In today’s competitive manufacturing landscape, finding the right Hot Forging Aluminum Supplier goes far beyond basic production capacity. True excellence in aluminum forging requires precision engineering, material expertise, comprehensive capabilities, and unwavering quality control. At MAIKONG, we’ve established ourselves as a leading Hot Forging Aluminum Supplier by exceeding these fundamental requirements while delivering exceptional value and customer service.Whether you’re seeking a partner for aerospace components, automotive parts, or industrial applications, understanding what truly defines excellence in aluminum forging will help you make the right supplier choice for your critical manufacturing needs.

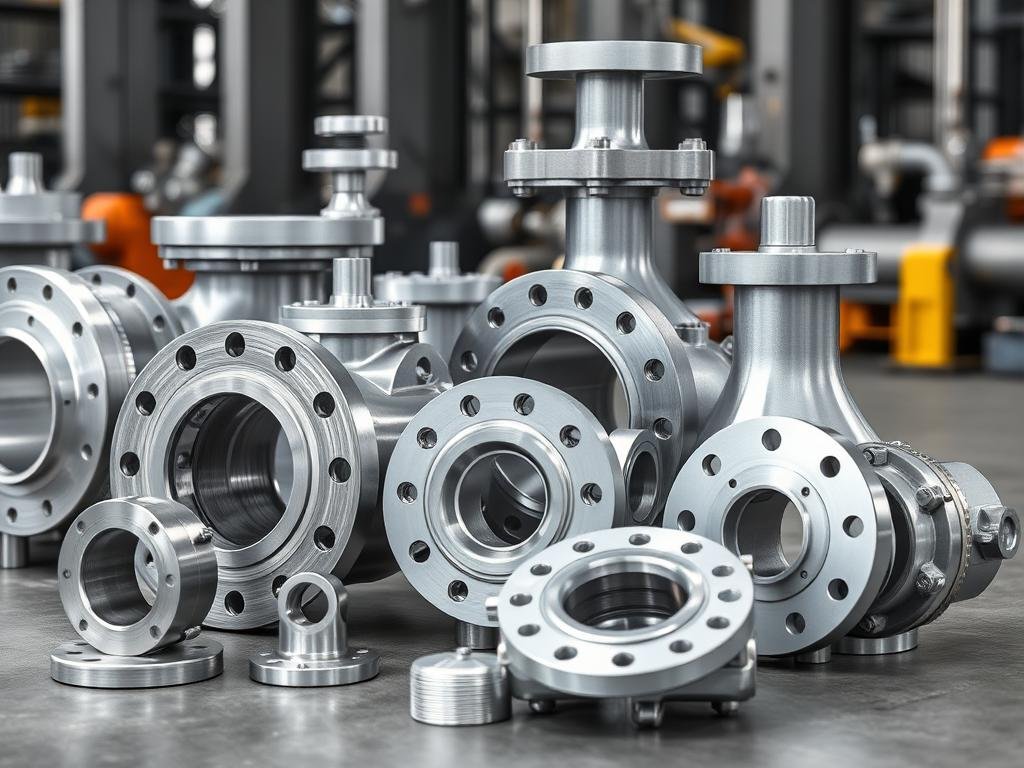

Comprehensive Aluminum Forging Capabilities

MAIKONG offers complete aluminum forging solutions with precision engineering and quality assurance. Ready to discuss your project?

MAIKONG offers complete aluminum forging solutions with precision engineering and quality assurance. Ready to discuss your project?

Get A Quick Quote

The Complete Arsenal of a Premium Hot Forging Aluminum Supplier

What truly distinguishes an exceptional Hot Forging Aluminum Supplier is the breadth and depth of their capabilities. At MAIKONG, we’ve developed a comprehensive suite of services that cover every aspect of the aluminum forging process.

MAIKONG’s state-of-the-art hot forging facility in GD, SZ with advanced hydraulic presses

Advanced Forging Processes for Superior Aluminum Components

As a leading Hot Forging Aluminum Supplier, MAIKONG employs multiple forging techniques to meet diverse manufacturing requirements:

Hot Forging Excellence

Our hot forging process shapes aluminum at temperatures between 700°F and 950°F (370°C-510°C), creating components with exceptional grain structure and mechanical properties. This technique is ideal for complex geometries and high-performance applications.

