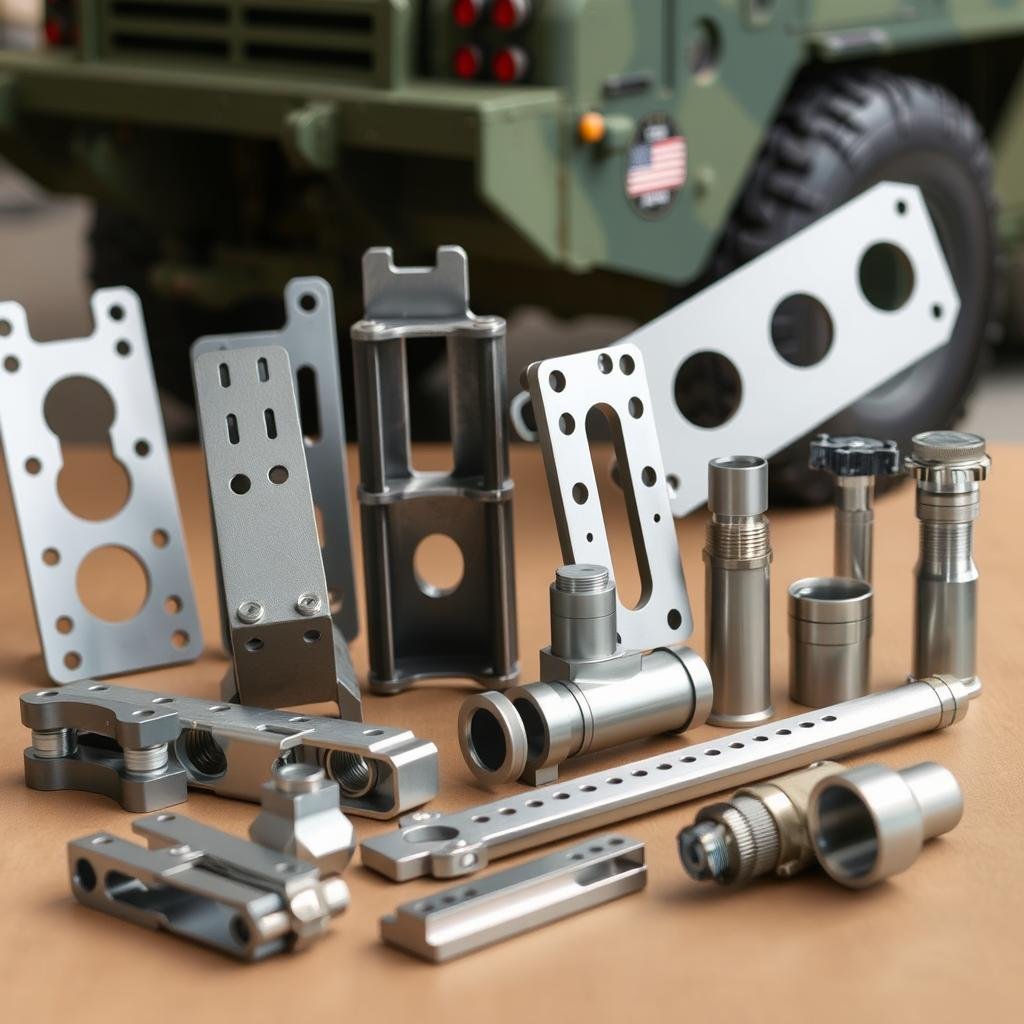

Defense

Our defense applications include critical components for vehicles, weapons systems, and equipment where reliability and performance are non-negotiable requirements.

Oil & Gas

Our aluminum forgings for the oil and gas industry include valve components, connectors, and structural elements designed to withstand harsh operating environments.

