The art and science of metal forging have evolved significantly since ancient times, but one element remains central to the process: the forging die. These specialized tools are the unsung heroes of modern manufacturing, enabling the transformation of raw metal into precision components with superior strength and durability. The Basics of Forging Dies encompass not just their physical design but also their critical role in determining the quality, consistency, and properties of the final forged product. At MAIKONG, we’ve mastered the intricate balance of die design, material selection, and precision manufacturing to deliver forging solutions that meet the most demanding industrial requirements.

What Are Forging Dies: The Foundation of Metal Forming

Forging dies are specialized tools used in the forging process to shape metal workpieces into desired forms through the application of pressure. These precision-engineered components serve as molds that define the final shape of the forged part, ensuring dimensional accuracy and consistent quality across production runs.

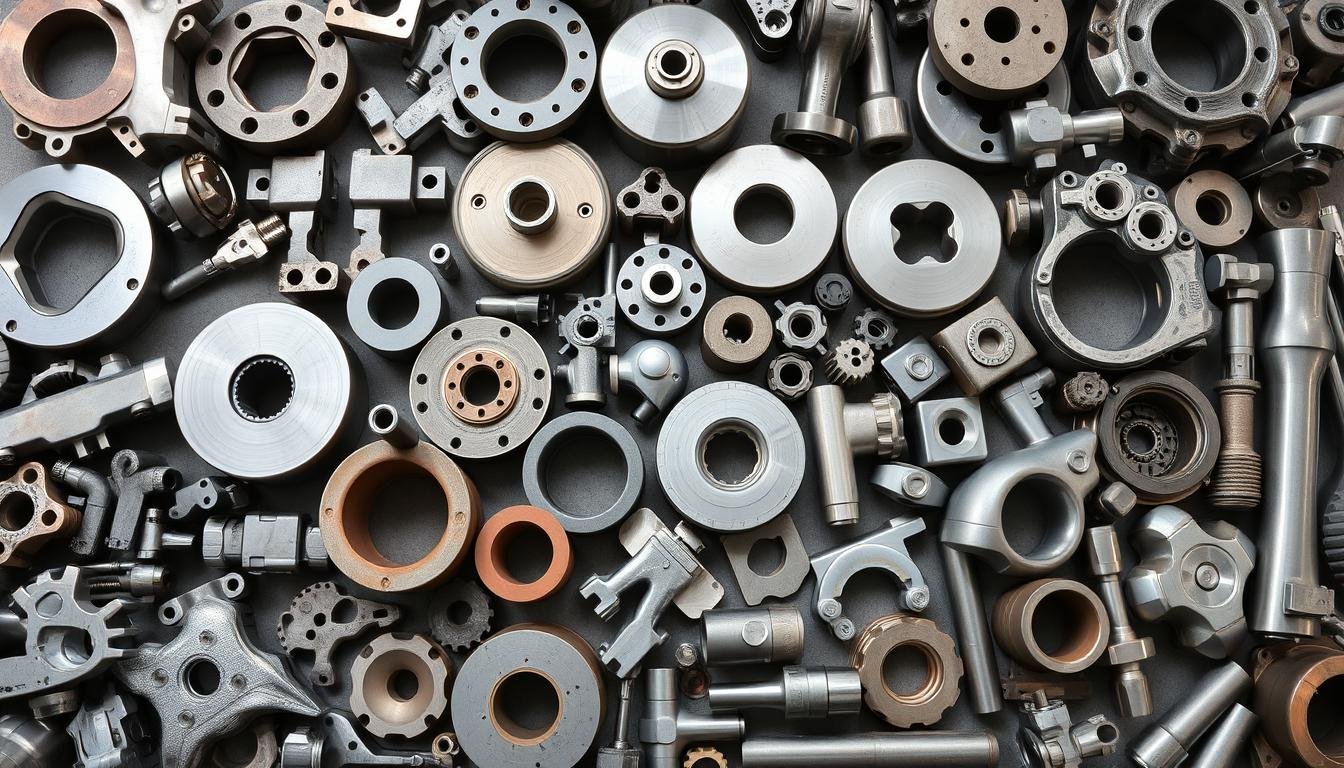

Various forging dies used in modern metal forming processes

At their core, forging dies consist of two or more sections that contain impressions (cavities) of the desired part shape. When a heated metal workpiece is placed between these dies and pressure is applied, the metal flows into the cavities, taking on the precise geometry defined by the die. The quality of the die directly influences the quality of the finished product, making die design and manufacturing a critical aspect of the forging process.

The Fundamental Basics of Forging Dies Components

Understanding the basic components of forging dies is essential for appreciating their function in the metal forming process:

Die Blocks

The main body of the die, typically made from tool steel or other high-strength alloys capable of withstanding extreme pressures and temperatures. Die blocks provide the structural integrity needed to maintain dimensional stability during repeated forging operations.

Die Cavities

The recessed areas within the die blocks that define the shape of the final forged component. These cavities are precision-machined to exacting tolerances to ensure consistent part dimensions across production runs.

Flash Gutter

A channel around the die cavity that collects excess material (flash) that flows out during the forging process. This feature helps control material flow and ensures complete filling of the die cavity.

Parting Line

The interface where the two die halves meet. The design of the parting line is crucial for proper die filling and ease of part removal after forging.

At MAIKONG, our engineering team specializes in optimizing each of these components to create forging dies that deliver superior performance and longevity. With our extensive experience in die design and manufacturing, we ensure that every die we produce meets the highest standards of quality and precision.

Types of Forging Dies: Versatility in Metal Forming

The forging industry utilizes various types of dies, each designed for specific applications and production requirements. Understanding these different die types is essential for selecting the most appropriate manufacturing process for your components.

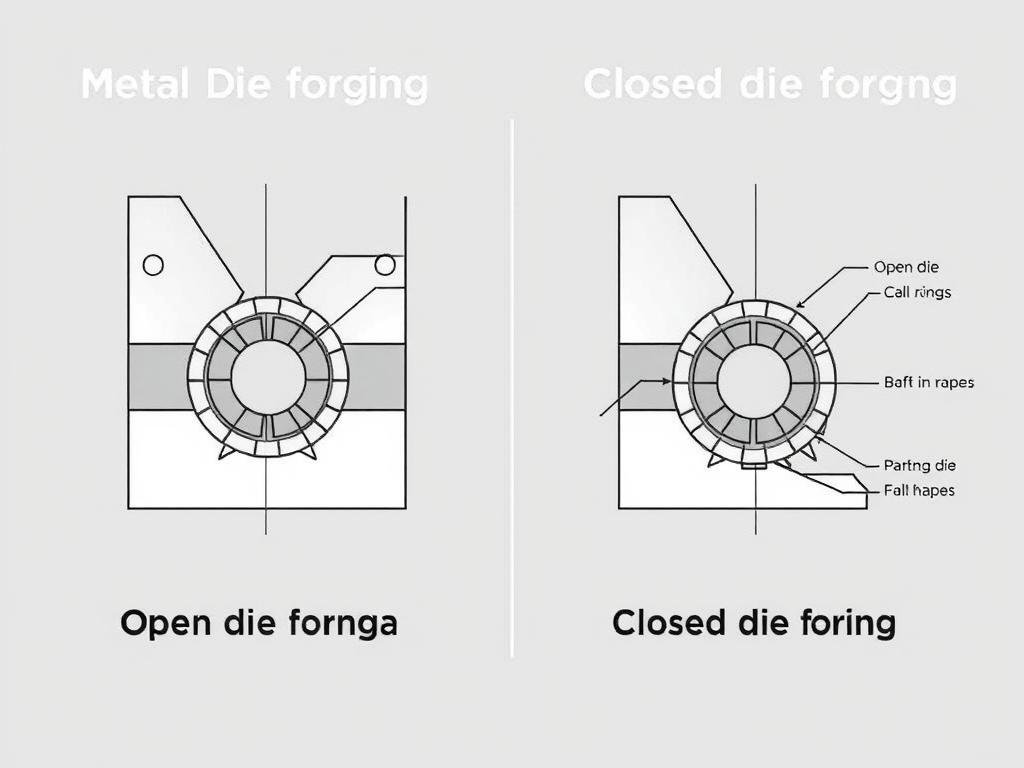

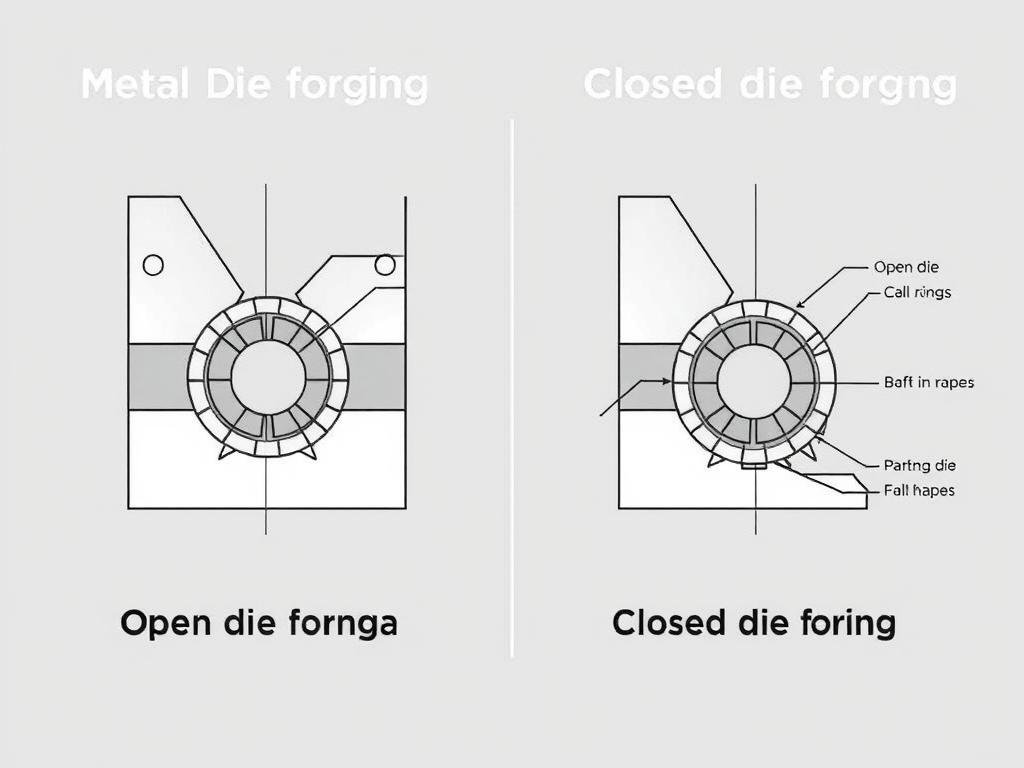

Comparison of open die and closed die forging processes

Open Die Forging: Flexibility in Form

Open die forging represents one of the most fundamental approaches in the spectrum of forging techniques. In this process, the metal workpiece is shaped between flat or simply contoured dies that do not completely enclose the material, allowing it to flow outward from the die contact areas.

Advantages of Open Die Forging

- Ideal for large or unique components where closed dies would be impractical

- Lower tooling costs compared to closed die forging

- Greater flexibility in producing a wide range of shapes and sizes

- Suitable for low to medium production volumes

- Excellent for improving internal material structure

Limitations of Open Die Forging

- Lower precision compared to closed die forging

- Typically requires more secondary machining

- Less material efficient due to greater allowances

- Generally slower production rates

- Requires skilled operators for complex shapes

Closed Die Forging: Precision and Complexity

Closed die forging, also known as impression die forging, utilizes dies that contain a cavity resembling the final shape of the desired part. The metal is compressed between the dies, forcing it to flow into and fill the die cavities.

