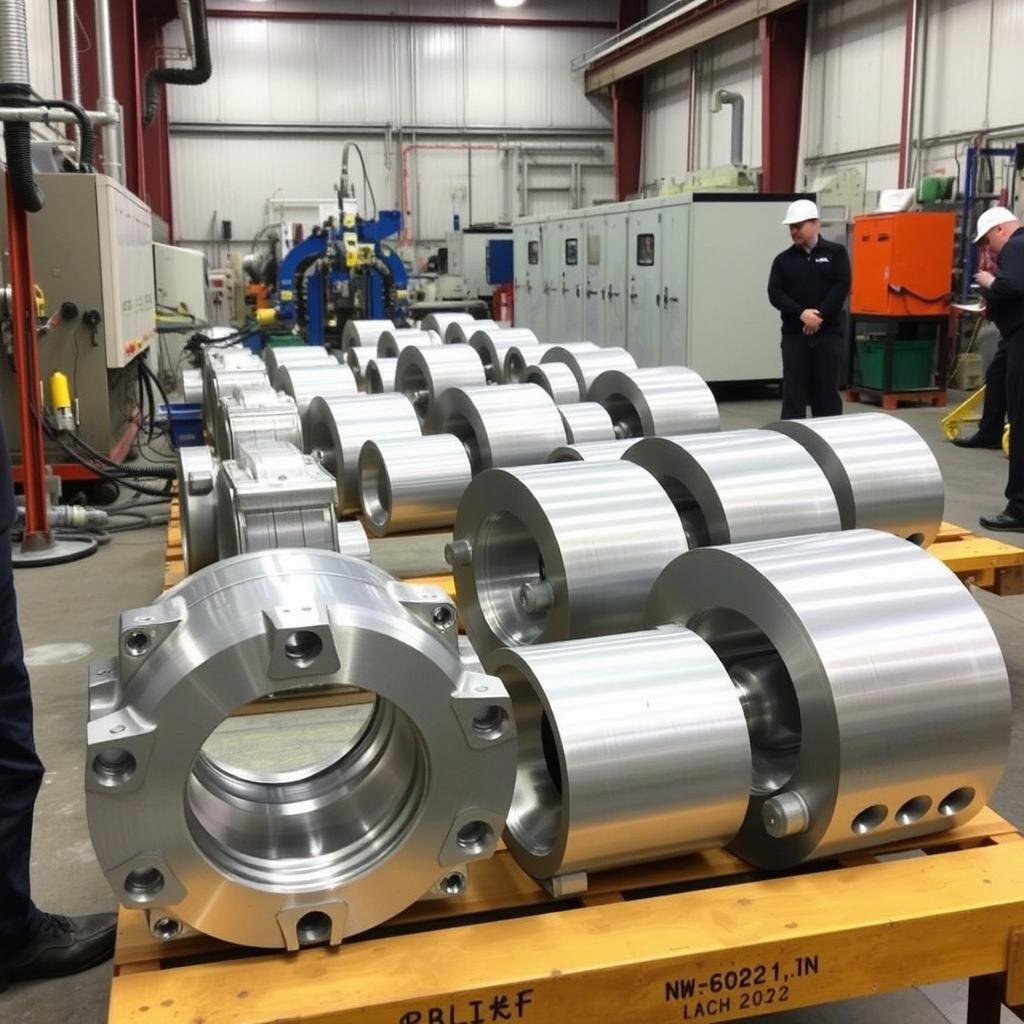

MAIKONG’s manufacturing facility, located in GD, SZ, houses a comprehensive range of well-maintained forging equipment. Our strategic location presents significant logistical advantages, facilitating efficient receipt of raw materials and prompt dispatch of finished parts to our partners worldwide.

