In the precision manufacturing industry, aluminum forgings and extrusions tool ferrules represent a critical component for countless applications. These specialized components demand exceptional quality, precision, and reliability. At MAIKONG, we’ve established ourselves as industry leaders in the production of high-performance aluminum forgings and extrusions tool ferrules through our advanced manufacturing processes, stringent quality control, and comprehensive service offerings. Our expertise in aluminum forging and extrusion ensures that your tool ferrules meet the exact specifications required for your applications.

Aluminum Forgings and Extrusions Tool Ferrules

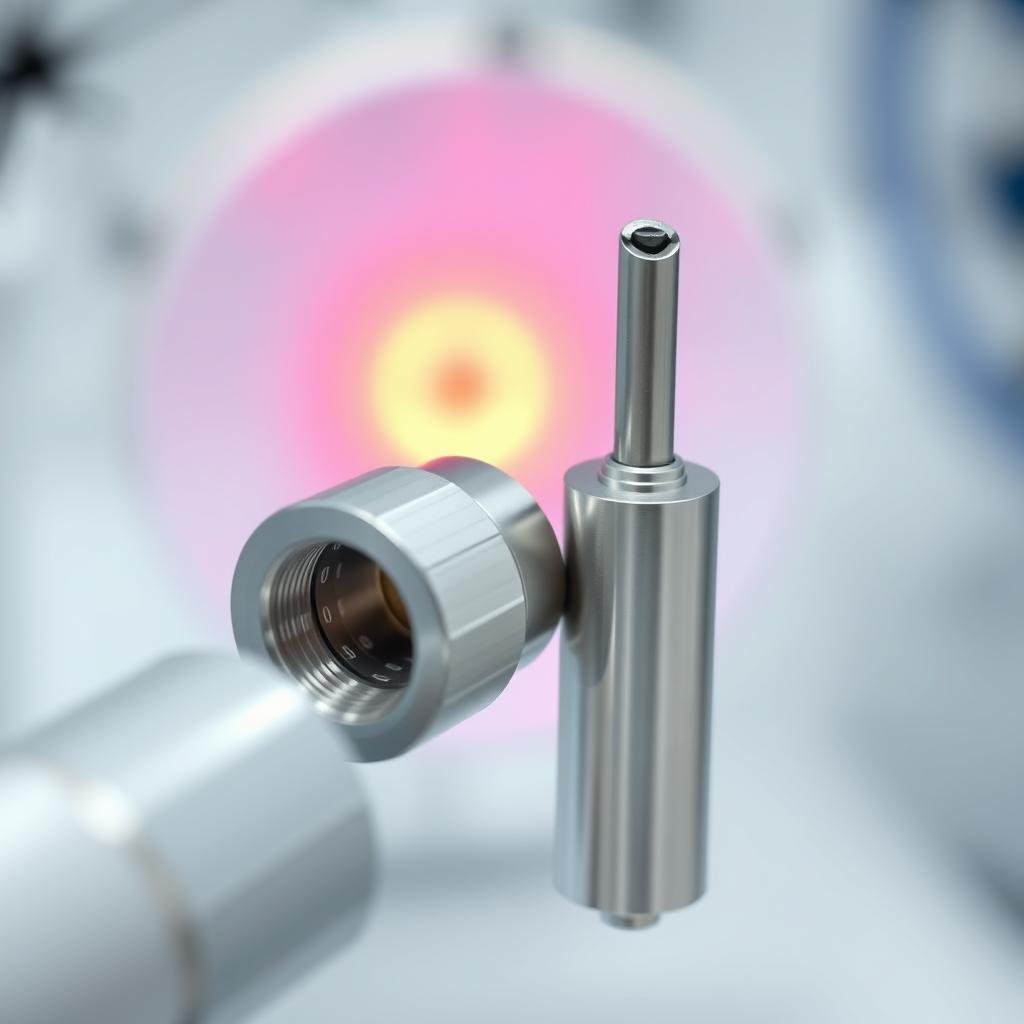

Precision-engineered aluminum tool ferrules manufactured by MAIKONG

Precision-engineered aluminum tool ferrules manufactured by MAIKONG

Tool ferrules are essential components that provide reinforcement and connection points in various tools and equipment. Aluminum forgings and extrusions tool ferrules offer superior strength-to-weight ratios compared to other materials, making them ideal for applications where both durability and weight considerations are critical. These components are typically used in hand tools, power tools, construction equipment, and various industrial applications.