Precision Cold Forging

For applications requiring tight tolerances and superior surface finish, our cold forging capabilities deliver exceptional dimensional accuracy and material utilization, perfect for high-volume precision components.

Closed Die Forging

Our closed die forging creates high-precision components using tightly shaped dies, ideal for critical applications requiring complex geometries and consistent mechanical properties.

Open Die Forging

For larger, simpler components, our open die forging delivers excellent grain refinement and improved mechanical properties, perfect for structural applications requiring strength and durability.

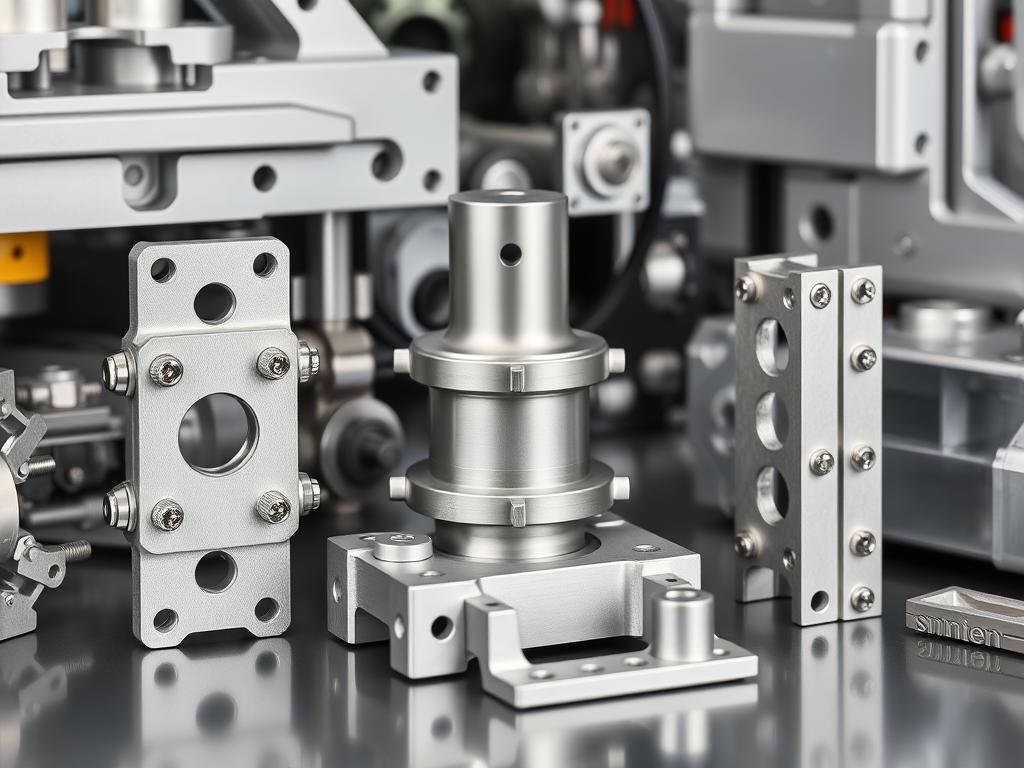

Comprehensive CNC Machining Services

MAIKONG’s integrated manufacturing approach includes advanced CNC machining capabilities that complement our forging expertise:

CNC Turning

Our precision CNC turning services create deep holes, machined threads, and cylindrical shapes with superior surface finishes, ideal for components requiring rotational symmetry.

CNC Milling

For complex prismatic shapes and flat surfaces, our multi-axis CNC milling machines deliver high accuracy without fixed tooling, offering exceptional flexibility for diverse component designs.

Swiss-Type Machining

Specialized in precision small parts and long shaft components, our Swiss-type machining equipment features dual spindles and multi-axis capabilities for one-stop manufacturing solutions.

By combining these advanced forging and machining capabilities, MAIKONG delivers comprehensive manufacturing solutions that few other suppliers can match. This integration ensures consistent quality, reduced lead times, and optimized costs for our customers.

Material Expertise: The Foundation of Superior Aluminum Forgings

A truly exceptional Hot Forging Aluminum Supplier must possess deep knowledge of aluminum alloys and their specific properties. At MAIKONG, our material expertise ensures optimal alloy selection for each application.

