The landscape of Brass Extrusion is rapidly evolving, bringing unprecedented opportunities for US industries seeking precision, durability, and cost-effectiveness. As manufacturing technologies advance, businesses across America are discovering the remarkable versatility and performance advantages of expertly extruded brass components. This comprehensive guide explores the cutting-edge trends, innovative techniques, and transformative applications that are shaping the future of Brass Extrusion in the United States.

Understanding Modern Brass Extrusion Technology

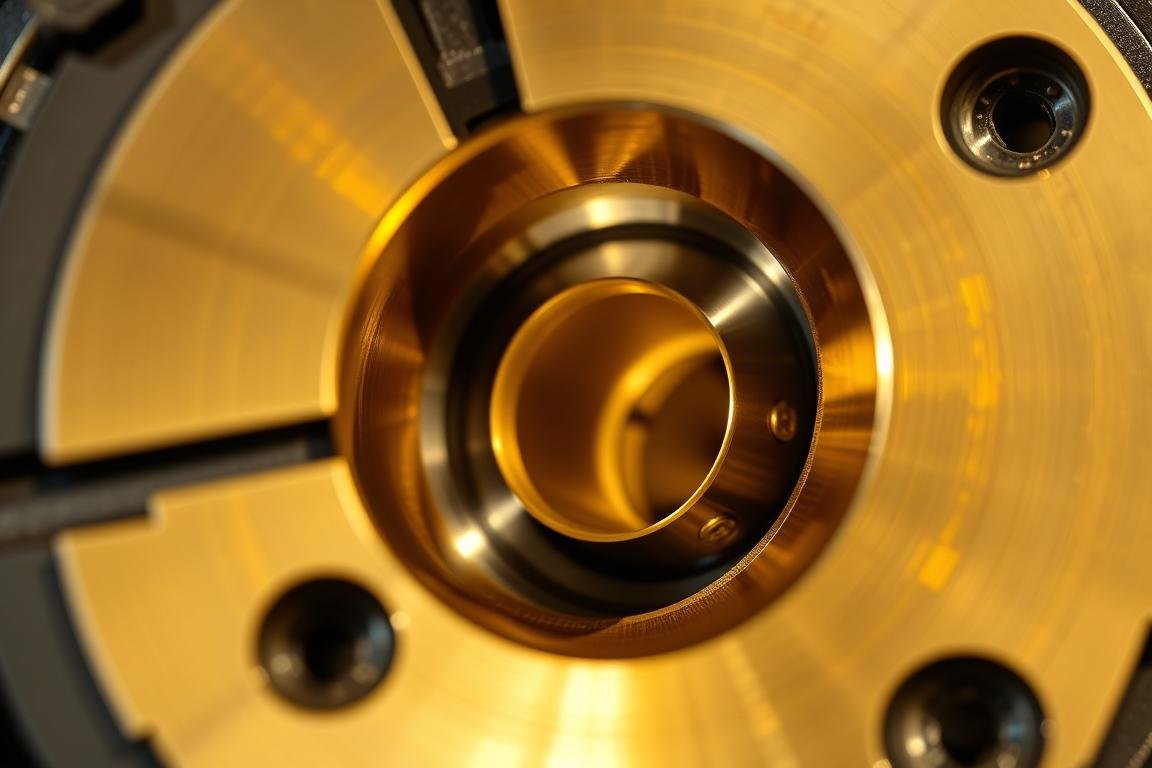

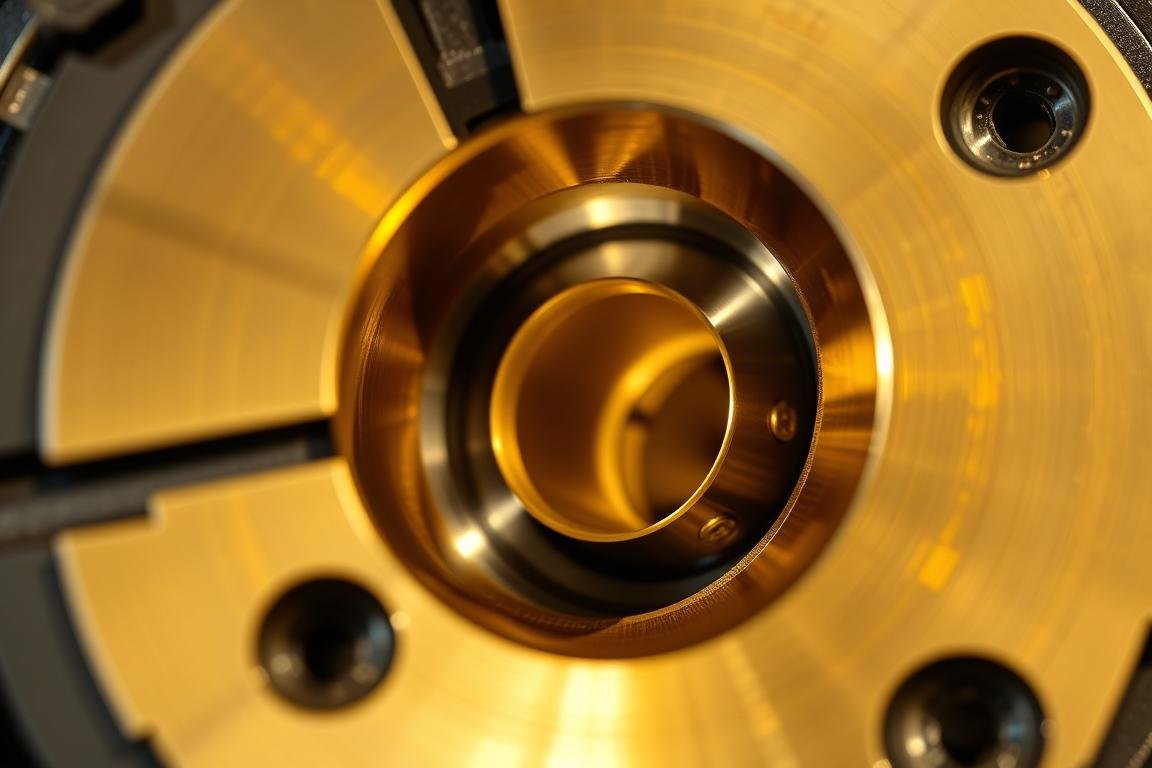

State-of-the-art Brass Extrusion process at MAIKONG’s manufacturing facility

State-of-the-art Brass Extrusion process at MAIKONG’s manufacturing facility

Brass Extrusion is a sophisticated metal working process where brass alloy is heated and forced through a die to create a specific cross-sectional profile. This manufacturing technique produces components with consistent dimensions, excellent surface finish, and superior mechanical properties. The extruded brass emerges with a uniform cross-section that can be cut to desired lengths, making it ideal for producing everything from simple rods and tubes to complex architectural elements and precision components.

At MAIKONG, we’ve refined this process to deliver exceptional quality and precision. Our advanced equipment and expertise enable us to produce extruded brass components with tight tolerances, outstanding surface finishes, and optimized material properties to meet the most demanding specifications across various industries.

Key Advantages of Brass Extrusion for US Manufacturing

- Exceptional dimensional accuracy and consistency

- Superior surface finish requiring minimal post-processing

- Excellent material utilization with reduced waste