Key Characteristics of Quality Aluminum Tool Ferrules

- Precision dimensions with tight tolerances

- Uniform material density throughout the component

- Excellent surface finish with minimal machining requirements

- Superior strength-to-weight ratio

- Enhanced durability through optimized grain structure

- Consistent performance under load conditions

- Resistance to corrosion and environmental factors

At MAIKONG, our aluminum forgings and extrusions tool ferrules are engineered to meet these critical characteristics through our advanced manufacturing processes and quality control systems. We understand that the performance of your products depends on the quality of every component, which is why we maintain the highest standards throughout our production process.

The MAIKONG Manufacturing Process for Aluminum Tool Ferrules

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

Our comprehensive manufacturing process ensures that every aluminum forgings and extrusions tool ferrule meets the highest standards of quality and performance. From initial design to final inspection, we maintain strict control over every aspect of production.

Our End-to-End Manufacturing Capabilities

Design & Engineering

Our engineering team works closely with clients to develop optimal designs for their specific applications. Using advanced CAD/CAM software, we create precise models that serve as the foundation for the manufacturing process.

Material Selection

We carefully select the appropriate aluminum alloys based on the specific requirements of each application. Our expertise in material properties ensures that the final product delivers the optimal balance of strength, weight, and performance.

Forging & Extrusion

Our advanced forging and extrusion processes create components with superior grain structure and mechanical properties. This results in tool ferrules with exceptional strength, durability, and consistency.

Heat Treatment

Precision heat treatment processes optimize the mechanical properties of our aluminum tool ferrules, ensuring they meet the specific requirements of each application.

CNC Machining

Our advanced CNC machining capabilities allow us to achieve precise dimensions and tolerances, ensuring that every tool ferrule meets exact specifications.

Quality Control

Rigorous inspection and testing procedures verify that every component meets our stringent quality standards before shipping to customers.

Experience Our Manufacturing Excellence

Discover how MAIKONG’s comprehensive manufacturing capabilities can deliver superior aluminum tool ferrules for your applications.

Request Manufacturing Information

The MAIKONG Advantage in Aluminum Forgings and Extrusions

Microscopic comparison showing superior grain structure in MAIKONG’s forged aluminum tool ferrules

Forging vs. Casting: Why Forged Aluminum Tool Ferrules Excel

| Performance Criteria |

MAIKONG Forged Aluminum Ferrules |

Cast Aluminum Ferrules |

| Strength & Durability |

Superior strength due to dense, uniform grain structure |

Lower strength potential due to porosity and inclusions |

| Tensile Properties |

Excellent tensile strength and resistance to deformation |

Reduced tensile strength and higher failure rates |

| Fatigue Resistance |

Enhanced resistance to cyclic loading and fatigue failure |

More susceptible to fatigue cracking under repeated stress |

| Dimensional Accuracy |

Precise dimensions with tight tolerances |

Potential for dimensional inconsistencies |

| Surface Finish |

Superior surface quality requiring minimal finishing |

Often requires extensive machining to achieve desired finish |

Our Commitment to Quality

Rigorous quality control inspection of tool ferrules at MAIKONG’s facility

At MAIKONG, quality is not just a department—it’s a core value that permeates every aspect of our operation. Our ISO 9001:2015 certified quality management system ensures consistent adherence to the highest standards throughout our manufacturing process. From material selection to final inspection, we maintain rigorous controls to deliver aluminum forgings and extrusions tool ferrules that consistently exceed customer expectations.

4.9

Overall Quality Rating

Applications of Aluminum Forgings and Extrusions Tool Ferrules

Diverse applications of MAIKONG’s aluminum tool ferrules across industries

Our aluminum forgings and extrusions tool ferrules find applications across a wide range of industries where precision, durability, and performance are critical. Our components are trusted by leading manufacturers worldwide for their consistent quality and reliability.

Construction & Power Tools

Our tool ferrules provide critical reinforcement and connection points in hammers, screwdrivers, drills, and other construction and power tools, ensuring durability and safety in demanding applications.

Precision Instruments

In precision measurement instruments and medical devices, our aluminum ferrules provide the perfect balance of lightweight construction and precise dimensional stability required for accurate performance.

Industrial Equipment

Manufacturing equipment and industrial machinery rely on our high-performance aluminum ferrules to maintain structural integrity and operational reliability in continuous use environments.

Find the Perfect Solution for Your Application

Discuss your specific requirements with our engineering team to develop custom aluminum tool ferrules optimized for your application.

Consult Our Engineers

Custom Aluminum Forgings and Extrusions Capabilities

Custom design and manufacturing of aluminum tool ferrules at MAIKONG

At MAIKONG, we specialize in developing custom aluminum forgings and extrusions tool ferrules tailored to your specific requirements. Our comprehensive capabilities allow us to handle projects of any complexity, from prototype development to high-volume production.

