The brass extrusion process transforms raw brass alloys into precisely shaped profiles with consistent cross-sections and superior mechanical properties. This comprehensive guide explores every aspect of brass extrusion, from material selection to finishing operations. Whether you’re designing components for plumbing systems, electrical applications, or architectural elements, understanding this versatile manufacturing method will help you make informed decisions for your next project.

What Is Brass Extrusion and Why Is It Important?

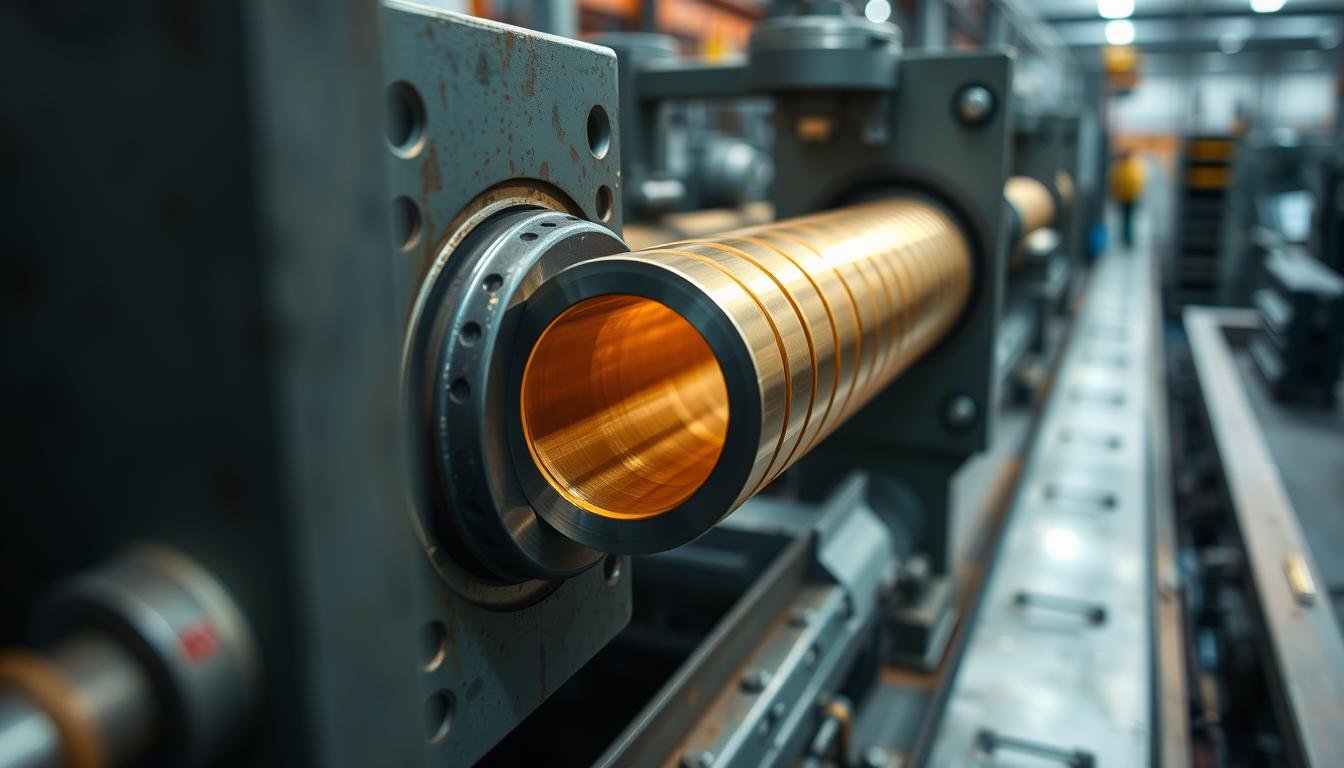

The brass extrusion process creates uniform cross-sections with excellent mechanical properties

Brass extrusion is a metal forming process where brass alloy is heated and forced through a die to create products with a specific cross-sectional profile. This manufacturing technique produces components with consistent dimensions, excellent surface finish, and enhanced mechanical properties. At MAIKONG, we’ve perfected this process to deliver superior quality extruded brass products with competitive pricing.

The versatility of brass extrusion makes it ideal for creating a wide range of products, from simple rods and tubes to complex architectural profiles. The process aligns the metal’s grain structure, resulting in stronger components compared to casting methods. This makes extruded brass particularly valuable in applications requiring both strength and precise dimensions.

