As a premier Hot Forging Aluminum Supplier, MAIKONG combines advanced manufacturing technology with metallurgical expertise to deliver superior aluminum forgings for demanding applications. Our comprehensive capabilities span from material selection through forging, heat treatment, precision machining, and surface finishing—all designed to provide you with components that exceed performance expectations while maintaining competitive pricing.

Who We Are: Your Trusted Hot Forging Aluminum Supplier

As both a producer and consumer of our customers’ products, we recognize the crucial importance of consistency, strength, and weight in each forged part for the final product. With a dedicated focus on crafting superior forged aluminum components, we fulfill your requirements for heat treating, machining, and testing.

Our material laboratory plays a vital role in our production process, enabling us to achieve the precise results you demand. Our team is committed to delivering optimal outcomes by possessing a profound understanding of materials, their properties, and their interactions. We ensure that our products consistently meet the highest standards of quality and performance.

Ready to Experience Superior Aluminum Forgings?

Contact our team today to discuss your specific requirements and discover how MAIKONG can deliver exceptional value as your forging partner.

Get A Quick Quote

Full-Service Aluminum Forging Center

Nowadays, aluminum and its alloys are widely used in various industries due to their high mechanical properties such as high modulus of elasticity, tensile strength, and yield strength, including automotive manufacturing, aerospace, construction, and electronics industries.

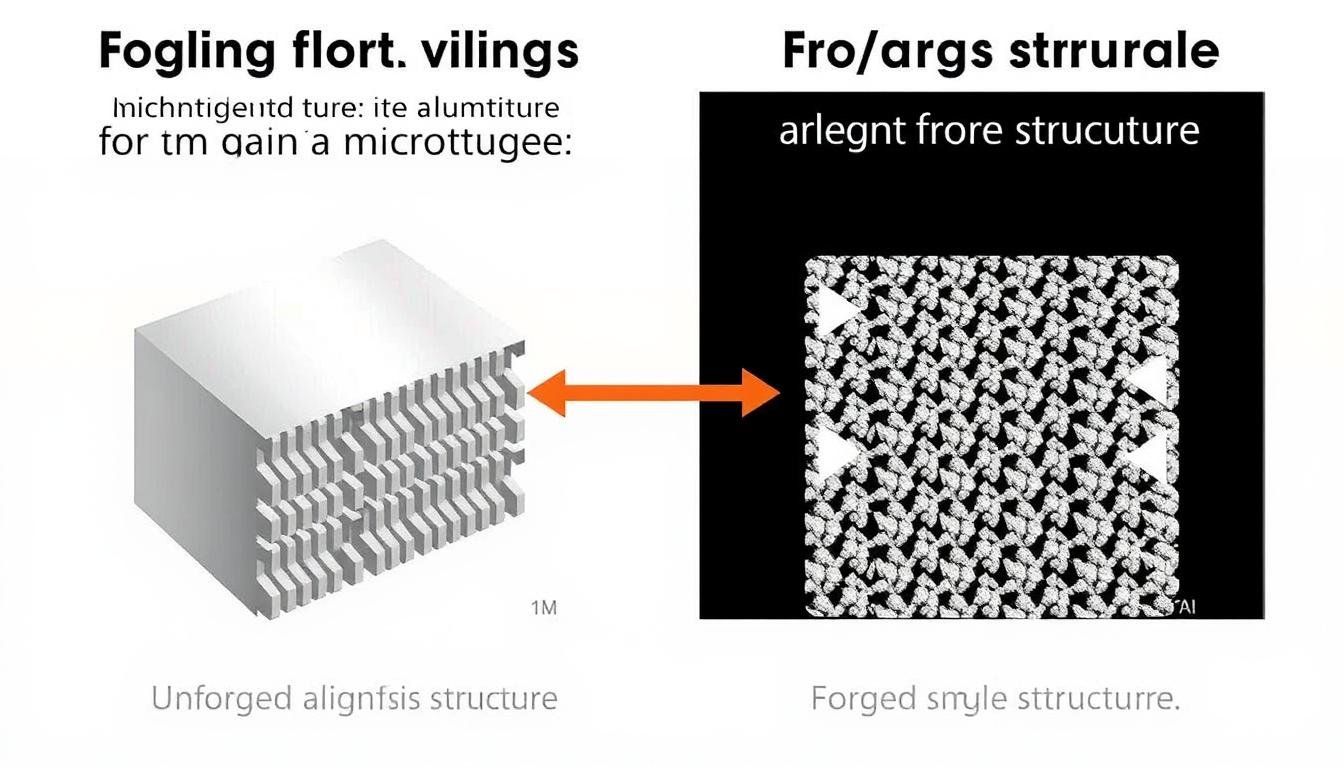

Through proper deformation and grain flow, combined with material homogeneity, the forging process not only maximizes impact toughness, fracture toughness, and fatigue strength but also ensures consistent performance and quality of aluminum forgings.

Forged aluminum is the ideal choice, especially in sectors where performance and safety are critical to prevent failures caused by shock, impact, cyclic loads, or vibration stresses. In-house secondary processing further highlights the advantages of forging, enabling the attainment of desired mechanical properties and achieving final shape and dimensional tolerances for aluminum forgings.

We don’t just supply aluminum forgings; we consider how to best support the end application at each step of our one-stop forging process. Therefore, we have established an unprecedented service center for aluminum forgings, providing comprehensive technical support and solutions to our customers.

