Forge Tooling

- What is Forge Tooling? A Comprehensive Introduction for US Industrial Businesses

- The Critical Role of Forge Tooling in Precision Metal Forging

- Understanding the Basics of Forging Dies and Their Importance

- Advanced Forge Tooling Solutions for Precision Manufacturing

- Aluminum Tool Forging Pricelist – Complete Guide by MAIKONG

- Why Quality Forge Tooling is Non-Negotiable for US Manufacturers

- Cold Forging Tools: Precision Manufacturing Solutions for Industrial Applications

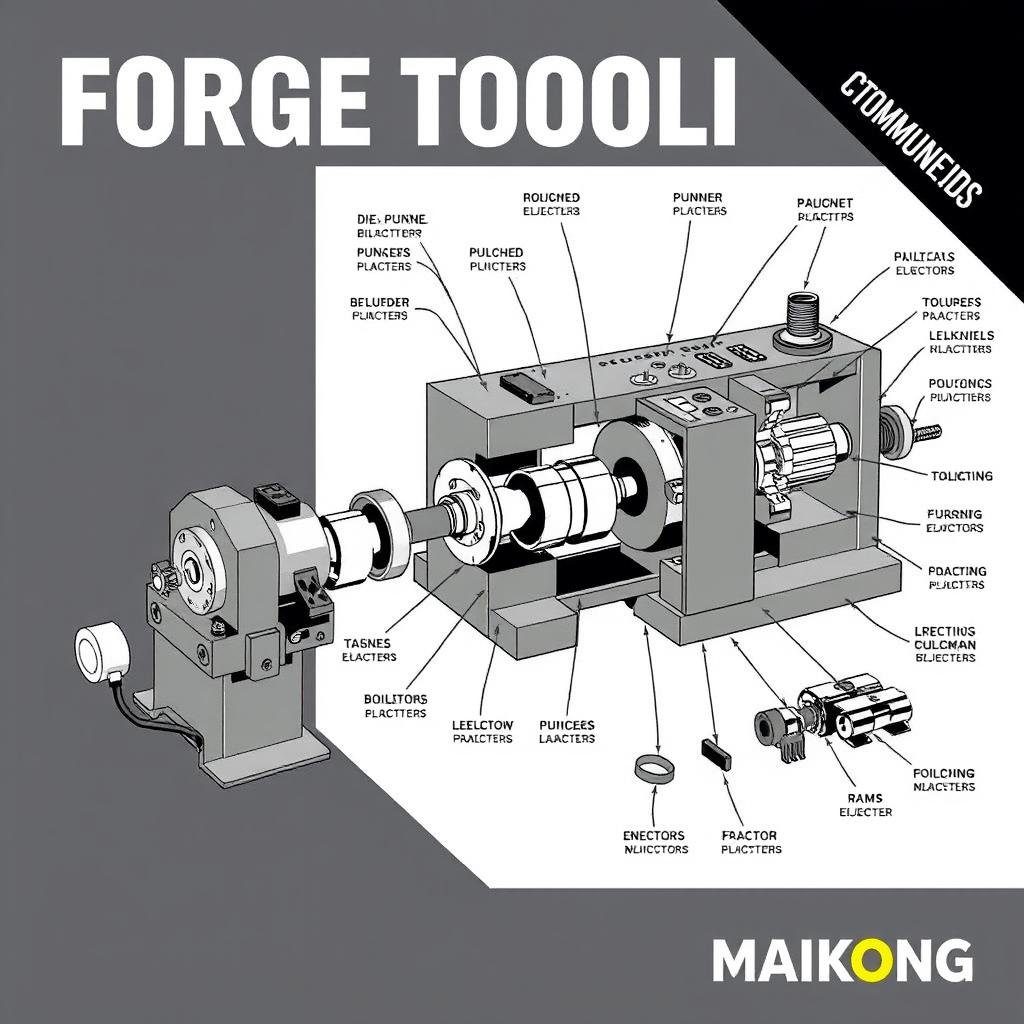

- Key Components of a Complete Forge Tooling System

- How Advanced Forge Tooling Drives Efficiency in American Forging Operations

- Aluminum Forgings and Extrusions Tool Ferrules: Premium Manufacturing Solutions

