Forge Tooling

- What is Forge Tooling? A Comprehensive Introduction for US Industrial Businesses

- The Critical Role of Forge Tooling in Precision Metal Forging

- Understanding the Basics of Forging Dies and Their Importance

- Advanced Forge Tooling Solutions for Precision Manufacturing

- Aluminum Tool Forging Pricelist – Complete Guide by MAIKONG

- Why Quality Forge Tooling is Non-Negotiable for US Manufacturers

- Cold Forging Tools: Precision Manufacturing Solutions for Industrial Applications

- Key Components of a Complete Forge Tooling System

- How Advanced Forge Tooling Drives Efficiency in American Forging Operations

- Aluminum Forgings and Extrusions Tool Ferrules: Premium Manufacturing Solutions

- The Future of Forge Tooling: Innovations Shaping US Metal Forging

- Rapid Aluminum Forged Tooling Companies United States: MAIKONG’s Premium Solutions

- Decoding Forge Tooling Terminology: Essential for US Procurement Professionals

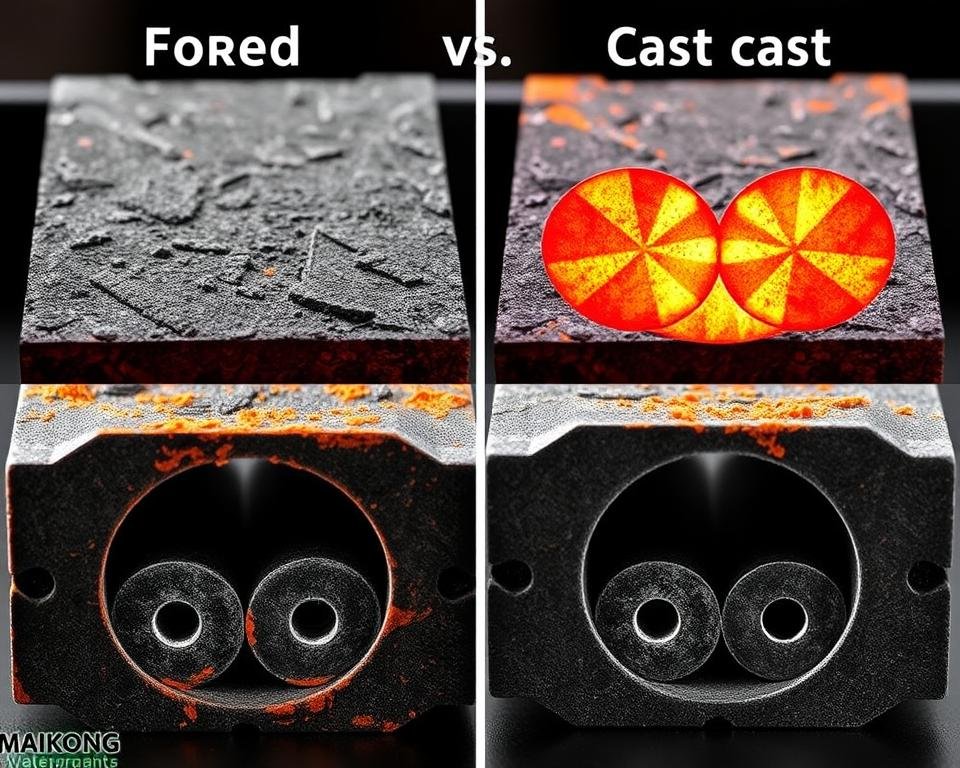

- The Difference Between Open-Die and Closed-Die Forging Tooling

Our material selection process considers:

Our material selection process considers: