Rapid Aluminum Forged Tooling Companies United States:In today’s competitive manufacturing landscape, finding reliable rapid aluminum forged tooling companies in the United States can be challenging. MAIKONG stands at the forefront of this specialized industry, offering premium aluminum forging solutions with unmatched precision, quality, and turnaround times. Our comprehensive services combine advanced forging techniques with state-of-the-art CNC machining to deliver exceptional custom metal components that meet the most demanding specifications.

Need Custom Aluminum Forged Components?

Our engineering team is ready to review your specifications and provide expert recommendations.

Our engineering team is ready to review your specifications and provide expert recommendations.

Get A Quick Quote

Comprehensive Aluminum Forging Services from MAIKONG

At MAIKONG, we’ve established ourselves as leaders among rapid aluminum forged tooling companies in the United States through our commitment to excellence and comprehensive service offerings. Our state-of-the-art facilities in GD, SZ are equipped with advanced forging equipment and precision CNC machining centers to handle projects of any complexity.

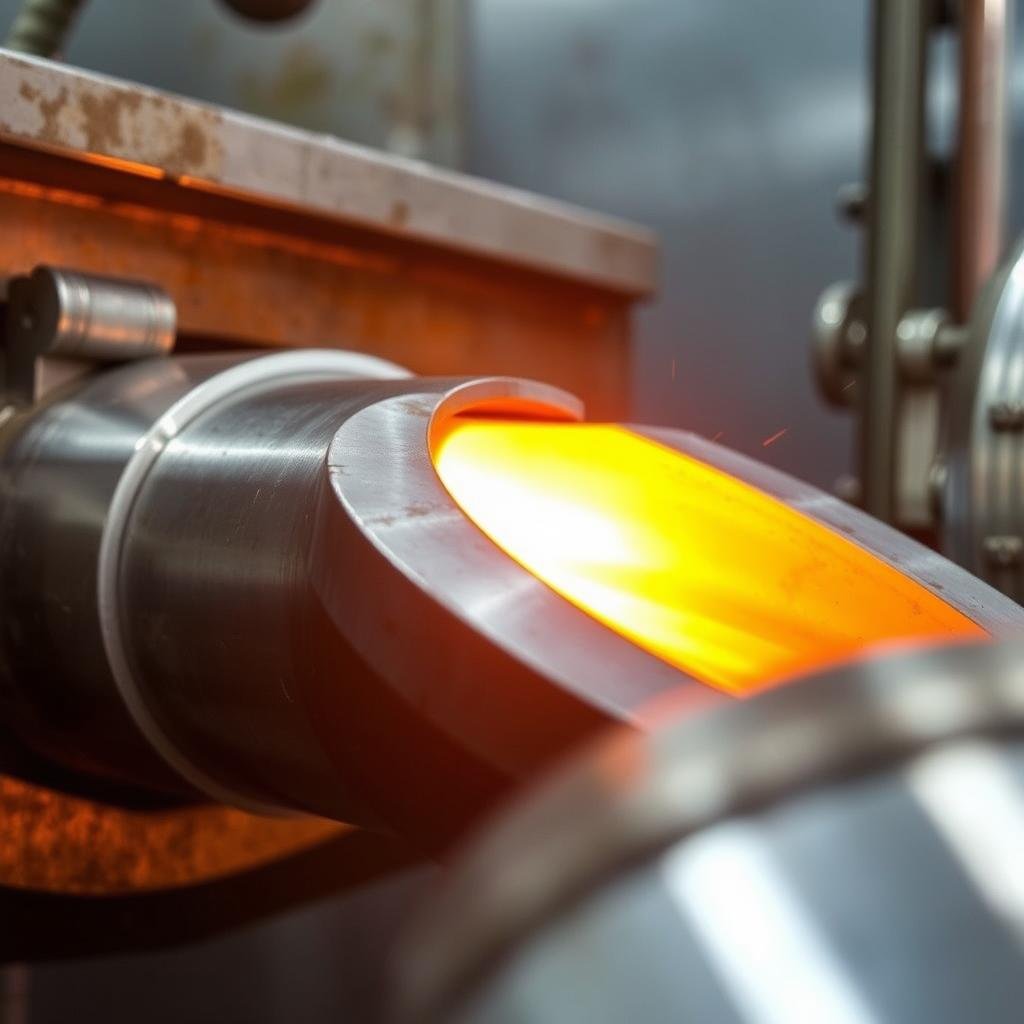

Aluminum Forging Excellence

Our specialized aluminum forging processes create high-strength, lightweight components with superior grain structure and mechanical properties compared to cast parts.