Our Comprehensive Aluminum Forging Services

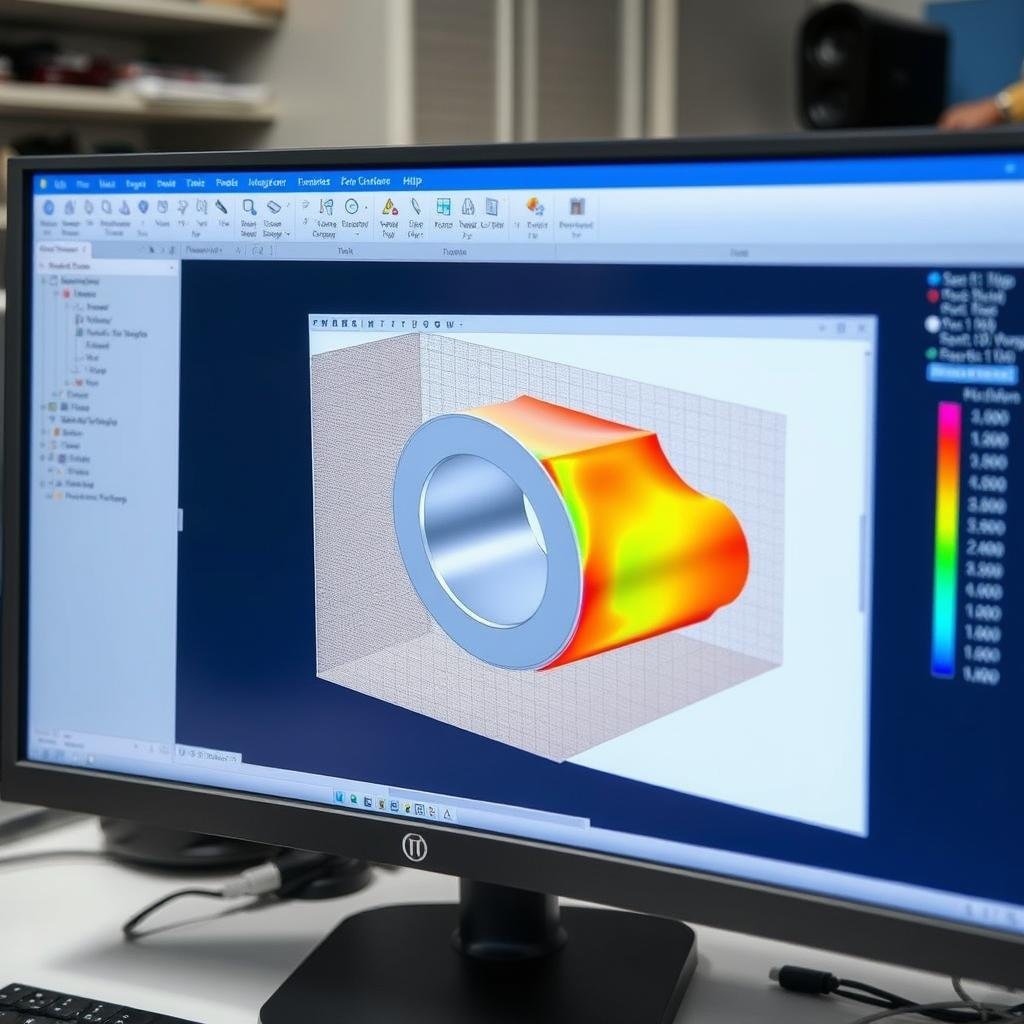

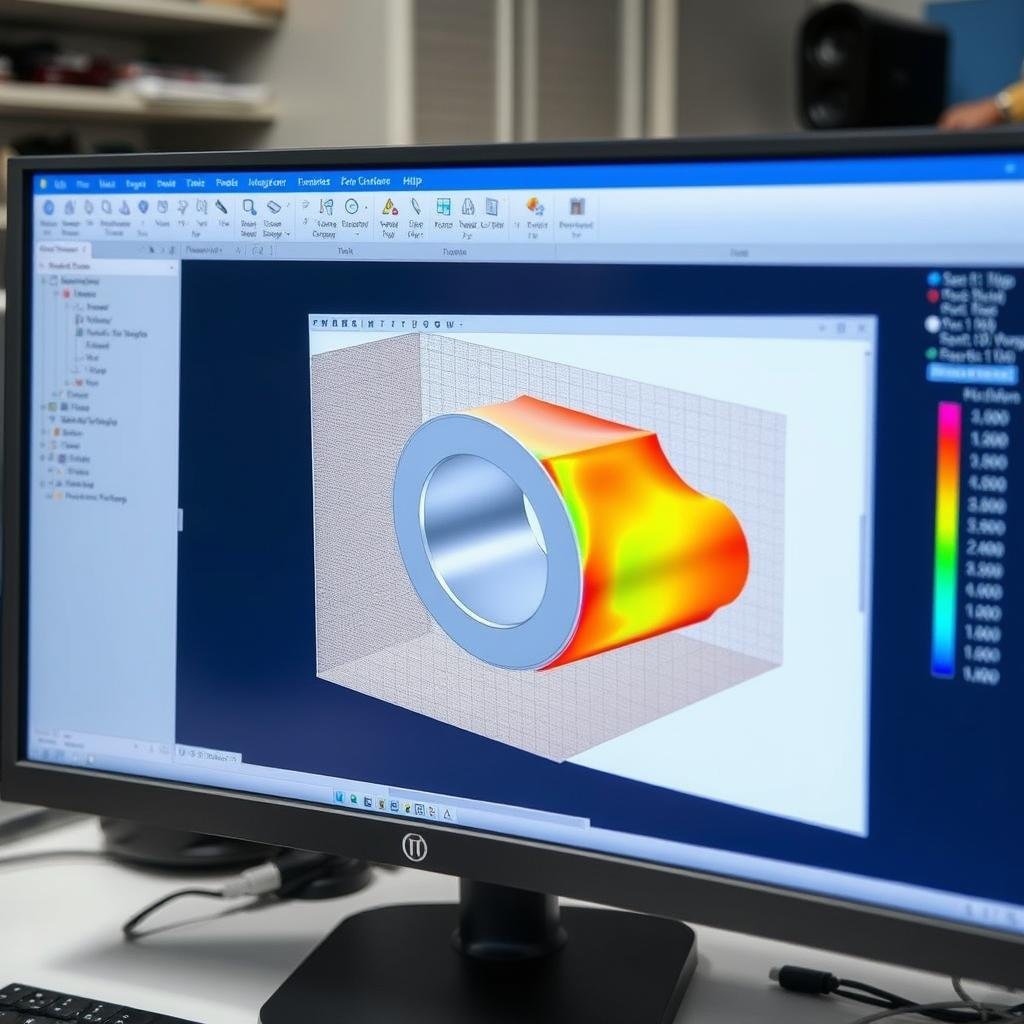

CAD/CAM Design

Utilizing analysis software facilitates early-stage issue identification and mitigation.

Material Selection

We thoroughly consider mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness of aluminum alloy.

Tooling Design

Our tooling design ensures initial quality, while regular maintenance preserves consistency, both critical for producing high-quality forgings.

