In the demanding world of metal manufacturing, the quality of your forge tooling directly impacts production efficiency, part quality, and your bottom line. At MAIKONG, we understand that superior tooling is the foundation of exceptional forging results. With decades of expertise in precision forge tooling design and manufacturing, we deliver solutions that extend tool life, enhance operational efficiency, and reduce costs for metal forging operations worldwide.

MAIKONG’s Forge Tooling Expertise

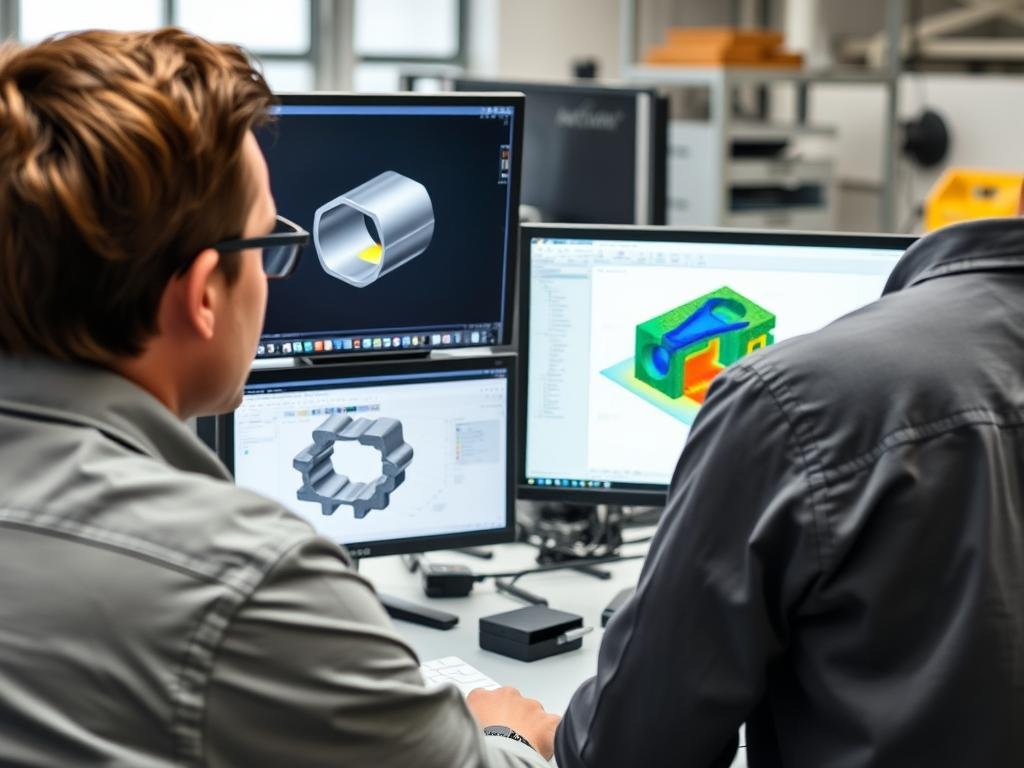

State-of-the-Art Facilities

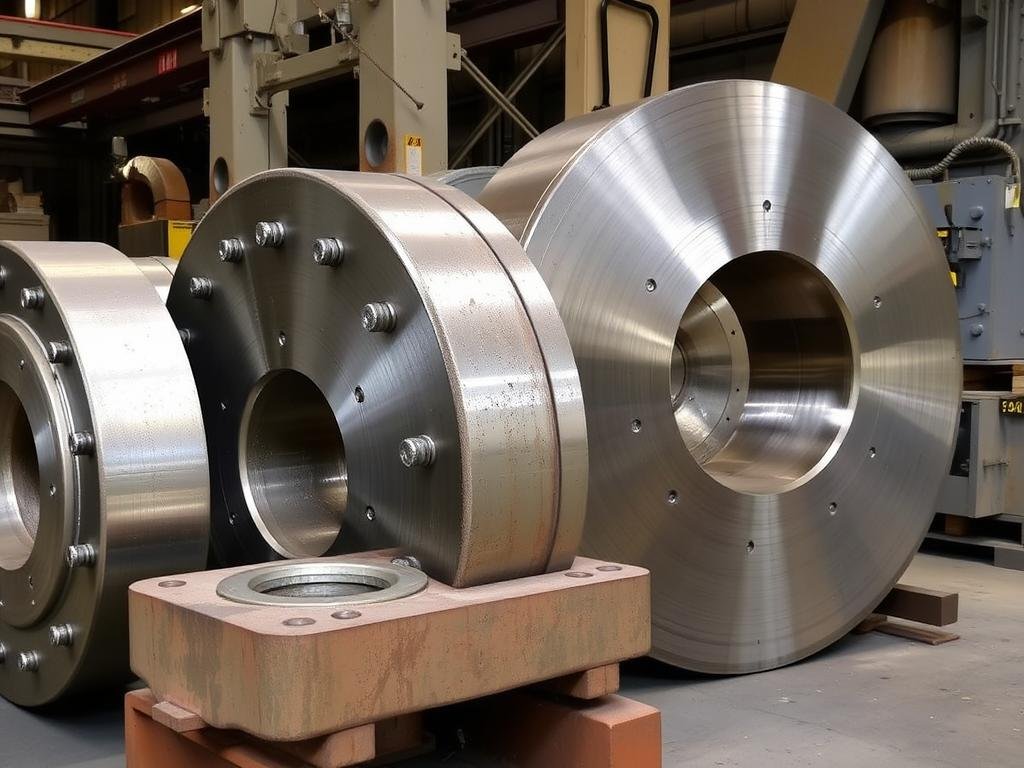

Our manufacturing facility in GD, SZ houses over 60 advanced CNC machines with a monthly capacity exceeding 100 tons of metal processing. Every aspect of our operation is dedicated to producing world-class forge tooling.

Expert Technical Team

Our engineers and technicians bring decades of combined experience in forge tooling design and manufacturing. This expertise allows us to routinely recommend material, design, and process modifications that significantly improve tooling performance.

Rigorous Quality Control

Every piece of forge tooling we produce undergoes comprehensive inspection and testing to ensure it meets the highest standards of quality and performance. Our ISO 9001:2015 certification reflects our commitment to excellence.

“MAIKONG’s forge tooling has been an integral part of our success. Through thoughtful inventory practices, quality work, and quick turnaround, they’ve helped us achieve significant improvements in our forging operations.”