- Enhanced mechanical properties through controlled grain structure

- Cost-effective production for both small and large volumes

- Versatility in creating complex cross-sectional profiles

- Excellent thermal and electrical conductivity

- Outstanding corrosion resistance for longevity

- Ability to create near-net shapes reducing machining costs

- Environmentally friendly with recyclable material

Emerging Trends in Brass Extrusion Technology

The Brass Extrusion industry is experiencing remarkable technological advancements that are transforming manufacturing capabilities and opening new possibilities for US businesses. These innovations are driving improved quality, efficiency, and application versatility.

Next-generation Brass Extrusion technology with digital monitoring systems

Precision Engineering in Brass Extrusion Processes

Today’s Brass Extrusion processes leverage advanced computer modeling and simulation to optimize die design and extrusion parameters. This precision engineering approach allows for tighter tolerances, more complex profiles, and enhanced material properties. At MAIKONG, we’ve implemented cutting-edge simulation software that predicts material flow behavior, allowing us to perfect our extrusion processes before production begins.

Automation and Smart Manufacturing

The integration of automation and smart manufacturing technologies is revolutionizing Brass Extrusion. Automated handling systems, real-time monitoring, and data analytics are improving consistency, reducing defects, and increasing productivity. Our state-of-the-art facility incorporates these technologies to ensure unmatched quality and efficiency in every brass component we produce.

Ready to Explore Advanced Brass Manufacturing Solutions?

Discover how MAIKONG’s cutting-edge Brass Extrusion capabilities can elevate your products and reduce costs.