Forging Process

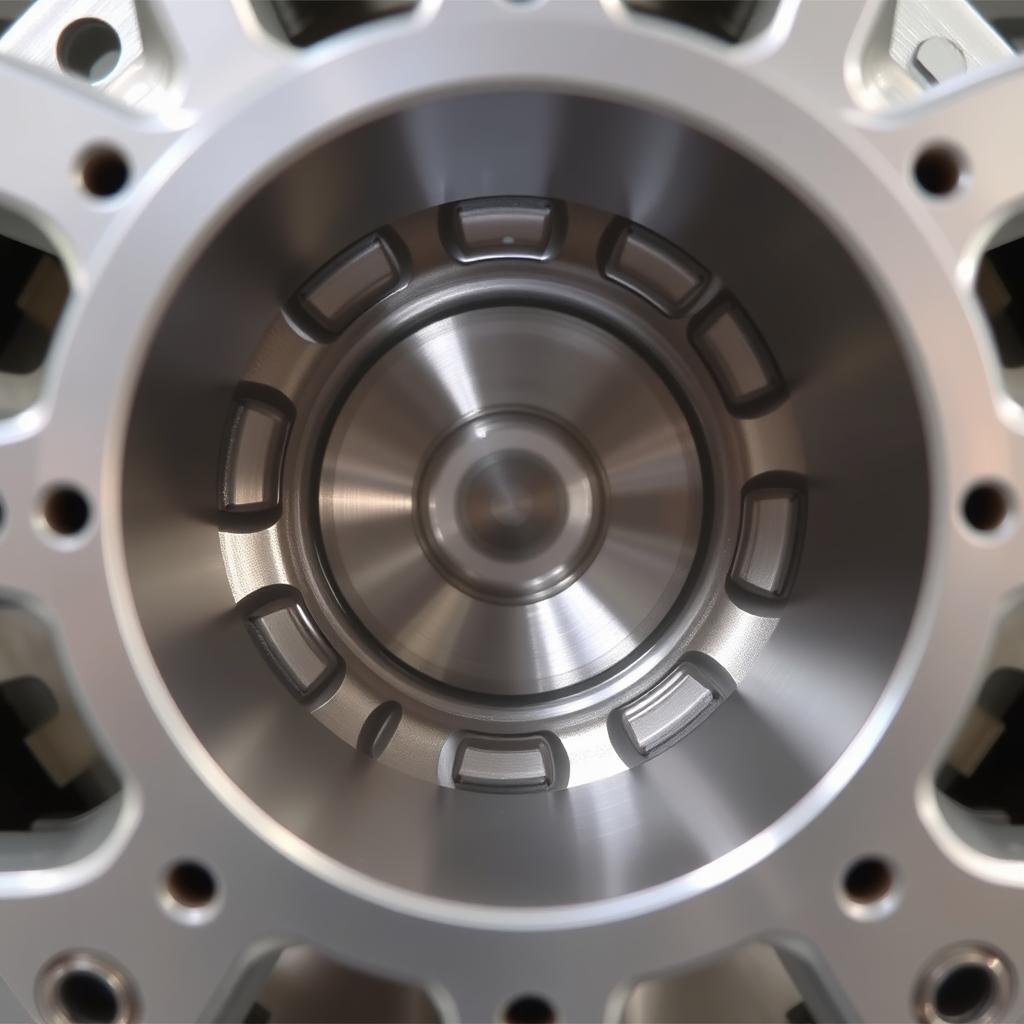

Our forging workshop is equipped to accommodate diverse aluminum forging specifications with precision and consistency.

Heat Treatment

We conduct comprehensive statistical analysis and documentation for our in-house heat treatment to ensure optimal material properties.

Precision Grinding

Automated grinding with a specialized robot is employed to remove parting lines and achieve precise dimensions.