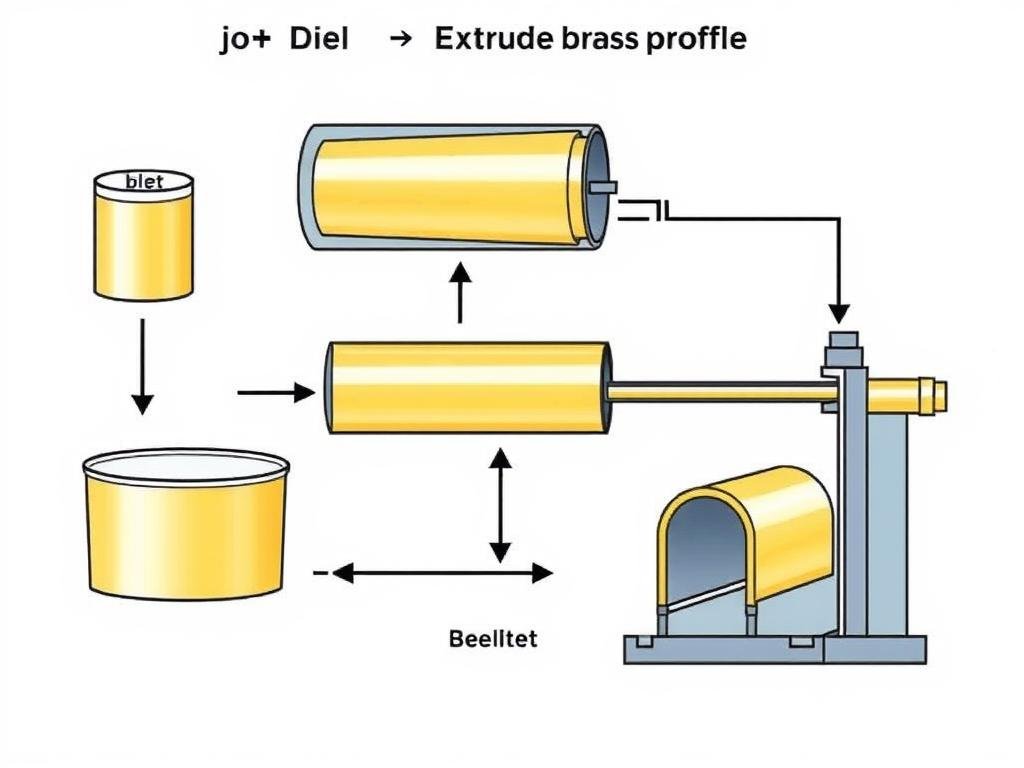

The Fundamental Principles of Brass Extrusion

At its core, brass extrusion relies on brass’s plasticity when heated. The process begins with a brass billet (a solid cylindrical block) that is heated to its recrystallization temperature—hot enough to become malleable but not molten. This heated billet is then forced through a shaped die using hydraulic pressure, creating a continuous length of material with a uniform cross-section.

The brass extrusion process can be performed at various temperatures, depending on the specific brass alloy and desired properties of the final product. MAIKONG utilizes both hot and cold extrusion techniques to achieve optimal results for different applications.