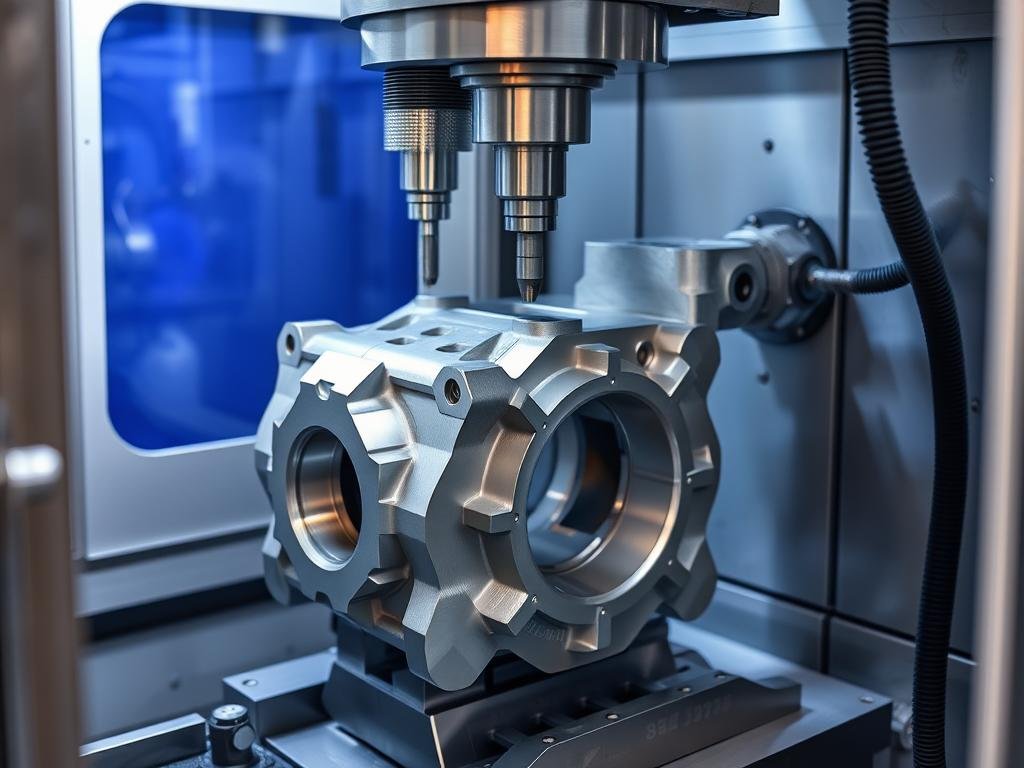

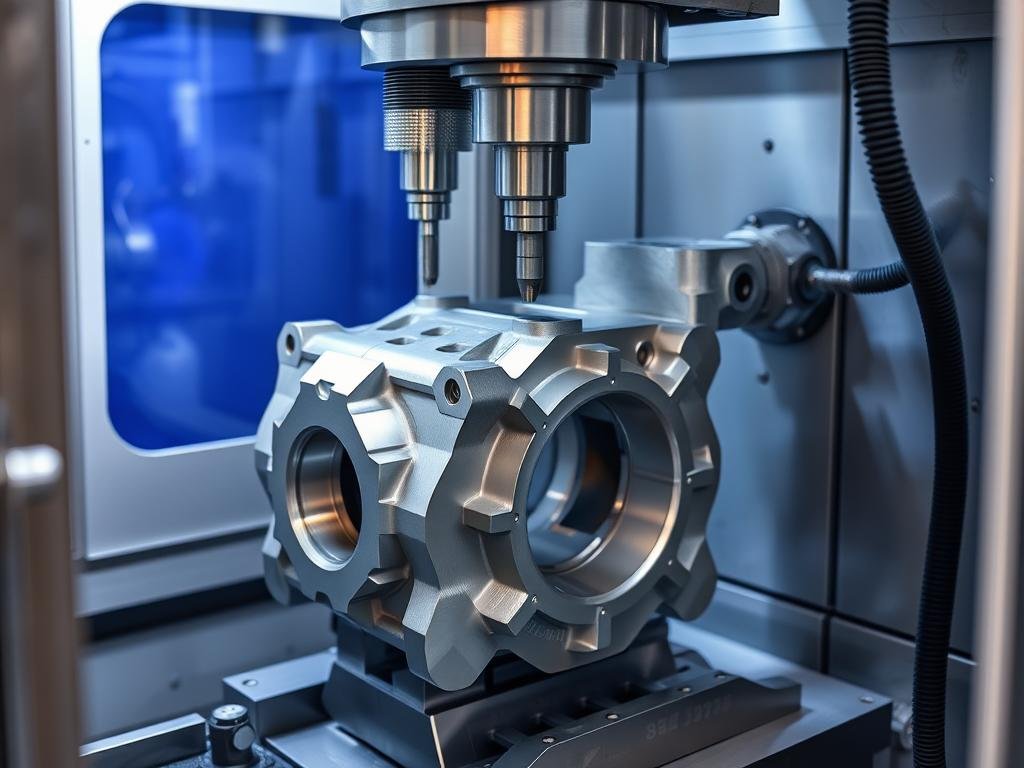

Precision CNC Machining

With 60+ CNC machines, we offer comprehensive machining services including turning, milling, and multi-axis machining for perfect dimensional accuracy.

Custom Metal Fabrication

Our comprehensive metal fabrication capabilities complement our forging services, allowing us to deliver fully finished components ready for assembly.

Explore Our Full Range of Services

Contact our technical team to discuss your specific requirements and discover how MAIKONG can support your manufacturing needs.