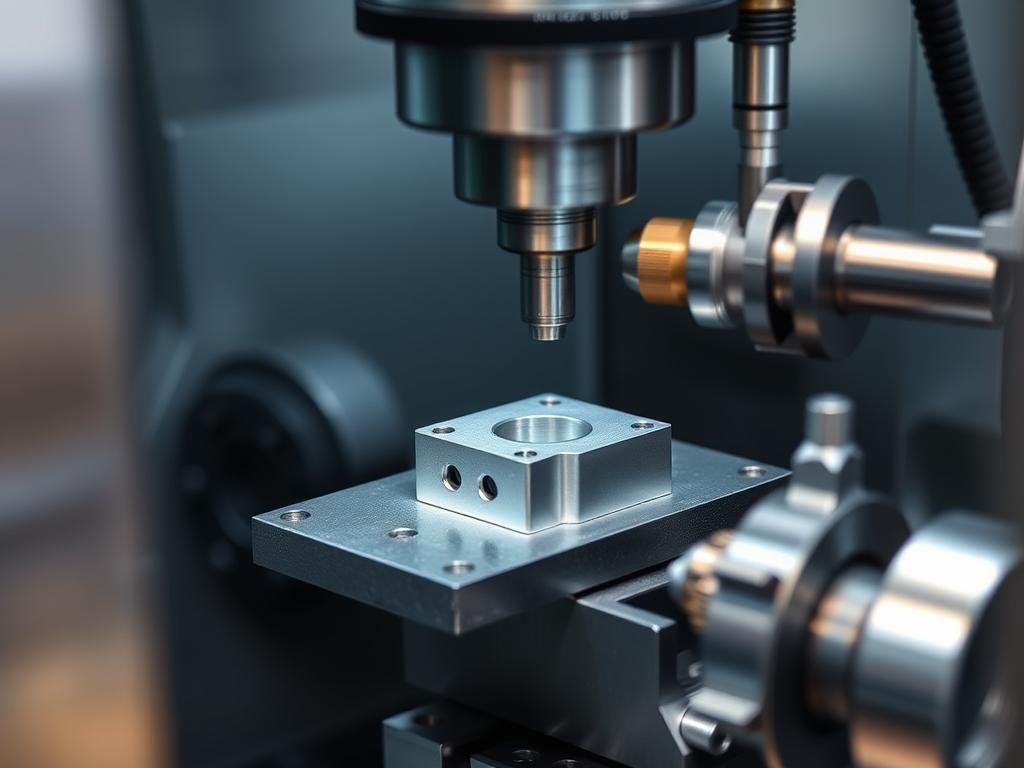

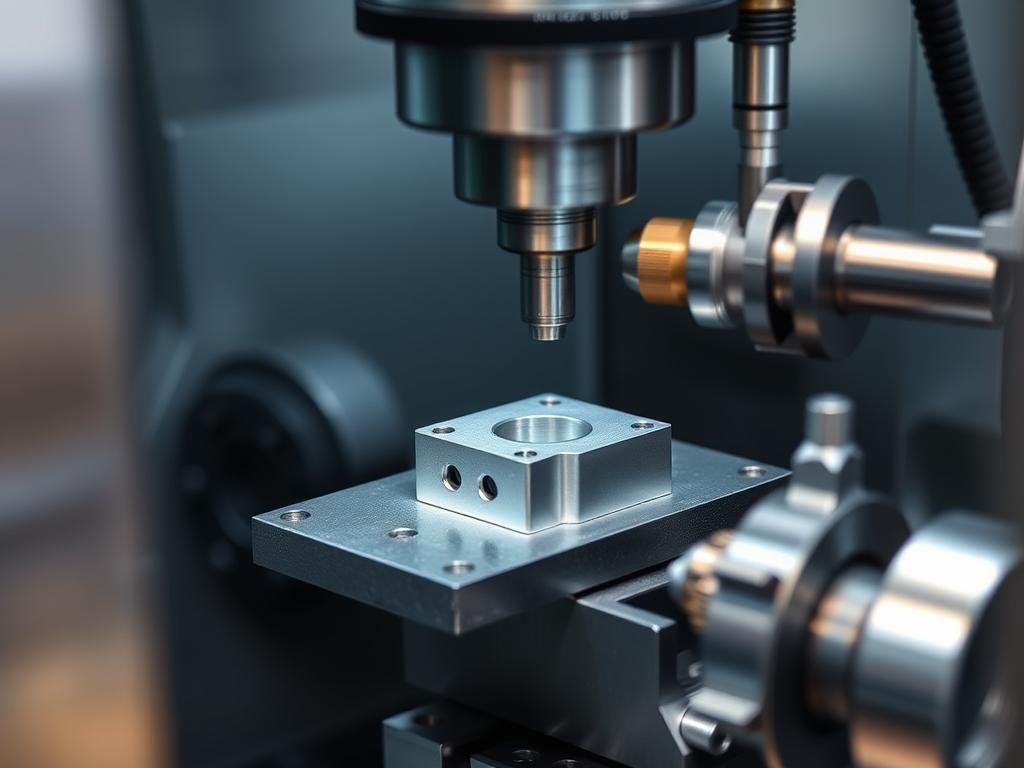

CNC Machining

Our machining workshop is equipped with state-of-the-art CNC machines capable of precise and intricate forging machining operations.

Surface Treatment

Surface treatment plays a vital role in manufacturing by enhancing the appearance, performance, and competitiveness of products.

Quality Control

Our quality control procedures are essential to ensure that forged components meet stringent standards for dimensional accuracy and material properties.

Experience Our Full-Service Capabilities

From design to delivery, MAIKONG handles every aspect of your aluminum forging needs with precision and expertise.

Get A Quick Quote

Why Choose Forged Aluminum?