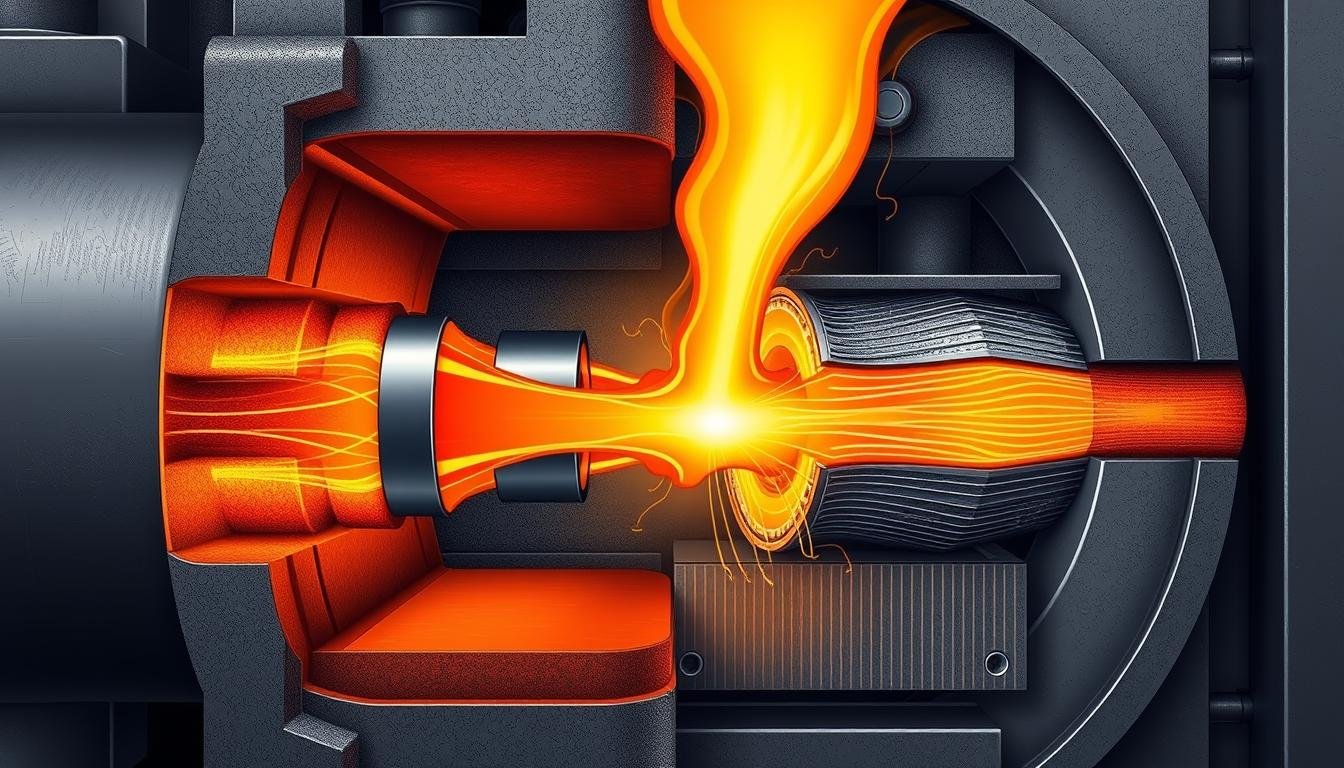

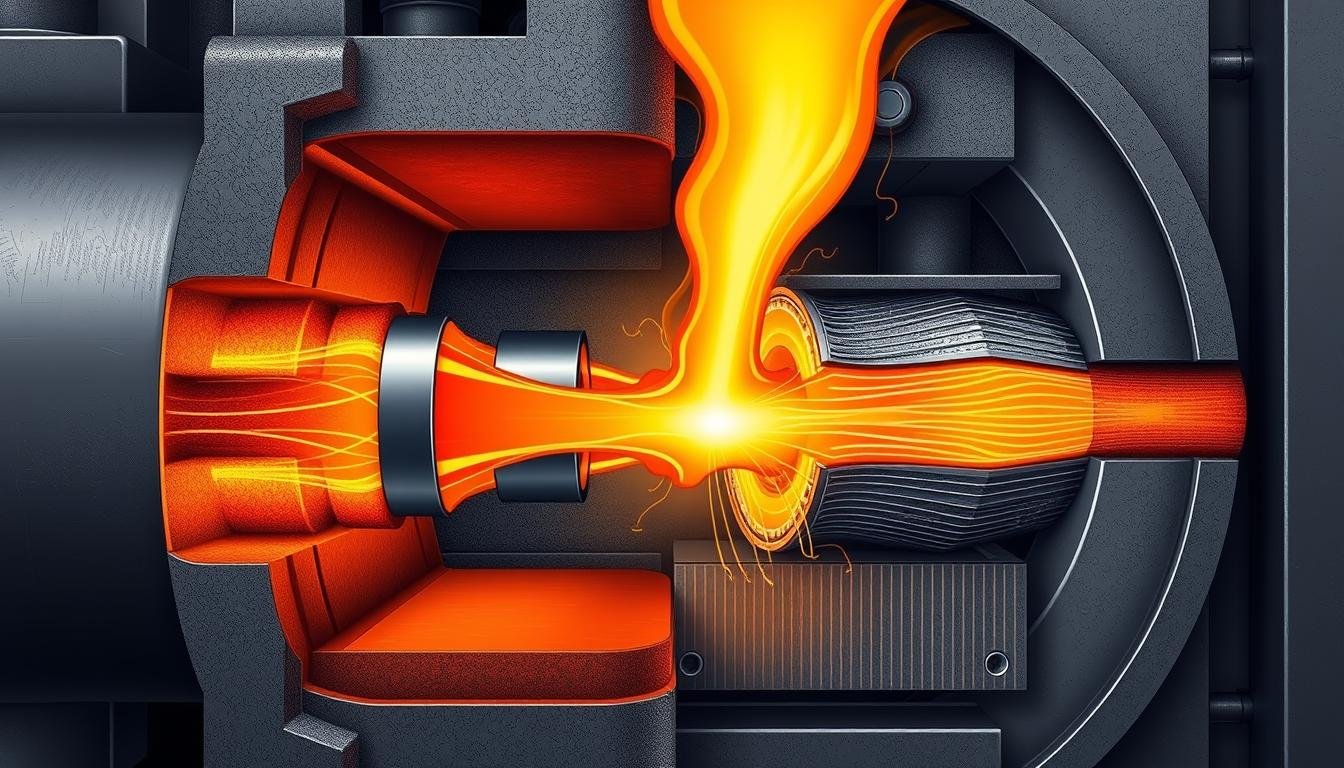

Cross-section view of closed die forging process showing metal flow

Advantages of Closed Die Forging

- Superior dimensional accuracy and surface finish

- Ability to produce complex geometries

- Excellent material utilization with minimal waste

- Consistent part quality across high-volume production

- Reduced need for secondary machining operations

Limitations of Closed Die Forging

- Higher initial tooling costs

- Size limitations compared to open die forging

- Less flexibility for design changes

- More complex die design and maintenance

- Generally not economical for low production volumes

Specialized Forging Die Types

Beyond the basic open and closed die categories, several specialized die types have been developed to address specific manufacturing challenges:

Blocker Dies

Preliminary dies used in multi-stage forging to distribute material before final forming. These dies create a rough approximation of the final shape, preparing the workpiece for subsequent operations.

Finisher Dies

The final dies in a multi-stage process that impart the precise dimensions and surface details to the forged component. These dies typically have tighter tolerances than blocker dies.

Precision Forging Dies

Highly accurate dies designed to produce near-net-shape components that require minimal or no secondary machining. These dies often incorporate sophisticated features like controlled flash and precise parting lines.

Expert Die Design and Manufacturing at MAIKONG

With over 60 CNC machines and 100+ tons of monthly metal processing capacity, MAIKONG specializes in creating high-performance forging dies for diverse applications. Our engineering team can help you select the optimal die type for your specific requirements.

Discuss Your Die Requirements

Die Materials: The Foundation of Durability

The selection of appropriate materials for forging dies is critical to their performance, durability, and cost-effectiveness. Die materials must withstand extreme conditions, including high temperatures, intense pressures, and repetitive impact forces.

Various tool steel grades used in forging die manufacturing

Common Materials for Forging Dies

The choice of die material depends on factors such as the type of forging process, operating temperature, production volume, and the material being forged. Here are the most commonly used materials in forging die construction:

| Material Type |

Properties |

Applications |

Temperature Range |

| H13 Tool Steel |

Excellent hot hardness, thermal fatigue resistance, and toughness |

Hot forging dies, extrusion dies, die-casting dies |

Up to 1200°F (650°C) |

| H11 Tool Steel |

Good hot hardness and thermal shock resistance |

Hot work dies, punches, and inserts |

Up to 1000°F (540°C) |

| D2 Tool Steel |

High wear resistance and moderate toughness |

Cold forging dies, trim dies |

Up to 900°F (480°C) |

| A2 Tool Steel |

Good wear resistance and dimensional stability |

Cold forging dies, forming tools |

Up to 800°F (425°C) |

| Tungsten Carbide |

Exceptional hardness and wear resistance |

Inserts for high-stress areas, precision dies |

Up to 1400°F (760°C) |

Material Selection Considerations

When selecting materials for forging dies, several factors must be carefully evaluated to ensure optimal performance and longevity:

Thermal Properties

Dies experience extreme temperature fluctuations during forging operations. Materials must possess good thermal conductivity to dissipate heat effectively, as well as thermal shock resistance to prevent cracking during heating and cooling cycles.

Mechanical Properties

Forging dies must withstand enormous pressures without deforming. Key mechanical properties include high compressive strength, adequate toughness to resist cracking, and good wear resistance to maintain dimensional accuracy over numerous forging cycles.

Machinability

Die materials should be reasonably machinable to allow for the creation of complex cavity geometries and surface details. Materials that are too difficult to machine can significantly increase manufacturing costs and lead times.

Cost Considerations

The initial cost of die materials must be balanced against their expected service life. Premium materials may have higher upfront costs but can offer superior durability and reduced maintenance requirements, resulting in lower long-term expenses.

At MAIKONG, our metallurgical expertise allows us to select the optimal die materials for each specific application, ensuring the perfect balance of performance, durability, and cost-effectiveness. Our material laboratory plays a vital role in our production process, enabling us to achieve the precise results our customers demand.

Die Design and Manufacturing: Crafting Precision Tools

The process of designing and manufacturing forging dies is a sophisticated blend of engineering expertise, material science, and precision machining. The quality of the die directly influences the quality of the forged components, making this stage critical to successful forging operations.