Get a Quick Quote

Innovative Techniques in Brass Extrusion Manufacturing

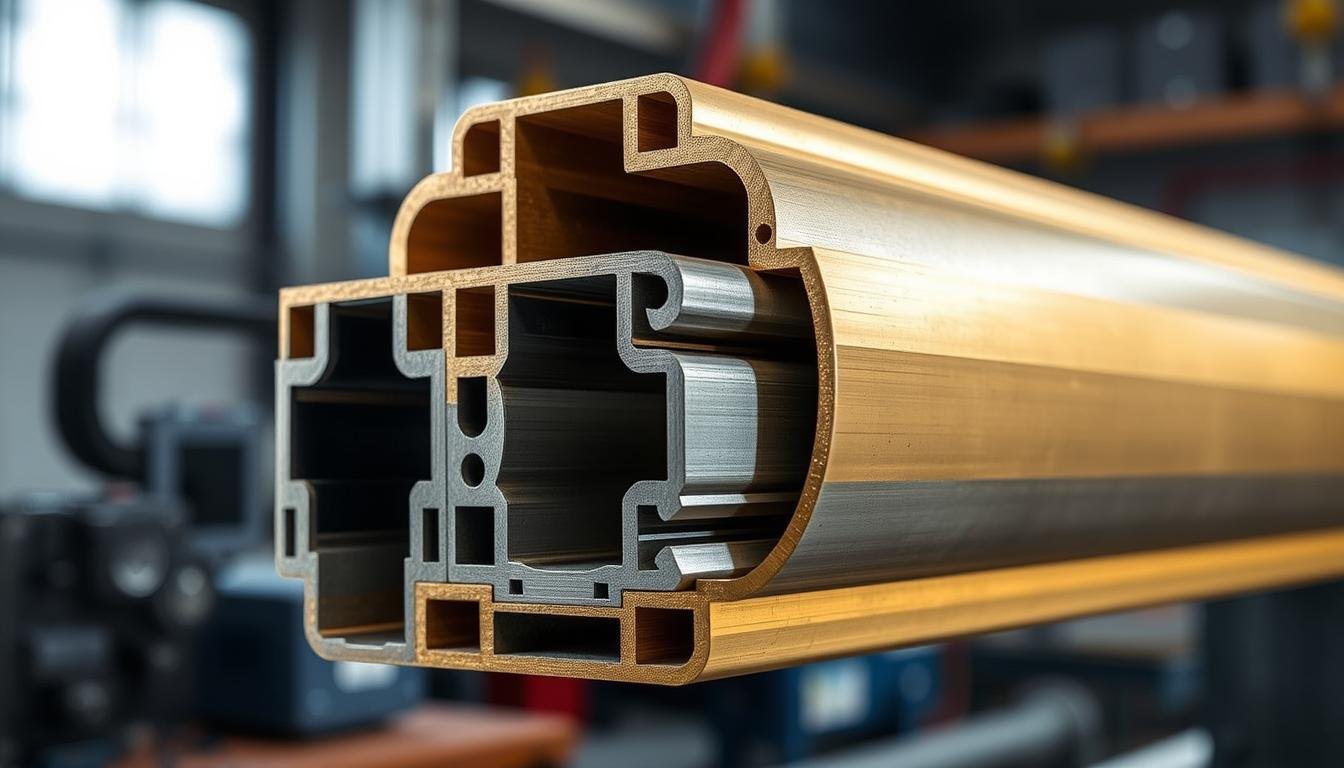

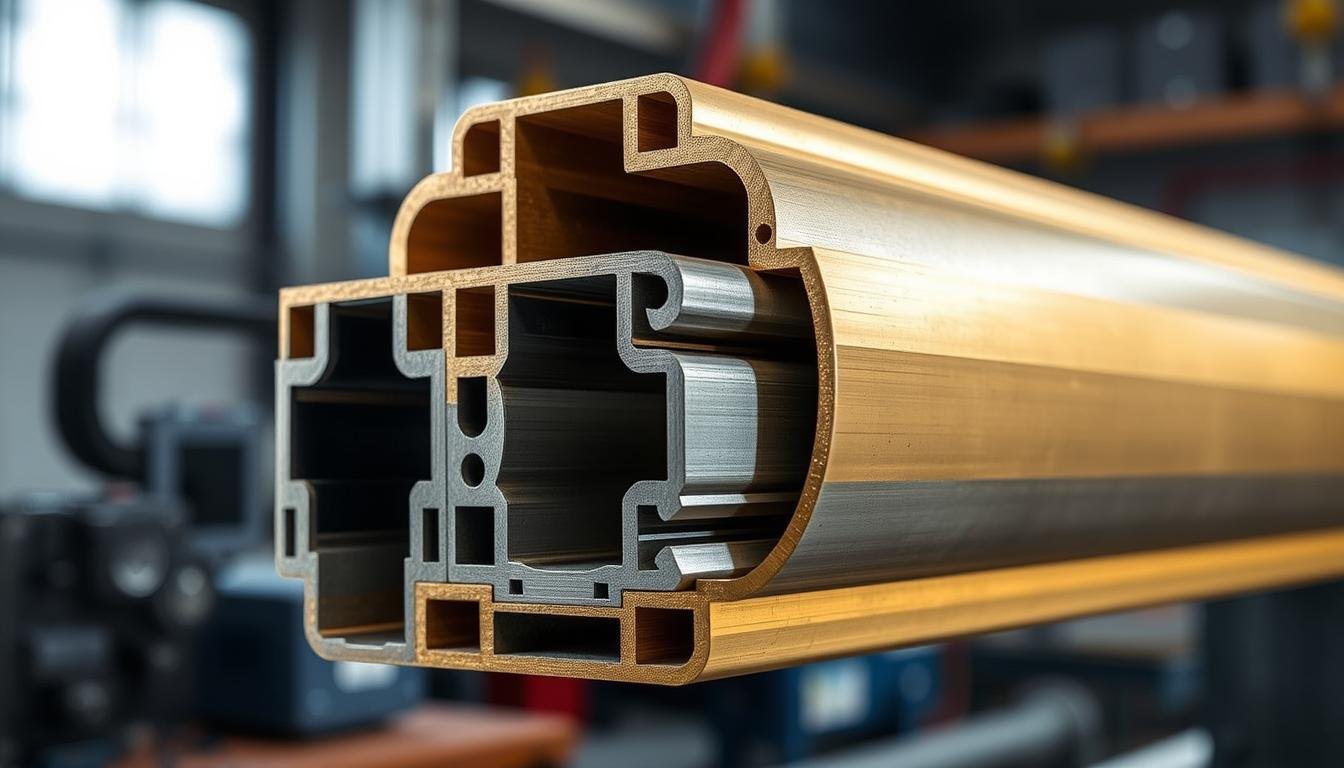

Precision die technology for complex Brass Extrusion profiles

Advanced Cold Extrusion Techniques

Cold extrusion of brass is gaining prominence for its ability to produce components with superior surface finish and enhanced mechanical properties. This technique, performed at room temperature, strengthens the brass through work hardening while maintaining tight dimensional tolerances. MAIKONG has perfected cold extrusion methods that deliver exceptional quality for precision components.

Multi-Material and Composite Brass Extrusion

Innovative co-extrusion techniques now allow for the creation of multi-material components, combining brass with other metals or polymers in a single extrusion process. This breakthrough enables the production of parts with optimized properties for specific applications, such as enhanced wear resistance or improved thermal management.

Multi-material Brass Extrusion technology creating composite components

Micro-Extrusion for Miniature Components

The demand for miniaturized components has driven advancements in micro-extrusion techniques for brass. This specialized process creates extremely small, precise components for industries like electronics, medical devices, and aerospace. MAIKONG’s micro-extrusion capabilities deliver components with microscopic features while maintaining exceptional quality and consistency.

MAIKONG’s Expertise in Brass Extrusion and Metal Fabrication

With decades of experience in precision metal manufacturing, MAIKONG has established itself as a leader in Brass Extrusion and comprehensive metal fabrication services. Our state-of-the-art facility in GD, SZ combines traditional craftsmanship with cutting-edge technology to deliver superior quality components for US industries.

MAIKONG’s advanced manufacturing facility with CNC machining and Brass Extrusion equipment