Our Custom Manufacturing Services

CNC Turning Services

Our advanced CNC turning capabilities deliver precision cylindrical components with superior surface finishes, accurate threading, and tight tolerances. Ideal for creating perfectly symmetrical tool ferrules with consistent quality.

CNC Milling Services

For complex geometries and precise features, our multi-axis CNC milling services provide the flexibility and accuracy needed to create custom tool ferrules with intricate designs and exact specifications.

Swiss-Type Machining

Our Swiss-type machining capabilities excel in producing small, precise components and long shaft parts with exceptional accuracy, offering a one-stop solution for specialized tool ferrule applications.

Material Options for Custom Tool Ferrules

| Aluminum Alloy |

Key Properties |

Recommended Applications |

| 6061 |

Excellent corrosion resistance, good strength-to-weight ratio, good machinability |

General-purpose tool ferrules, construction tools, outdoor equipment |

| 7075 |

High strength, good fatigue resistance, moderate corrosion resistance |

High-performance tools, aerospace applications, precision instruments |

| 2024 |

High strength and hardness, good machinability, moderate corrosion resistance |

Industrial tools, mechanical components, high-stress applications |

| 5052 |

Excellent corrosion resistance, good formability, moderate strength |

Marine applications, chemical processing equipment, food industry tools |

Range of custom aluminum tool ferrules manufactured by MAIKONG

Quality Control for Aluminum Forgings and Extrusions

Comprehensive quality testing of aluminum tool ferrules at MAIKONG’s laboratory

Quality is the cornerstone of our operations at MAIKONG. Our comprehensive quality control system ensures that every aluminum forgings and extrusions tool ferrule meets the highest standards of performance, reliability, and consistency.

Our Quality Assurance Process

- Material Verification: Each batch of aluminum is tested to verify chemical composition and mechanical properties before entering production.

- In-Process Inspection: Critical dimensions and characteristics are checked throughout the manufacturing process to catch any deviations early.

- Heat Treatment Validation: Our heat treatment processes are carefully monitored and validated to ensure consistent material properties.

- Dimensional Inspection: Precision measuring equipment verifies that all dimensions meet specified tolerances.

- Surface Quality Assessment: Visual and automated inspection systems ensure surface finish meets requirements.

- Mechanical Testing: Sample testing verifies strength, hardness, and other mechanical properties.

- Final Inspection: Comprehensive inspection before packaging ensures only conforming products are shipped.

“Our commitment to quality is unwavering. We believe that every component we produce reflects our dedication to excellence and our customers’ trust in the MAIKONG brand.”

– Quality Director, MAIKONG

MAIKONG’s ISO 9001:2015 certification and quality documentation

Why Choose MAIKONG for Aluminum Forgings and Extrusions Tool Ferrules

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

The MAIKONG Advantage

- Comprehensive manufacturing capabilities from design to finishing

- Advanced CNC machining with 60+ machines and 100+ tons monthly capacity

- ISO 9001:2015 certified quality management system

- Expertise in aluminum alloy selection and optimization

- Superior forging techniques for enhanced grain structure

- Competitive pricing with excellent value

- Flexible production volumes from prototypes to high-volume runs

- Comprehensive testing and verification laboratory

Our Commitment to Customer Satisfaction

At MAIKONG, we understand that your success depends on receiving high-quality components that meet your exact specifications, delivered on time and at competitive prices. Our customer-focused approach ensures that we work closely with you throughout the entire process, from initial design consultation to final delivery, to ensure your complete satisfaction.

Become a MAIKONG Distributor in the United States

We’re currently seeking distributors across the United States for our high-quality aluminum forgings and extrusions, including tool ferrules. Join our network and offer your customers superior manufacturing solutions at competitive prices.

Distributor Inquiry

Excellence in Aluminum Forgings and Extrusions Tool Ferrules

At MAIKONG, we’re committed to delivering exceptional quality and value in every aluminum forgings and extrusions tool ferrule we produce. Our comprehensive capabilities, advanced manufacturing processes, and unwavering commitment to quality make us the ideal partner for your custom manufacturing needs. Whether you’re seeking a reliable supplier for your existing designs or need assistance developing new components, our team is ready to help you achieve your goals.

Contact us today to experience the MAIKONG difference in aluminum forgings and extrusions. We look forward to building a lasting partnership based on quality, reliability, and mutual success.

Precision-engineered aluminum tool ferrules manufactured by MAIKONG

Precision-engineered aluminum tool ferrules manufactured by MAIKONG