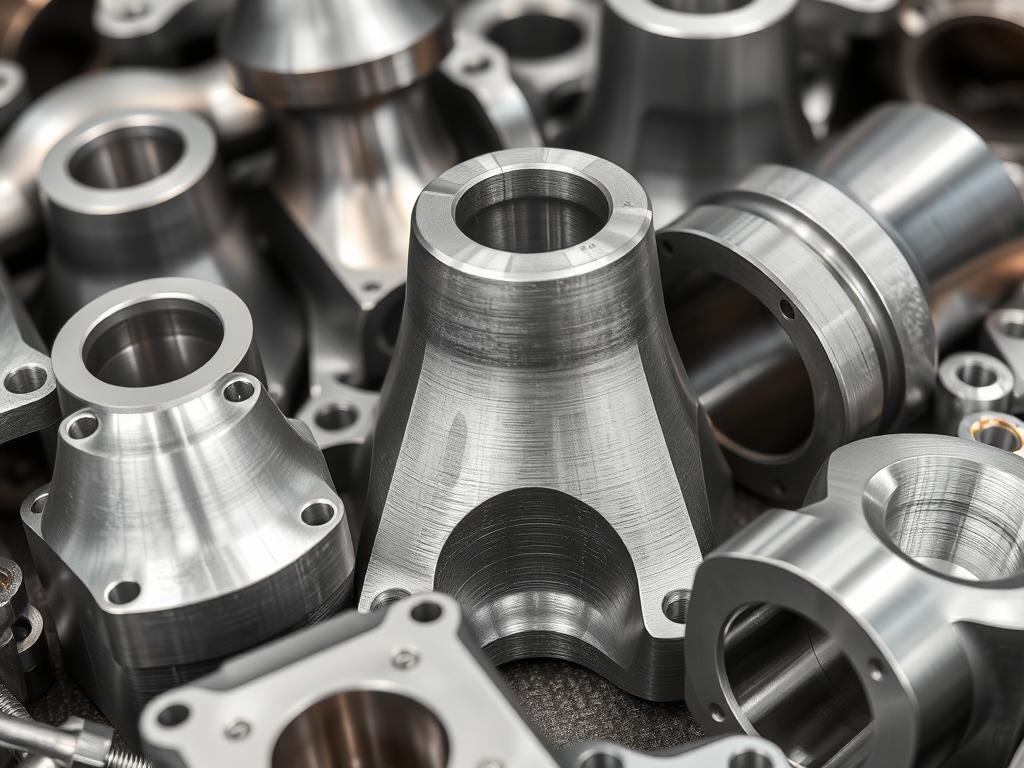

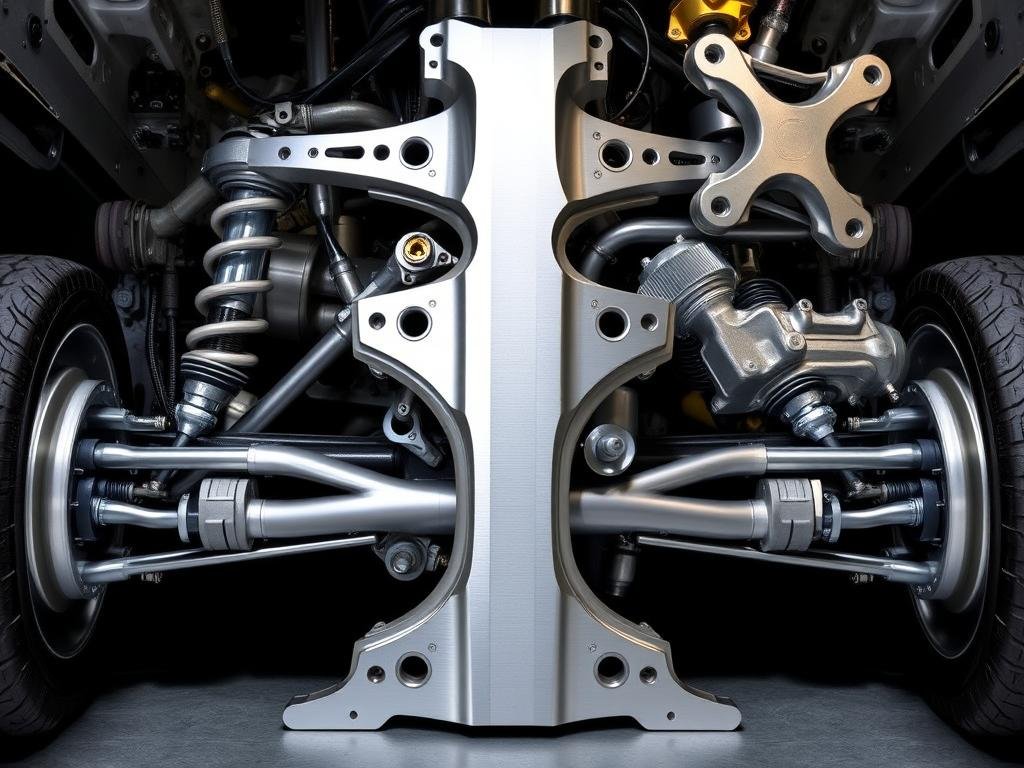

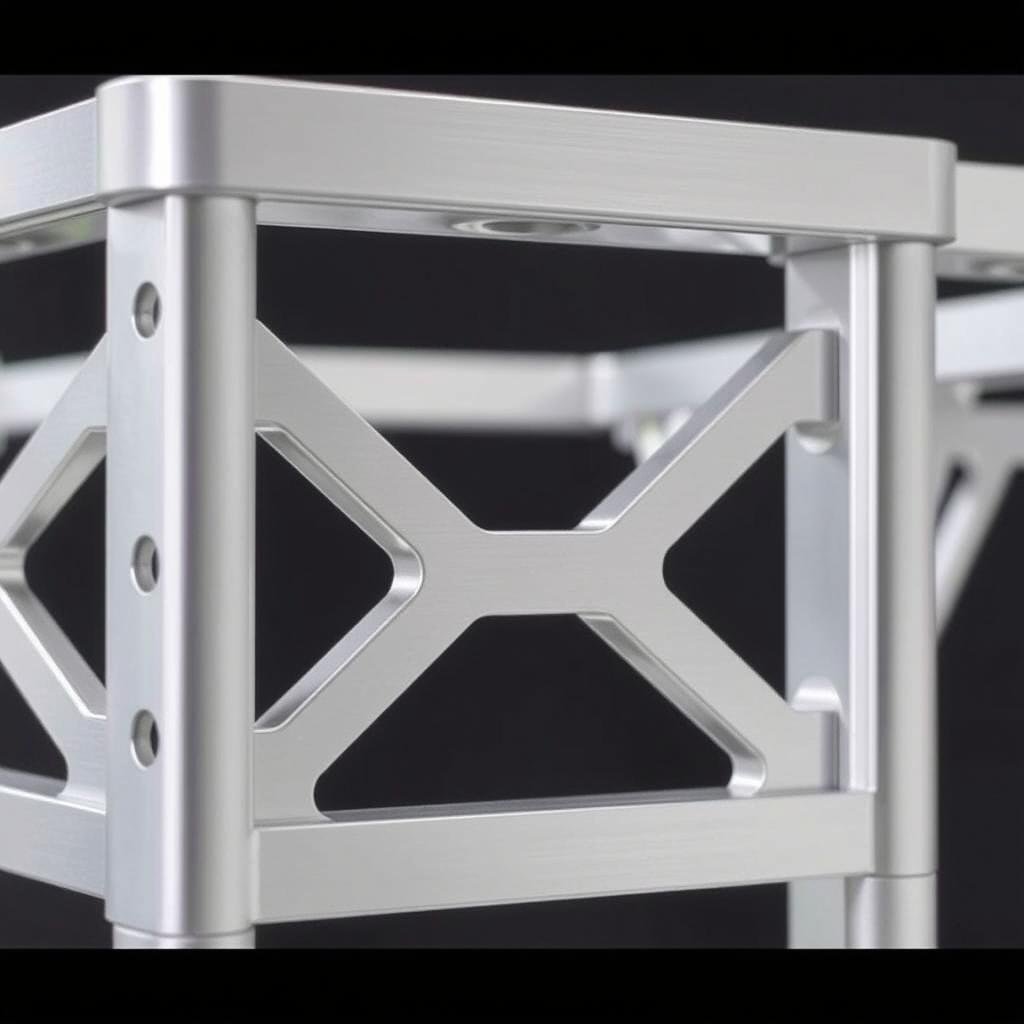

Our suite of machinery, encompassing hydraulic forging presses, uniform heat treatment furnaces, and precision-driven CNC machines, assures