Advantages and Limitations of Extruded Brass

Key Benefits of Brass Extrusion

- Efficient mass production with short cycle times

- Ability to create products with complex cross-sectional profiles

- Superior corrosion resistance compared to cast products

- Enhanced mechanical properties due to grain alignment

- High dimensional accuracy for precision applications

- Excellent machinability for secondary operations

- Smooth surface finish requiring minimal post-processing

Limitations to Consider

- Higher initial setup costs for tooling and equipment

- Requires significant force to squeeze material through dies

- Not economically viable for very small production runs

- Cross-section remains uniform throughout the entire length

- Some complex shapes may require additional machining

- Limited to materials with suitable plasticity characteristics

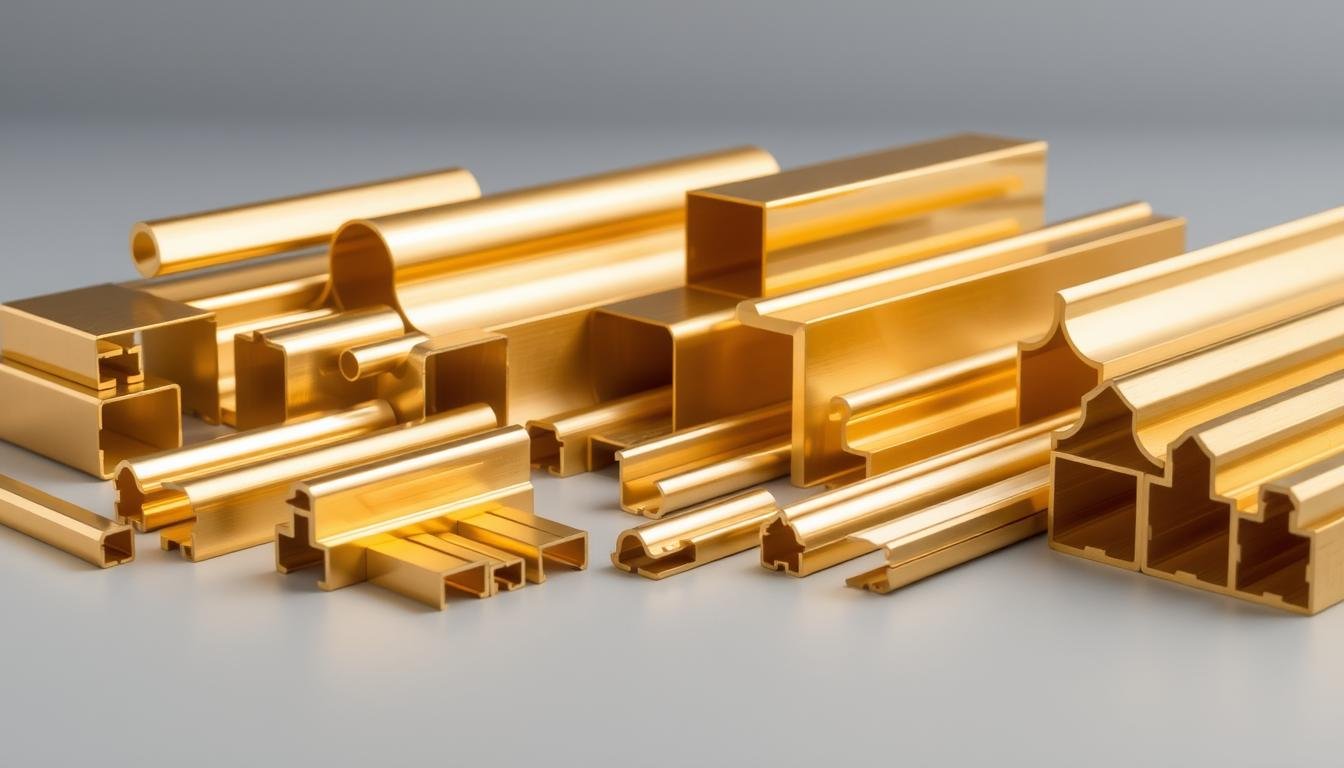

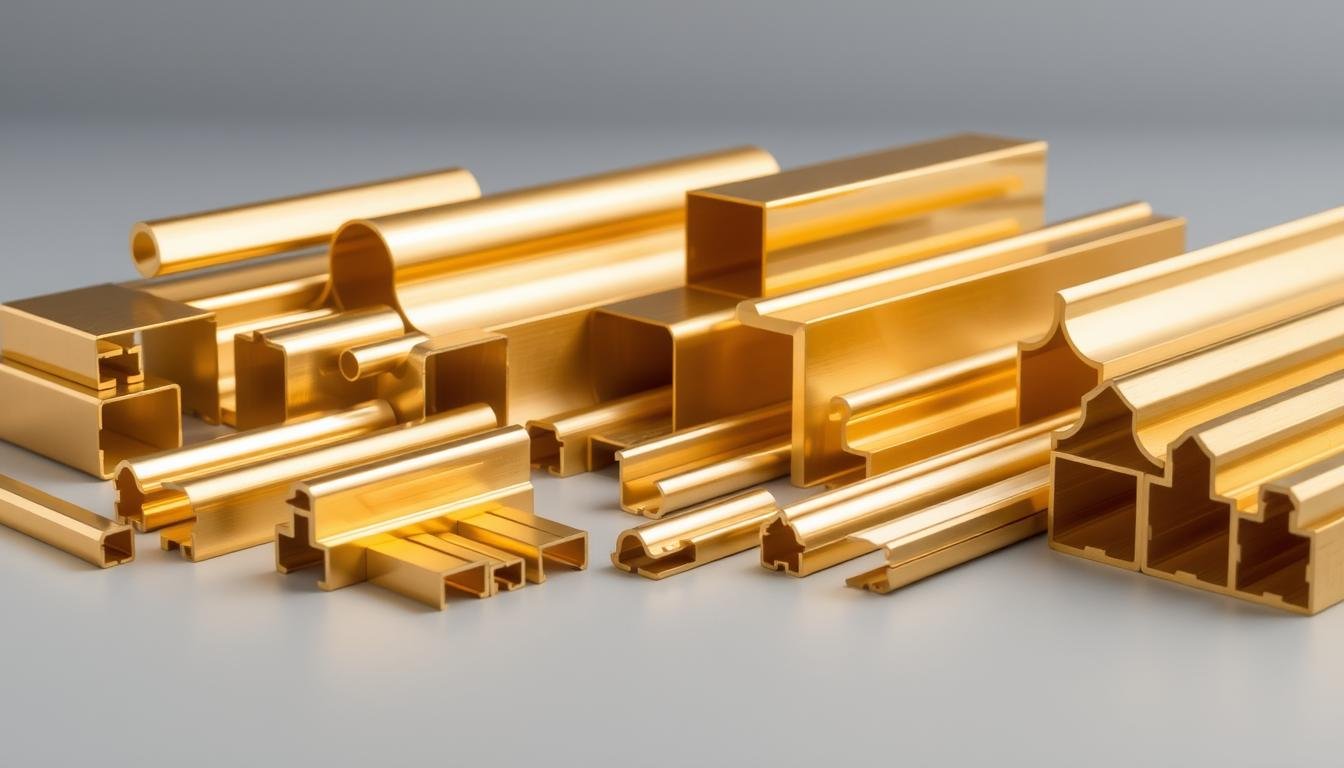

MAIKONG produces a wide variety of brass extrusion profiles for diverse applications

Types of Brass Extrusion Processes

The brass extrusion process can be categorized into several distinct methods, each with specific advantages for different applications. At MAIKONG, we utilize multiple extrusion techniques to deliver the optimal solution for each client’s requirements.

