Understanding the distinction between open-die and closed-die forging tooling is crucial for manufacturing professionals seeking optimal metal forming solutions. The tooling used in these processes significantly impacts part quality, production efficiency, and overall costs. This comprehensive guide explores how these forging methods differ in tooling requirements, capabilities, and applications, helping you make informed decisions for your manufacturing needs.

Understanding Metal Forging Fundamentals

Metal forging is one of humanity’s oldest metalworking processes, dating back thousands of years. At its core, forging involves applying compressive forces to metal, typically heated to increase malleability, to shape it into desired forms. Unlike casting, which melts metal completely, forging preserves and enhances the metal’s grain structure, resulting in stronger, more durable parts.

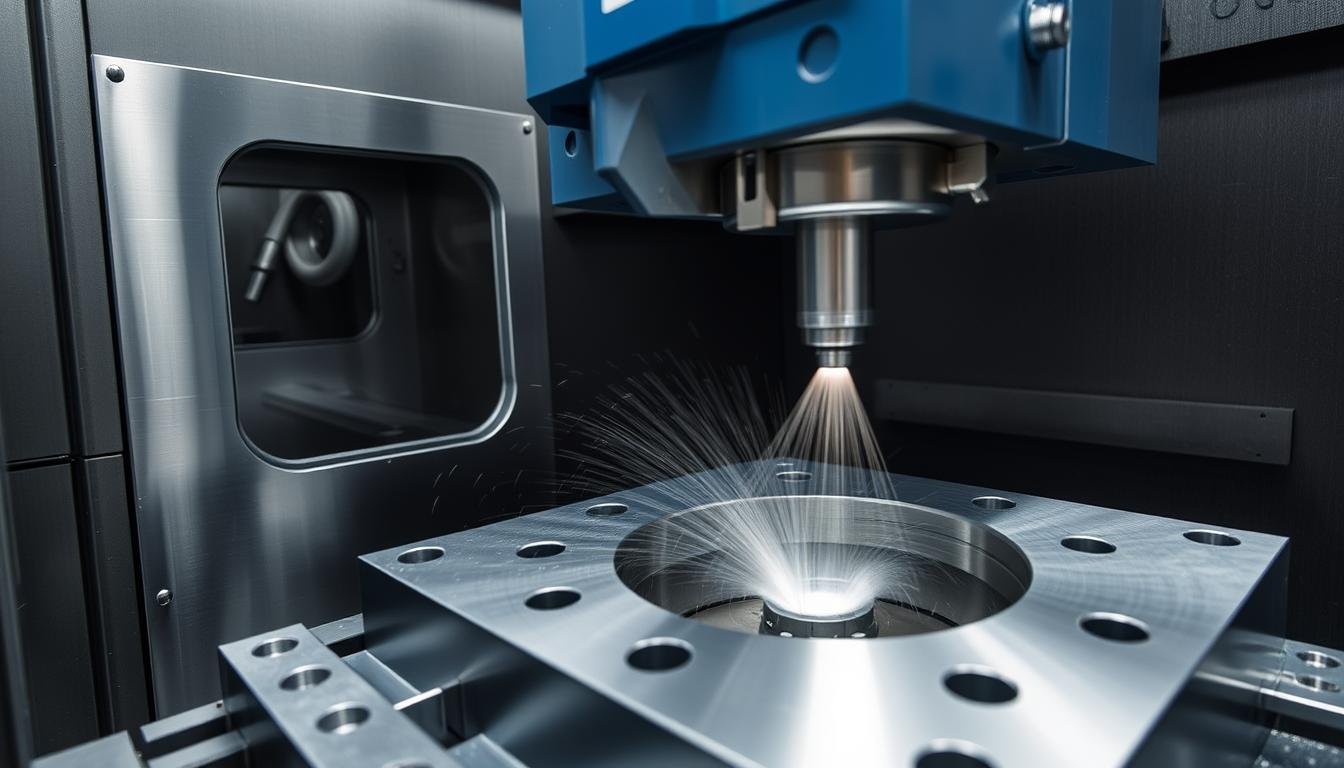

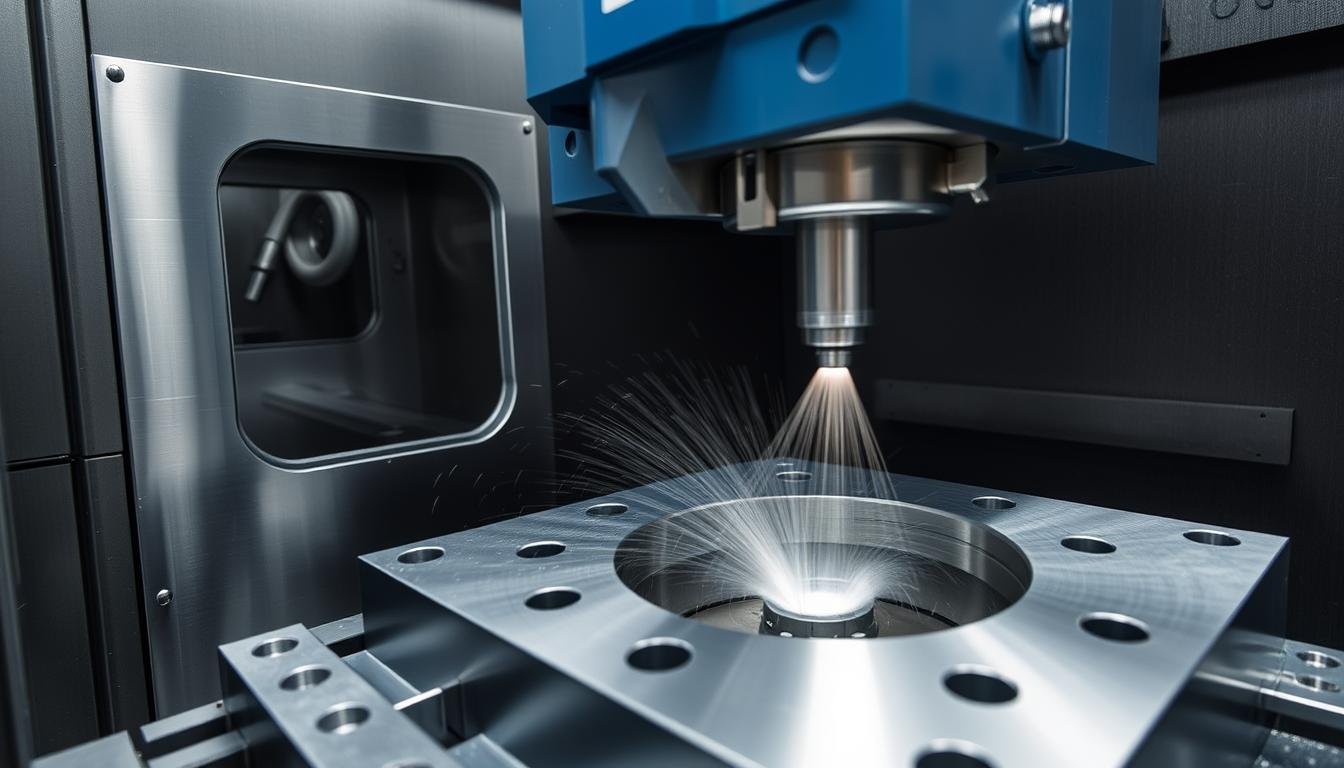

Modern metal forging process at MAIKONG’s manufacturing facility

Modern metal forging process at MAIKONG’s manufacturing facility

The two primary approaches to die forging—open-die and closed-die—differ fundamentally in how the metal is constrained during the deformation process. These differences in tooling design and application create distinct advantages for specific manufacturing scenarios.