Aluminum Forging and its Optimal Strength-to-Weight Ratio

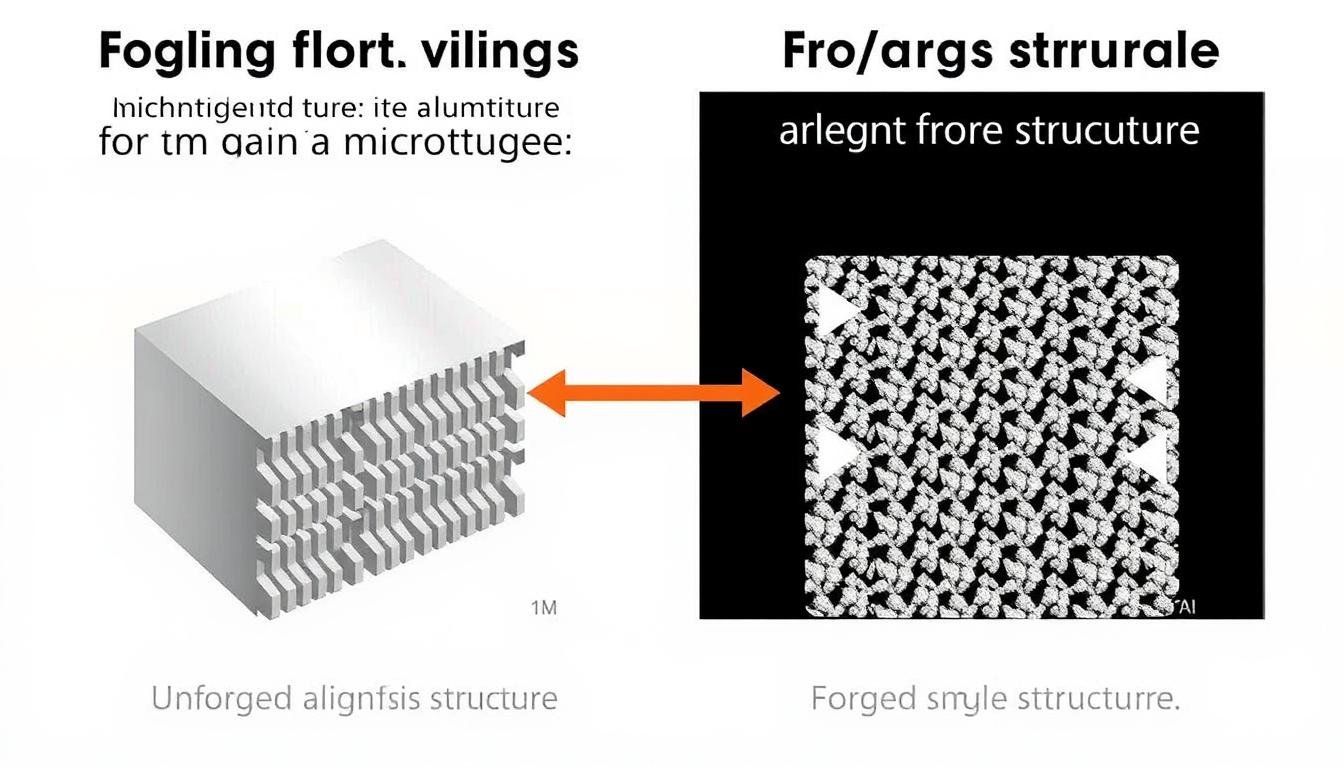

Strength-to-weight ratio is a fundamental engineering principle that addresses the balance between material strength and weight—an essential consideration in industries prioritizing performance, efficiency, and safety. Aluminum, recognized for its lightweight properties and robust mechanical characteristics, is enhanced through forging, refining its internal grain structure for enhanced resilience and strength.

This makes aluminum forgings the optimal choice for withstanding static and dynamic loads. With optimal strength-to-weight ratio showcases engineering excellence, a combination of material science, metallurgy, and precision manufacturing. It embodies efficiency and performance, reshaping possibilities across industries.

Forging process aligns the grain structure of aluminum for superior strength and performance

The Advantage of Aluminum Forging over Casting Aluminum

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps of effort to achieve complex shape |

✅Can achieve complex shape in one session |

| Dimensional Accuracy |

✅Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅Smoother surfaces, reduced post-processing |

Might require more machining due to air pocket |

| Heat Treatment Response |

✅Responsive for controlled material properties |

Less predictable response |

| Grain Structure |

✅Directional grain flow for improved properties |

No directional grain structure |

| Weight-to-Strength Ratio |

✅High strength-to-weight ratio |

Bulkier parts may be needed |

| Resistance to Corrosion |

✅Improved due to denser structure |

Naturally forming oxide layer for resistance |

| Engineering Consistency |

✅Controlled material characteristics |

Variability in material properties |

| Critical Applications |

✅Structural Members and load-bearing capabilities |

Limited suitability for critical applications |

| Focus Usage |

Enhanced mechanical performance and precision |

Less demanding applications and complex shapes |

| Ideal Industry |

Aerospace, automotive, medical devices, etc. |

Consumer goods, simple parts, non-critical sectors |

Seeking Superior Strength and Performance?

Discover how MAIKONG’s aluminum forging expertise can elevate your product’s performance and reliability.

Contact Us on WhatsApp

Our Comprehensive Manufacturing Services

At MAIKONG, we specialize in aluminum forging, a process that meticulously shapes aluminum into precise forms using compressive forces. This process has a wide array of applications across various industries such as aerospace, automotive, bicycle, construction, electronics, and motorcycle, to name a few. Our dedicated team handles every step of the aluminum forging process, starting from the design phase to the final finishing touches.

CNC Machining Services

MAIKONG operates 60+ CNC machines providing 100+ tons of metal processing capacity per month. Our CNC machining service offers precision fabrication of plastic and metal parts in any volume. We ensure all raw materials meet your exact specifications through our best-in-class testing and verification laboratory.