both the quality and volume of our production. The factory layout is designed to foster optimal efficiency, with production lines engineered to minimize waste and expedite the manufacturing process.

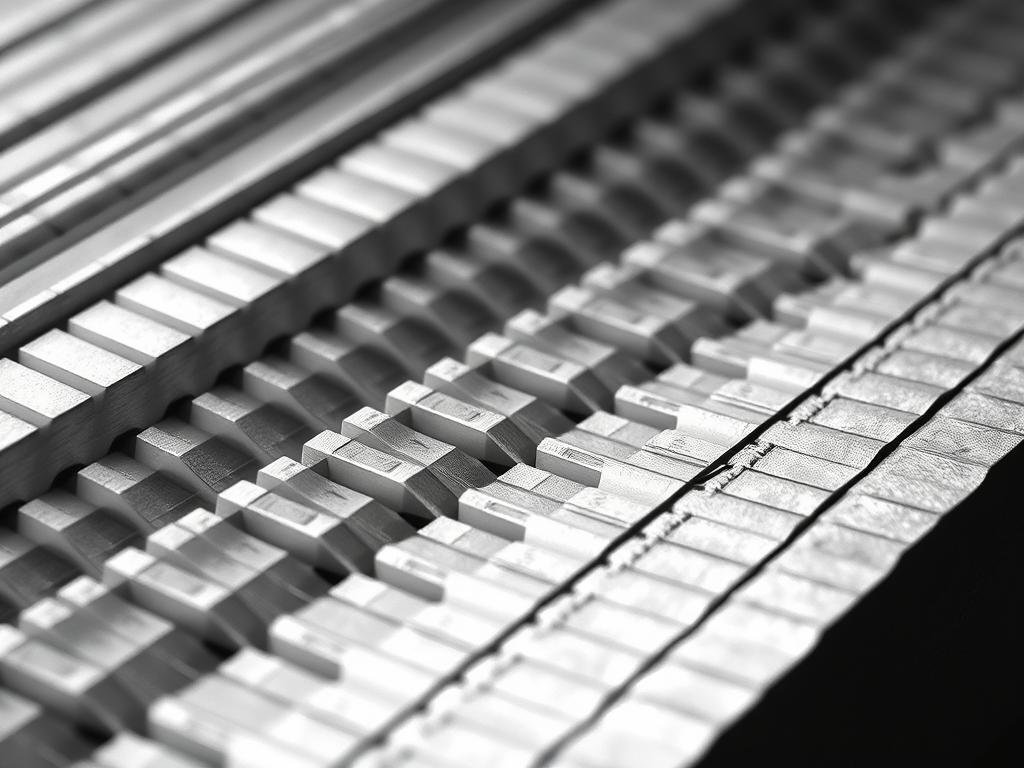

This strategic arrangement ensures a smooth and uninterrupted flow of materials, from the moment raw aluminum enters our premises to the point where completed parts are prepared for dispatch. Every aspect of our operation is informed by our commitment to efficiency, quality, and sustainability.