Comprehensive Brass Extrusion Capabilities

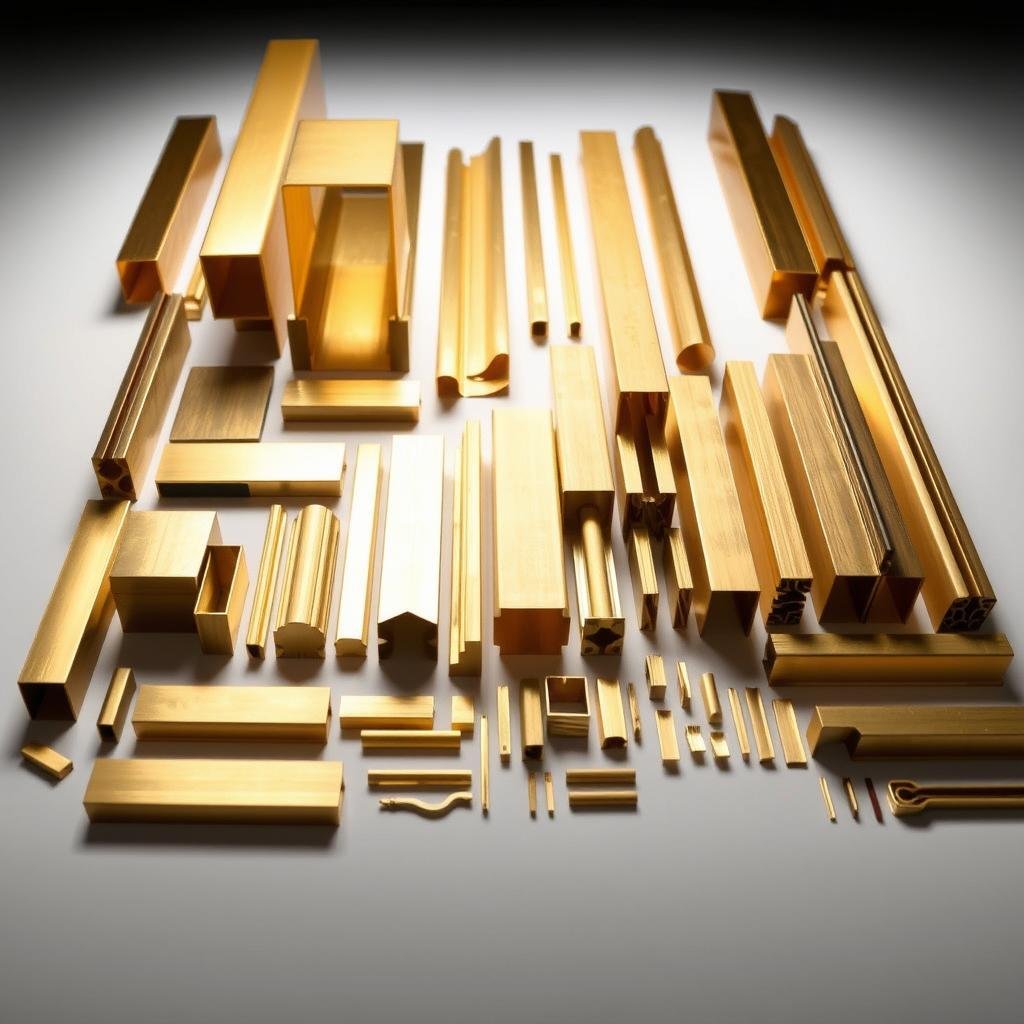

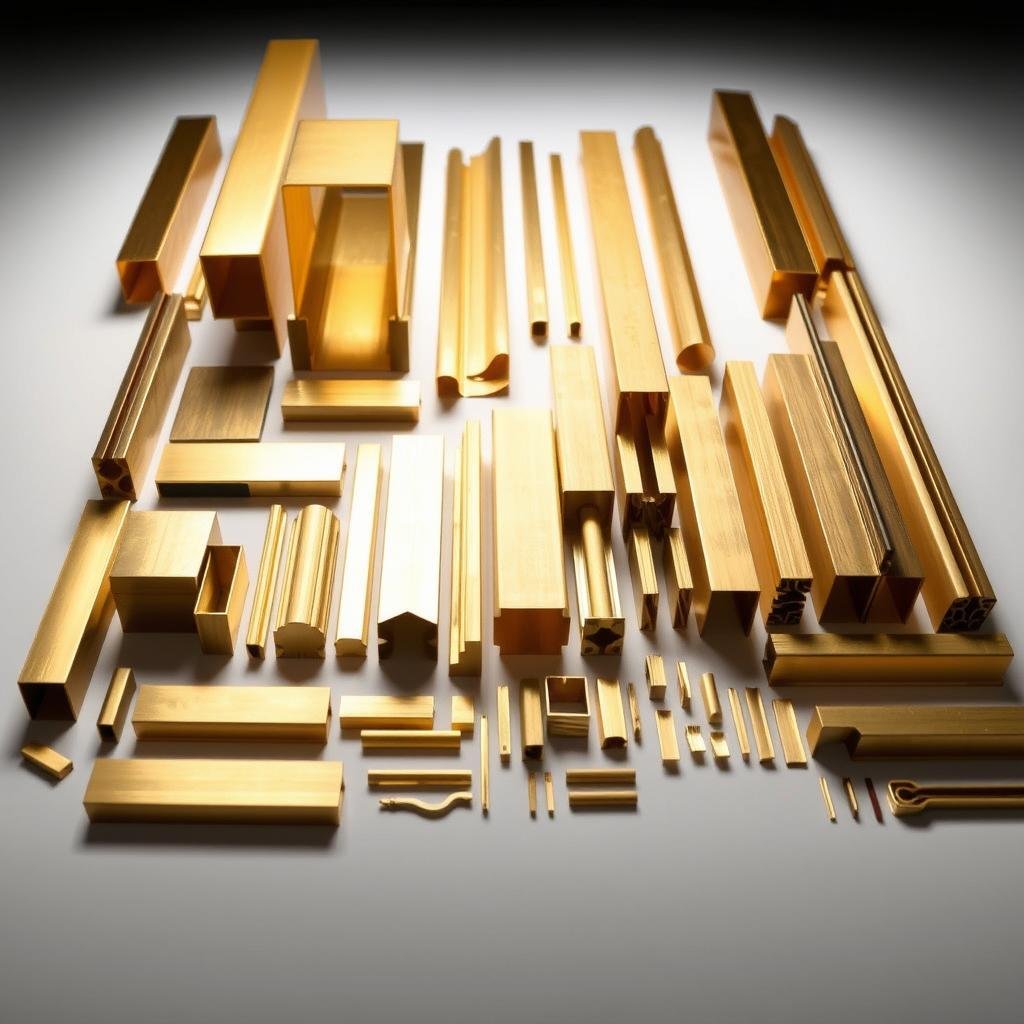

Our Brass Extrusion services encompass the complete production process, from initial design consultation to finished components. We specialize in both standard and custom profiles, offering:

- Direct and indirect extrusion methods

- Hot and cold extrusion techniques

- Complex profile design and optimization

- Precision cutting and machining

- Comprehensive quality testing

Variety of Brass Extrusion profiles manufactured by MAIKONG

Integrated CNC Machining Services

MAIKONG’s 60+ CNC machines provide over 100 tons of metal processing capacity monthly, complementing our Brass Extrusion capabilities with precision secondary operations. Our CNC services include:

CNC Turning

Ideal for creating deep holes, machined threads, and cylindrical shapes with superior surface finishes. Our advanced CNC turning centers deliver precision components with fast turnaround times.

CNC Milling

Perfect for complex prismatic shapes and flat surfaces. Our multi-axis CNC milling machines require no fixed tooling, offering high flexibility and extreme accuracy for brass components.

CNC SWISS Type Machining

Specialized in precision small parts and long shaft components. Our equipment features dual spindles and multi-axis capabilities for one-stop manufacturing solutions.

Become a US Distributor for MAIKONG

Join our network of successful partners and offer your customers high-quality, cost-effective Brass Extrusion and metal fabrication solutions.

Apply to Become a Distributor

Comparing Brass Extrusion to Alternative Manufacturing Methods

Understanding the advantages of Brass Extrusion compared to other manufacturing methods is crucial for making informed production decisions. This comparison highlights why extruded brass is often the optimal choice for many applications.

| Comparison Categories |

Extruded Brass |

Cast Brass |

Machined Brass |

| Strength and Durability |

Superior due to dense, uniform grain structure |

Lower due to potential air pockets and inclusions |

Good but limited by original stock properties |

| Surface Finish |

Excellent, smooth surfaces with minimal post-processing |

Requires significant machining due to porosity |

Very good but at higher production cost |

| Dimensional Accuracy |

High precision with tight tolerances |

Potential inconsistencies and shrinkage issues |

Excellent but with material waste |

| Complex Geometries |

Excellent for consistent cross-sections |

Can achieve complex 3D shapes in one process |

Limited by machining access and tooling |

| Production Efficiency |

High output with excellent material utilization |

Good for low volumes but slower cycle times |

Lower efficiency with significant material waste |

| Cost-Effectiveness |

Excellent for medium to high volumes |

Good for low volumes and complex shapes |

Higher cost due to material waste and processing time |

Visual comparison of extruded, cast, and machined brass components

Quality Control in Brass Extrusion Manufacturing

At MAIKONG, quality is the cornerstone of our Brass Extrusion processes. Our comprehensive quality management system ensures that every component meets or exceeds the most stringent specifications and standards.

Advanced quality control inspection of Brass Extrusion components

Comprehensive Testing Procedures

Our quality assurance process for Brass Extrusion components includes:

- Dimensional verification using high-precision measuring equipment

- Material composition analysis to ensure alloy specifications

- Mechanical property testing including tensile strength and hardness

- Surface finish inspection and roughness measurement

- Non-destructive testing for internal integrity

- Functional testing for application-specific requirements

International Quality Standards

MAIKONG maintains rigorous quality management systems certified to international standards, ensuring consistent quality across all our Brass Extrusion and metal fabrication services. Our commitment to quality has earned us the trust of clients across diverse industries throughout the United States.

