In the demanding world of metal forming, cold forging tools represent the pinnacle of precision engineering. At MAIKONG, we’ve perfected the art and science of creating superior cold forging tools that deliver exceptional performance and longevity. With our state-of-the-art manufacturing facilities in GD, SZ, we provide cost-effective solutions for businesses across the United States and beyond. Whether you’re seeking high-precision dies, advanced forming equipment, or complete cold forging tools systems, our team delivers unmatched quality and value. Contact us today at 8613-51090-74-01 or via email at Lucy@maikongforge.us to discover how our expertise can enhance your manufacturing processes.

Whether you’re seeking high-precision dies, advanced forming equipment, or complete cold forging tools systems, our team delivers unmatched quality and value. Contact us today at 8613-51090-74-01 or via email at Lucy@maikongforge.us to discover how our expertise can enhance your manufacturing processes.

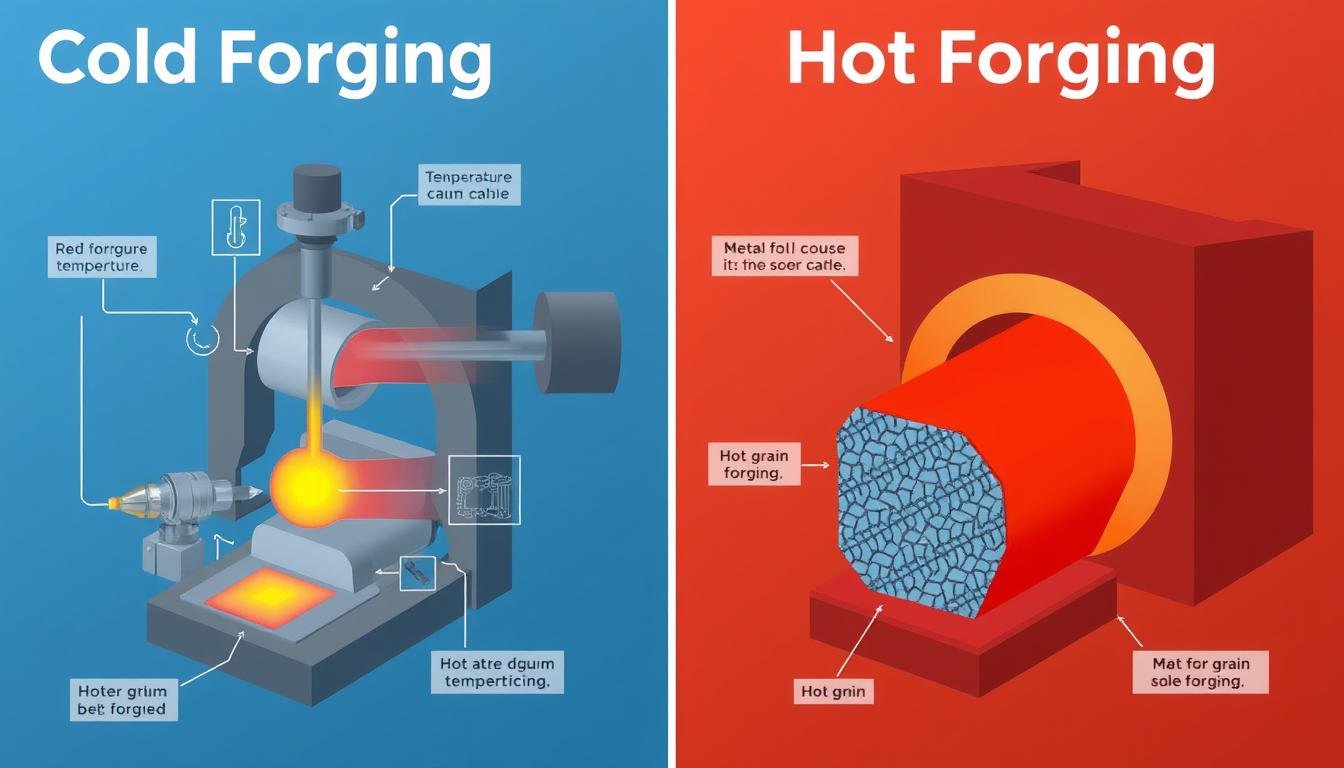

Cold Forging vs. Hot Forging: Choosing the Right Tools for Your Application

Understanding the fundamental differences between cold and hot forging is essential for selecting the appropriate tools and processes for your manufacturing needs. Each method requires specialized equipment and offers distinct advantages.