Premium aluminum alloy billets ready for forging at MAIKONG’s facility

Aluminum Alloy Selection for Optimal Performance

We work with a comprehensive range of aluminum alloys, each offering specific advantages for different applications:

| Alloy Series |

Key Properties |

Ideal Applications |

| 2000 Series (2014, 2024, 2219) |

High strength, excellent fatigue resistance |

Aerospace structural components, aircraft parts |

| 6000 Series (6061, 6082) |

Good corrosion resistance, excellent weldability |

Automotive components, structural applications |

| 7000 Series (7050, 7075) |

Superior strength-to-weight ratio, high mechanical strength |

Aerospace, defense, high-performance applications |

| 4000 Series (4032) |

High wear resistance, low thermal expansion |

Pistons, engine components, high-temperature applications |

The Strength-to-Weight Advantage of Forged Aluminum

One of the most compelling reasons to choose forged aluminum components is their exceptional strength-to-weight ratio. This fundamental engineering principle addresses the critical balance between material strength and weight—essential for industries prioritizing performance, efficiency, and safety.

Aluminum’s naturally lightweight properties combined with the enhanced mechanical characteristics achieved through forging create components that offer:

- Superior tensile strength compared to cast aluminum

- Enhanced fatigue resistance for dynamic loading applications

- Improved directional strength through controlled grain flow

- Excellent corrosion resistance for demanding environments

- Reduced weight for improved fuel efficiency and performance

Need Expert Material Selection Guidance?

Our metallurgists can help you select the optimal aluminum alloy for your specific application requirements.