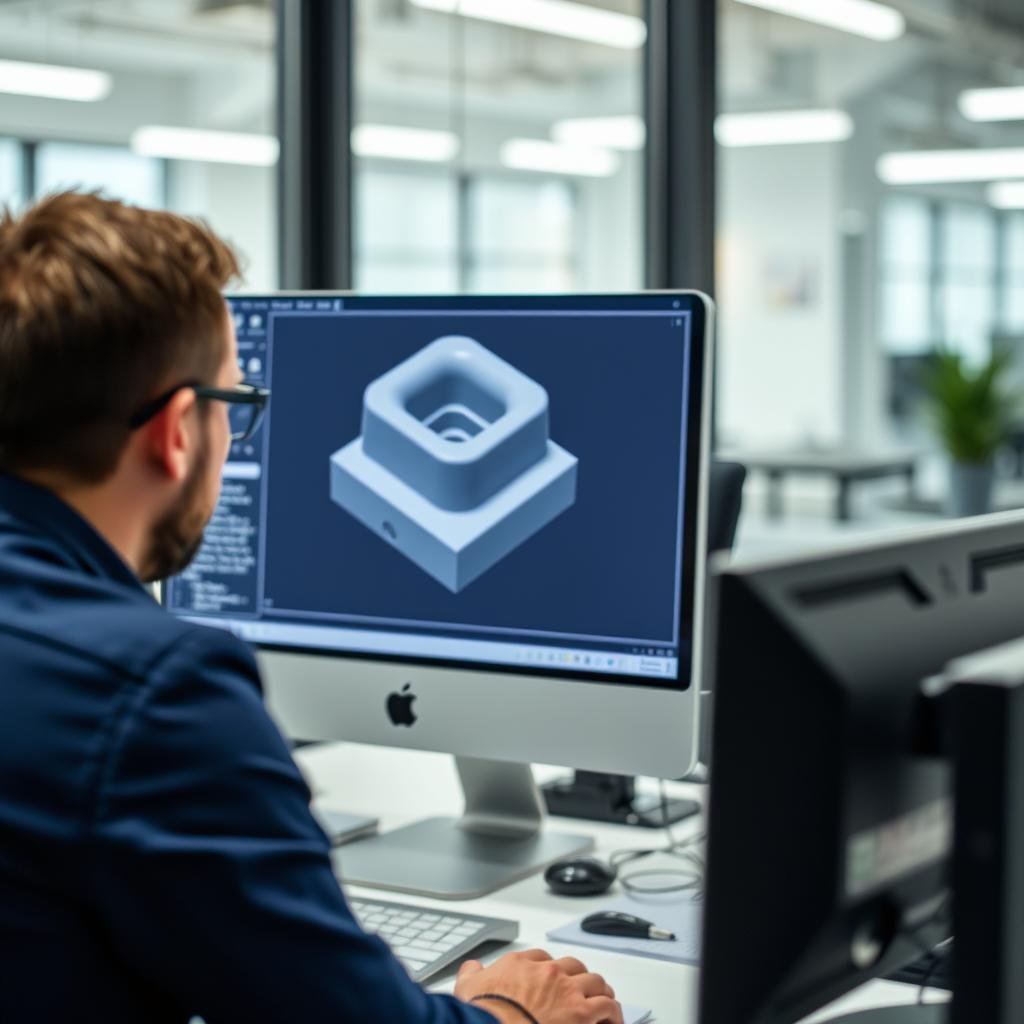

CAD/CAM design process for creating precision forging dies

The Die Design Process

Effective die design requires a comprehensive understanding of metal flow behavior, material properties, and the specific requirements of the finished component. The design process typically involves several key stages:

1. Part Analysis

The process begins with a thorough analysis of the part to be forged, including its geometry, dimensional requirements, material specifications, and functional characteristics. This analysis helps identify potential challenges in the forging process and informs subsequent design decisions.

2. Process Planning

Based on the part analysis, engineers determine the optimal forging sequence, including the number of forging operations, preform shapes, and die configurations required to produce the final component. This stage often involves computer simulation to predict metal flow and identify potential defects.

3. Die Design

Using advanced CAD/CAM software, engineers create detailed 3D models of the forging dies, incorporating features such as draft angles, fillets, parting lines, and flash gutters. The design must account for material shrinkage, die wear, and ease of part removal.

At MAIKONG, our engineering team utilizes state-of-the-art simulation software to optimize die designs before manufacturing begins. This approach allows us to identify and address potential issues early in the process, saving time and resources while ensuring superior die performance.

Advanced Manufacturing Techniques for Basics of Forging Dies

The manufacturing of forging dies requires precision machining capabilities and specialized equipment. Modern die manufacturing typically involves a combination of traditional and advanced techniques:

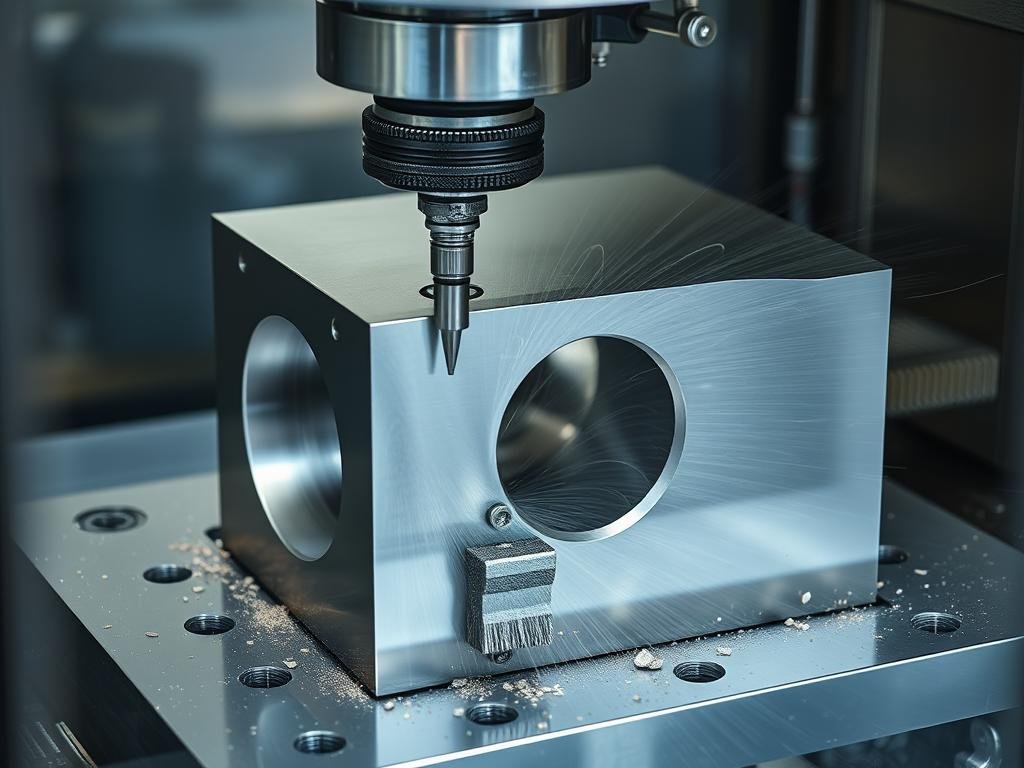

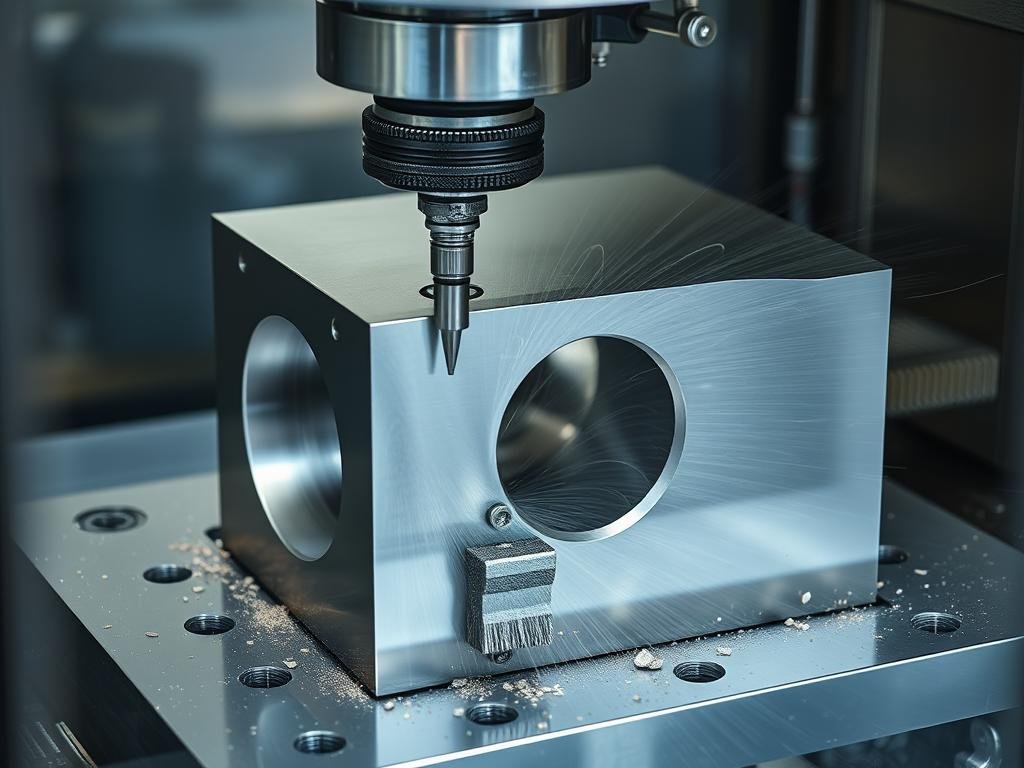

CNC machining of a forging die block at MAIKONG’s facility

CNC Machining

Computer Numerical Control (CNC) machining is the primary method for creating die cavities and features. Multi-axis CNC machines can produce complex geometries with exceptional precision, ensuring that dies meet exacting dimensional requirements.

EDM Processing

Electrical Discharge Machining (EDM) is used for creating intricate details and features that would be difficult to achieve with conventional machining. This process is particularly valuable for hardened die materials and complex cavity shapes.