Contact via WhatsApp

Email Our Team

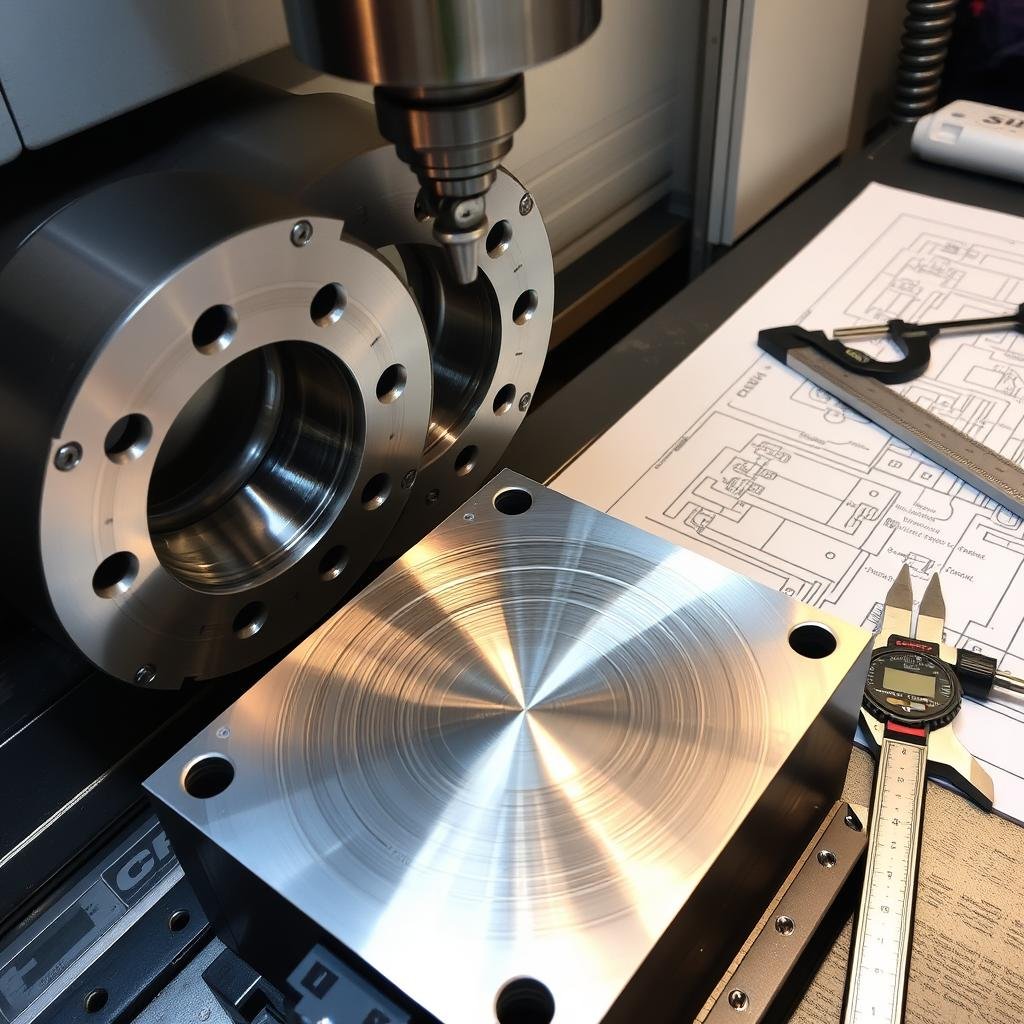

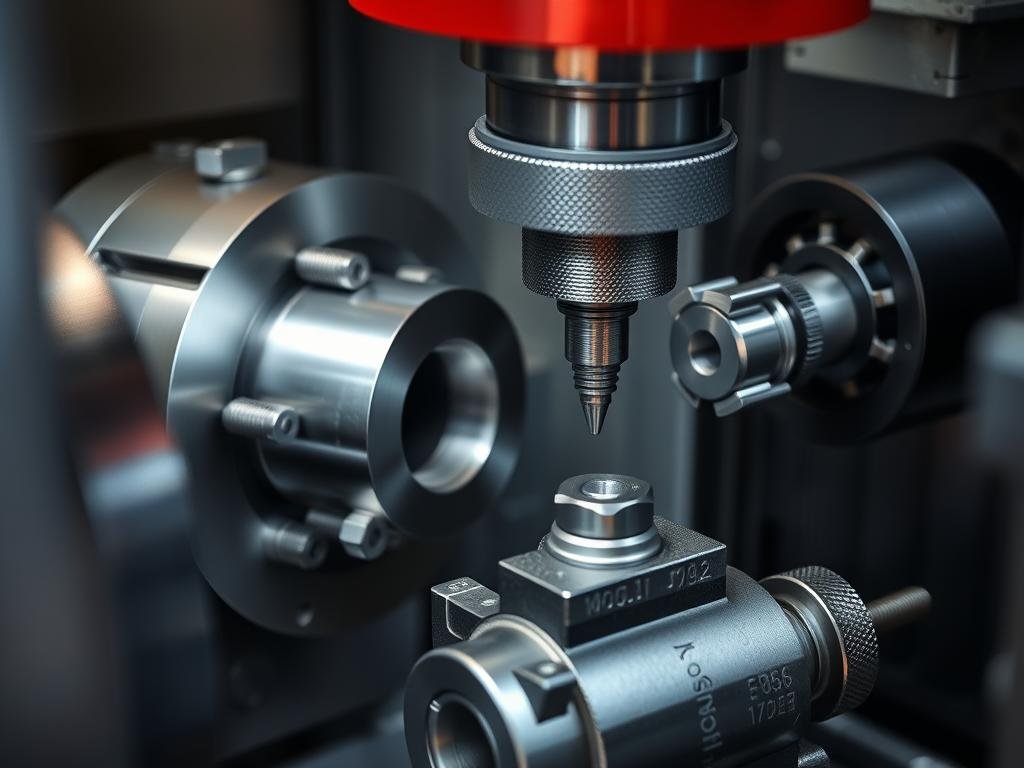

Advanced CNC Machining Capabilities

As one of the leading rapid aluminum forged tooling companies in the United States, MAIKONG offers comprehensive CNC machining services that complement our forging expertise. Our advanced machining capabilities ensure that your forged components achieve precise tolerances and superior surface finishes.

CNC Turning Services

Our CNC turning capabilities are ideal for creating precise cylindrical shapes, deep holes, and machined threads with exceptional surface finishes. We specialize in high-precision turning for aluminum components that require tight tolerances and complex geometries.

- Multi-axis CNC turning centers

- Precision threading and grooving

- Capacity for components up to 24″ diameter

- Tolerances to ±0.0005″

CNC Milling Services

Our advanced CNC milling services create complex prismatic shapes and flat surfaces with exceptional precision. Our multi-axis machines require no fixed tooling, offering flexibility and accuracy for your most demanding aluminum components.