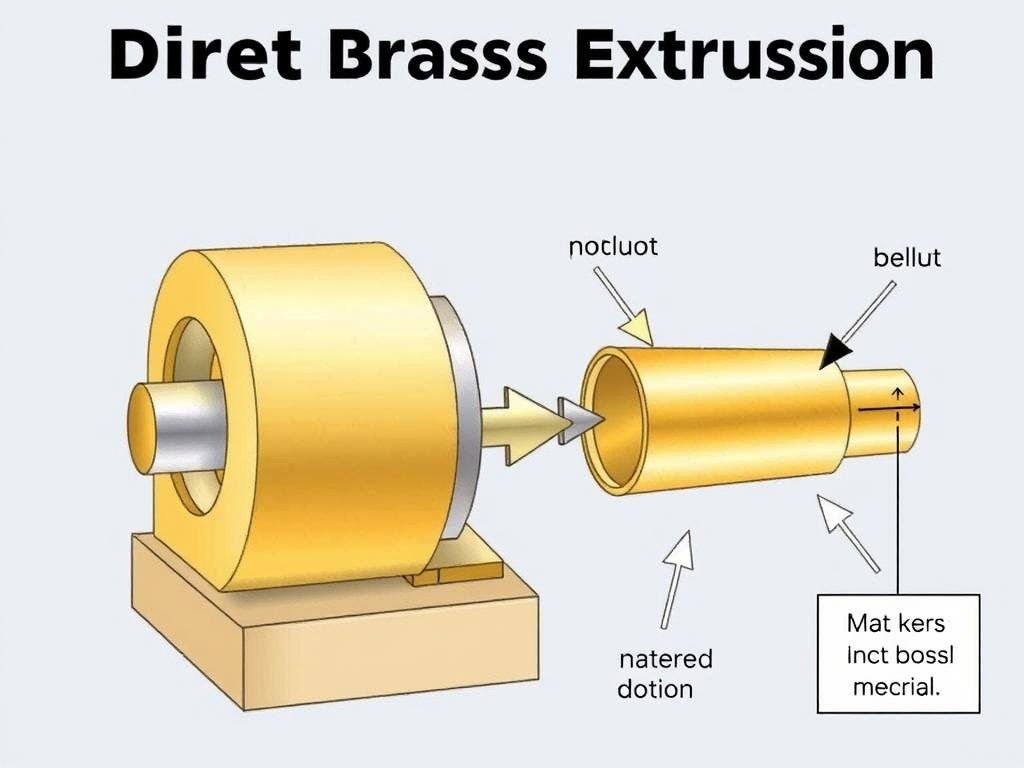

Direct Extrusion of Brass

Also known as forward extrusion, this method involves the billet, ram, and punch moving in the same direction. The brass billet slides against the container wall, creating friction that increases as the process continues. Direct extrusion is our most commonly used method at MAIKONG due to its efficiency and versatility.

Advantages

- Simple and efficient process

- Lower cost per component

- Suitable for high-volume production

- Excellent for simple shapes

- Can produce longer brass components

- Superior surface finish

Limitations

- Requires higher extrusion pressures

- Needs dummy blocks with smaller diameters

- Lubricants necessary to reduce friction

Indirect Extrusion of Brass

Also called backward extrusion, this process features the punch and billet moving in opposite directions. Since there’s no relative motion between the container and billet, friction is significantly reduced. MAIKONG employs indirect extrusion for applications requiring lower force and specialized profiles.