Open-Die Forging Tooling: Characteristics and Applications

Open-die forging, sometimes called free forging, uses uncomplicated tooling that doesn’t fully enclose the workpiece during deformation. This approach offers specific advantages for certain applications while presenting limitations for others.

Open-Die Forging Tooling Components

Basic open-die forging tooling components

The tooling used in open-die forging typically consists of:

- Flat dies or anvils that provide simple shaping surfaces

- Basic shaped tools for creating elementary forms

- Manipulators for handling and positioning large workpieces

- Hydraulic or mechanical presses that apply controlled force

- Heating equipment to bring metal to optimal forging temperature

Advantages of Open-Die Forging Tooling

Advantages

- Lower tooling costs due to simpler die designs

- Greater flexibility for producing various shapes with the same tooling

- Better suited for large-scale components that wouldn’t fit in closed dies

- Ideal for low-volume production where custom die costs aren’t justified

- Allows for incremental forming of complex shapes through multiple operations

Limitations

- Lower precision requiring additional machining for tight tolerances

- More operator skill and involvement needed for consistent results

- Slower production rates compared to closed-die operations

- Limited ability to create complex geometries in a single operation

- Less control over material flow and grain structure

Typical Applications for Open-Die Forging

Open-die forging tooling is particularly well-suited for:

- Large industrial shafts and axles

- Heavy equipment components

- Power generation equipment parts

- Custom, low-volume industrial components

- Preliminary forming before closed-die operations

Closed-Die Forging Tooling: Components and Capabilities

In contrast to open-die forging, closed-die forging tooling (also known as impression-die forging) uses dies that partially or completely enclose the workpiece, forcing the metal to conform precisely to the die cavity shape. This method delivers higher precision but requires more sophisticated tooling.

Precision closed-die forging tooling manufactured by MAIKONG

Essential Components of Closed-Die Forging Tooling

| Tooling Component |

Function |

Design Considerations |

| Upper and Lower Dies |

Contain cavities that shape the heated billet into the desired part |

Must account for material shrinkage and flow patterns |

| Flash Land |

Controls material flow and flash thickness |

Width and thickness affect die filling and pressure |

| Gutter |

Collects excess material (flash) |

Must accommodate maximum flash volume |

| Die Inserts |

Create specific features in high-wear areas |

Material selection for wear resistance |

| Ejectors |

Remove finished parts from die cavities |

Positioning to avoid part damage |

| Die Holders |

Secure dies to the forging press |

Alignment and rigidity under high pressure |

| Trimming Dies |

Remove flash after forging |

Match part profile precisely |

Material Selection for Closed-Die Forging Tooling

The choice of die materials significantly impacts tooling performance and lifespan. Common materials include:

Tool Steels

- H13 Tool Steel: Excellent hot hardness and thermal fatigue resistance

- H11 Tool Steel: Good balance of toughness and wear resistance

- H21 Tool Steel: Superior heat resistance for high-temperature applications

Other Materials

- Tungsten Carbide: Exceptional wear resistance for high-volume production

- Nickel-based Superalloys: For extreme temperature applications

- Die Steel with Surface Treatments: Enhanced surface properties

CNC machining of closed-die forging tooling at MAIKONG’s facility

Expert Tooling Design & Manufacturing

MAIKONG specializes in precision closed-die forging tooling design and manufacturing. Our engineering team can help optimize your tooling for maximum performance and longevity.

Request Tooling Consultation

Open-Die vs. Closed-Die Forging Tooling: A Comprehensive Comparison

When selecting between open-die and closed-die forging processes, understanding the tooling differences is crucial for making the right manufacturing decision. Each approach offers distinct advantages depending on your specific requirements.