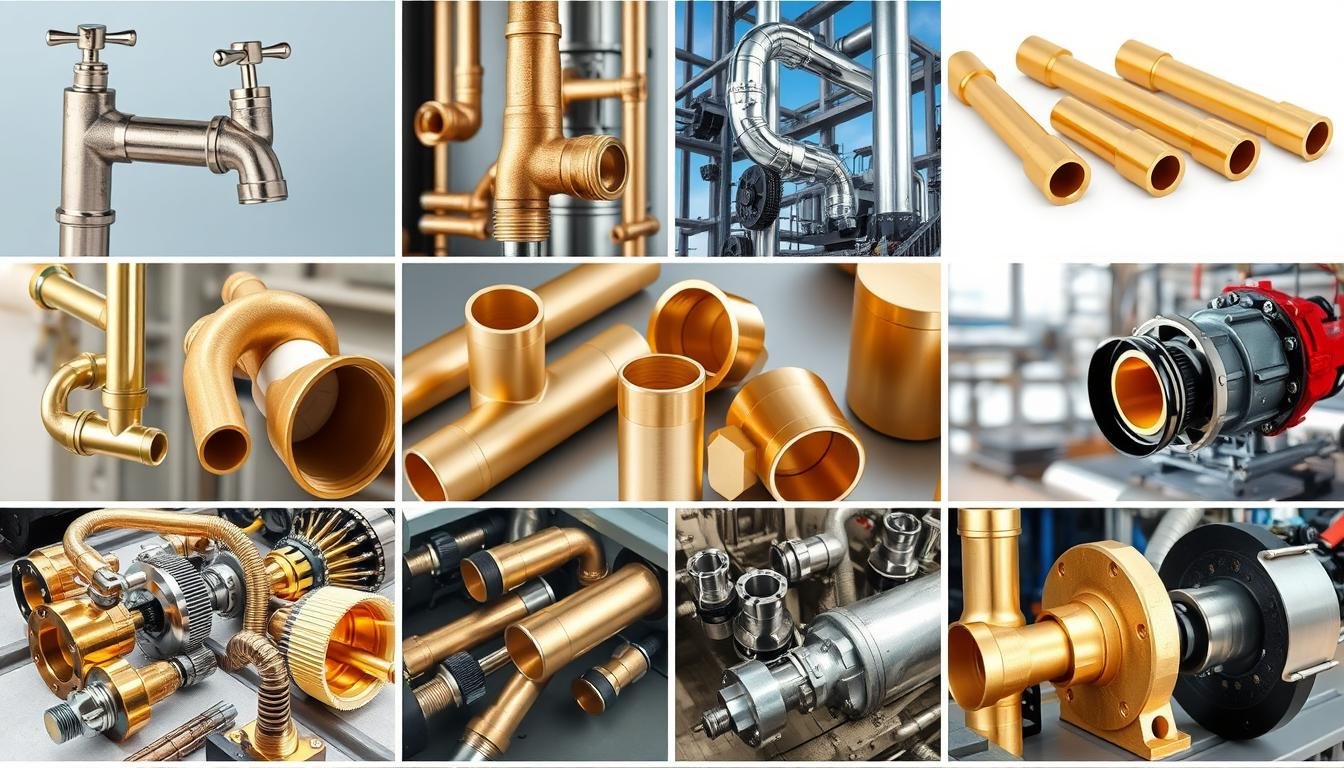

Diverse Applications of Brass Extrusion Across US Industries

The versatility and performance advantages of Brass Extrusion make it an ideal manufacturing method for a wide range of applications across numerous industries. MAIKONG supplies precision extruded brass components to diverse sectors throughout the United States.