Advantages

- Requires less force than direct extrusion

- Produces minimal friction

- Suitable for large production operations

- Container experiences less wear

Limitations

- Not suitable for long extrusions

- Cross-section limited by stem size

- More complex equipment required

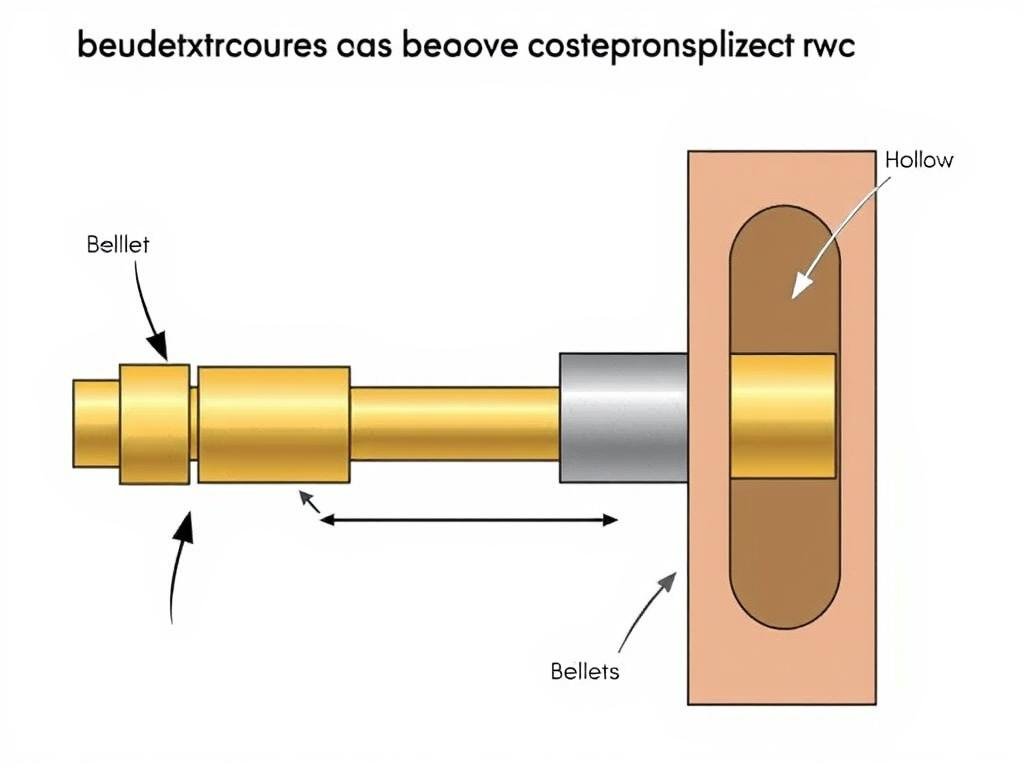

Impact Brass Extrusion

This specialized method is particularly effective for creating hollow brass items like cups and containers. MAIKONG utilizes impact extrusion for clients requiring thin-walled components with consistent wall thickness.

Advantages

- Ideal for thin-walled brass tubes

- Simple process with minimal steps

- Relatively low tooling costs

- Good dimensional control

Limitations

- Limited to specific product types

- Not suitable for complex profiles

Hydrostatic Brass Extrusion

In this advanced method, a fluid medium transmits pressure to the brass billet. Since the billet doesn’t contact the container wall, friction is virtually eliminated. MAIKONG employs hydrostatic extrusion for specialized applications requiring exceptional precision.

Advantages

- Zero friction between billet and container

- Ideal for brittle materials

- Can operate at room temperature

- Produces excellent surface finish

Limitations

- More complex equipment required

- Higher operational costs

- Limited production speed

Surface Finishes for Extruded Brass Products

The appearance and functionality of brass extrusion products can be significantly enhanced through various surface finishing techniques. At MAIKONG, we offer comprehensive finishing services to meet diverse aesthetic and performance requirements.

MAIKONG offers multiple surface finish options for extruded brass components

Anodizing Brass Parts

This electrochemical process creates a protective oxide layer on the brass surface. By passing an electrical current through an electrolyte bath, we create a durable finish that enhances corrosion resistance while allowing for decorative coloring options.

Polishing Brass Parts

Our precision polishing processes smooth and shine the surface of extruded brass components. This enhances aesthetic appeal while potentially improving performance by reducing surface friction and creating a more hygienic surface.

Electroplating Brass Parts

MAIKONG’s electroplating services deposit a thin layer of metal onto brass extrusions. This process can enhance corrosion resistance, improve wear characteristics, and create distinctive aesthetic finishes including chrome, nickel, or gold appearances.

Powder Coating Brass Parts

For applications requiring exceptional durability and aesthetic versatility, MAIKONG offers powder coating services. This process applies a fine powder to the brass surface, which is then heated to create a fused protective layer. Powder coating provides excellent corrosion resistance, impact protection, and virtually unlimited color options.

Custom Surface Finishing Solutions

MAIKONG provides comprehensive surface finishing services tailored to your specific requirements. Our engineering team can recommend the optimal finish for your application based on environmental exposure, aesthetic requirements, and performance specifications.

Request Surface Finish Consultation

Best Brass Grades for Extrusion

Selecting the appropriate brass alloy is crucial for successful extrusion. Different alloys offer varying combinations of extrudability, strength, corrosion resistance, and machinability. At MAIKONG, we work with a wide range of brass alloys to ensure optimal performance for each application.

