When searching for a reliable Hot Forging Aluminum Supplier, technical expertise and production capability are paramount. MAIKONG stands as an industry leader, combining advanced hot forging techniques with precision engineering to deliver superior aluminum components. Our comprehensive approach to aluminum forging ensures optimal strength-to-weight ratios, enhanced material properties, and exceptional performance across aerospace, automotive, and defense applications.

Why MAIKONG Excels as Your Hot Forging Aluminum Supplier

MAIKONG has established itself as a premier Hot Forging Aluminum Supplier through years of specialized experience and continuous innovation. Our state-of-the-art facilities in GD, SZ feature 60+ CNC machines with a monthly capacity exceeding 100 tons of metal processing, ensuring we can meet both high-volume production needs and specialized custom requirements.

MAIKONG’s advanced hot forging facility in GD, SZ

MAIKONG’s advanced hot forging facility in GD, SZ

Ready to Experience Superior Aluminum Forging?

Our technical team is available to discuss your specific requirements and provide expert guidance.

Get A Quick Quote

The MAIKONG Hot Forging Aluminum Process

At MAIKONG, our hot forging process transforms aluminum alloys into high-performance components with superior mechanical properties. Unlike casting or machining from solid stock, hot forging aligns the grain structure of aluminum, significantly enhancing strength, durability, and fatigue resistance.

Hot forging process aligns aluminum grain structure for superior strength

Our 5-Step Hot Forging Aluminum Process

- Material Selection: Choosing the optimal aluminum alloy based on your application requirements

- Heating: Precisely heating the aluminum to 700-950°F (370-510°C) for optimal malleability

- Forging: Applying controlled pressure to shape the aluminum while maintaining ideal grain flow

- Heat Treatment: Enhancing mechanical properties through controlled cooling and aging

- Precision Finishing: CNC machining, surface treatments, and quality inspection

Why Choose Hot Forged Aluminum Over Cast Aluminum

Understanding the differences between forging and casting is crucial when selecting the right manufacturing process for your aluminum components. MAIKONG specializes in hot forging aluminum, which offers significant advantages for critical applications.

| Comparison Categories |

Hot Forged Aluminum |

Cast Aluminum |

| Strength and Durability |

✓ Superior strength due to dense, uniform grain structure |

Lower strength with potential air pockets and inclusions |

| Tensile Properties |

✓ Excellent tensile strength and resistance |

Reduced tensile properties |

| Fatigue Resistance |

✓ Enhanced resistance against cyclic loading |

More susceptible to fatigue failure |

| Dimensional Accuracy |

✓ Precise tolerances with consistent results |

Potential for dimensional inconsistencies |

| Grain Structure |

✓ Directional grain flow for improved properties |

Random grain structure without directional strength |

| Weight-to-Strength Ratio |

✓ Optimal strength-to-weight ratio |

Requires bulkier designs for equivalent strength |

| Corrosion Resistance |

✓ Enhanced resistance due to denser structure |

Adequate for non-critical applications |

Need Technical Guidance on Your Aluminum Component?

Our engineers can help determine if hot forging is the optimal process for your application.

Consult Our Experts

Premium Aluminum Alloys for Hot Forging Applications

MAIKONG works with a comprehensive range of aluminum alloys, each offering unique properties suited for specific applications. Our metallurgical expertise ensures we select the optimal alloy for your hot forging requirements.

6000 Series

6061/6082: Excellent corrosion resistance and weldability, ideal for structural applications requiring good strength-to-weight ratio.

Key Applications: Structural components, marine parts, transportation

7000 Series

7075/7050: Superior strength-to-weight ratio, excellent for high-stress applications where performance is critical.

Key Applications: Aerospace structures, defense components, high-performance equipment

2000 Series

2024/2618: High fatigue resistance and excellent strength at elevated temperatures, perfect for demanding environments.