Contact Our Material Experts

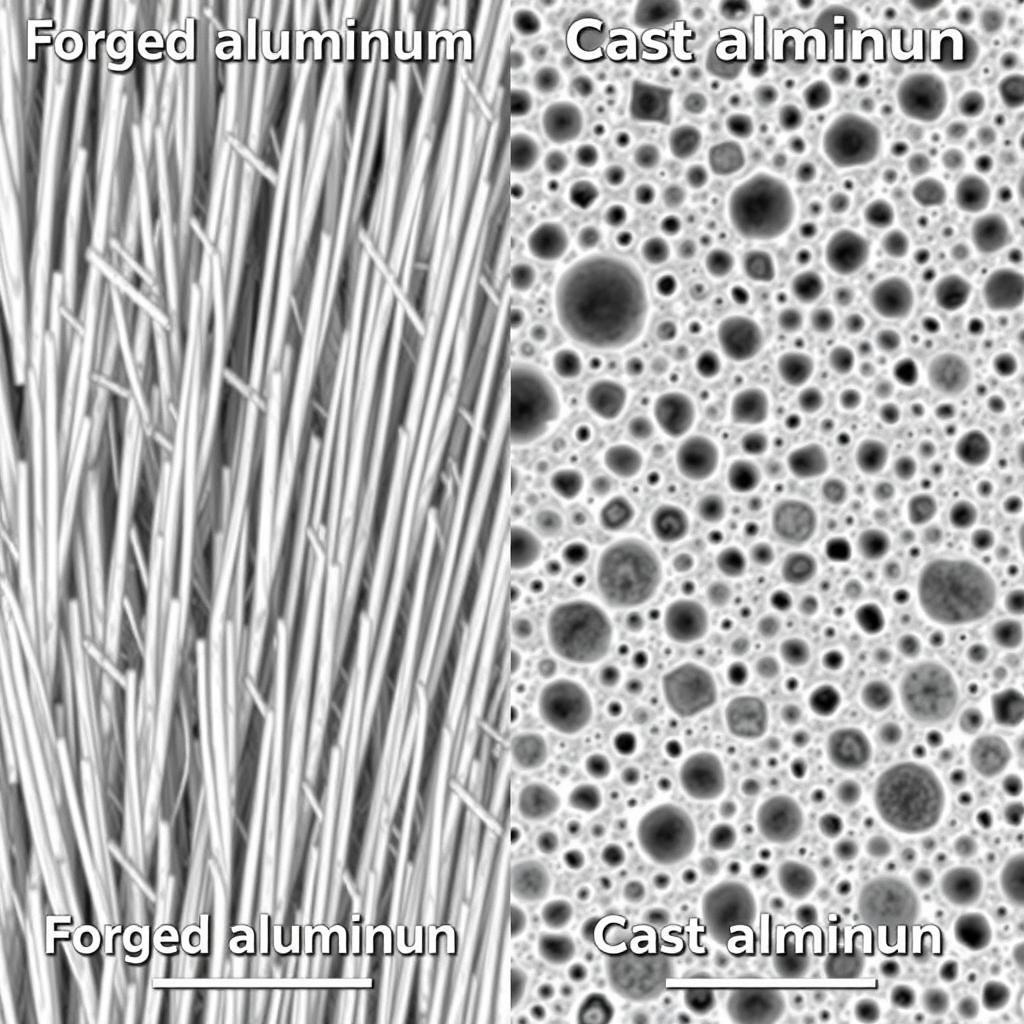

Forged vs. Cast Aluminum: Understanding the Critical Differences

When evaluating a Hot Forging Aluminum Supplier, it’s essential to understand the fundamental advantages that forging offers over casting. This knowledge helps appreciate the value that expert forging brings to critical components.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Critical Applications |

✅ Ideal for structural and load-bearing components |

Limited suitability for critical applications |

For applications where performance, reliability, and safety are paramount, forged aluminum components provide significant advantages that justify their selection over cast alternatives. MAIKONG’s expertise in aluminum forging ensures these advantages are fully realized in every component we produce.

Quality Assurance: The Hallmark of a Premium Supplier

What truly distinguishes an exceptional Hot Forging Aluminum Supplier is their commitment to rigorous quality control throughout the manufacturing process. At MAIKONG, quality is not just a department—it’s a fundamental aspect of our company culture.

MAIKONG’s quality control laboratory with advanced inspection equipment

Comprehensive Quality Management System

Our quality management system is built on internationally recognized standards and best practices:

- ISO 9001:2015 certified quality management system

- 100% material traceability from raw material to finished product

- In-process inspection at critical manufacturing stages

- Advanced non-destructive testing capabilities

- Comprehensive dimensional verification using CMM technology

- Material testing and verification in our in-house laboratory

Testing and Verification Capabilities

Our comprehensive testing capabilities ensure every component meets or exceeds specifications:

Mechanical Testing

We conduct tensile testing, hardness testing, and impact testing to verify mechanical properties meet required specifications.

Non-Destructive Testing

Our NDT capabilities include ultrasonic testing, dye penetrant inspection, and magnetic particle inspection to detect any internal or surface defects.

Metallurgical Analysis

Our metallurgical laboratory performs microstructure analysis, grain flow evaluation, and chemical composition verification.