MAIKONG utilizes various brass alloys optimized for different extrusion applications

Commonly Extruded Brass Alloys

| Alloy Designation |

Common Name |

Composition |

Key Properties |

Typical Applications |

| C26000 |

Cartridge Brass |

70% Cu, 30% Zn |

Excellent cold workability, good strength |

Ammunition casings, hardware, fasteners |

| C27000 |

Yellow Brass |

65% Cu, 35% Zn |

Good formability, moderate strength |

Plumbing components, decorative hardware |

| C35300 |

Low-Lead Brass |

62% Cu, 37% Zn, 0.3% Pb |

Good machinability, corrosion resistance |

Potable water applications, valves |

| C38000 |

Architectural Bronze |

57% Cu, 40% Zn, 3% Pb |

Excellent machinability, good strength |

Architectural components, decorative elements |

| C48200 |

Naval Brass |

60% Cu, 39% Zn, 1% Sn |

Superior corrosion resistance, especially in seawater |

Marine hardware, propeller shafts |

At MAIKONG, our metallurgical expertise ensures we select the optimal brass alloy for your specific application requirements. We consider factors including mechanical properties, corrosion resistance, cost-effectiveness, and regulatory compliance when recommending materials for your project.

Applications of Extruded Brass Parts

The versatility, durability, and aesthetic appeal of extruded brass make it an ideal material for countless applications across diverse industries. MAIKONG produces precision brass extrusions for clients worldwide, serving sectors from construction to electronics.

MAIKONG’s extruded brass components serve diverse industries with precision and reliability

Brass Profile Extrusions

From simple shapes like rods, tubes, and flat bars to complex profiles for specialized applications, MAIKONG produces precision brass profiles for electrical components, plumbing fixtures, automotive parts, and more. Our advanced extrusion capabilities ensure consistent dimensions and superior surface finish.

Extruded Brass Channels

Our U-shaped and C-shaped brass channels provide structural support, guides, and barriers for construction and architectural applications. MAIKONG’s extruded brass channels are widely used in window and door frames, curtain walls, and other architectural elements requiring both strength and aesthetic appeal.

Architectural Brass Extrusions

MAIKONG creates decorative and functional architectural elements including handrails, door handles, trim pieces, and decorative moldings. Our architectural brass extrusions combine durability, corrosion resistance, and timeless aesthetic appeal for both contemporary and traditional designs.

Extruded Electrical Parts

Leveraging brass’s excellent electrical conductivity, MAIKONG produces precision electrical components including connectors, terminals, and busbars. Our extruded electrical parts offer reliable performance in power distribution systems, telecommunications equipment, and consumer electronics.

Extruded Plumbing Components

MAIKONG’s brass plumbing components include fittings, valves, and pipe sections that meet international standards for potable water applications. Our precision extrusion process ensures leak-free performance and long service life in residential and commercial plumbing systems.

Extruded Automotive Parts

The automotive industry relies on MAIKONG’s precision brass extrusions for components including radiator cores, transmission parts, and fluid system components. Our automotive brass extrusions offer excellent thermal conductivity, corrosion resistance, and machinability for critical vehicle systems.

Custom Brass Extrusion Solutions

MAIKONG specializes in custom brass extrusions tailored to your specific application requirements. Our engineering team works closely with clients to develop optimal solutions for even the most challenging applications.

Explore Custom Extrusion Options

Factors Determining Quality of Custom Brass Extrusion

Producing high-quality brass extrusions requires careful control of multiple variables throughout the manufacturing process. At MAIKONG, we maintain rigorous quality control protocols to ensure consistent excellence in every component we produce.

MAIKONG’s quality control process ensures dimensional accuracy and surface quality

Critical Quality Factors in Brass Extrusion

Material Quality

The quality of the brass alloy is fundamental to successful extrusion. At MAIKONG, we source only premium-grade materials with verified composition and mechanical properties. Our brass must have appropriate ductility to flow through the die and form the desired shape, with crystals that glide smoothly against each other during the extrusion process.

Temperature Control

Precise temperature management is essential for optimal extrusion results. MAIKONG’s advanced heating systems ensure brass billets reach the ideal temperature to increase ductility and facilitate grain movement. This precise temperature control allows us to achieve stable extrusion with minimal force while maintaining material integrity.

Extrusion Speed

The rate at which brass flows through the die significantly impacts product quality. MAIKONG’s extrusion specialists carefully balance speed and temperature to maintain process stability. Our precision control systems ensure optimal surface finish, grain size, and grain direction in the finished extrusion.

Advanced Quality Control Measures

Pressure Management

Controlling extrusion pressure is critical for consistent results. MAIKONG’s hydraulic systems apply precisely calculated force to press the brass through the die profile. By heating the brass to its recrystallization temperature, we minimize the required force while ensuring complete die filling and dimensional accuracy.

Die Design and Maintenance

The extrusion die is perhaps the most critical component in determining product quality. MAIKONG’s tooling specialists design and maintain precision dies that account for material flow characteristics and cooling-related dimensional changes. Regular inspection and maintenance ensure consistent performance throughout production runs.

Cooling Process

Controlled cooling after extrusion is essential for dimensional stability and desired mechanical properties. MAIKONG employs specialized cooling systems that prevent distortion while achieving the optimal microstructure in the finished product. This careful cooling management ensures consistent quality across production batches.