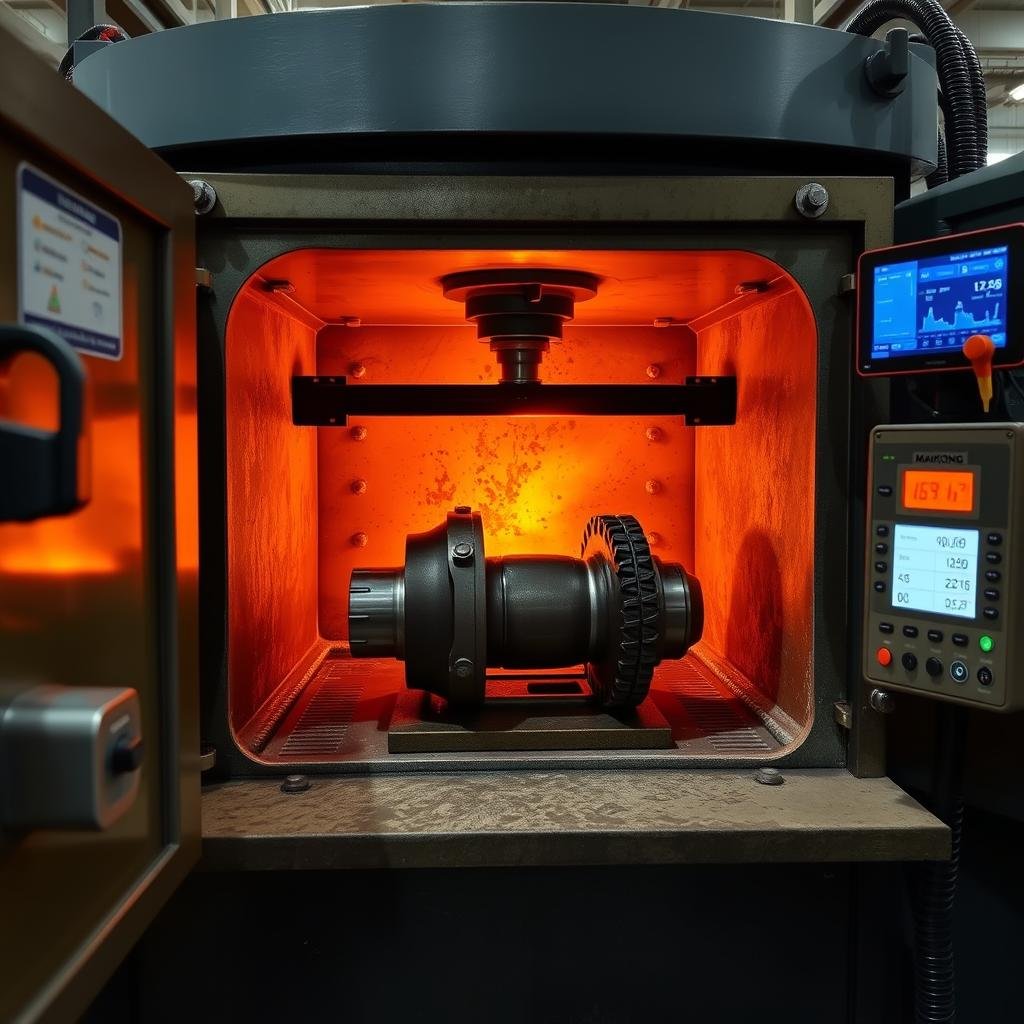

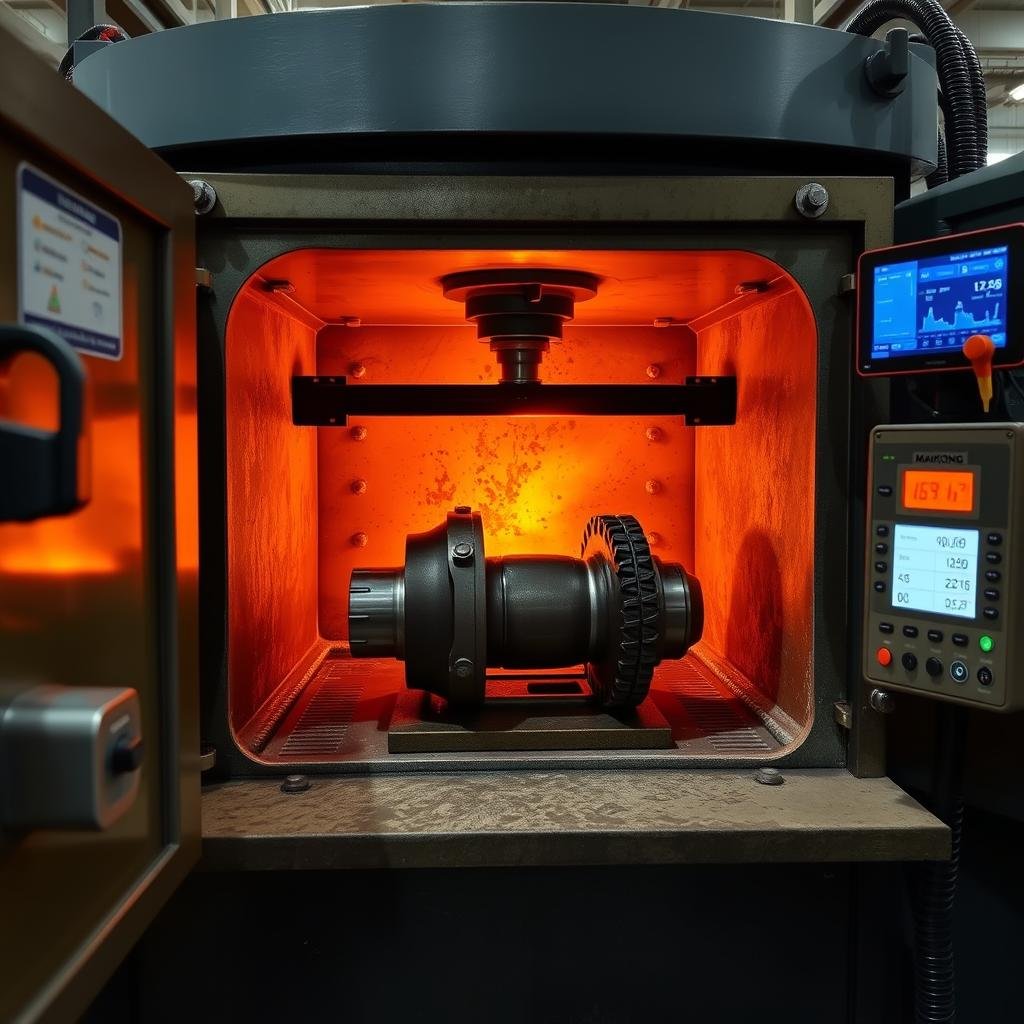

Heat Treatment

After initial machining, dies undergo carefully controlled heat treatment processes to achieve the desired mechanical properties. These processes may include hardening, tempering, and stress relieving to optimize hardness, toughness, and dimensional stability.

Surface Finishing

The final stage involves precision grinding, polishing, and surface treatments to achieve the required surface finish and dimensional accuracy. These operations are critical for ensuring proper metal flow and part release during forging.

MAIKONG’s Precision Die Manufacturing

With our advanced CNC machining capabilities and comprehensive quality control systems, MAIKONG delivers forging dies that meet the most demanding specifications. Our 60+ CNC machines provide 100+ tons of metal processing capacity per month, ensuring timely delivery of your custom dies.

Request a Quote

Die Maintenance and Lifespan: Maximizing Return on Investment

Forging dies represent a significant investment in the production process. Proper maintenance and care are essential for maximizing die lifespan and ensuring consistent part quality throughout the production run.

Technician performing maintenance on a forging die to extend service life

Common Die Failure Mechanisms

Understanding the typical failure modes of forging dies is crucial for implementing effective maintenance strategies. The most common failure mechanisms include:

Wear

Gradual removal of die material due to friction between the die and workpiece. This mechanism is particularly prevalent in areas with high metal flow velocity and can lead to dimensional changes in the forged parts.

Thermal Fatigue

Formation of a network of fine cracks on the die surface due to repeated heating and cooling cycles. These cracks can propagate deeper into the die material, eventually leading to catastrophic failure.

Mechanical Fatigue

Development of cracks due to cyclic loading during the forging process. This type of failure is often associated with areas of stress concentration in the die design.

Preventive Maintenance Strategies

Implementing a comprehensive preventive maintenance program can significantly extend die life and reduce production interruptions. Key maintenance practices include:

Regular Inspection

Scheduled visual and dimensional inspections to identify early signs of wear, cracking, or other damage. Advanced techniques such as dye penetrant testing or ultrasonic inspection may be used for detecting subsurface defects.

Proper Lubrication

Application of appropriate lubricants to reduce friction between the die and workpiece, minimize wear, and facilitate part release. The selection of lubricants should consider factors such as forging temperature, material, and die design.

Temperature Management

Controlling die temperature through preheating, cooling systems, and proper production scheduling. Maintaining consistent die temperature helps minimize thermal fatigue and extends die life.

Surface Treatments

Application of specialized coatings or surface treatments to enhance wear resistance, reduce friction, and improve thermal properties. These treatments can significantly extend die life in high-stress applications.

Die Repair and Reconditioning

Even with proper maintenance, forging dies will eventually require repair or reconditioning to restore their functionality. Common repair techniques include:

- Welding to rebuild worn or damaged areas

- Re-machining to restore dimensional accuracy

- Polishing to improve surface finish

- Heat treatment to restore mechanical properties

- Replacement of inserts or components in modular dies

At MAIKONG, we offer comprehensive die maintenance and repair services to help our customers maximize the return on their die investments. Our experienced technicians can assess die condition, recommend appropriate maintenance actions, and perform repairs to extend die life and maintain part quality.

Applications and Industry Uses: Versatility of Forging Dies

Forging dies are essential tools in numerous industries, enabling the production of high-strength, durable components for critical applications. The versatility of forging dies allows them to be used in a wide range of sectors, each with specific requirements and challenges.

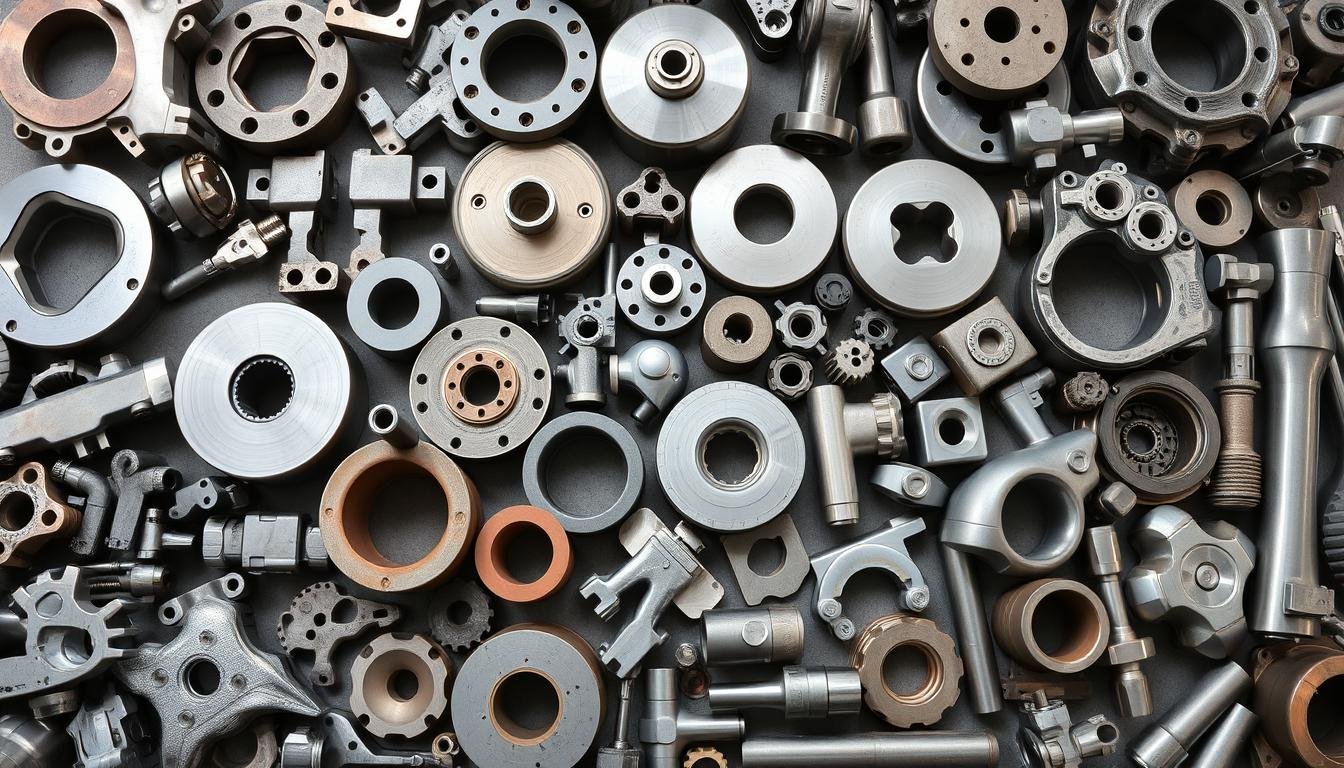

Diverse forged components produced using MAIKONG’s precision dies

Key Industries Utilizing Forging Dies

The unique capabilities of forging dies make them indispensable in several critical industries:

Automotive

The automotive industry relies heavily on forged components for their superior strength and durability. Common applications include crankshafts, connecting rods, transmission gears, steering components, and suspension parts. Forging dies in this sector must produce high-volume components with consistent quality and excellent fatigue resistance.

Aerospace

Aerospace applications demand components with exceptional reliability and performance under extreme conditions. Forged parts such as turbine discs, blades, landing gear components, and structural elements benefit from the improved grain structure and mechanical properties achieved through precision forging dies.

Oil and Gas

The oil and gas industry requires components that can withstand harsh environments, high pressures, and corrosive conditions. Forging dies are used to produce valve bodies, flanges, fittings, and other critical components where failure is not an option.

Power Generation

Power plants and energy infrastructure depend on forged components for turbines, generators, and structural elements. These applications require exceptional dimensional stability, heat resistance, and long-term reliability.

Heavy Equipment

Construction and mining equipment utilize forged components for their superior strength-to-weight ratio and ability to withstand shock loads. Applications include gears, shafts, tracks, and structural components.

Hand Tools and Hardware

Professional-grade tools and hardware benefit from the enhanced durability and performance of forged construction. Forging dies are used to produce wrenches, hammers, pliers, and other tools that require exceptional strength and wear resistance.

Case Study: MAIKONG’s Precision Dies in Action

At MAIKONG, we’ve developed specialized forging dies for a wide range of applications across multiple industries. Our comprehensive approach to die design and manufacturing has delivered exceptional results for our customers:

MAIKONG’s state-of-the-art forging facility in GD, SZ

Automotive Component Case

For a major automotive supplier, MAIKONG designed and manufactured precision forging dies for aluminum connecting rods. Our optimized die design reduced material waste by 15% while improving grain flow for enhanced fatigue resistance. The result was a 20% increase in component lifespan and significant cost savings in the production process.

Industrial Equipment Case

A manufacturer of industrial pumps approached MAIKONG for help with a complex impeller design that was proving difficult to produce consistently. Our engineering team developed a multi-stage forging die solution that not only improved dimensional accuracy but also reduced production time by 30%, allowing the customer to meet increased demand without sacrificing quality.

Discover MAIKONG’s Industry-Specific Forging Solutions

Whether you’re in automotive, aerospace, energy, or any other industry requiring high-performance metal components, MAIKONG has the expertise and capabilities to deliver custom forging solutions tailored to your specific needs.

Explore Industry Solutions

The Advantages of Forging: Strength Through Structure

Understanding the fundamental advantages of forged components helps appreciate why the Basics of Forging Dies are so critical to modern manufacturing. The forging process, when executed with precision-engineered dies, creates components with superior mechanical properties compared to alternative manufacturing methods.