| Comparison Factor |

Open-Die Forging Tooling |

Closed-Die Forging Tooling |

| Tooling Complexity |

Simple, often flat or basic shaped dies |

Complex with precisely machined cavities |

| Initial Tooling Cost |

Lower initial investment |

Higher initial investment |

| Tooling Lifespan |

Longer due to less complex geometry |

Shorter due to higher wear in complex areas |

| Part Precision |

Lower precision, requires more machining |

Higher precision, near-net shape possible |

| Production Volume |

Ideal for low to medium volumes |

Economical for medium to high volumes |

| Part Size Capability |

Suitable for very large components |

Limited by press size and die strength |

| Geometric Complexity |

Limited to simpler shapes |

Can produce complex geometries |

| Material Utilization |

Less efficient, more machining waste |

More efficient, reduced machining |

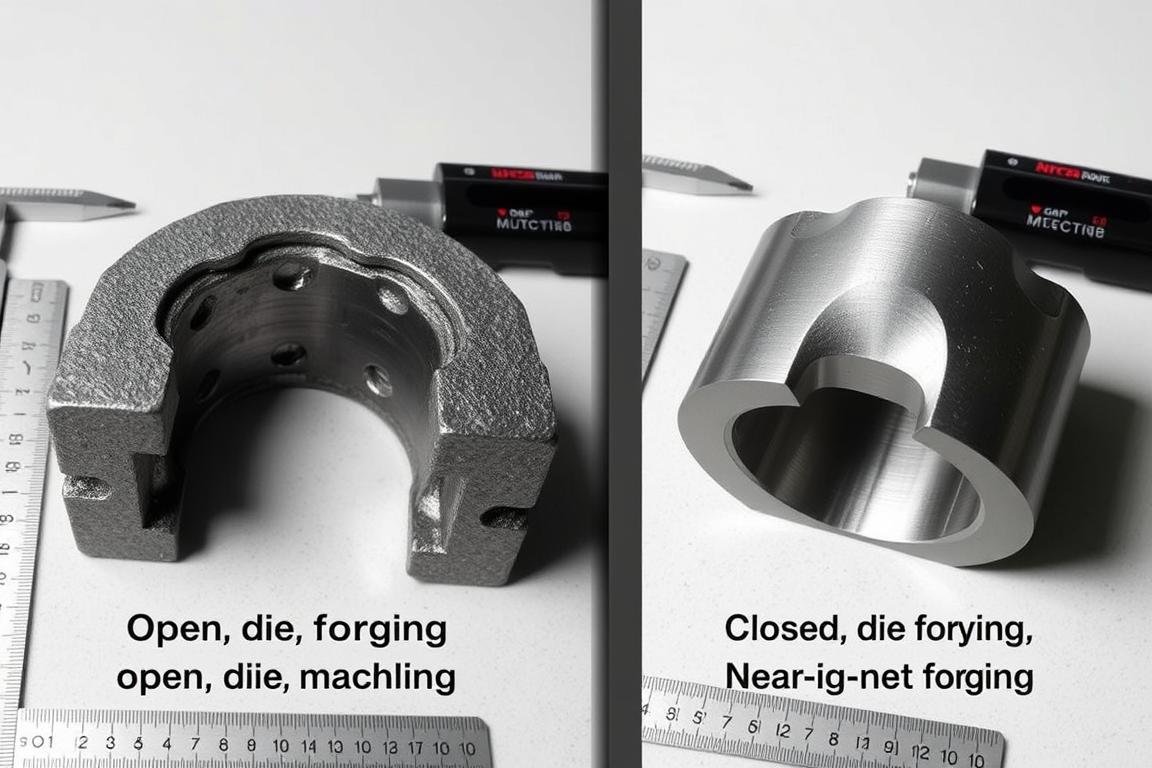

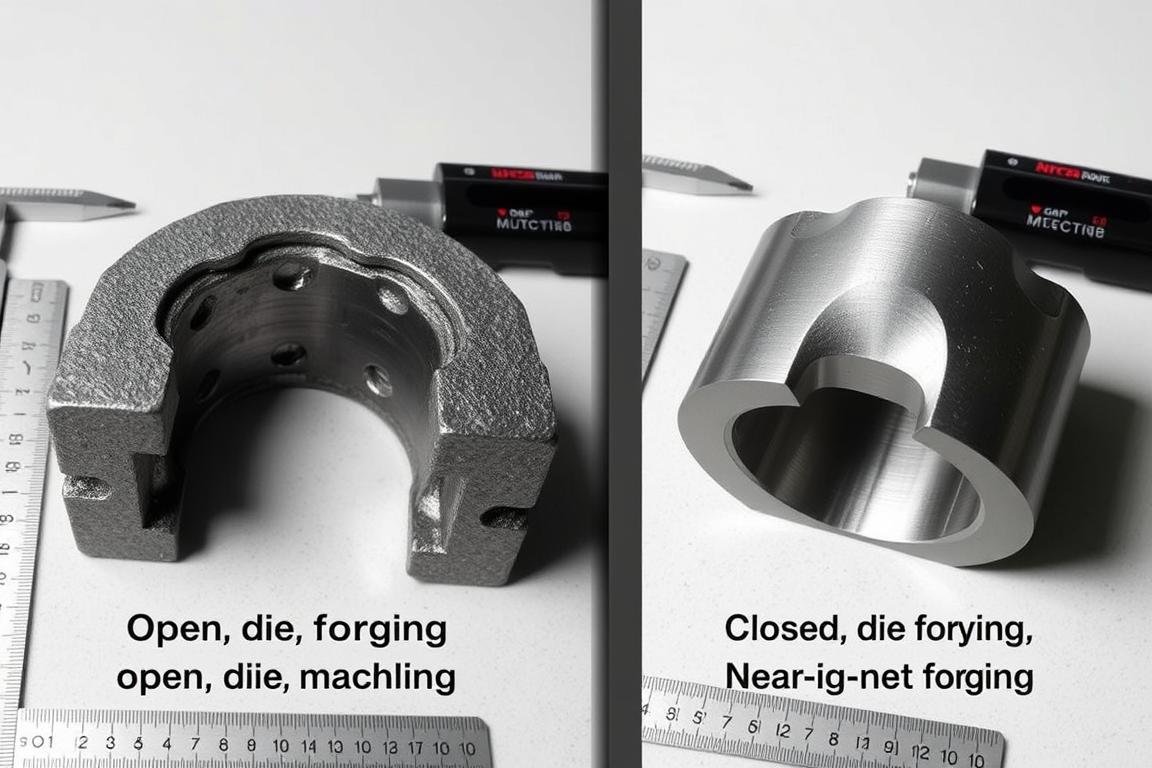

Comparison of parts produced using open-die (left) vs. closed-die forging tooling (right)

MAIKONG’s Advanced Closed-Die Forging Tooling Capabilities

At MAIKONG, we combine decades of forging expertise with state-of-the-art technology to deliver superior closed-die forging tooling and finished components. Our comprehensive approach ensures optimal results from design through production.

MAIKONG’s advanced forging and machining facility

Comprehensive Forging Solutions

Our integrated approach includes:

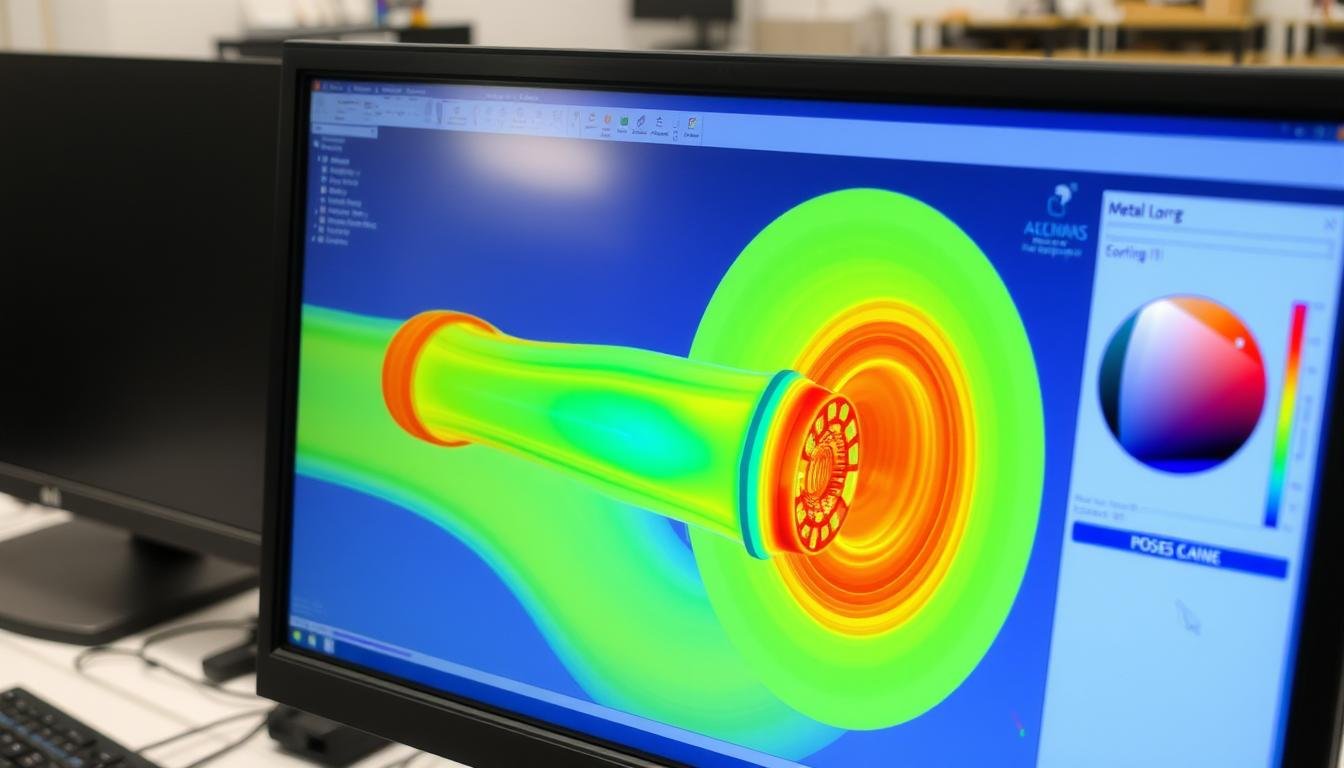

Design & Engineering

- Advanced CAD/CAM design

- FEA simulation for process optimization

- Material flow analysis

- Tooling lifecycle optimization

Manufacturing Excellence

- 60+ CNC machines

- 100+ tons monthly capacity

- Precision die manufacturing

- Multi-axis machining capabilities

Quality Assurance

- Comprehensive material testing

- Dimensional verification

- Non-destructive testing

- ISO 9001:2015 certified processes

Materials Expertise

We specialize in forging a wide range of materials:

Steel Alloys

- Carbon steel

- Alloy steel

- Stainless steel

- Tool steel

Non-ferrous Metals

- Aluminum alloys

- Copper and brass

- Titanium alloys

- Nickel-based alloys

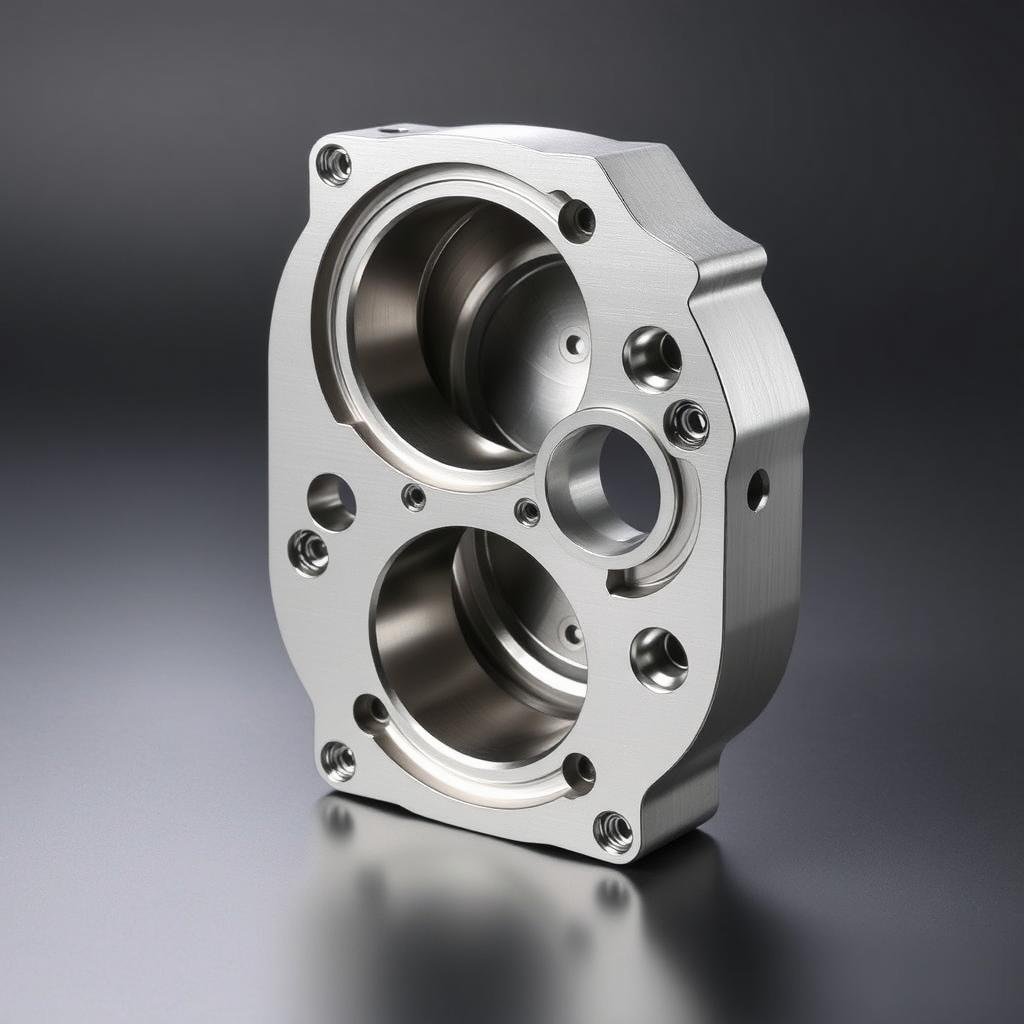

Gallery of precision forged parts manufactured by MAIKONG

Partner with MAIKONG for Your Forging Needs

Experience the MAIKONG difference with our comprehensive forging and machining capabilities. We deliver high-quality, cost-effective solutions for the most demanding applications.

Get A Quick Quote

MAIKONG Forging Capabilities Gallery

Choosing the Right Forging Process for Your Application

The choice between open-die and closed-die forging tooling depends on your specific requirements including part complexity, production volume, dimensional precision, and budget constraints. While open-die forging offers advantages for larger, simpler components with lower production volumes, closed-die forging tooling delivers superior precision, complex geometries, and better material properties for critical applications.

At MAIKONG, we specialize in both processes and can help you determine the optimal approach for your specific needs. Our engineering team works closely with clients to develop cost-effective forging solutions that meet the most demanding specifications. Contact us today to discuss your project requirements and discover how our expertise in forging and precision machining can benefit your manufacturing operations.

Ready to Start Your Next Project?

Contact MAIKONG today for expert guidance on your forging and machining needs. We offer competitive pricing, exceptional quality, and comprehensive manufacturing services.

Contact Us Today

Modern metal forging process at MAIKONG’s manufacturing facility

Modern metal forging process at MAIKONG’s manufacturing facility