- 3-axis, 4-axis, and 5-axis machining centers

- High-speed machining capabilities

- Complex contour machining

- Micro-machining for intricate features

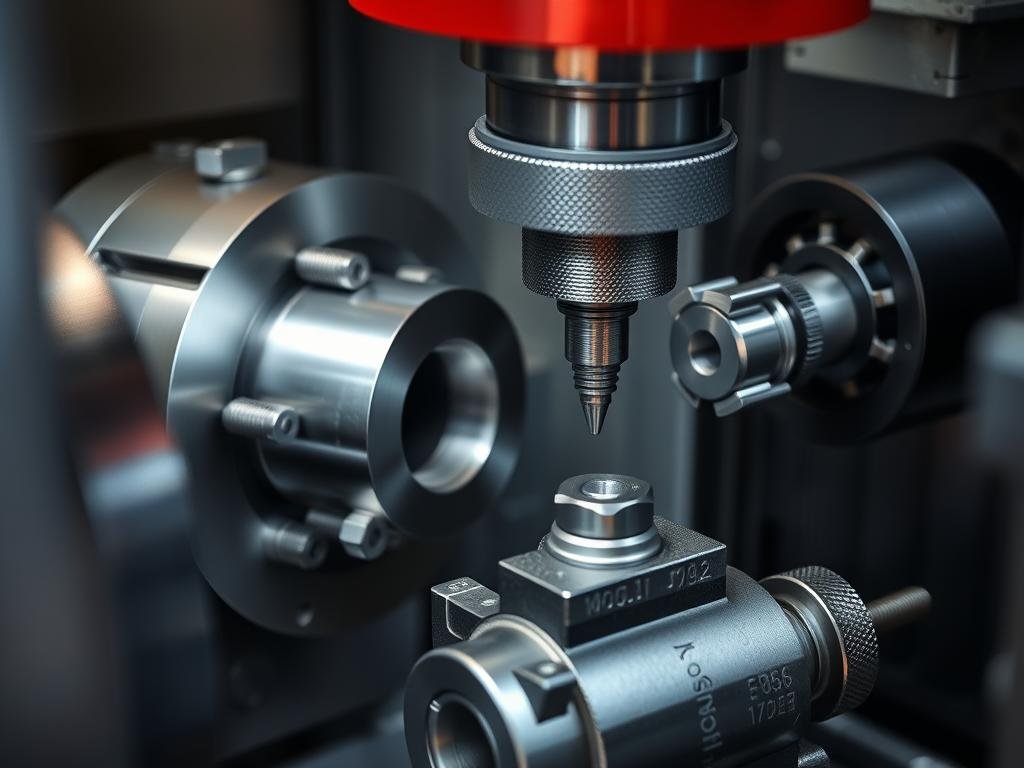

Swiss-Type Machining

Our Swiss-type machining specializes in precision small parts and long shaft components. With dual spindles and multi-axis capabilities, we provide one-stop solutions for the most intricate aluminum components without requiring additional equipment.

- Precision small parts manufacturing

- Long shaft components with tight tolerances

- Complex geometries in a single setup

- High-volume production capabilities

Need Precision CNC Machining for Your Aluminum Components?

Our engineering team can help you optimize your designs for manufacturability and cost-effectiveness.