CNC Turning Services

CNC turning is the ideal way to make deep holes, machined threads, and all types of cylindrical shapes with superior surface finishes. When you need precisely manufactured parts with fast turnaround, MAIKONG’s CNC turning is your solution.

CNC Milling Services

CNC milling makes complex prismatic shapes and flat surfaces for a limitless variety of commercial and industrial products. Our multi-axis metal CNC machines require no fixed tooling, are highly flexible, and extremely accurate.

CNC SWISS Type Machining

CNC Swiss-type machining at MAIKONG specializes in precision small parts and long shaft parts. Our equipment features dual spindles, 3-axis, 4-axis, and 5-axis capabilities, allowing for a one-stop solution. This ensures the highest level of accuracy without the need for additional equipment.

Heat Treatment Services

We provide heat treatment for aluminum parts to improve their mechanical properties, making them not just fit for purpose but also long-lasting. Our comprehensive statistical analysis and documentation ensure consistent quality.

Surface Treatment

Our surface treatments encompass anodizing, painting, laser engraving, and sand blasting. We leverage advanced tools like spectrophotometers for color and gloss measurement, adhesion testers, and precisely configured laser engraving settings.

Need Custom Manufacturing Solutions?

Contact MAIKONG today to discuss your specific requirements and discover how our comprehensive services can meet your needs.

Or email us at: Lucy@maikongforge.us

State-of-the-Art Manufacturing Facility

MAIKONG’s manufacturing facility, located in GD, SZ, houses a range of well-maintained forging equipment. Our strategic location presents us with logistical advantages, facilitating efficient receipt of raw materials and prompt dispatch of finished parts to our partners worldwide.

Our suite of machinery, encompassing hydraulic forging presses, uniform heat treatment furnaces, and precision-driven CNC machines, assures both the quality and volume of our production. The factory layout is planned to foster optimal efficiency. Our production lines have been engineered to minimize waste and expedite the manufacturing process.

This strategic arrangement ensures a smooth and uninterrupted flow of materials, right from the moment raw aluminum enters our premises to the point where completed parts are prepared for dispatch. Every aspect of our operation, from the configuration of our production floors to the maintenance of our machinery, is informed by our commitment to efficiency, quality, and sustainability.

Quality Assurance

MAIKONG is proud to be ISO 9001:2015 and AS9100D certified, and our team is committed to providing outstanding customer satisfaction. Our quality engineering staff monitors the production process and quality at all times to ensure the consistency and quality of the components.

When a problem is identified, we conduct a systematic root cause analysis using methods like the 5 Whys and advanced statistical techniques. The objective is not just to identify the immediate cause but to understand and address the underlying factors to prevent the issue from recurring.

Become a US Distributor for MAIKONG

We’re actively recruiting distributors across the United States. Join us in delivering high-quality, cost-effective aluminum forging solutions to the American market.

Apply to Become a Distributor

Industry Applications for Aluminum Forgings

Aerospace

Aircraft structures, rocket adapters, space frames, satellite panels, and aerospace-grade fasteners require the superior strength-to-weight ratio that only forged aluminum can provide.

Automotive

Forged wheels, suspension arms, transmission components, and heavy vehicle linkages benefit from aluminum’s lightweight properties and durability under cyclic loading.

Defense

Missile casings, armored vehicle frames, launch tubes, and tactical weapon components rely on the consistent performance of forged aluminum under extreme conditions.

Industrial & Construction

Structural connectors, load-bearing joints, brackets, and pressure equipment components benefit from aluminum’s corrosion resistance and strength.

Medical & Precision Components

Orthopedic parts, surgical components, and precision medical-grade equipment require the reliability and biocompatibility of properly forged aluminum.

Sports & Recreation

Bicycle frames, archery components, motorsports parts, and high-performance gear leverage aluminum’s lightweight strength for optimal performance.

Find the Perfect Aluminum Forging Solution

Whatever your industry, MAIKONG has the expertise to deliver aluminum forgings that meet your exact specifications.

Get A Quick Quote

Choose the Right Aluminum Alloy for Your Application

Selecting the optimal aluminum alloy is crucial for ensuring your forged components deliver the performance characteristics required for your specific application. MAIKONG offers expertise in a wide range of aluminum alloys, each with unique properties suited to different uses.

6061 Aluminum

Excellent corrosion resistance and weldability, ideal for structural applications requiring good strength and finishing characteristics.

Structural

Corrosion-Resistant

7075 Aluminum

Superior strength-to-weight ratio, commonly used in aerospace and automotive industries where maximum strength is required.

High-Strength

Aerospace

2024 Aluminum

High fatigue resistance and excellent strength, best for aerospace components and structural applications requiring durability.

Fatigue-Resistant

Durable

2618 Aluminum

High strength at elevated temperatures, perfect for aerospace and high-performance engines operating in demanding conditions.

Heat-Resistant

Engine Components

7050 Aluminum

Excellent toughness and corrosion resistance, suitable for aerospace structural parts requiring superior damage tolerance.

Damage-Tolerant

Tough

5083 Aluminum

Outstanding resistance to seawater corrosion, ideal for marine applications and structures exposed to harsh environments.

Marine-Grade

Saltwater-Resistant

Not sure which alloy is right for your application? Our metallurgical experts can help you select the optimal material based on your specific requirements for strength, weight, corrosion resistance, and cost considerations.

Expert Alloy Selection Assistance

Contact our metallurgical team for guidance on selecting the perfect aluminum alloy for your specific application.