- The Future of Forge Tooling: Innovations Shaping US Metal Forging

- Rapid Aluminum Forged Tooling Companies United States: MAIKONG’s Premium Solutions

- Decoding Forge Tooling Terminology: Essential for US Procurement Professionals

- The Difference Between Open-Die and Closed-Die Forging Tooling

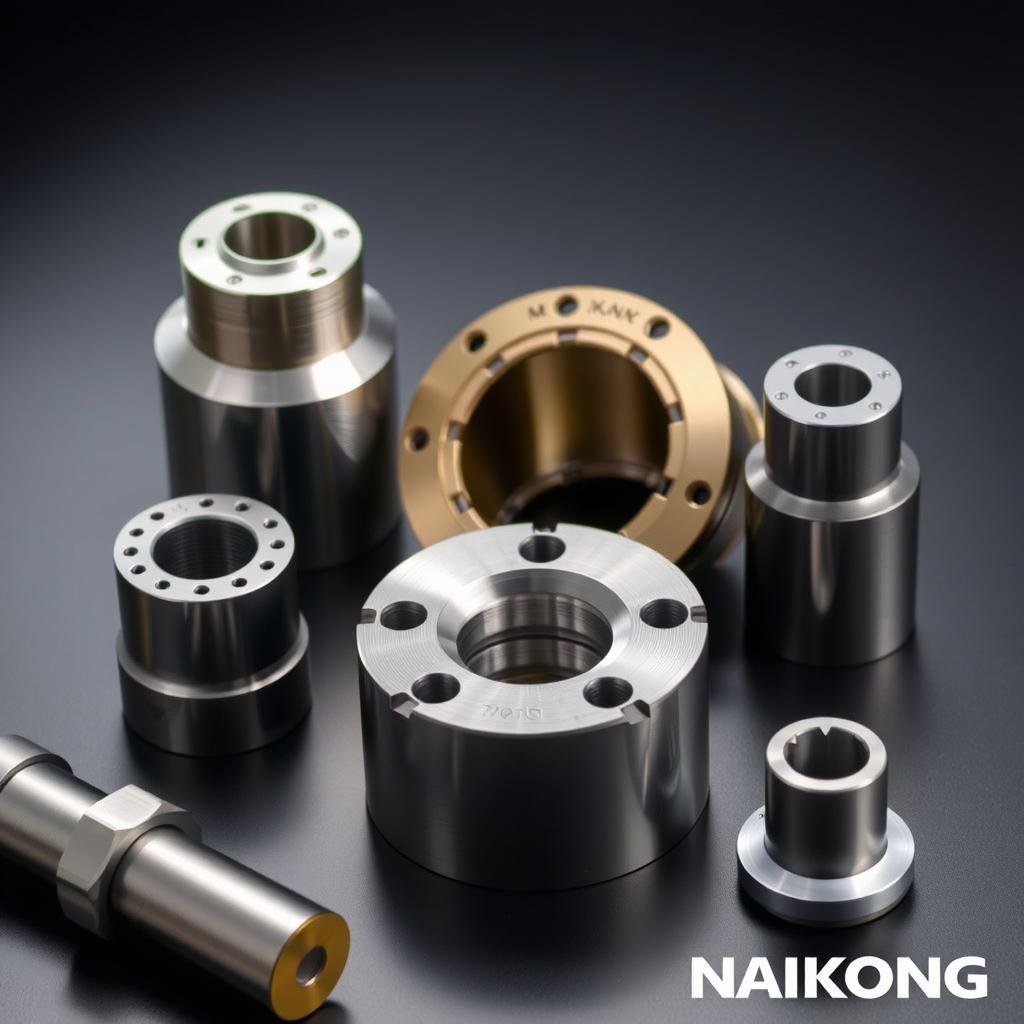

MAIKONG’s precision forge tooling equipment ready for industrial applications

MAIKONG’s precision forge tooling equipment ready for industrial applications

Automotive Components

Automotive Components Aerospace Parts

Aerospace Parts Industrial Machinery

Industrial Machinery Energy Sector

Energy Sector Defense Industry

Defense Industry Medical Equipment

Medical Equipment