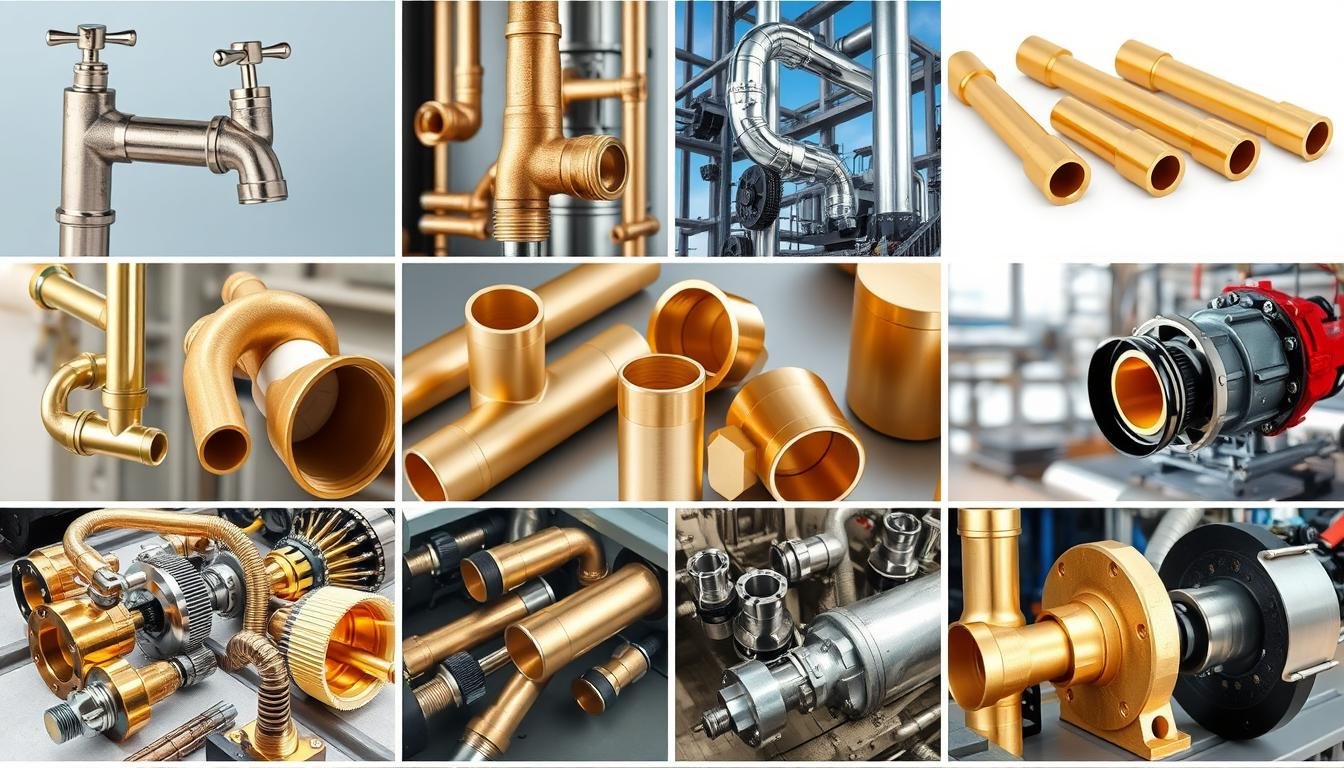

Diverse industrial applications of Brass Extrusion components

Key Brass Extrusion Applications by Industry

Plumbing & Construction

- Pipe fittings and valves

- Decorative architectural elements

- Door and window hardware

- Structural components

- Handrails and fixtures

Electrical & Electronics

- Electrical connectors and terminals

- Heat sinks and cooling components

- Enclosures and housings

- Switch components

- Conductive elements

Automotive & Transportation

- Radiator components

- Hydraulic system fittings

- Decorative trim elements

- Electrical system components

- Structural reinforcements

Industrial Equipment

- Pneumatic system components

- Hydraulic fittings

- Bearing housings

- Gear components

- Wear-resistant elements

Marine Applications

- Corrosion-resistant fittings

- Propeller components

- Navigation equipment parts

- Decorative hardware

- Plumbing systems

Medical & Scientific

- Instrument components

- Laboratory equipment parts

- Antimicrobial touch surfaces

- Precision mechanisms

- Fluid handling components

Need Custom Brass Extrusion Solutions?

Contact our engineering team to discuss your specific requirements and discover how MAIKONG can deliver the perfect brass components for your application.

Email Our Engineering Team

Why Choose MAIKONG for Your Brass Extrusion Needs

MAIKONG’s expert team ensuring precision in every Brass Extrusion project

Unmatched Expertise and Capabilities

With decades of experience in Brass Extrusion and metal fabrication, MAIKONG offers unparalleled expertise and technical capabilities. Our team of skilled engineers and technicians combines traditional craftsmanship with cutting-edge technology to deliver superior quality components that meet the most demanding specifications.

Comprehensive Manufacturing Solutions

As a full-service metal fabrication partner, MAIKONG provides end-to-end solutions from initial design consultation through production and finishing. Our integrated services include Brass Extrusion, CNC machining, heat treatment, surface finishing, and comprehensive quality testing, eliminating the need for multiple suppliers.

Exceptional Quality and Reliability

Quality is at the core of everything we do at MAIKONG. Our rigorous quality management systems and comprehensive testing procedures ensure that every Brass Extrusion component meets or exceeds the highest standards. This commitment to excellence has earned us the trust of clients across diverse industries throughout the United States.

Competitive Pricing and Fast Turnaround

MAIKONG combines advanced manufacturing capabilities with efficient operations to offer highly competitive pricing without compromising on quality. Our streamlined processes and substantial production capacity enable us to deliver Brass Extrusion components with industry-leading turnaround times, helping you meet your project deadlines.

At MAIKONG, we don’t just supply Brass Extrusion components; we provide comprehensive manufacturing solutions that add value to your business. Our commitment to quality, innovation, and customer satisfaction makes us the ideal partner for US companies seeking reliable, high-performance brass components.

Partner with MAIKONG for Advanced Brass Extrusion Solutions

The future of Brass Extrusion is bright, with continuous innovations driving improvements in quality, efficiency, and application versatility. As a leader in precision metal manufacturing, MAIKONG is at the forefront of these advancements, delivering cutting-edge solutions to meet the evolving needs of US industries.

Whether you’re seeking standard brass profiles or custom components for specialized applications, MAIKONG has the expertise, capabilities, and commitment to quality to exceed your expectations. Our comprehensive services, competitive pricing, and dedication to customer satisfaction make us the ideal partner for all your Brass Extrusion and metal fabrication needs.

MAIKONG’s complete Brass Extrusion manufacturing process

Ready to Elevate Your Products with Premium Brass Extrusion Components?

Contact MAIKONG today to discuss your requirements and discover how our expertise can benefit your business.

Email: Lucy@maikongforge.us | Website: https://maikongforge.us

State-of-the-art Brass Extrusion process at MAIKONG’s manufacturing facility

State-of-the-art Brass Extrusion process at MAIKONG’s manufacturing facility