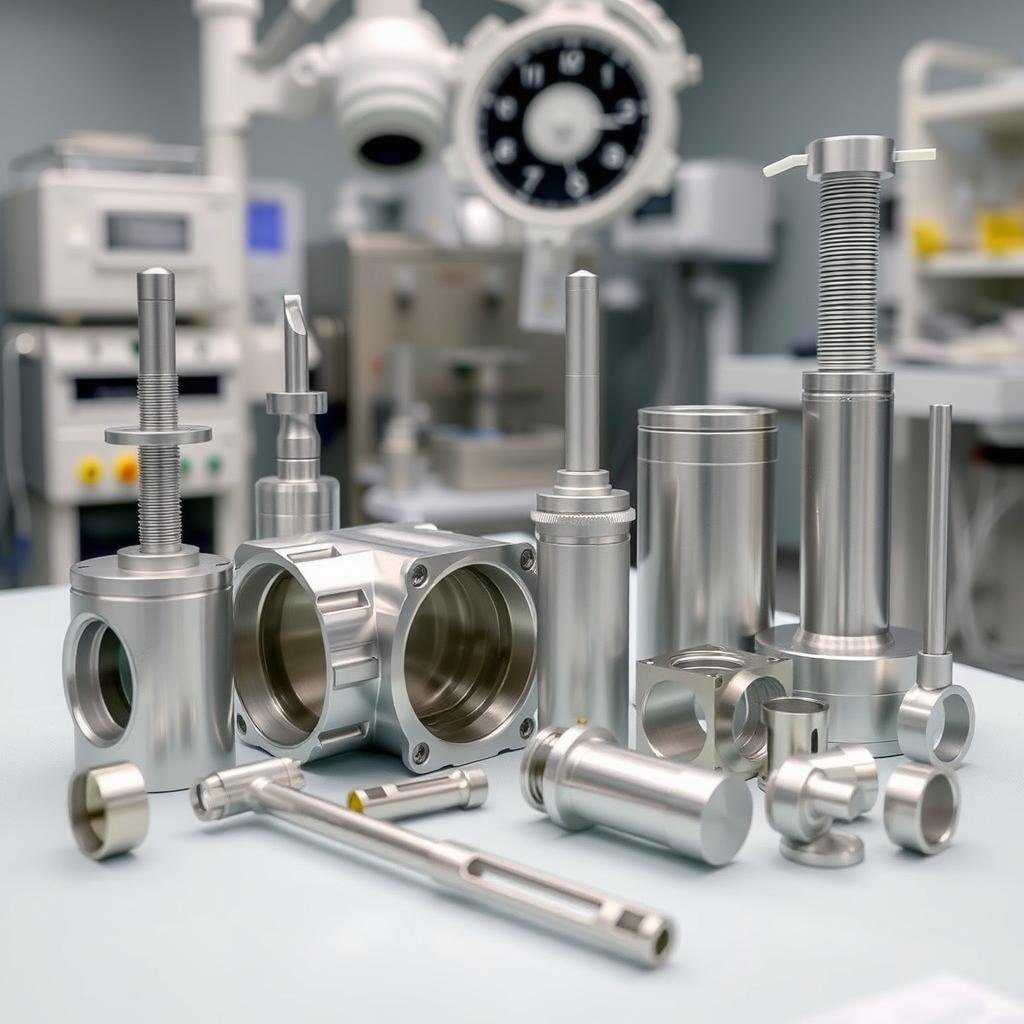

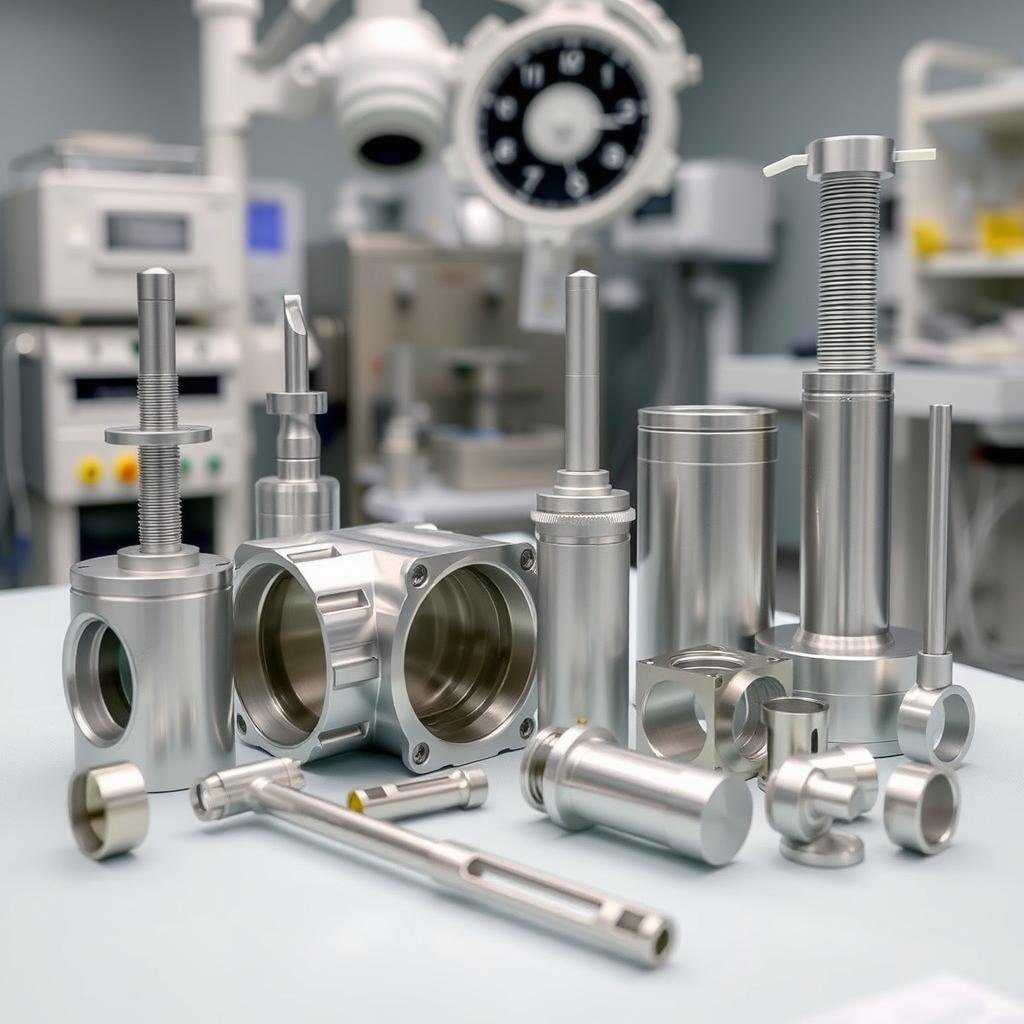

Medical

Precision aluminum forgings for medical devices and equipment where exacting tolerances, biocompatibility, and reliability are essential requirements.

Electronics

Our aluminum forgings for electronics include heat sinks, housings, and structural components that provide excellent thermal management and EMI shielding.

US Distribution Opportunities

MAIKONG is actively seeking US distributors and agents for our high-quality aluminum forging solutions. We offer competitive pricing, reliable delivery, and comprehensive technical support to help you succeed in the North American market.

Distribution Benefits

- Competitive pricing for market advantage

- Comprehensive technical support

- Reliable delivery schedules

- Diverse product capabilities

- Quality assurance with full certification

- Custom manufacturing solutions

Your Trusted Hot Forging Aluminum Supplier Partner

MAIKONG stands ready as your dedicated partner in aluminum forging excellence. With our comprehensive capabilities, quality focus, and competitive pricing, we deliver the precision components your products demand. From initial design consultation through final delivery, our team works tirelessly to ensure your complete satisfaction.

Contact us today to discuss your aluminum forging requirements and discover how MAIKONG can drive your success through strategic partnership.