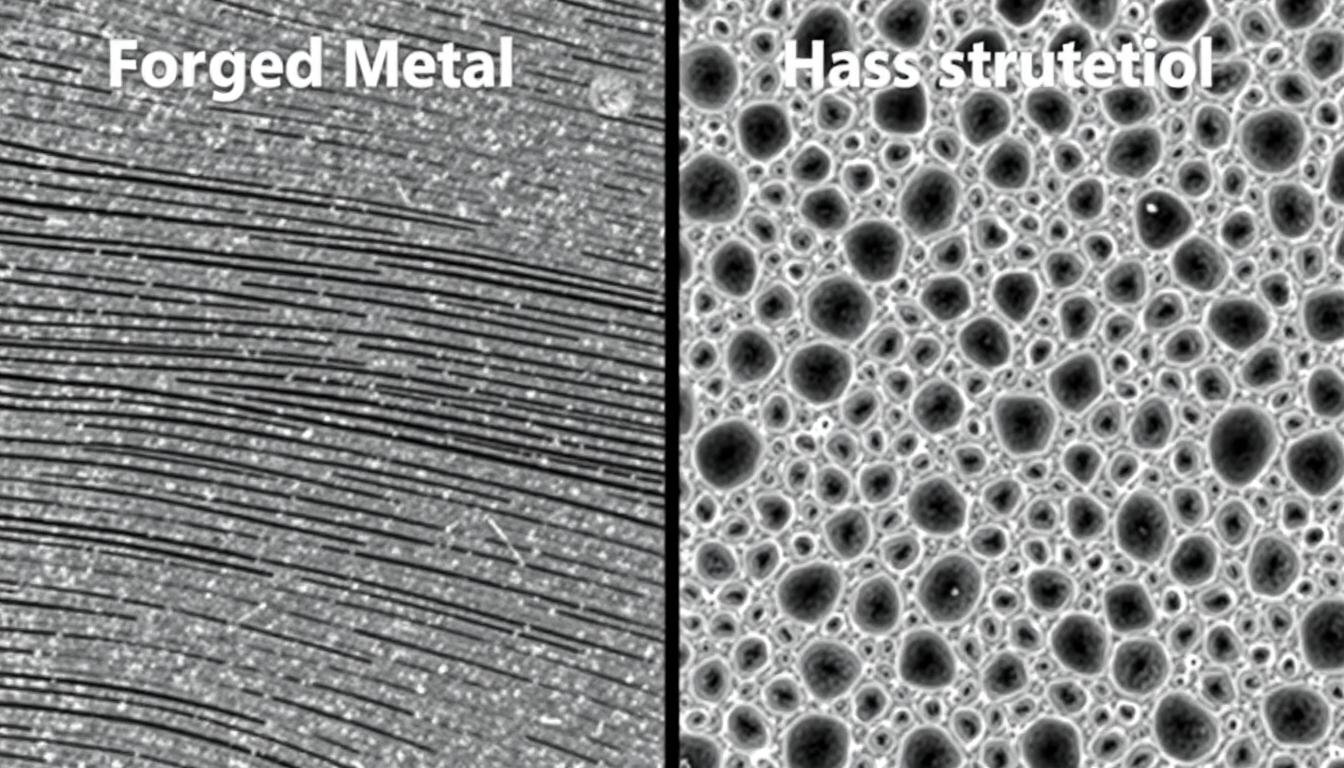

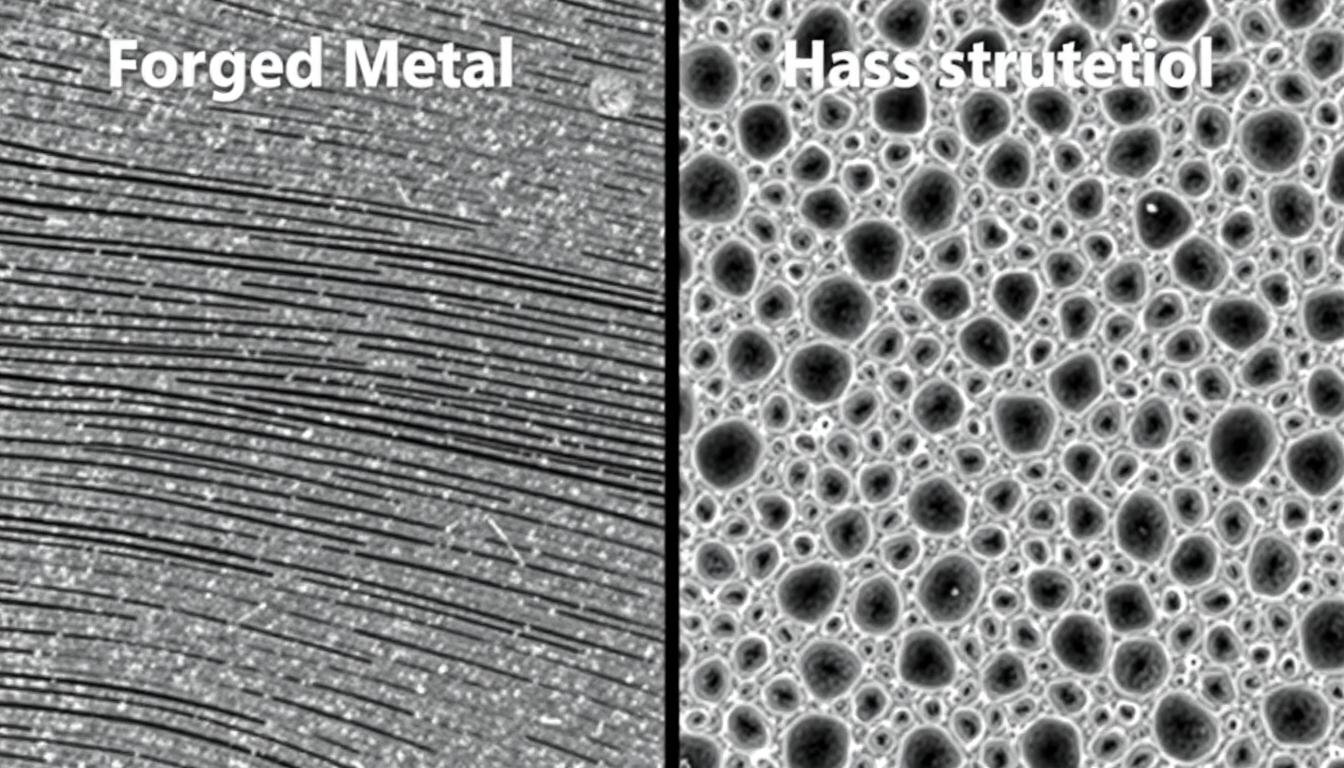

Comparison of grain structure: forged metal (left) vs. cast metal (right)

Forging vs. Casting: A Structural Comparison

The fundamental differences between forging and casting processes result in distinct material properties that directly impact component performance and reliability:

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps of effort to achieve complex shape |

✅Can achieve complex shape in one session |

| Dimensional Accuracy |

✅Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅Smoother surfaces, reduced post-processing |

Might require more machining due to air pocket |

| Heat Treatment Response |

✅Responsive for controlled material properties |

Less predictable response |

| Grain Structure |

✅Directional grain flow for improved properties |

No directional grain structure |

| Weight-to-Strength Ratio |

✅High strength-to-weight ratio |

Bulkier parts may be needed |

| Ideal Industry |

Aerospace, automotive, medical devices, etc. |

Consumer goods, simple parts, non-critical sectors |

Key Benefits of Precision Forging Dies

The quality and design of forging dies directly influence the benefits achieved in the final components. Well-designed dies provide several critical advantages:

Enhanced Grain Structure

Properly designed forging dies control metal flow to create a refined, directional grain structure that follows the contours of the part. This aligned grain structure significantly improves mechanical properties, particularly in high-stress areas.

Material Efficiency

Precision dies minimize material waste by optimizing preform shapes and flash requirements. This efficiency not only reduces raw material costs but also decreases energy consumption and processing time.

Consistent Quality

Well-maintained forging dies produce components with consistent dimensions and properties across production runs, reducing variation and improving overall product reliability.

At MAIKONG, we leverage our deep understanding of the Basics of Forging Dies to design and manufacture dies that maximize these advantages for our customers. Our comprehensive approach to die engineering ensures that each component we produce delivers the full benefits of the forging process.

MAIKONG’s Comprehensive Forging and Machining Services

As a leading provider of metal forging and precision machining services, MAIKONG offers a complete range of capabilities to meet your manufacturing needs. Our integrated approach ensures seamless coordination from design to finished component, delivering superior quality and value.

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

Our Core Capabilities

MAIKONG’s extensive manufacturing capabilities enable us to handle projects of any complexity and scale:

CNC Machining Services

With over 60 CNC machines providing 100+ tons of metal processing capacity per month, our precision fabrication services cover a wide range of materials and specifications. We specialize in turning, milling, Swiss machining, multi-axis machining, surface grinding, laser engraving, and more.

Forging Expertise

Our forging operations include open-die, closed-die, and precision forging processes for aluminum, steel, brass, and other alloys. We’ve mastered the art and science of metal forming to produce components with superior strength, durability, and performance.

Comprehensive Testing

Our in-house material laboratory ensures that all raw materials and finished components meet exact specifications. We employ advanced testing methods to verify mechanical properties, dimensional accuracy, and surface quality, guaranteeing consistent performance.

Our End-to-End Process

MAIKONG provides a complete solution for your manufacturing needs, from initial concept to finished component:

CAD/CAM Design

CAD/CAM Design

Material Selection

Material Selection

Tooling Design

Tooling Design

Forging Process

Forging Process

Heat Treatment

Heat Treatment

CNC Machining

CNC Machining

Partner with MAIKONG for Your Manufacturing Needs

Experience the MAIKONG difference with our comprehensive forging and machining services. Our team of experts is ready to help you optimize your component design, select the appropriate materials, and implement the most efficient manufacturing processes.

Get A Quick Quote

Conclusion: Mastering the Basics of Forging Dies for Manufacturing Excellence

The journey through the Basics of Forging Dies reveals their fundamental importance in modern manufacturing. From their design and material selection to their maintenance and application across industries, forging dies are the unsung heroes behind countless critical components that power our world.

At MAIKONG, we’ve built our reputation on mastering these basics and extending them to advanced applications. Our comprehensive understanding of forging die technology, combined with our state-of-the-art manufacturing capabilities, allows us to deliver superior forged components that meet the most demanding requirements.

Whether you’re seeking a manufacturing partner for high-volume production or specialized components for critical applications, MAIKONG offers the expertise, capabilities, and commitment to quality that ensure success. Our integrated approach—from CAD/CAM design and material selection to forging, heat treatment, CNC machining, and quality control—provides a seamless experience and exceptional results.

Ready to Elevate Your Manufacturing with MAIKONG?

Contact us today to discuss your forging and machining needs. Our team of experts is ready to help you optimize your component design, select the appropriate materials, and implement the most efficient manufacturing processes.

CAD/CAM Design

CAD/CAM Design Material Selection

Material Selection Tooling Design

Tooling Design Forging Process

Forging Process Heat Treatment

Heat Treatment CNC Machining

CNC Machining