Key Applications: Aircraft components, high-temperature applications, engine parts

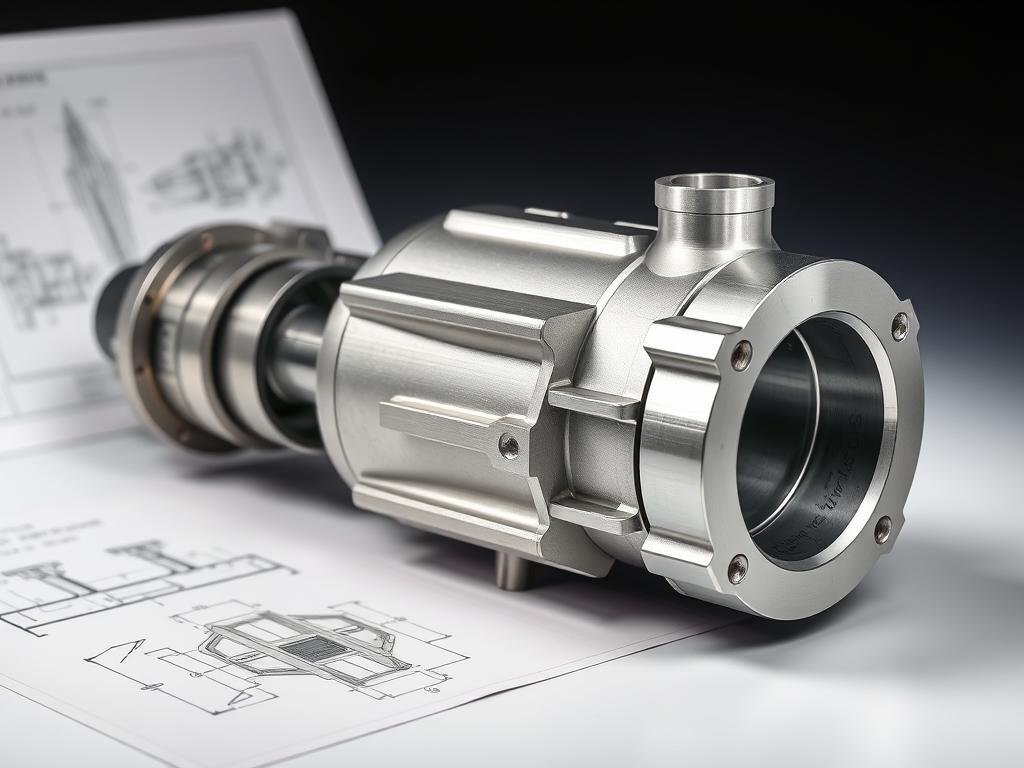

MAIKONG’s Comprehensive Hot Forging Aluminum Capabilities

As a leading Hot Forging Aluminum Supplier, MAIKONG offers end-to-end solutions from design to delivery. Our integrated approach ensures quality control at every stage of production.