| Characteristic |

Cold Forging Tools |

Hot Forging Tools |

| Operating Temperature |

Room temperature to below recrystallization point |

Above recrystallization temperature (often 1,150°C for steel) |

| Tool Materials |

High-grade tool steel, tungsten carbide |

Heat-resistant alloys, ceramic coatings |

| Tool Lifespan |

Longer due to lower temperature stress |

Shorter due to thermal fatigue |

| Precision |

Higher dimensional accuracy |

Lower precision due to thermal expansion |

| Surface Finish |

Superior, minimal oxidation |

Requires additional finishing to remove scale |

| Force Requirements |

Higher forces needed |

Lower forces due to increased material plasticity |

| Material Limitations |

Best for softer metals (aluminum, copper, low-carbon steel) |

Suitable for harder metals and complex alloys |

MAIKONG specializes in manufacturing high-performance cold forging tools that deliver exceptional results for applications requiring precision, superior surface finish, and enhanced material properties. Our engineering team can help you determine whether cold forging is the optimal solution for your specific manufacturing requirements.

The Advantages of Cold Forging Tools in Modern Manufacturing

Benefits of Cold Forging Tools

- Enhanced material strength through grain refinement

- Superior dimensional accuracy and tight tolerances

- Excellent surface finish requiring minimal post-processing

- Improved mechanical properties of forged components

- Reduced material waste compared to machining

- Lower energy consumption than hot forging

- Higher production rates for suitable applications

- Extended tool life with proper maintenance

Limitations to Consider

- Higher initial force requirements

- Limited complexity for certain geometries

- Material restrictions for harder metals

- Higher initial tooling investment

- Potential for work hardening in some materials

- Size limitations for very large components

MAIKONG’s advanced cold forging tools are engineered to maximize these benefits while mitigating potential limitations. Our design expertise helps customers achieve optimal results even for challenging applications.

Ready to Enhance Your Manufacturing Process?

Discover how our precision cold forging tools can improve your product quality and reduce production costs.