Email Our Experts

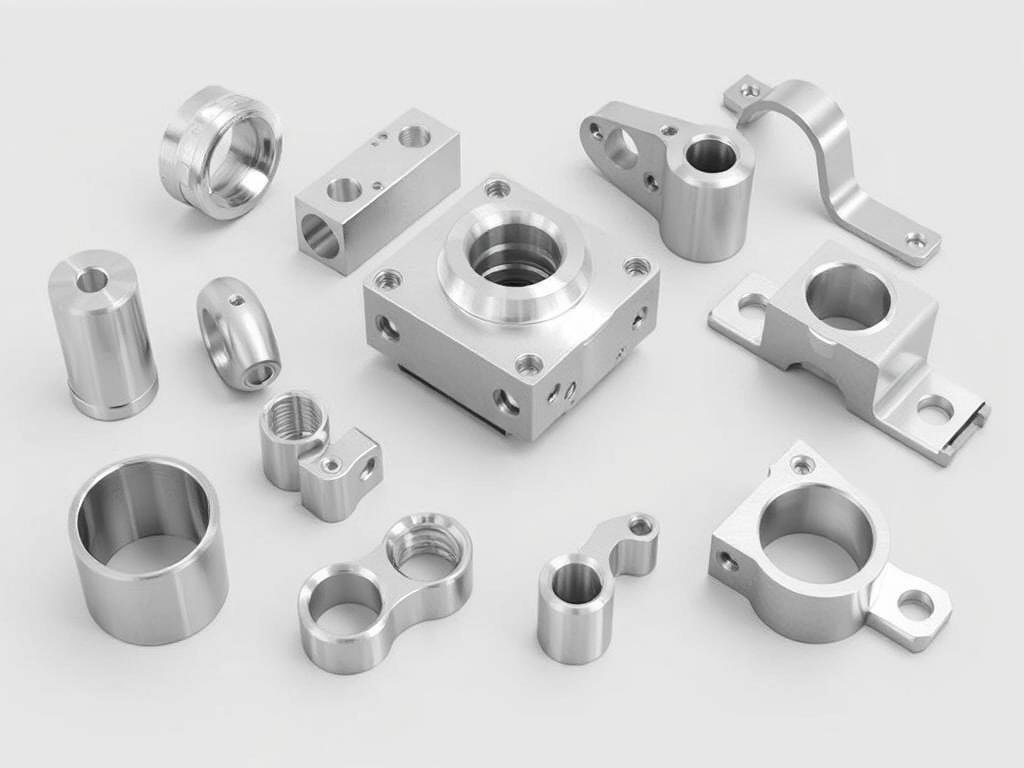

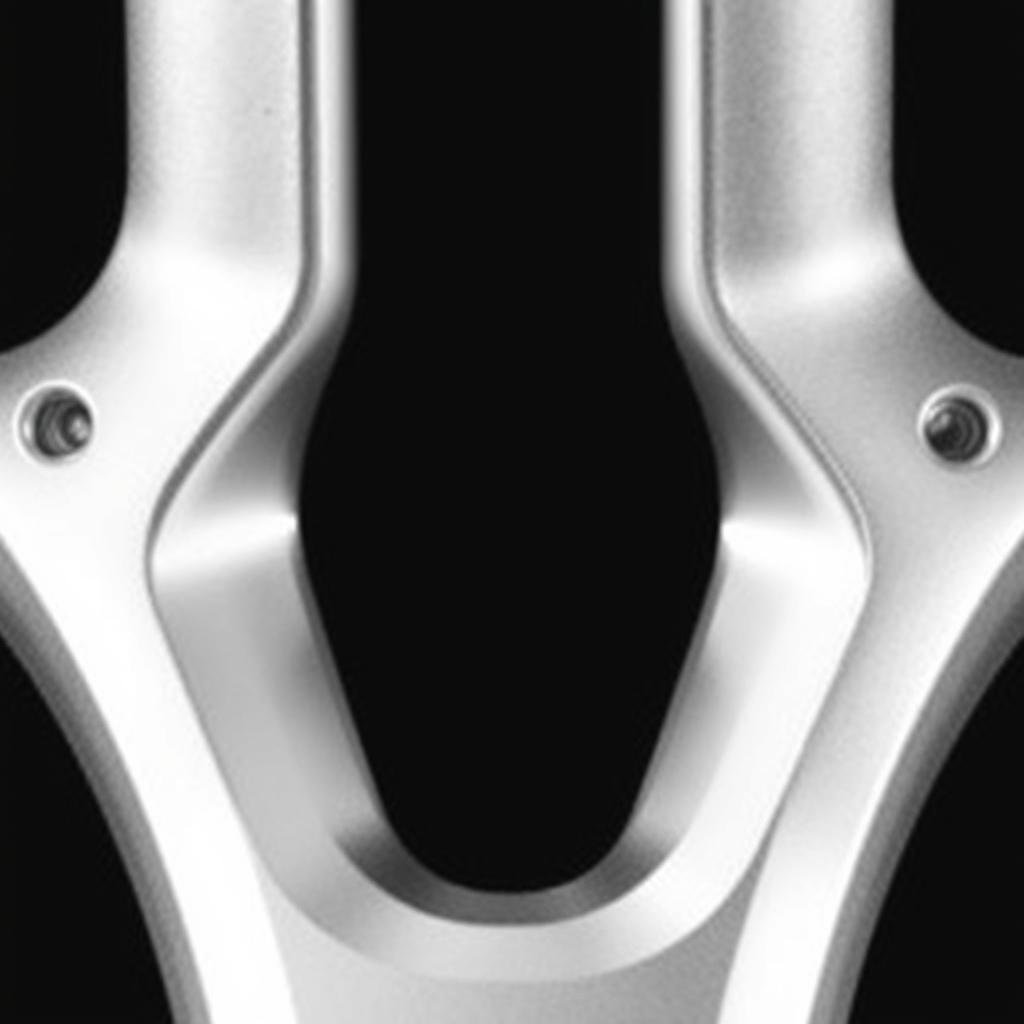

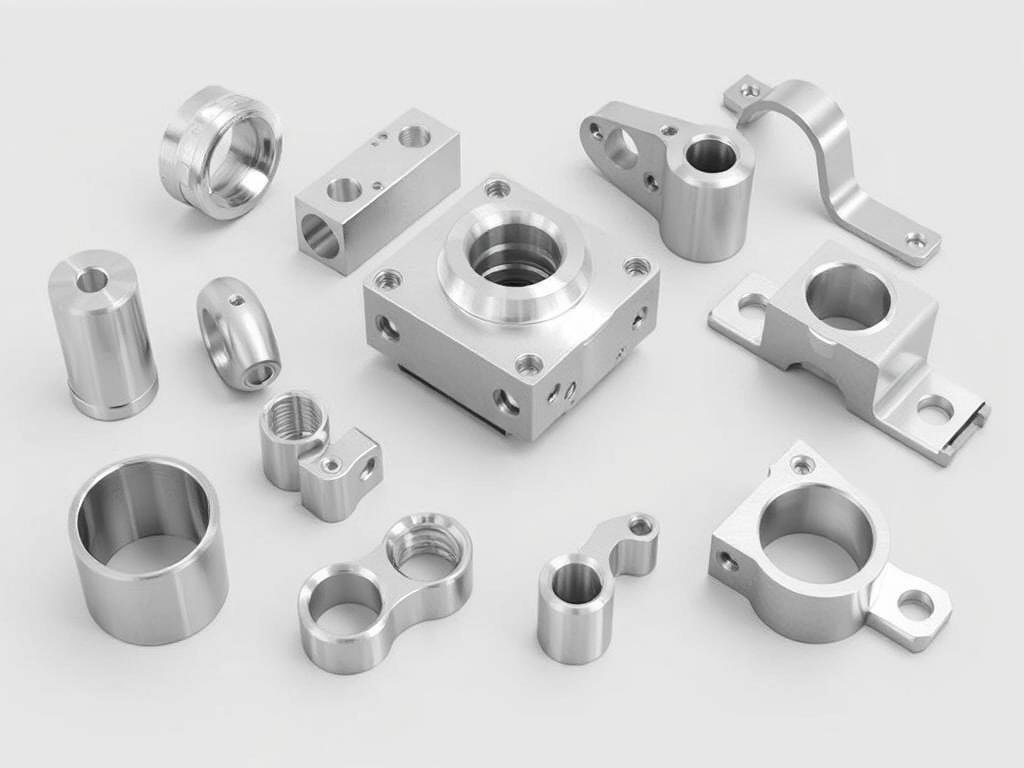

Work Samples Gallery

Browse our gallery of aluminum forged components to see examples of our craftsmanship and capabilities across various industries and applications.

Request Custom Samples

Interested in seeing samples specific to your industry or application? Contact us to request custom samples or a detailed capabilities presentation.

Contact Us on WhatsApp

About MAIKONG

MAIKONG is a one-stop forging solutions service provider and contract OEM manufacturer. With a registered capital of 30 million RMB, the company now has 200 employees and a plant area of 18,000 square meters.

We strive to bring value-added services to high-end customers around the world. We started with the production of high-end aluminum alloy bicycle parts (2D hot forging) and gradually expanded to various fields, including precision parts for 3C products (mobile phone and computer covers, TV brackets, speakers, etc.); structural parts for sports equipment (bicycles, scooters, motorcycles, robots); precision structural forging parts for automotive; and structural parts solution services for 5G communication base stations.

Quality and Team Assurance

Our company has a skilled R&D and engineering technical team focused on optimizing manufacturing processes and implementing 6S, PDCA, and lean production management. We have introduced advanced production equipment and testing instruments to ensure that our product quality meets industry-leading standards. We strictly execute the ISO 90001 and IATF16949 quality management systems to guarantee product quality and service reliability.

Enterprise Vision

To become a forging enterprise that stands for a hundred years and affects the world

Enterprise Mission

Professional aluminum forging solution provider and one-stop platform, committed to global high-end customers value-added

“Quality first, customer supreme”

MAIKONG Business Philosophy

Partner with MAIKONG Today

Experience the difference of working with a dedicated aluminum forging partner committed to your success.

Get A Quick Quote

Why Choose MAIKONG as Your Hot Forging Aluminum Supplier

The MAIKONG Advantage

- Comprehensive capabilities from design to delivery

- 60+ CNC machines with 100+ tons monthly capacity

- ISO 9001:2015 and AS9100D certified quality systems

- Expert metallurgical knowledge and material selection

- Competitive pricing with superior quality

- Responsive communication and customer service

- Flexible production capabilities for various volumes

- Extensive experience across multiple industries

As your trusted Hot Forging Aluminum Supplier, MAIKONG is committed to delivering exceptional value through superior quality, competitive pricing, and comprehensive service. Whether you need aerospace-grade components, automotive parts, or industrial applications, our team has the expertise and capabilities to exceed your expectations.

Ready to Experience the MAIKONG Difference?

Contact us today to discuss your aluminum forging requirements and discover how we can help you achieve your manufacturing goals.

Get A Quick Quote