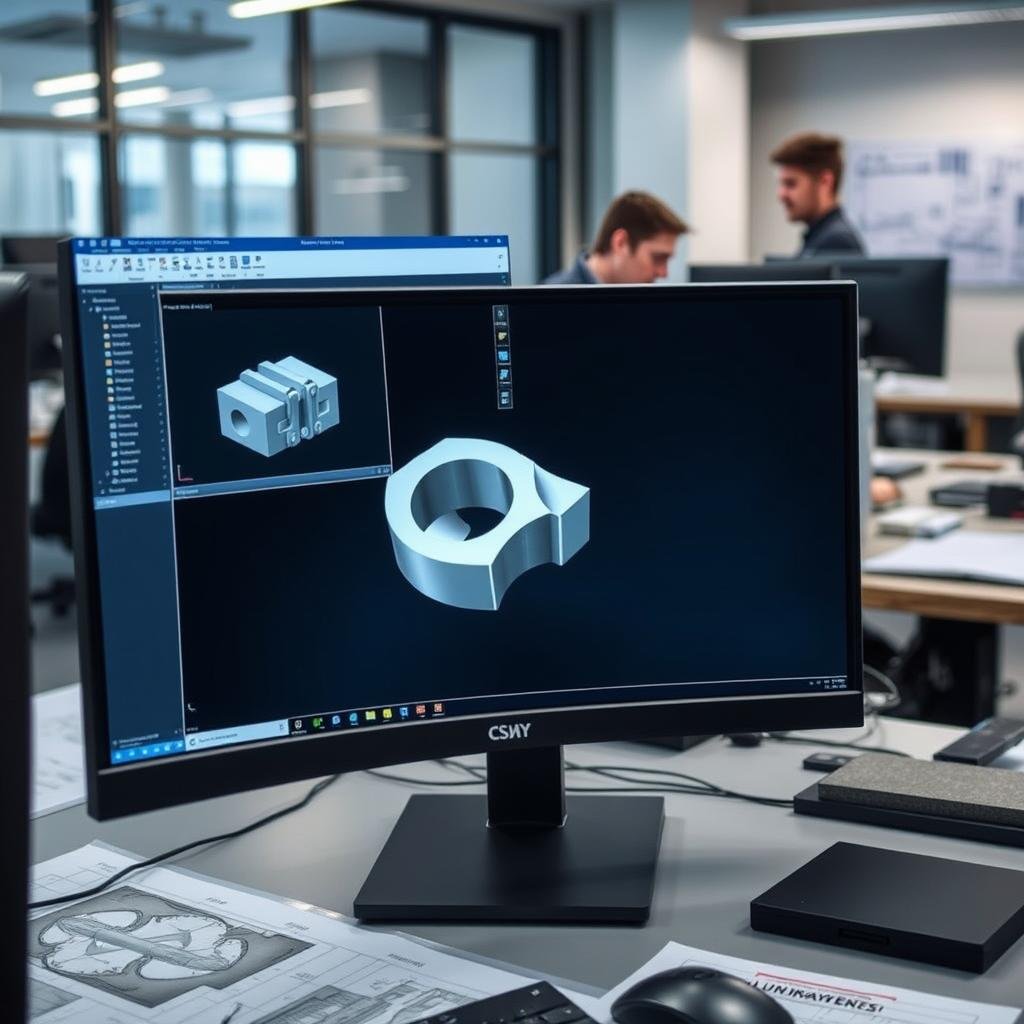

Design & Engineering

- Advanced CAD/CAM systems

- Finite Element Analysis (FEA)

- Material selection expertise

- Design for manufacturability

Forging & Processing

- Open die forging

- Closed die forging

- Ring rolling capabilities

- In-house heat treatment

Finishing & Quality

- Precision CNC machining

- Surface treatments

- Comprehensive testing

- ISO 9001:2015 certified

Maximum Forging Capabilities

| Forging Type |

Maximum Dimensions |

Maximum Weight |

| Aluminum Rings |

OD up to 1,800 mm (70″) |

Up to 4,500 kg (9,900 lbs) |

| Aluminum Discs |

Diameter up to 1,800 mm (70″) |

Up to 6,800 kg (15,000 lbs) |

| Aluminum Blocks |

Cross-section up to 1,370 mm (54″) |

Up to 6,800 kg (15,000 lbs) |

| Aluminum Bars |

Length up to 6,000 mm (236″) |

Up to 9,000 kg (19,800 lbs) |

Industry-Specific Hot Forged Aluminum Applications

MAIKONG’s hot forged aluminum components deliver exceptional performance across diverse industries where reliability, strength, and precision are non-negotiable.

Aerospace & Defense

Our aerospace-grade hot forged aluminum components meet rigorous standards for structural integrity and weight optimization.

- Aircraft structural components

- Landing gear parts

- Engine mounts and brackets

- Defense equipment housings

Automotive & Transportation

Lightweight yet robust hot forged aluminum components that enhance vehicle performance and efficiency.

- Suspension components

- Engine brackets and mounts

- Transmission housings

- Structural chassis elements

Industrial & Energy

Durable hot forged aluminum components designed to withstand demanding industrial environments.

- Pressure equipment components

- Valve bodies and flanges

- Renewable energy structures

- Heavy machinery parts

Specialized Hot Forging Solutions for Your Industry

Whether you’re in aerospace, automotive, or industrial sectors, our engineering team can develop custom hot forged aluminum solutions for your specific application.