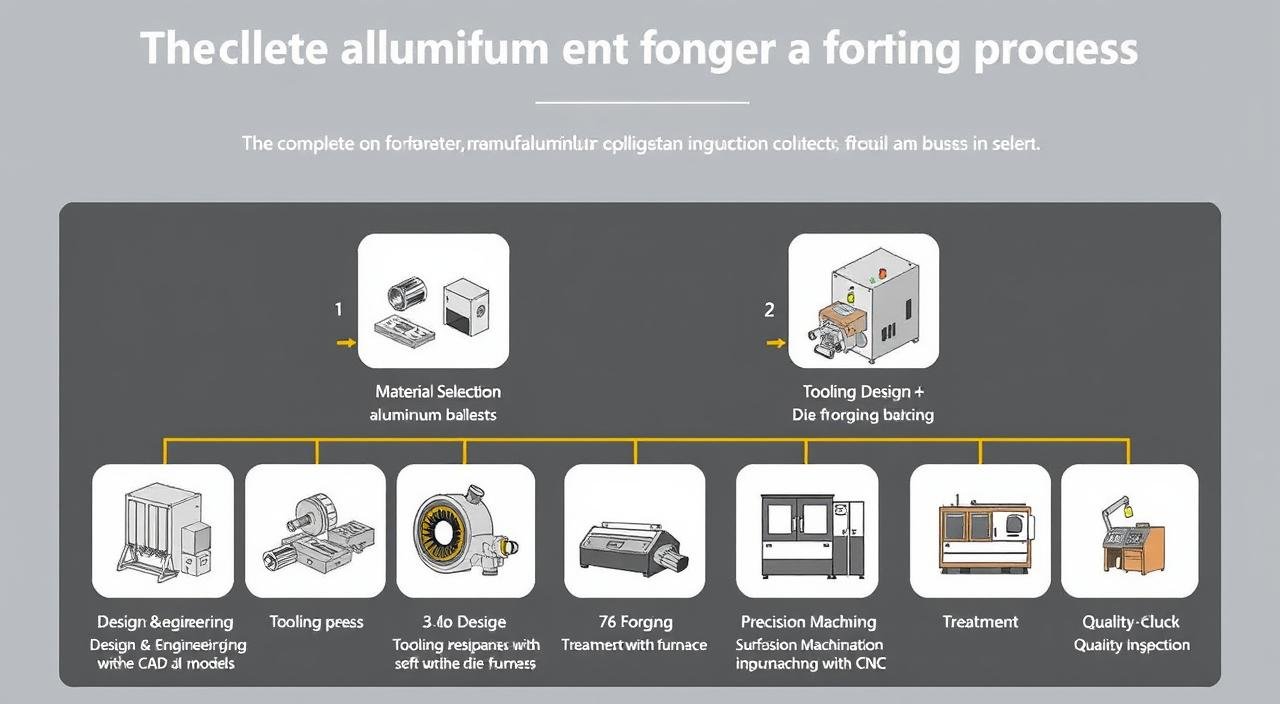

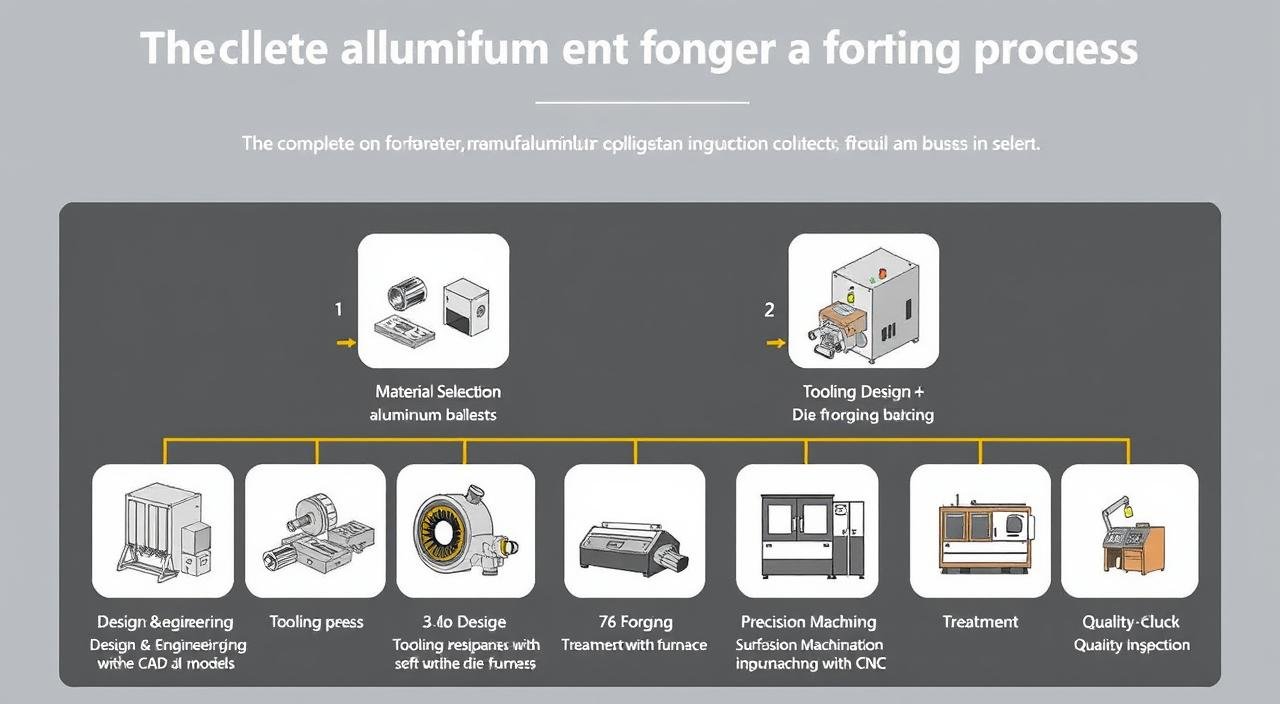

The Comprehensive Manufacturing Process

A superior Hot Forging Aluminum Supplier must master every step of the manufacturing process. At MAIKONG, our integrated approach ensures excellence at each stage from design to delivery.