Get A Quick Quote

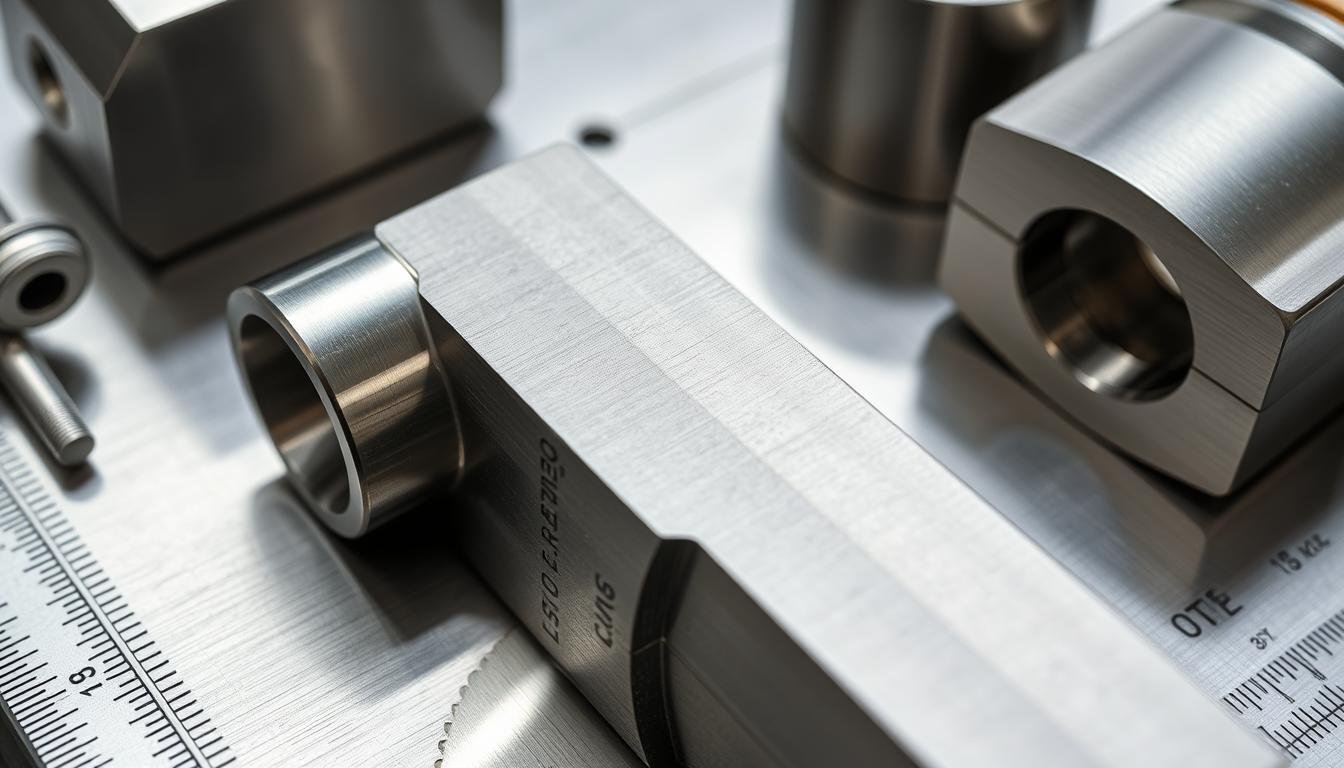

MAIKONG’s Cold Forging Tool Manufacturing Capabilities

With over 60 advanced CNC machines and a monthly metal processing capacity exceeding 100 tons, MAIKONG stands at the forefront of cold forging tools manufacturing. Our state-of-the-art facilities in GD, SZ combine traditional craftsmanship with cutting-edge technology to deliver exceptional quality and precision.

Our Comprehensive Manufacturing Services

CNC Machining Services

- CNC Turning

- CNC Milling

- Swiss-Type Machining

- Multi-Axis Machining

- Surface Grinding

Metal Forging Expertise

- Aluminum Forging

- Steel Forging

- Brass Forging

- Custom Metal Parts

- Precision Components

Additional Services

- Material Testing

- Heat Treatment

- Surface Finishing

- Quality Inspection

- Custom Prototyping

Our dedicated team of engineers and technicians brings decades of combined experience to every project, ensuring that our cold forging tools meet the most demanding specifications. We maintain rigorous quality control standards throughout the manufacturing process, from material selection to final inspection.

Applications and Industries Served by MAIKONG Cold Forging Tools

Our precision cold forging tools enable manufacturers across diverse industries to produce high-quality components with exceptional consistency and efficiency. MAIKONG’s solutions are tailored to meet the specific requirements of each application.

Automotive

- Transmission components

- Steering system parts

- Engine components

- Suspension elements

- Drivetrain parts

Aerospace

- Structural components

- Fastening systems

- Landing gear parts

- Engine mounting brackets

- Control system elements

Industrial Machinery

- Hydraulic components

- Gears and shafts

- Fasteners and connectors

- Valve bodies

- Structural elements

Electronics

- Heat sinks

- Connector housings

- Structural frames

- Component mounts

- Cooling system parts

Medical Devices

- Surgical instruments

- Implant components

- Equipment housings

- Precision mechanisms

- Structural supports

Consumer Products

- Sporting equipment

- Hardware components

- Appliance parts

- Tool elements

- Recreational equipment

Our engineering team works closely with clients to develop cold forging tools that optimize production efficiency while maintaining the highest quality standards. Whether you’re manufacturing high-volume automotive components or precision aerospace parts, MAIKONG delivers solutions tailored to your specific requirements.

Quality Assurance in Cold Forging Tool Manufacturing

At MAIKONG, quality is not just a goal—it’s a fundamental principle that guides every aspect of our cold forging tools manufacturing process. Our comprehensive quality assurance system ensures that each tool meets or exceeds the most demanding specifications.

Our Quality Control Process

Material Verification

- Chemical composition analysis

- Hardness testing

- Microstructure examination

- Mechanical property testing

- Supplier certification verification

In-Process Inspection

- Dimensional verification

- Surface quality assessment

- Heat treatment validation

- Coating inspection

- Assembly verification

Final Testing

- Functional performance testing

- Load capacity verification

- Wear resistance assessment

- Fatigue testing

- Documentation and certification

Our quality management system is certified to international standards, ensuring consistent excellence in every cold forging tool we produce. We maintain detailed documentation throughout the manufacturing process, providing complete traceability for all components and materials.