Discuss Your Industry Needs

Quality Assurance from Your Trusted Hot Forging Aluminum Supplier

At MAIKONG, quality is embedded in every aspect of our operation. Our comprehensive quality management system ensures that each hot forged aluminum component meets or exceeds industry standards and customer specifications.

Comprehensive quality testing ensures each component meets rigorous standards

Certifications & Standards

- ISO 9001:2015 certified quality management system

- Compliance with ASTM B247, AMS 4127, and AMS 4143 standards

- Rigorous material traceability and documentation

- Comprehensive statistical process control

Testing Capabilities

- Mechanical property testing (tensile, yield, elongation)

- Non-destructive testing (ultrasonic, dye penetrant)

- Dimensional inspection with CMM technology

- Metallurgical analysis and microstructure evaluation

Value-Added Services from MAIKONG

Beyond our core hot forging capabilities, MAIKONG offers comprehensive value-added services to streamline your supply chain and enhance component performance.

CNC Machining

Our advanced CNC machining centers provide precision finishing for hot forged components:

- 3-axis, 4-axis, and 5-axis machining

- Swiss-type machining for small precision parts

- CNC turning for cylindrical components

- High-precision surface grinding

Surface Treatments

Enhance performance and aesthetics with our surface treatment options:

- Anodizing (Type I, II, and III)

- Powder coating and painting

- Chemical conversion coating

- Laser engraving and marking

Assembly & Packaging

Complete your supply chain with our assembly and packaging services:

- Component assembly and sub-assembly

- Custom protective packaging

- Kitting and inventory management

- Global logistics coordination

Success Stories: MAIKONG Hot Forged Aluminum Solutions

Explore how our hot forging expertise has helped clients across industries solve complex challenges and achieve superior performance.

Aerospace Structural Component

Challenge: An aerospace client needed a complex structural component with exceptional strength-to-weight ratio and fatigue resistance for a new aircraft design.

Solution: MAIKONG developed a custom 7075-T73 hot forged aluminum solution with optimized grain flow and comprehensive testing to meet aerospace standards.

Result: The component achieved a 22% weight reduction while exceeding strength requirements, contributing to improved fuel efficiency and performance.

Automotive Suspension Component

Challenge: An automotive manufacturer sought to reduce unsprung weight in a performance vehicle’s suspension system without compromising durability.

Solution: MAIKONG engineered a 6082-T6 hot forged aluminum component with optimized topology and integrated mounting features.

Result: The solution delivered a 31% weight reduction, improved handling characteristics, and passed accelerated life testing equivalent to 300,000 kilometers.

Ready to Develop Your Custom Hot Forged Aluminum Solution?

Our engineering team is prepared to tackle your most challenging applications with innovative hot forging solutions.

Start Your Project

Why Choose MAIKONG as Your Hot Forging Aluminum Supplier

MAIKONG combines technical expertise, production capability, and customer-focused service to deliver exceptional value as your hot forging partner.

Technical Excellence

- Specialized metallurgical expertise

- Advanced process simulation

- Optimized die design

- Continuous innovation

Production Capability

- 60+ CNC machines

- 100+ tons monthly capacity

- Comprehensive in-house capabilities

- Scalable production volumes

Customer Focus

- Dedicated project management

- Transparent communication

- Flexible scheduling

- Competitive global pricing

Elevate Your Products with MAIKONG Hot Forged Aluminum

As your dedicated Hot Forging Aluminum Supplier, MAIKONG is committed to delivering superior components that enhance the performance, reliability, and efficiency of your products. Our comprehensive capabilities, technical expertise, and customer-focused approach make us the ideal partner for your most demanding aluminum forging requirements.

Contact MAIKONG today to discover how our hot forging solutions can transform your manufacturing process and product performance.

Ready to Get Started?

Our team is standing by to discuss your hot forging aluminum needs.

Contact MAIKONG Today

MAIKONG’s advanced hot forging facility in GD, SZ

MAIKONG’s advanced hot forging facility in GD, SZ