MAIKONG’s comprehensive quality testing ensures every extrusion meets rigorous standards

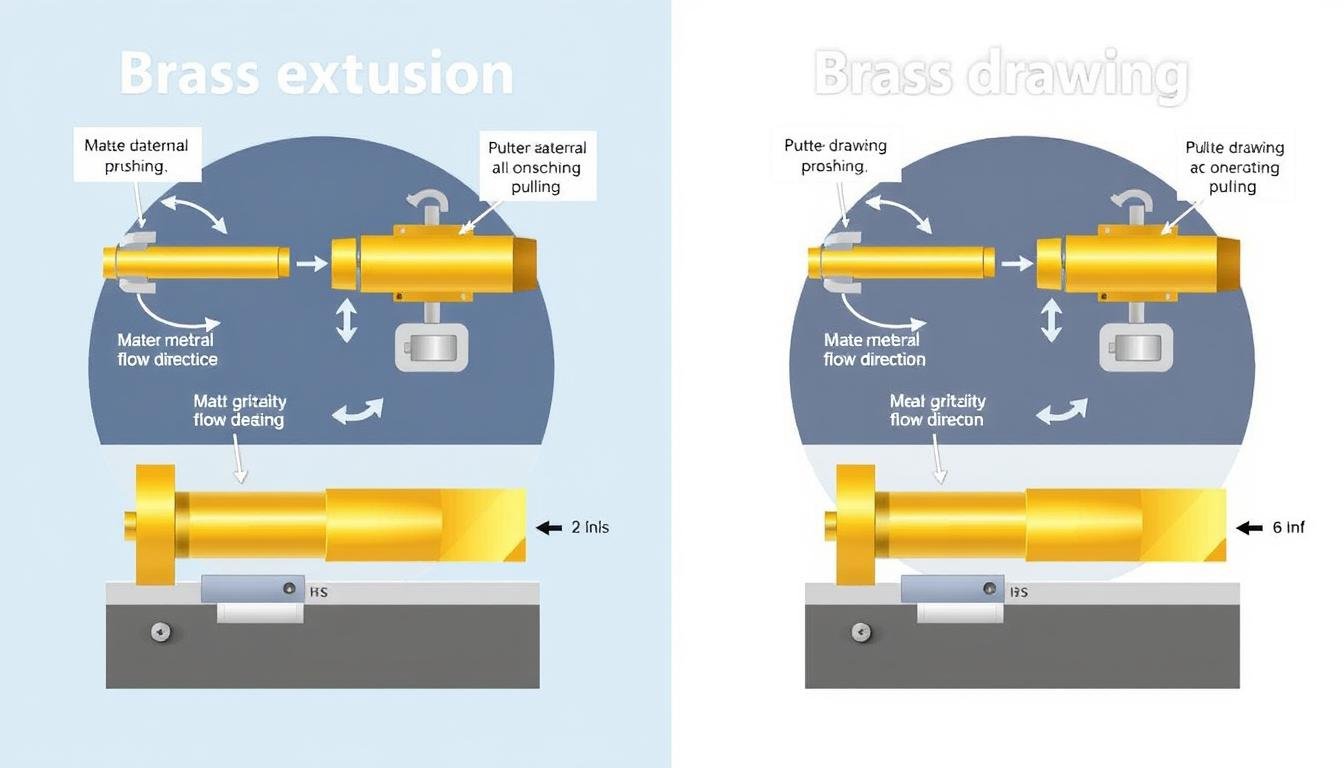

How Brass Extrusion Compares to Brass Drawing

While both extrusion and drawing are important manufacturing processes for brass components, they differ significantly in methodology, capabilities, and applications. Understanding these differences helps in selecting the optimal process for specific requirements.