4.9

Overall Quality Rating

Customer Satisfaction

5.0

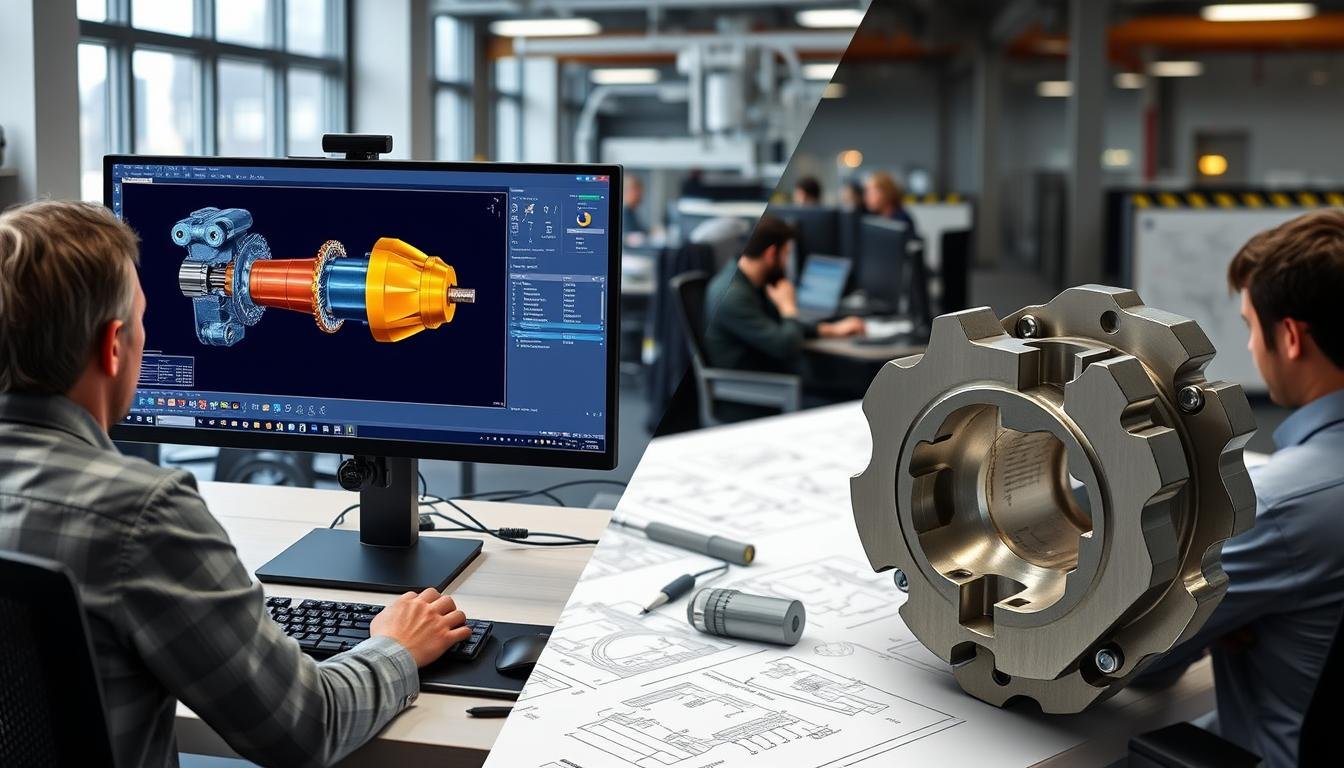

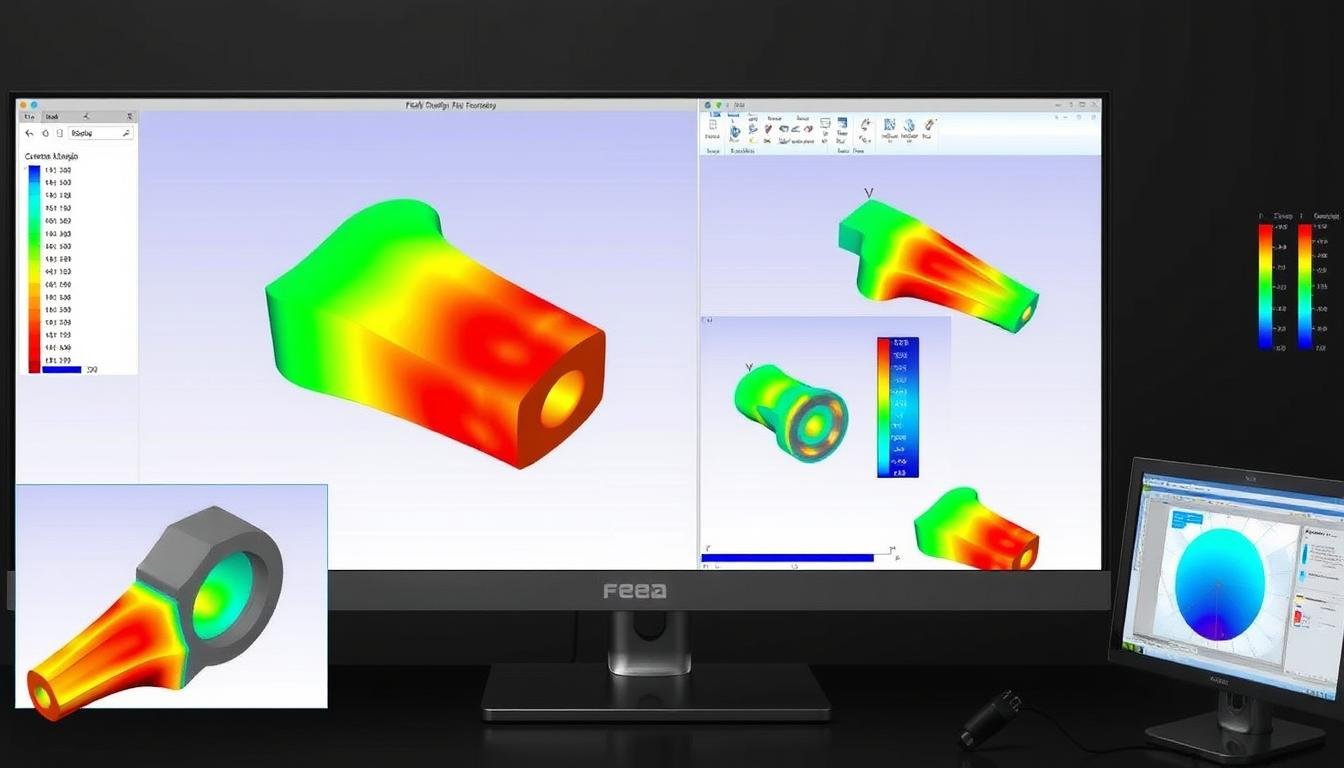

Advanced Design and Engineering for Cold Forging Tools

Creating effective cold forging tools requires a sophisticated understanding of material behavior, stress distribution, and manufacturing processes. MAIKONG’s engineering team employs advanced CAD/CAM systems and simulation software to design tools that deliver optimal performance and longevity.

Our Design and Engineering Process

- Requirements AnalysisWe begin by thoroughly understanding your specific needs, including part geometry, material specifications, production volume, and quality requirements.

- Conceptual DesignOur engineers develop initial concepts for the cold forging tools, considering factors such as material flow, stress distribution, and tool life.

- Computer SimulationAdvanced finite element analysis (FEA) and computational fluid dynamics (CFD) simulations help optimize the design before manufacturing begins.

- Detailed DesignComprehensive 3D models and technical drawings are created, specifying all dimensions, tolerances, materials, and surface treatments.

- Prototype DevelopmentFor complex applications, we can produce prototype tools to validate the design before full production.

- Manufacturing PlanningDetailed production plans ensure efficient manufacturing while maintaining the highest quality standards.

Our engineering team’s expertise in metallurgy, mechanical design, and manufacturing processes ensures that every cold forging tool we produce is optimized for your specific application. We continuously refine our designs based on performance data and customer feedback.

Become a US Distributor for MAIKONG Cold Forging Tools

MAIKONG is actively seeking distribution partners across the United States to expand our market presence and deliver our premium cold forging tools to more manufacturers. As a MAIKONG distributor, you’ll gain access to our comprehensive product line, competitive pricing, and dedicated support.