Request Machining Quote

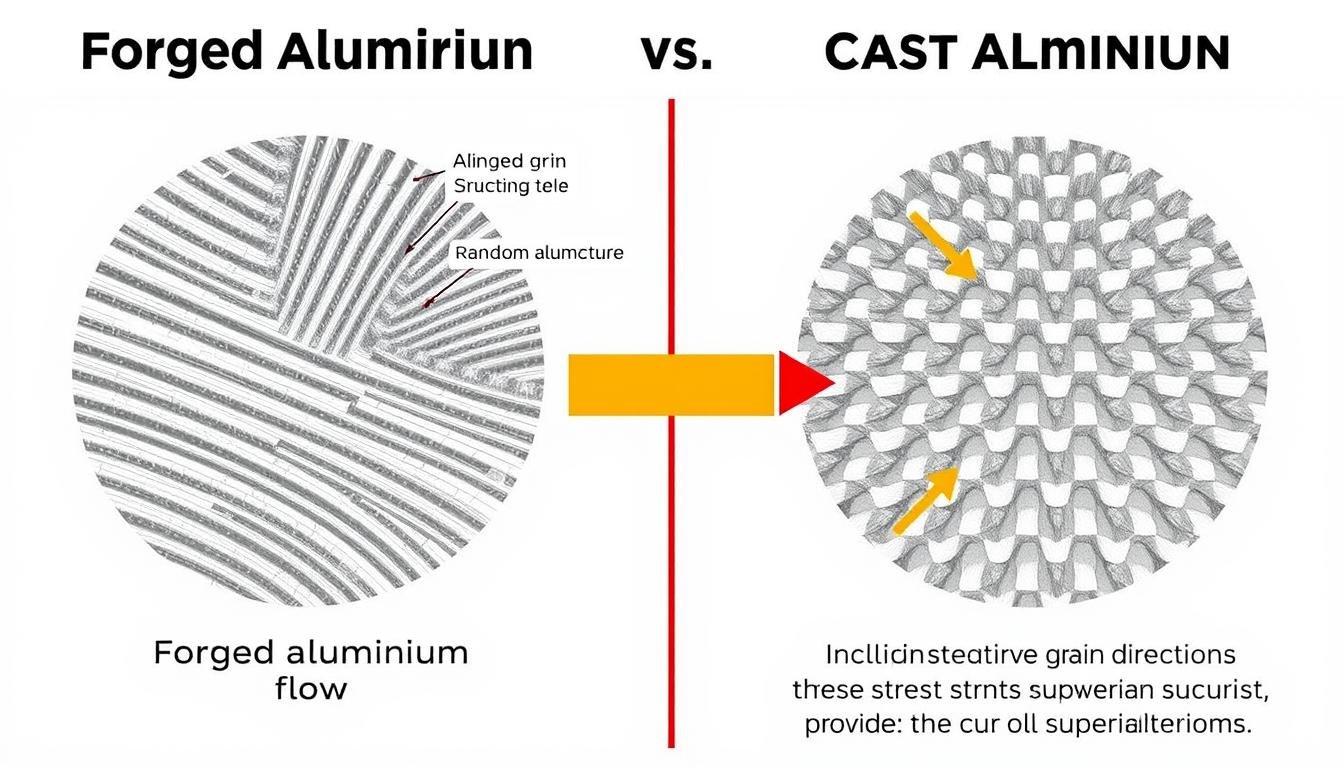

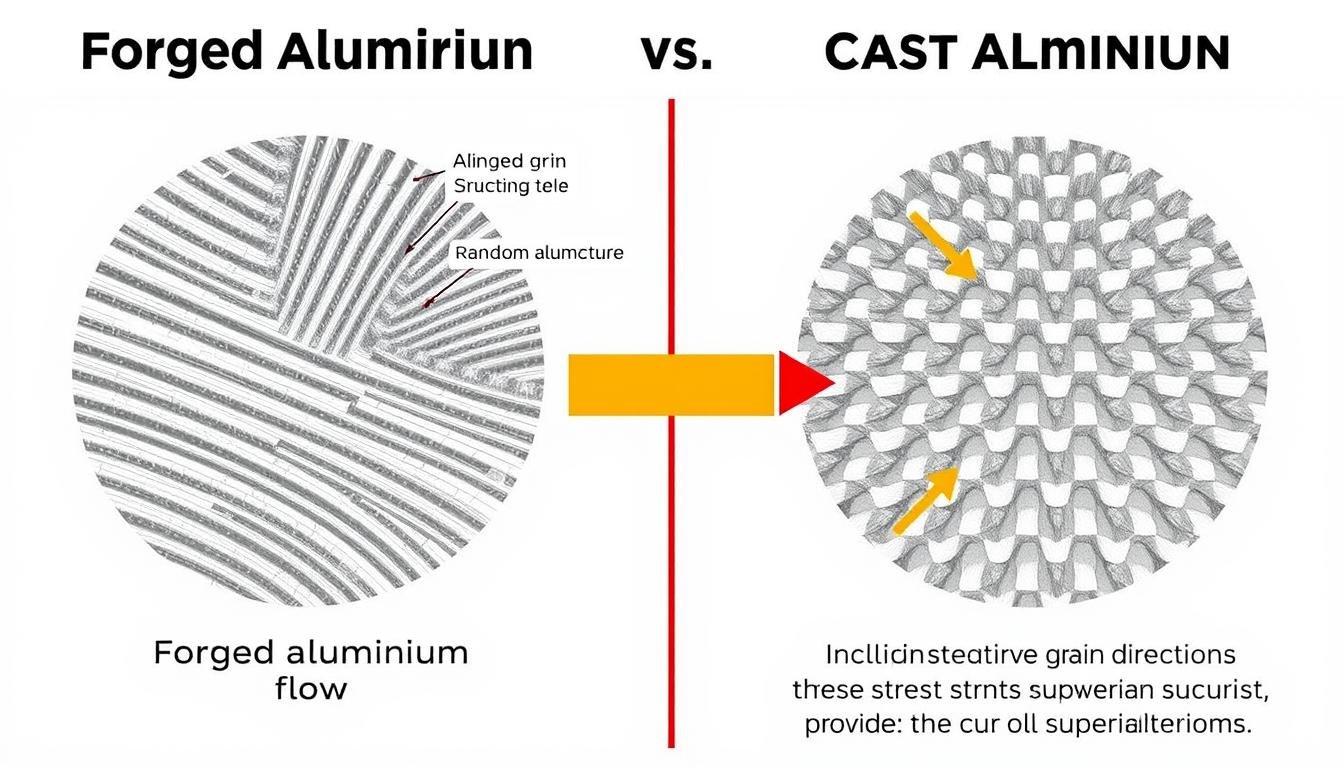

Why Choose Aluminum Forging for Your Components

When selecting manufacturing processes for critical components, understanding the advantages of aluminum forging is essential. As specialists among rapid aluminum forged tooling companies in the United States, MAIKONG leverages these benefits to deliver superior products for our clients.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Weight-to-Strength Ratio |

✅ High strength-to-weight ratio |

Bulkier parts may be needed |

| Ideal Applications |

Aerospace, automotive, medical devices |

Consumer goods, simple parts, non-critical sectors |

Optimal Strength-to-Weight Ratio in Aluminum Forgings

The forging process aligns the grain structure of aluminum, significantly enhancing its mechanical properties. This results in components with an optimal strength-to-weight ratio—a critical factor in industries where performance, efficiency, and safety are paramount. MAIKONG’s aluminum forgings showcase engineering excellence through a combination of material science, metallurgy, and precision manufacturing.

Forging Process Types

- Open Die Forging – Ideal for large components with simpler geometries

- Closed Die Forging – Perfect for complex shapes requiring tight tolerances

- Rolled Ring Forging – Specialized for circular components with consistent properties