– John Miller, Production Manager

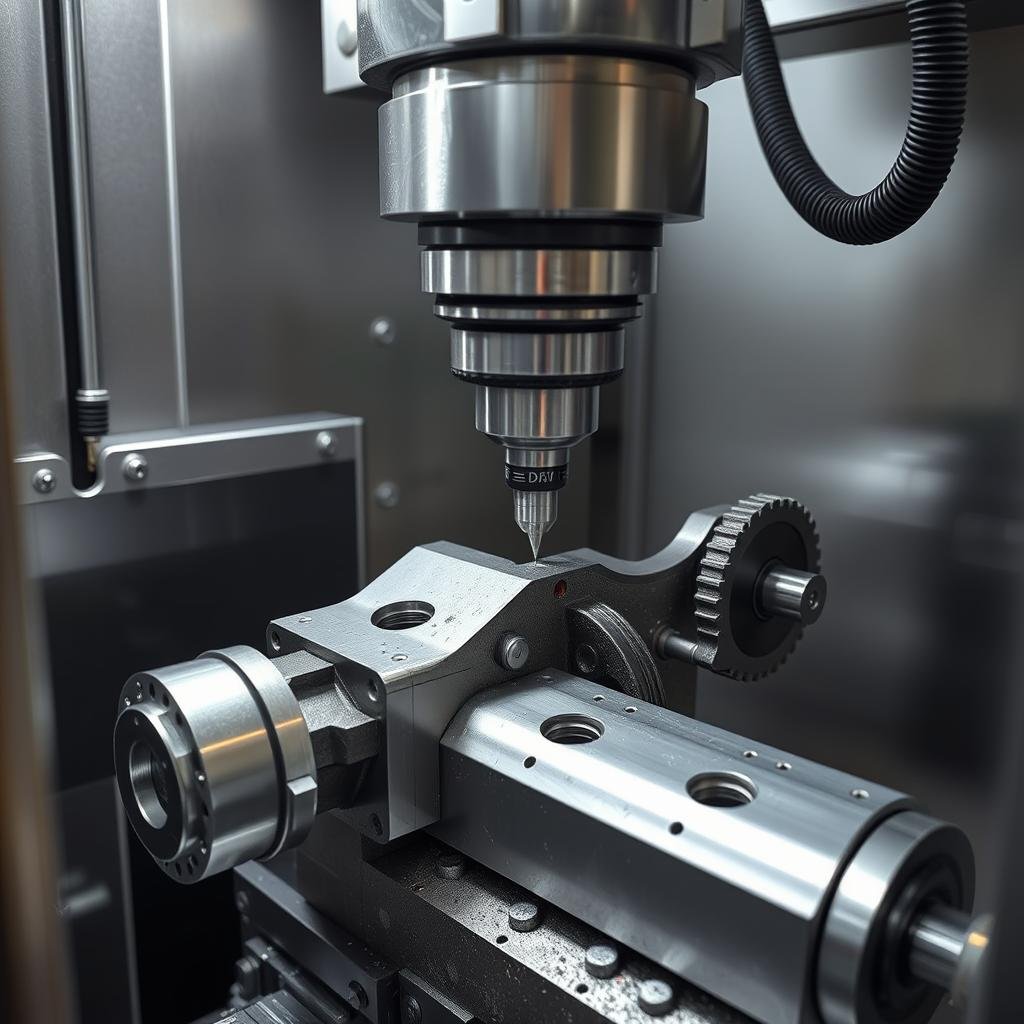

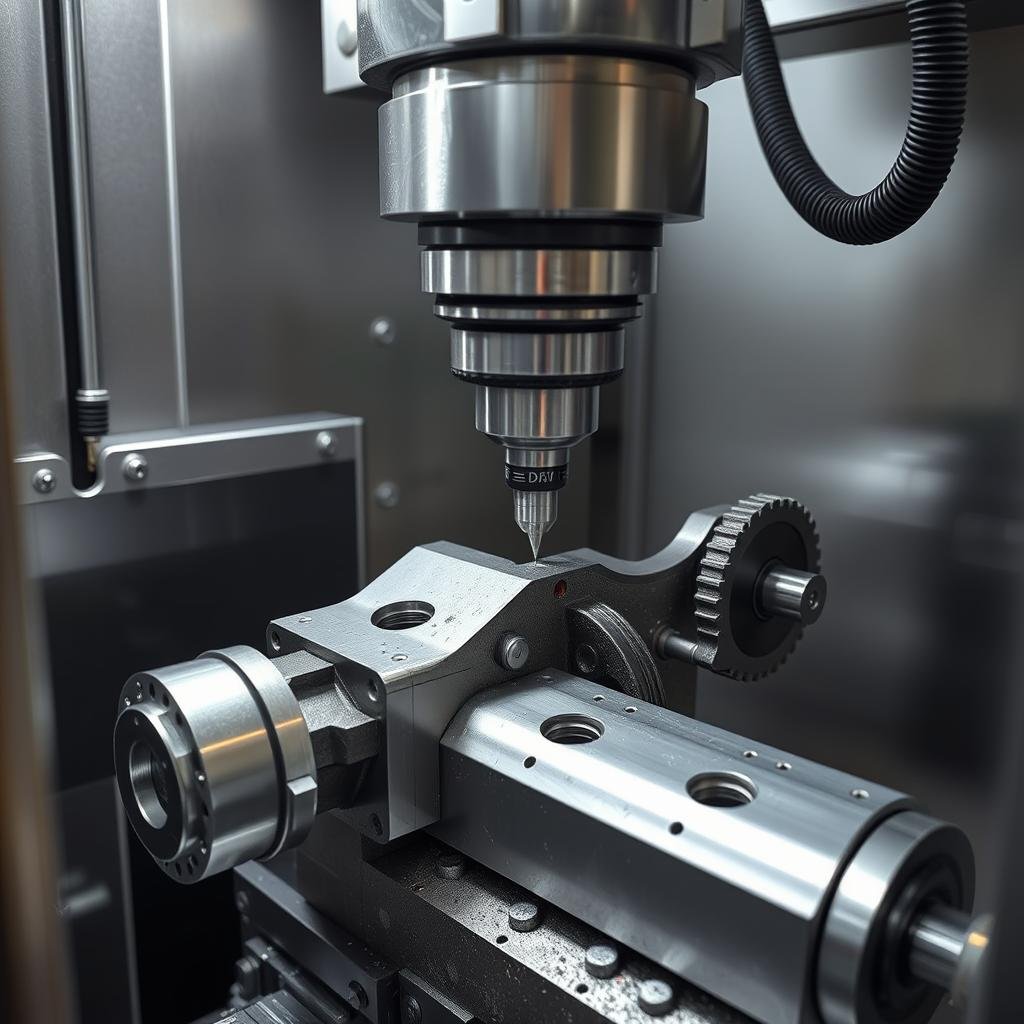

Advanced CNC Machining for Forge Tooling

Our state-of-the-art CNC machining capabilities enable us to produce forge tooling with exceptional precision and consistency. From complex geometries to tight tolerances, our advanced equipment and skilled operators deliver outstanding results.