Integrated Manufacturing Approach

Our comprehensive manufacturing process includes:

1. Design & Engineering

Our engineering team collaborates with customers to optimize component design for manufacturability, performance, and cost-effectiveness. Using advanced CAD/CAM systems and simulation tools, we identify potential issues early and develop optimal forging processes.

2. Material Selection

We carefully select the appropriate aluminum alloy based on application requirements, considering mechanical properties, machinability, heat treatment characteristics, and cost-effectiveness.

3. Tooling Design & Fabrication

Our expert tooling engineers design and fabricate precision dies that ensure initial quality and consistency throughout production runs. Regular maintenance preserves die integrity for consistent quality.

4. Forging Process

Our forging workshop accommodates diverse aluminum forging specifications, with precise temperature control and hydraulic presses capable of delivering the optimal pressure for each application.

5. Heat Treatment

In-house heat treatment facilities allow precise control over critical processes like solution treatment, quenching, and aging to achieve specified mechanical properties.

6. Precision Machining

Our state-of-the-art CNC machines perform precise and intricate machining operations to achieve final dimensions and features with tight tolerances.

7. Surface Treatment

We offer comprehensive surface treatment options including anodizing, painting, and mechanical finishing to enhance appearance, performance, and corrosion resistance.

8. Quality Inspection

Rigorous quality control procedures ensure every component meets stringent standards, with comprehensive documentation and traceability throughout the process.

MAIKONG’s comprehensive manufacturing process ensures quality at every stage

Industry Applications: Versatility of Hot Forged Aluminum

A premier Hot Forging Aluminum Supplier must demonstrate versatility across multiple industries. MAIKONG’s expertise spans diverse sectors with specialized solutions for each.

Aerospace

Our aerospace-grade aluminum forgings meet stringent industry standards for critical components including structural parts, landing gear components, and engine mounts where reliability is paramount.

Automotive

We produce lightweight, high-strength aluminum forgings for suspension components, engine parts, and structural elements that help automotive manufacturers improve fuel efficiency and performance.

Defense

Our defense industry forgings meet exacting specifications for mission-critical applications including weapons systems, vehicle components, and tactical equipment where failure is not an option.

Medical

Precision aluminum forgings for medical equipment and devices where dimensional accuracy, surface quality, and material purity are essential for patient safety and equipment reliability.

Energy

Our aluminum forgings for the energy sector include components for renewable energy systems, oil and gas equipment, and power generation where durability in harsh environments is critical.

Industrial

We provide custom aluminum forgings for industrial machinery, robotics, and manufacturing equipment where precision, strength, and reliability ensure operational efficiency.

Industry-Specific Aluminum Forging Solutions

Whatever your industry, MAIKONG has the expertise to deliver custom aluminum forgings that meet your specific requirements.

Discuss Your Industry Application

Value-Added Services: Beyond Basic Manufacturing

What truly sets apart an exceptional Hot Forging Aluminum Supplier is their ability to provide comprehensive value-added services that streamline the supply chain and enhance product quality.

MAIKONG’s comprehensive value-added services enhance product quality and reduce supply chain complexity

Comprehensive Support Services

MAIKONG offers a complete range of value-added services that complement our core forging capabilities:

Design Optimization

Our engineering team provides design-for-manufacturing consultation to optimize component designs for improved performance, reduced weight, and cost-effectiveness.

Prototype Development

Rapid prototype development services help validate designs before full production, reducing time-to-market and ensuring manufacturing feasibility.

Precision Machining

In-house CNC machining capabilities allow for complete component finishing, ensuring dimensional accuracy and feature integrity.

Surface Treatments

Comprehensive surface finishing options including anodizing, painting, powder coating, and mechanical finishing enhance component performance and aesthetics.