Common Aluminum Alloys

- 2000 Series – High strength with excellent fatigue resistance

- 6000 Series – Good formability with moderate strength

- 7000 Series – Highest strength aluminum alloys available

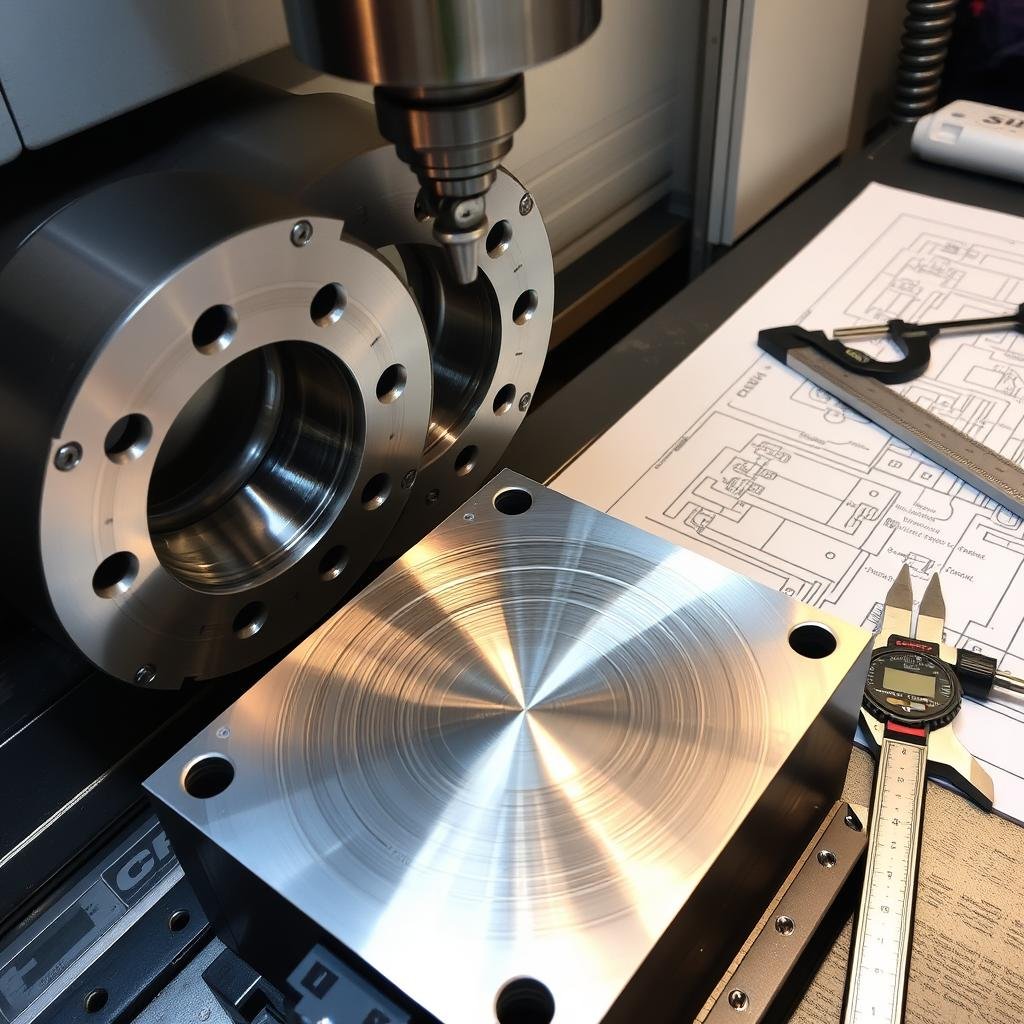

Quality Assurance and Certifications

As a leading provider among rapid aluminum forged tooling companies in the United States, MAIKONG maintains rigorous quality control standards throughout our manufacturing processes. Our comprehensive quality management system ensures consistent excellence in every component we produce.

ISO 9001:2015 Certified

Our quality management system meets international standards for consistent quality and continuous improvement. This certification demonstrates our commitment to delivering products that consistently meet customer and regulatory requirements.

IATF 16949 Compliant

We adhere to the automotive industry’s stringent quality management standards, ensuring our components meet the exacting requirements of automotive manufacturers and their suppliers worldwide.

Material Testing Laboratory

Our in-house material testing facilities allow us to verify material properties, ensuring every component meets specified mechanical and physical requirements before delivery.

Comprehensive Quality Control Process

At MAIKONG, quality isn’t just inspected—it’s built into every step of our manufacturing process. Our quality control procedures include:

- Raw material verification and testing

- In-process inspections during forging and machining

- Dimensional verification using coordinate measuring machines (CMM)

- Non-destructive testing including ultrasonic and penetrant testing

- Mechanical property testing for strength and hardness

- Final inspection and documentation

Quality You Can Trust

Experience the MAIKONG difference with our commitment to exceptional quality and reliability.