CNC Turning Services

Our CNC turning capabilities are ideal for creating cylindrical forge tooling components with superior surface finishes. We specialize in producing deep holes, machined threads, and precision cylindrical shapes for various forging applications.

Learn More

CNC Milling Services

Our multi-axis CNC milling equipment allows us to create complex prismatic shapes and flat surfaces for forge tooling with exceptional accuracy. These machines require no fixed tooling, offering flexibility and precision for diverse applications.

Learn More

Swiss-Type Machining

For small, precision forge tooling components, our Swiss-type machining services offer unmatched accuracy. With dual spindles and multi-axis capabilities, we provide one-stop solutions for complex, high-precision parts.

Learn More

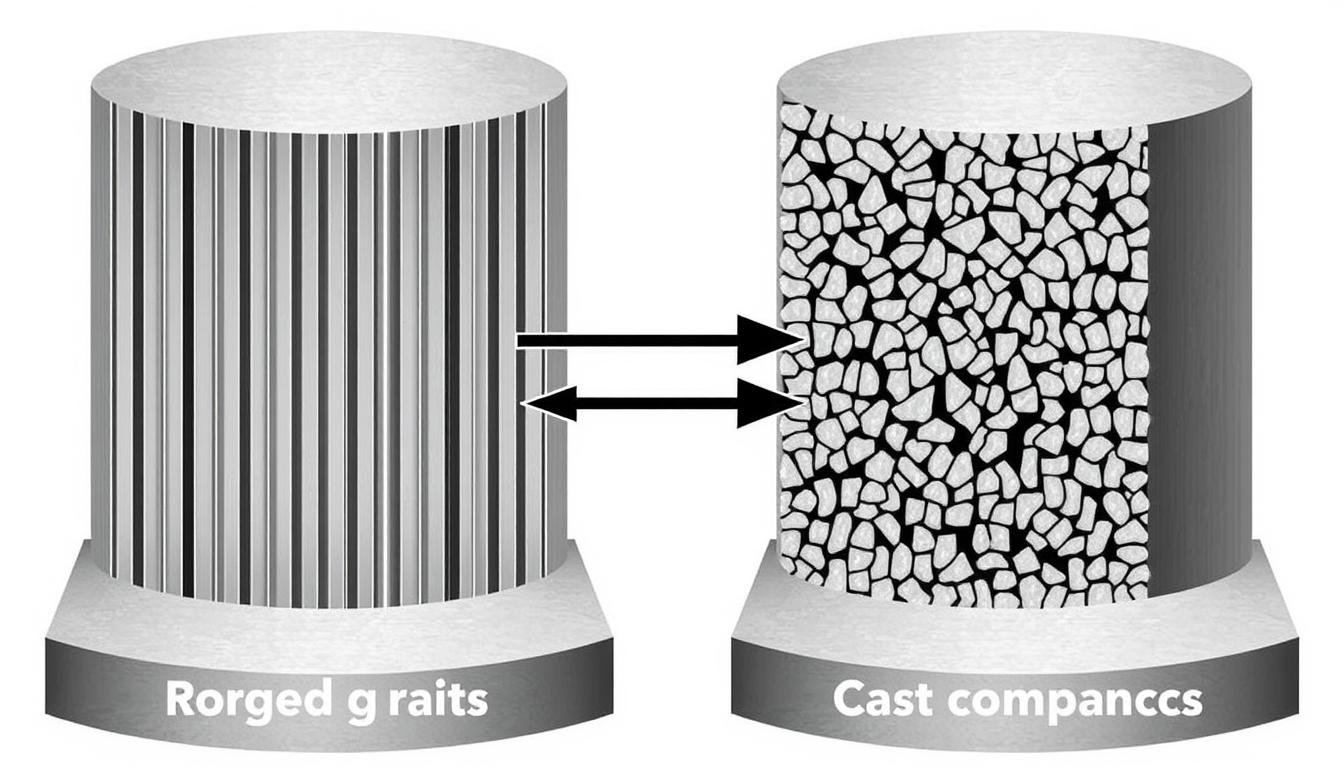

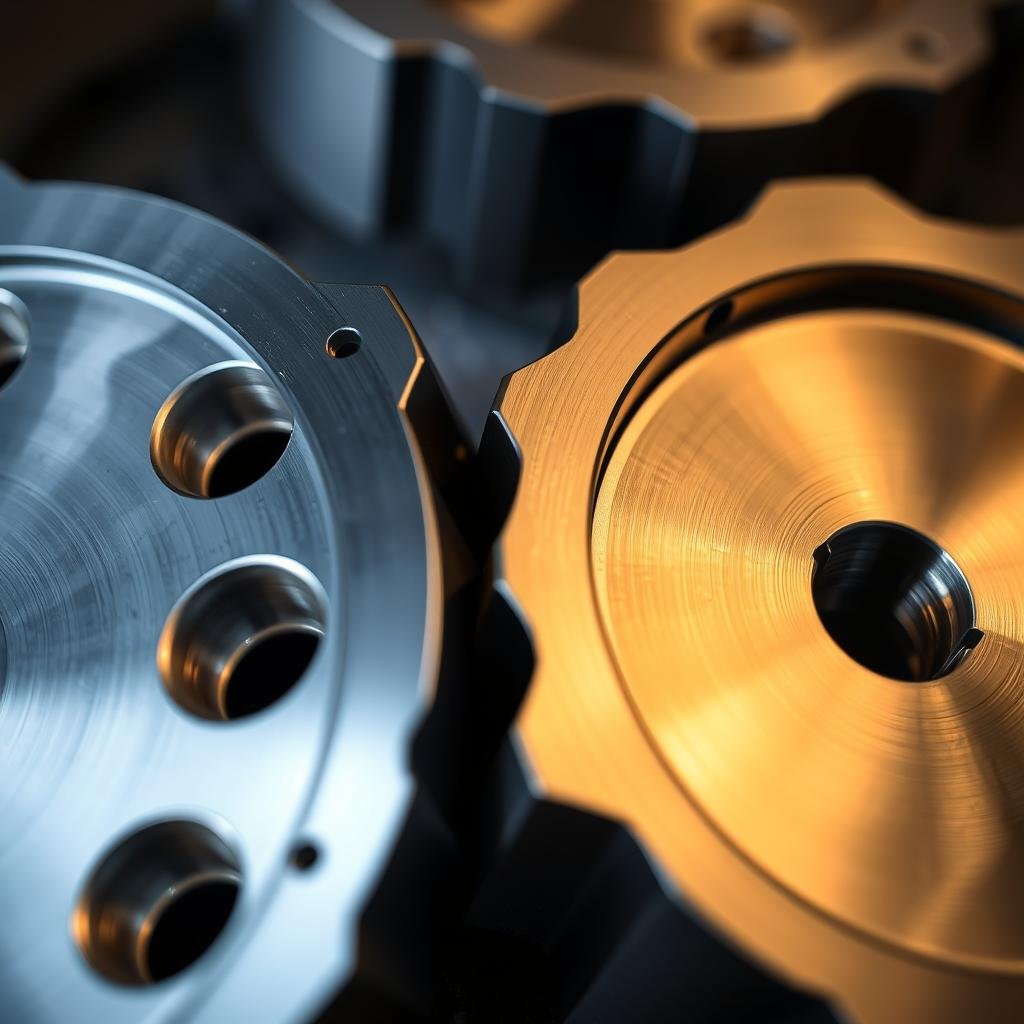

The Advantages of Precision Forging with Quality Tooling

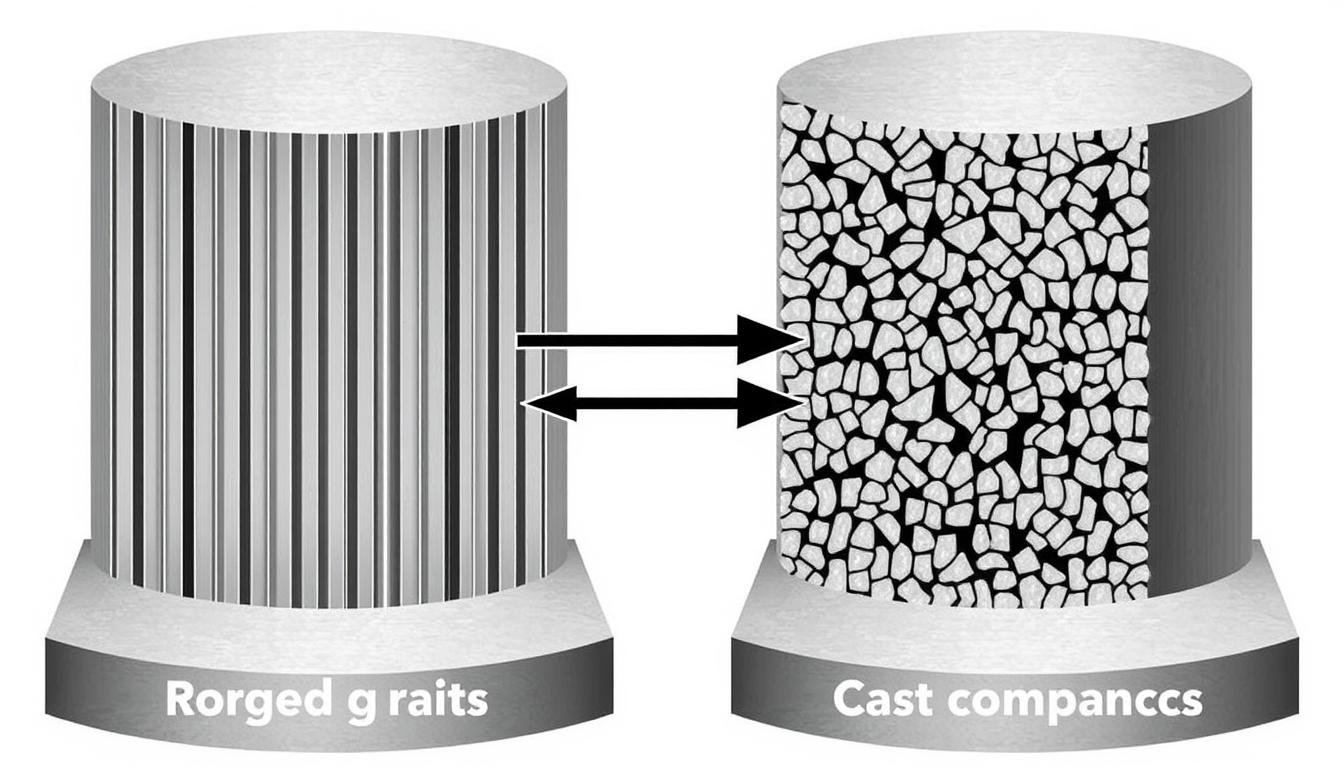

Understanding the benefits of forged components helps illustrate why investing in superior forge tooling is critical for manufacturing success. Forging, particularly when performed with precision-engineered tooling, offers significant advantages over alternative manufacturing methods.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Weight-to-Strength Ratio |

High strength-to-weight ratio |

Bulkier parts may be needed |

The superior properties of forged components are directly influenced by the quality of the forge tooling used in their production. Precision-engineered tooling ensures optimal grain flow, consistent dimensional accuracy, and superior surface finish—all critical factors in producing high-performance forged parts.