Assembly Services

Component assembly capabilities reduce supply chain complexity and ensure proper integration of forged parts into larger systems.

Testing & Certification

Complete material and component testing with comprehensive documentation ensures compliance with industry standards and customer specifications.

By offering these value-added services, MAIKONG simplifies the supply chain for our customers, reducing the need for multiple vendors and ensuring consistent quality throughout the manufacturing process.

The Partnership Approach: Collaboration for Success

A truly exceptional Hot Forging Aluminum Supplier approaches customer relationships as long-term partnerships rather than transactional engagements. At MAIKONG, we believe in collaborative relationships that create mutual success.

Our Collaborative Process

We engage with customers through a structured yet flexible process designed to ensure optimal outcomes:

1. Requirements Analysis

We begin by thoroughly understanding your application requirements, performance expectations, and business objectives to ensure our solution addresses your specific needs.

2. Collaborative Design

Our engineering team works closely with your designers to optimize component design for manufacturability, performance, and cost-effectiveness.

3. Process Development

We develop a customized manufacturing process tailored to your specific requirements, leveraging our expertise to ensure optimal results.

4. Prototype & Validation

Rapid prototype development and comprehensive testing validate the design and manufacturing process before full production.

5. Production Optimization

Continuous improvement processes identify opportunities for enhanced efficiency, quality, and cost-effectiveness throughout production.

6. Ongoing Support

We provide comprehensive post-production support including documentation, technical assistance, and continuous improvement initiatives.

Experience the MAIKONG Partnership Difference

Discover how our collaborative approach can enhance your manufacturing outcomes and streamline your supply chain.

Start Your Partnership Today

Global Capabilities with Local Responsiveness

An exceptional Hot Forging Aluminum Supplier must combine global manufacturing capabilities with responsive local service. MAIKONG’s strategic approach delivers this critical balance.

MAIKONG’s global logistics capabilities ensure timely delivery worldwide

Strategic Manufacturing Facilities

Our manufacturing facility in GD, SZ is strategically positioned to serve global markets efficiently:

- State-of-the-art production facility with 18,000 square meters of manufacturing space

- Advanced forging equipment including hydraulic presses and precision heat treatment furnaces

- Comprehensive CNC machining capabilities for complete component finishing

- Proximity to major shipping ports for efficient global logistics

- Capacity for both high-volume production and specialized custom orders

Global Supply Chain Management

Our comprehensive supply chain capabilities ensure reliable delivery worldwide:

Logistics Expertise

Our experienced logistics team manages global shipping, customs clearance, and documentation to ensure smooth international deliveries.

Inventory Management

Flexible inventory programs including just-in-time delivery and safety stock management help optimize your supply chain.

With MAIKONG as your Hot Forging Aluminum Supplier, you gain a global manufacturing partner with the capabilities, expertise, and responsiveness to support your business objectives worldwide.

The MAIKONG Competitive Advantage

What truly distinguishes MAIKONG as an exceptional Hot Forging Aluminum Supplier is our unique combination of technical expertise, manufacturing capabilities, and customer-focused approach.

The MAIKONG Advantage

- Comprehensive in-house capabilities from design to delivery

- Advanced forging techniques for superior component quality

- Integrated CNC machining for complete component finishing

- Rigorous quality control with ISO 9001:2015 certification

- Competitive pricing with exceptional value

- Responsive customer service and technical support

- Global logistics capabilities for worldwide delivery

- Collaborative partnership approach to customer relationships

Challenges of Traditional Suppliers

- Limited manufacturing capabilities requiring multiple vendors

- Inconsistent quality control and documentation

- Restricted material options and technical expertise

- Inflexible production processes unable to accommodate custom requirements

- Communication barriers and unresponsive customer service

- Limited value-added services increasing supply chain complexity

- Unreliable delivery schedules impacting production planning

- Transactional approach rather than collaborative partnership

Experience the MAIKONG Difference

Discover how our comprehensive capabilities and customer-focused approach can enhance your manufacturing outcomes.