Benefits of Becoming a MAIKONG Distributor

- Exclusive territory rights

- Competitive pricing structure

- Comprehensive product training

- Marketing and sales support

- Technical assistance for your customers

- Regular product updates

- Custom manufacturing capabilities

- Reliable supply chain

- Quality assurance guarantees

- Growing product portfolio

Our partnership approach focuses on long-term relationships built on mutual success. We provide our distributors with the tools, knowledge, and support they need to effectively serve their markets and grow their businesses.

– MAIKONG Management Team

Interested in Distribution Opportunities?

Contact our partnership team today to discuss how we can work together to bring MAIKONG’s premium cold forging tools to your market.

Contact via WhatsApp

Email Us

Why Choose MAIKONG for Your Cold Forging Tool Needs

MAIKONG combines advanced technology, engineering expertise, and manufacturing excellence to deliver cold forging tools that exceed expectations. Our commitment to quality, innovation, and customer satisfaction has established us as a trusted partner for manufacturers worldwide.

With our comprehensive capabilities in CNC machining, metal forging, and precision manufacturing, we offer complete solutions for your most demanding applications. From concept to completion, MAIKONG provides the expertise, resources, and support you need to succeed.

Ready to Experience the MAIKONG Difference?

Contact us today to discuss your cold forging tools requirements and discover how our solutions can enhance your manufacturing processes.

Start Your Project Today

Let us help you optimize your manufacturing process with our premium cold forging tools.

Get A Quick Quote

Whether you’re seeking high-precision dies, advanced forming equipment, or complete cold forging tools systems, our team delivers unmatched quality and value. Contact us today at

Whether you’re seeking high-precision dies, advanced forming equipment, or complete cold forging tools systems, our team delivers unmatched quality and value. Contact us today at