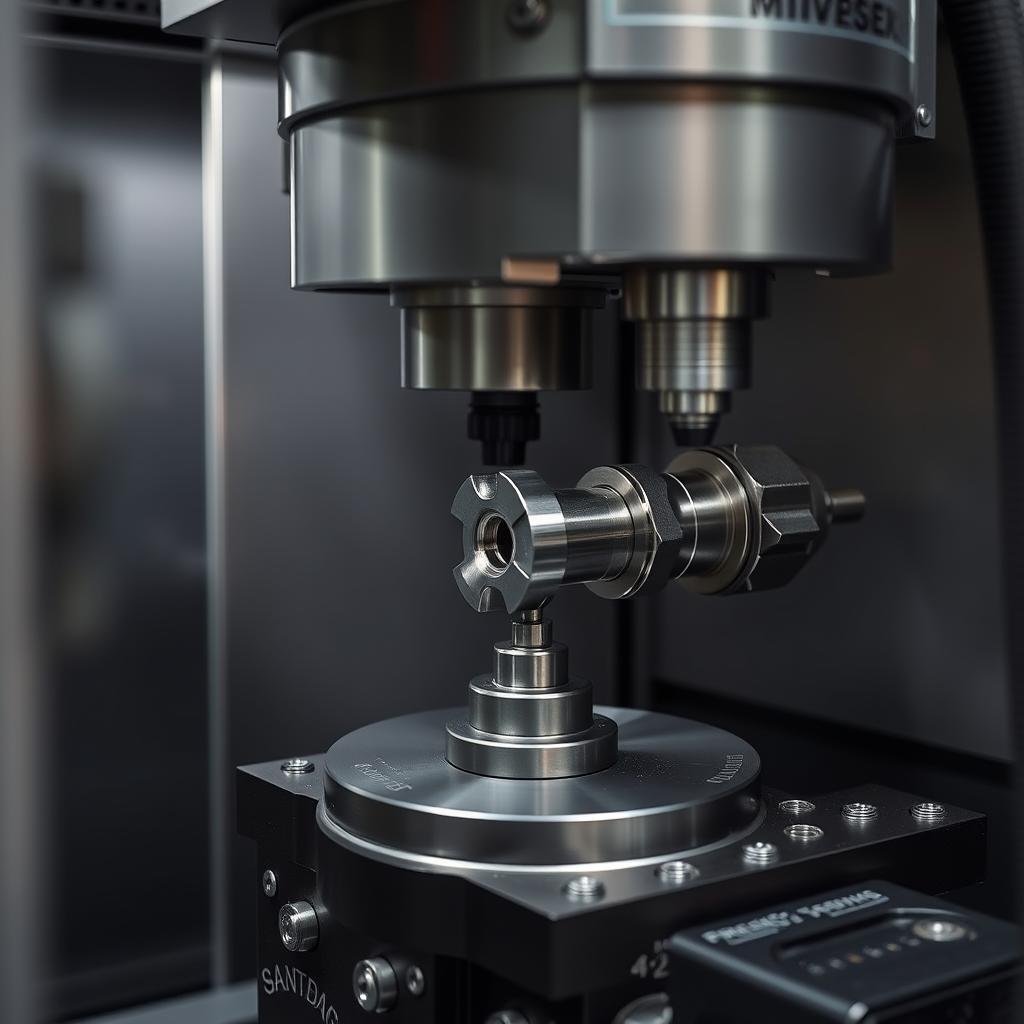

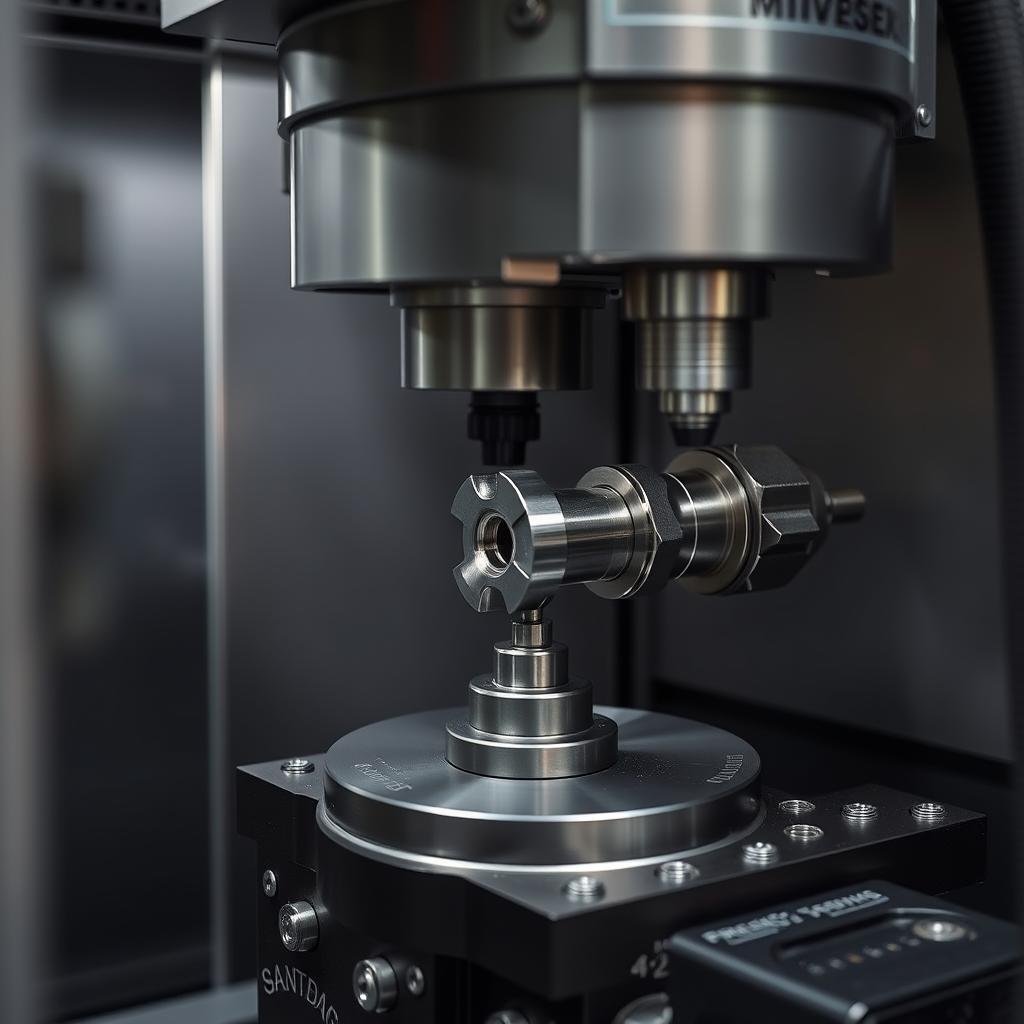

Quality Assurance in Forge Tooling Manufacturing

Quality is at the heart of everything we do at MAIKONG. Our comprehensive quality assurance program ensures that every piece of forge tooling we produce meets or exceeds the highest standards of performance and reliability.

Advanced Inspection

We utilize state-of-the-art inspection equipment, including coordinate measuring machines (CMMs), optical comparators, and laser scanning systems, to verify that all forge tooling components meet exact dimensional specifications.

Material Verification

Our in-house material testing laboratory conducts comprehensive analysis of raw materials and finished forge tooling components to ensure they meet specified mechanical properties and composition requirements.

Documentation & Certification

We maintain detailed records of all inspection and testing results, providing comprehensive documentation and certification for our forge tooling products to support your quality assurance requirements.

Our Quality Commitment

At MAIKONG, we are dedicated to delivering forge tooling of exceptional quality. Our ISO 9001:2015 certification reflects our commitment to continuous improvement and customer satisfaction.

Surface Finish Quality

94%

Comprehensive Customer Support for Forge Tooling

At MAIKONG, we believe that exceptional forge tooling should be complemented by outstanding customer support. Our comprehensive service offerings are designed to ensure your complete satisfaction and success.

Technical Consultation

Our forge tooling specialists are available to provide expert guidance on tooling design, material selection, and process optimization. With decades of combined experience, our team can help you identify opportunities to improve efficiency, extend tool life, and enhance part quality.

Inventory Management Programs

Our stocking programs for high-usage forge tooling offer significant benefits, including reduced lead times, lower inventory costs, and volume-based pricing. Many customers realize savings of 25-40% on a per-tool basis, with delivery times of just 2-5 days for stocked items.

Experience the MAIKONG Difference

Join the growing number of manufacturers who rely on MAIKONG for premium forge tooling and exceptional service.