Contact Us Today

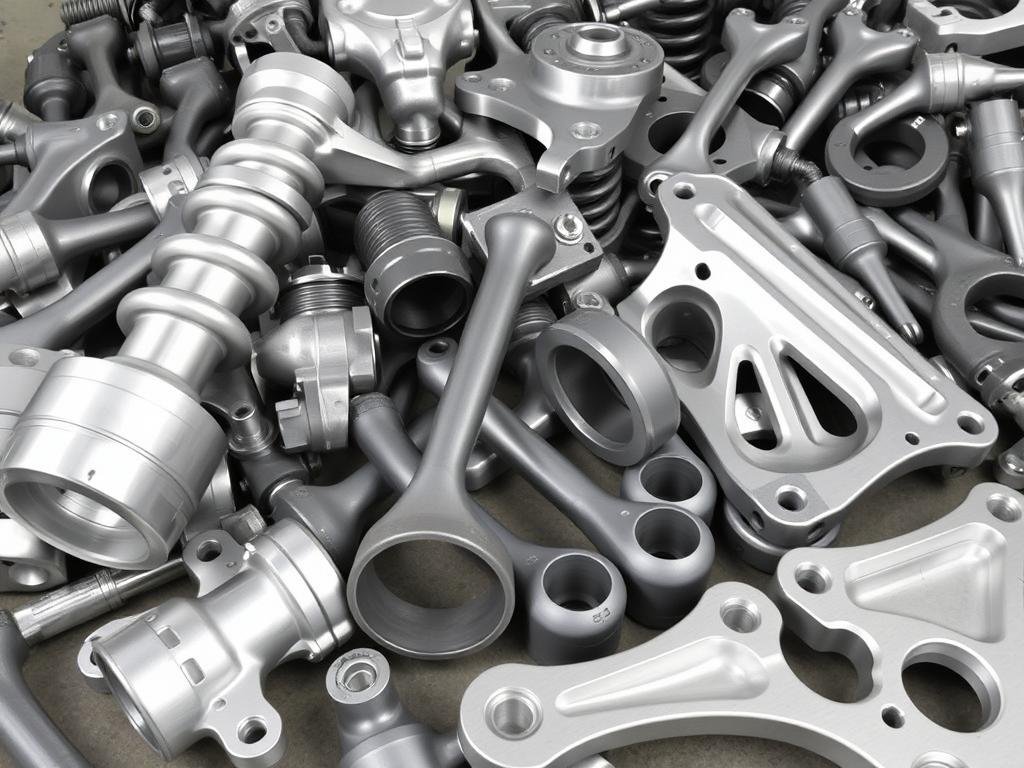

Our Work: Excellence in Aluminum Forging

The true measure of an exceptional Hot Forging Aluminum Supplier is the quality and diversity of their work. Explore some examples of MAIKONG’s aluminum forging expertise across various industries and applications.

These examples represent just a small sample of our capabilities. As a leading Hot Forging Aluminum Supplier, MAIKONG has the expertise and facilities to produce custom aluminum forgings for virtually any application across diverse industries.

Ready to Discuss Your Custom Aluminum Forging Needs?

Contact MAIKONG today to explore how our aluminum forging expertise can benefit your specific application.

Get A Quick Quote

Conclusion: Choosing the Right Hot Forging Aluminum Supplier

Selecting the right Hot Forging Aluminum Supplier is a critical decision that impacts product quality, performance, and reliability. MAIKONG stands apart through our comprehensive capabilities, technical expertise, quality commitment, and customer-focused approach.

From aerospace and automotive to defense and industrial applications, our aluminum forging expertise delivers components that meet the most demanding requirements. Our integrated manufacturing approach—encompassing design, forging, heat treatment, machining, and surface finishing—ensures consistent quality and streamlined supply chains.

Experience the MAIKONG difference and discover why leading manufacturers worldwide trust us as their preferred Hot Forging Aluminum Supplier. Contact us today to discuss your specific aluminum forging requirements and explore how our expertise can enhance your manufacturing outcomes.

Ready to Partner with a Leading Hot Forging Aluminum Supplier?

Contact MAIKONG today to discuss your aluminum forging requirements and experience our commitment to excellence.

Get Started Today

MAIKONG offers complete aluminum forging solutions with precision engineering and quality assurance. Ready to discuss your project?

MAIKONG offers complete aluminum forging solutions with precision engineering and quality assurance. Ready to discuss your project?