Request Quality Documentation

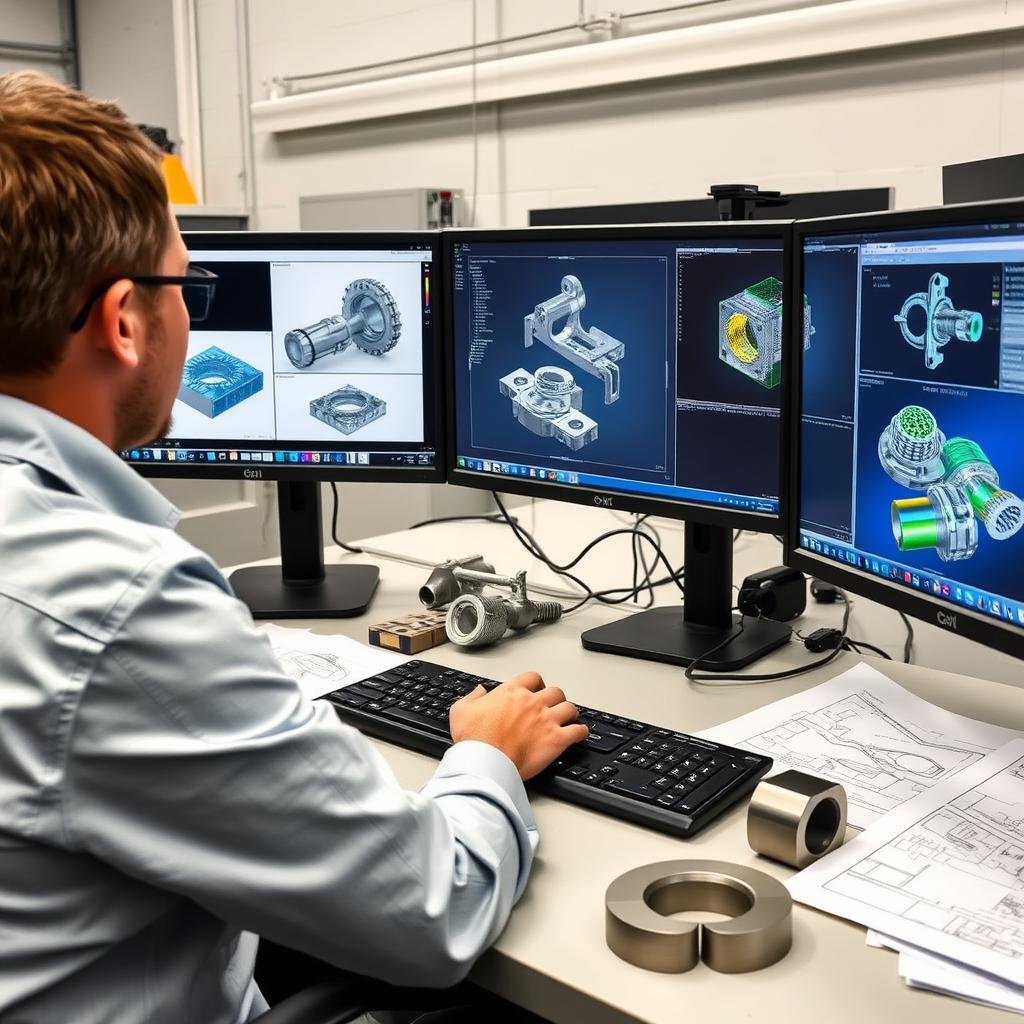

Our Comprehensive Manufacturing Process

MAIKONG stands out among rapid aluminum forged tooling companies in the United States through our integrated manufacturing approach. From initial design to final delivery, we maintain complete control over every aspect of production to ensure superior quality and consistency.

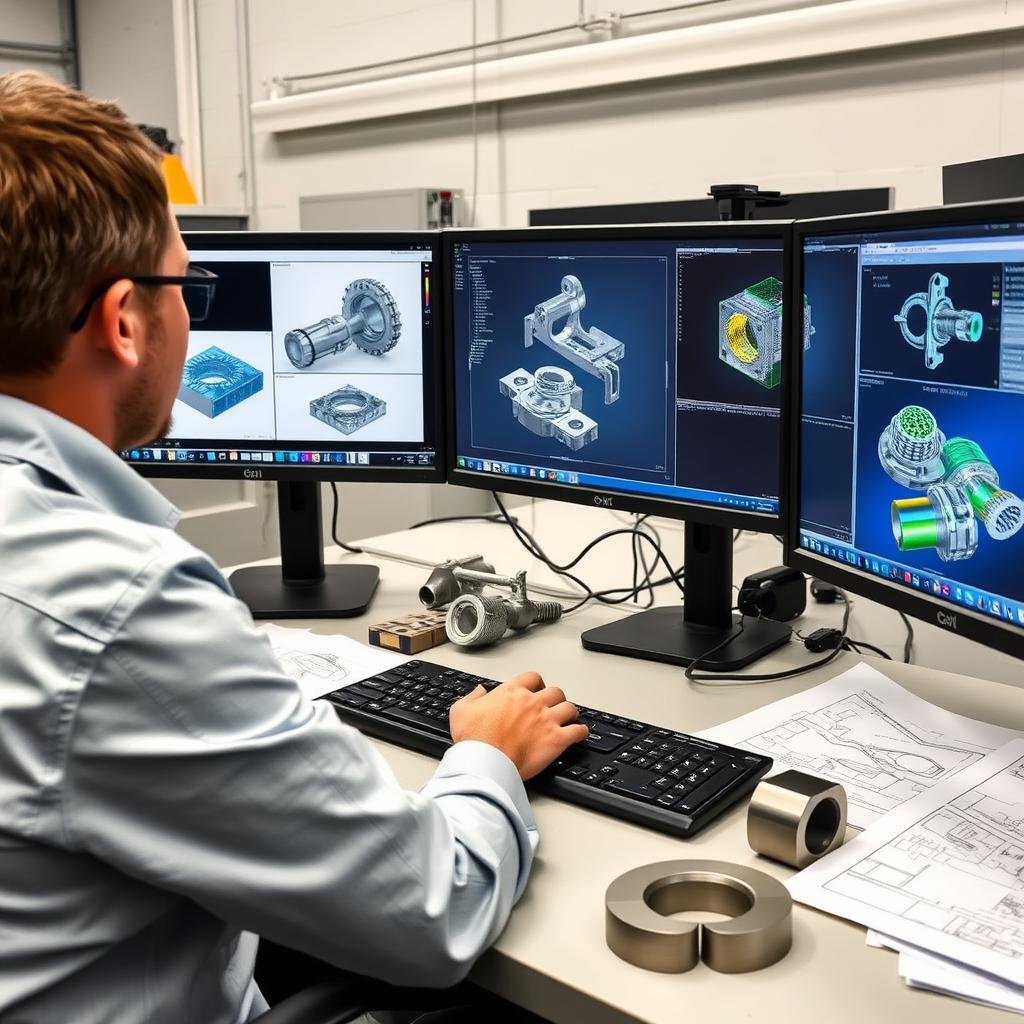

CAD/CAM Design

Our engineering team uses advanced CAD/CAM software to optimize designs for manufacturability. Finite element analysis (FEA) simulations predict component performance and identify potential issues before production begins.

Tooling Design

We design and manufacture custom tooling in-house, ensuring optimal die design for each component. Our tooling expertise minimizes flash, reduces material waste, and extends die life for consistent quality.

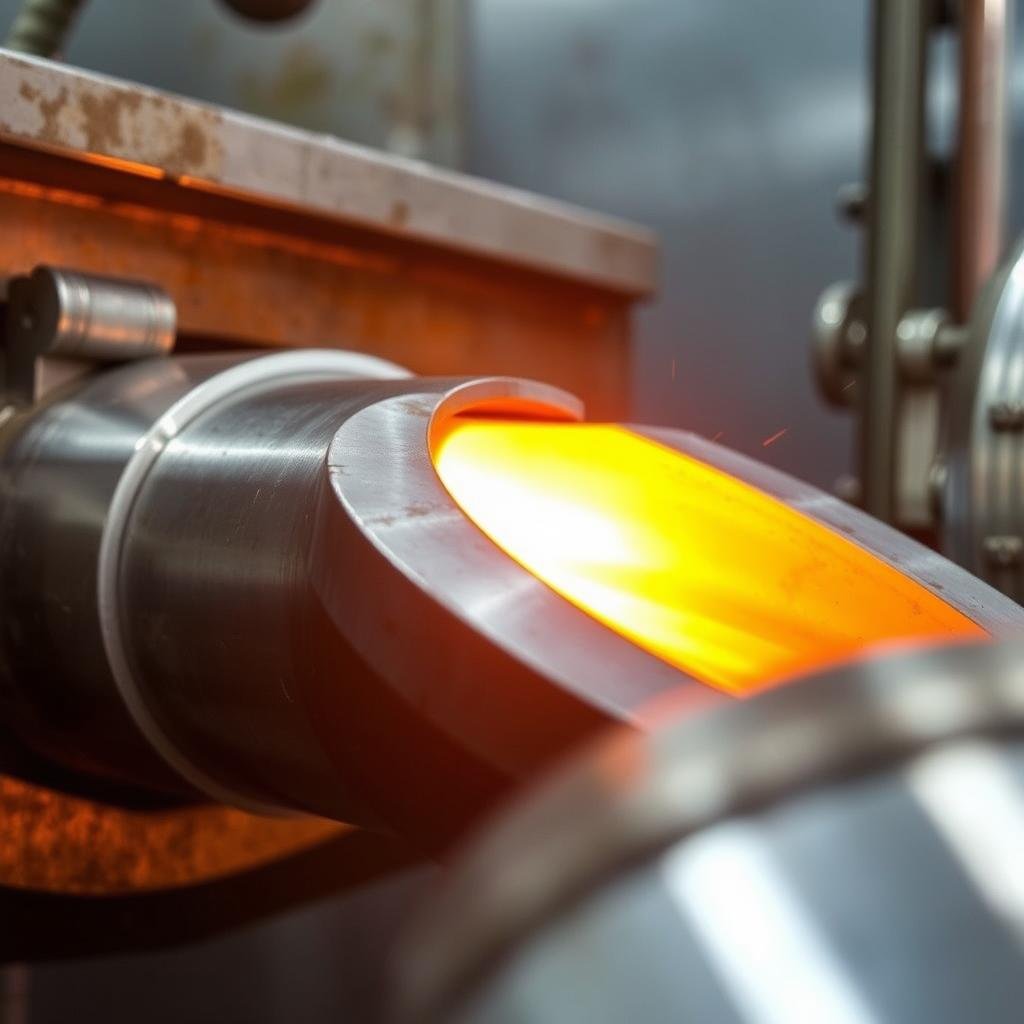

Heat Treatment

Our controlled heat treatment processes optimize the mechanical properties of aluminum components. In-house heat treatment capabilities include solution heat treating and aging to achieve specific tempers (T4, T6, etc.).

Surface Treatment Options

MAIKONG offers comprehensive surface treatment services to enhance the appearance, performance, and durability of your aluminum components:

Anodizing

Our anodizing processes create durable, corrosion-resistant surfaces in a variety of colors. Type II and Type III (hard) anodizing available to meet specific application requirements.

Powder Coating

Superior to conventional paint, our powder coating services provide excellent adhesion, uniform coverage, and exceptional durability for aluminum components exposed to harsh environments.

Laser Engraving

Precision laser engraving for part identification, branding, or functional markings. Our advanced laser systems create permanent, high-contrast markings without affecting component integrity.

Ready to Start Your Project?

Our engineering team is ready to review your specifications and provide expert recommendations.

Get A Quick Quote

Industries Served by MAIKONG

As one of the premier rapid aluminum forged tooling companies in the United States, MAIKONG serves diverse industries with custom aluminum forged components. Our expertise in aluminum forging and precision machining makes us the ideal partner for applications requiring high performance and reliability.

Aerospace

Our high-strength aluminum forgings meet the rigorous demands of aerospace applications, where weight reduction and structural integrity are critical. We produce components for aircraft structures, landing gear, and engine systems.

Automotive

MAIKONG supplies the automotive industry with lightweight, high-strength aluminum components that improve fuel efficiency and performance. Our forgings are used in suspension systems, drivetrain components, and structural applications.

Medical

The medical industry relies on our precision aluminum components for surgical instruments, imaging equipment, and medical device housings. Our manufacturing processes ensure the highest levels of quality and consistency.

Additional Markets We Serve

- Defense and military

- Robotics and automation

- Renewable energy

- Consumer electronics

- Sporting equipment

- Industrial machinery

- Transportation

- Agricultural equipment

- Construction equipment

US Agent Recruitment Opportunity

MAIKONG is actively seeking distribution partners and sales agents throughout the United States. Join our team and represent our premium aluminum forging and CNC machining services in your region.

We offer competitive commission structures, comprehensive product training, and ongoing technical support to ensure your success.

Contact for Agent Opportunities

Why Choose MAIKONG for Your Aluminum Forging Needs

When searching for rapid aluminum forged tooling companies in the United States, MAIKONG stands apart through our commitment to quality, technical expertise, and customer satisfaction. Our comprehensive capabilities in aluminum forging, precision CNC machining, and surface treatments provide a complete solution for your most demanding applications.

The MAIKONG Advantage

- Comprehensive in-house capabilities from design to delivery

- Advanced aluminum forging techniques for superior grain structure

- Precision CNC machining for tight tolerances and excellent surface finishes

- Rigorous quality control and material testing

- Competitive pricing and responsive customer service

- ISO 9001:2015 and IATF 16949 quality management systems

Challenges of Inferior Suppliers

- Inconsistent quality and material properties

- Limited technical expertise and support

- Restricted capabilities requiring multiple vendors

- Poor communication and project management

- Missed deadlines and delivery delays

- Inadequate quality control processes

Partner with MAIKONG Today

Experience the difference that technical expertise, quality manufacturing, and responsive service can make for your aluminum forging projects.

Get A Quick Quote

Or contact us directly:

8613-51090-74-01

Our engineering team is ready to review your specifications and provide expert recommendations.

Our engineering team is ready to review your specifications and provide expert recommendations.