Email Us Today

Our Forge Tooling Portfolio

Browse our gallery of completed forge tooling projects to see examples of our precision manufacturing capabilities and the diverse range of industries we serve.

Ready to Discuss Your Forge Tooling Needs?

Contact us today to speak with one of our forge tooling specialists about your specific requirements.

Get a Quick Quote

Become a MAIKONG Forge Tooling Representative

MAIKONG is actively seeking representatives throughout the United States to promote our premium forge tooling and precision machining services. As a MAIKONG representative, you’ll have the opportunity to partner with an industry leader known for quality, reliability, and customer satisfaction.

Why Represent MAIKONG?

- High-quality products with competitive pricing

- Comprehensive technical support

- Attractive commission structure

- Established brand with proven track record

- Growing market for precision forge tooling

Representative Opportunities

We offer flexible representation arrangements tailored to your specific market and capabilities. Whether you’re an established sales representative with existing industry connections or a motivated professional looking to expand your portfolio, we have opportunities for you to grow with MAIKONG.

Interested in Representing MAIKONG?

Contact us today to learn more about our representative program and how you can join our growing team.

Become a Representative

Elevate Your Forging Operations with MAIKONG

In the competitive world of metal manufacturing, the quality of your forge tooling can make the difference between mediocre results and exceptional performance. At MAIKONG, we combine decades of expertise with state-of-the-art technology to deliver tooling solutions that help you achieve new levels of efficiency, quality, and profitability.

From precision dies and punches to comprehensive design and engineering services, we offer everything you need to optimize your forging operations. Contact us today to discover how our premium forge tooling solutions can transform your manufacturing process and help you stay ahead of the competition.

Ready to Transform Your Forging Operations?

Contact MAIKONG today to discuss your forge tooling needs and discover the difference that premium quality can make.

Contact Us Now