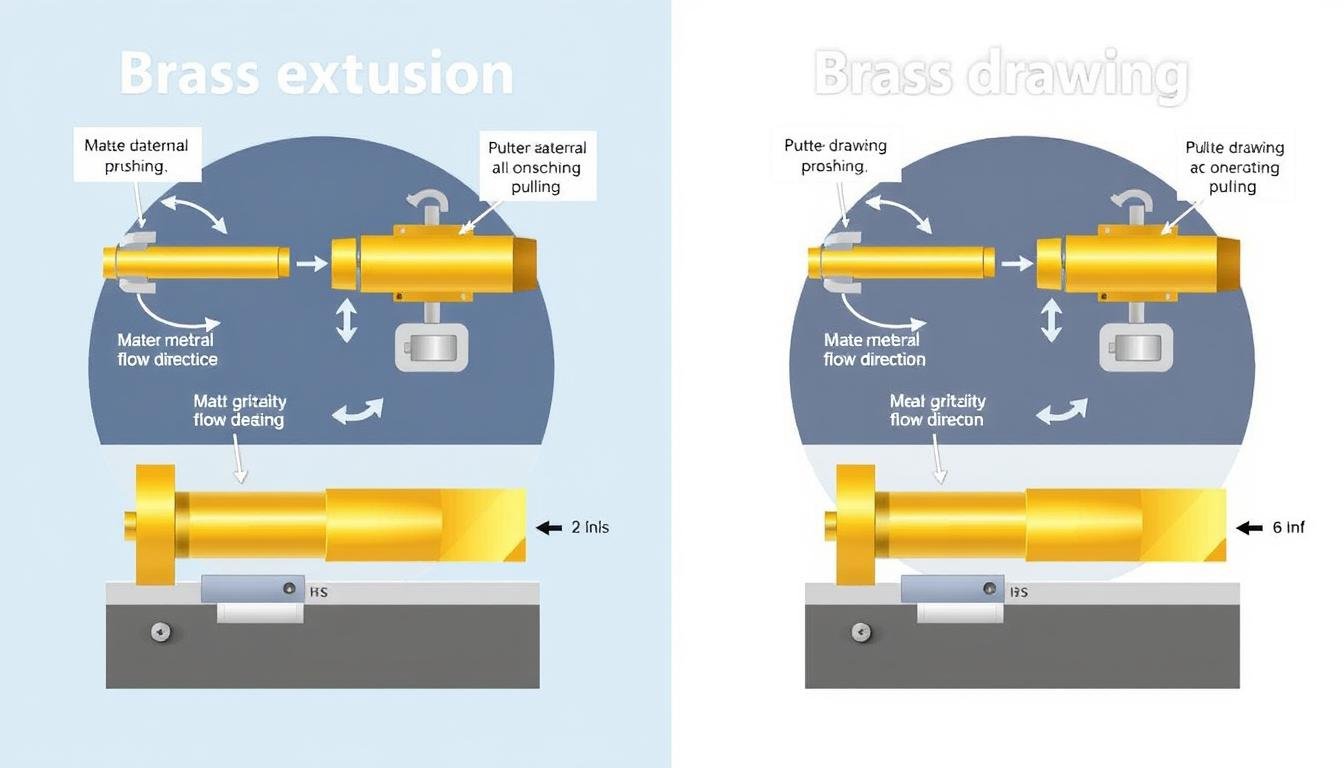

Brass extrusion (pushing) vs. brass drawing (pulling) – fundamental process differences

| Characteristic |

Brass Extrusion |

Brass Drawing |

| Process Mechanics |

Pushes brass through dies to produce shapes |

Pulls brass through dies to produce shapes |

| Cross-section Uniformity |

Produces brass products with highly uniform cross-sections |

May have varying cross-sectional areas along length |

| Production Speed |

Faster production rates |

Generally slower process |

| Production Cost |

More economical for high-volume production |

Higher cost per unit in most applications |

| Operating Speed |

Typically operates at higher speeds |

Operates at slower speeds |

| Force Requirements |

Requires less force for equivalent profiles |

Requires more tensile force |

| Surface Finish |

Excellent surface finish with proper die design |

Can achieve very smooth surfaces with multiple draws |

| Complexity Capability |

Ideal for complex cross-sections |

Better for simpler profiles with tight tolerances |

At MAIKONG, we offer both extrusion and drawing capabilities, allowing us to recommend and implement the optimal process for each client’s specific requirements. Our engineering team evaluates factors including production volume, dimensional requirements, surface finish specifications, and cost considerations when determining the most appropriate manufacturing approach.

Recommended Tolerances in Extruded Brass Parts

Achieving precise dimensional control is critical for functional brass components. MAIKONG maintains rigorous tolerance standards that meet or exceed industry requirements across diverse applications.

MAIKONG’s quality control ensures tight tolerances for all brass extrusions

Tolerance in brass extrusion refers to the acceptable variation in dimensions and shape. While standard tolerances for extruded brass typically range from ±0.120″ to ±0.120 mm, MAIKONG can achieve tighter tolerances for applications requiring exceptional precision. The specific tolerance requirements depend on the application, with more precise components requiring stricter controls.

Factors Affecting Tolerance Levels

- Billet Temperature – Consistent heating ensures uniform material flow and dimensional stability

- Extrusion Speed – Carefully controlled rates prevent distortion and ensure consistent dimensions

- Press Capacity – Appropriate press size and force distribution for the specific application

- Cooling Time – Controlled cooling prevents warping and ensures dimensional stability

- Die Design – Precision-engineered dies account for material flow characteristics

- Material Properties – Different brass alloys exhibit varying flow and shrinkage characteristics

MAIKONG’s advanced extrusion equipment and rigorous quality control processes ensure consistent adherence to specified tolerances. Our comprehensive inspection protocols include both in-process monitoring and final verification using precision measurement equipment.

Precision Brass Extrusions for Critical Applications

MAIKONG specializes in high-precision brass extrusions for applications with demanding tolerance requirements. Our engineering team can work with you to determine the optimal tolerance specifications for your specific application.

Contact Our Engineering Team

MAIKONG’s Comprehensive Brass Manufacturing Capabilities

As a leading manufacturer of precision metal components, MAIKONG offers end-to-end solutions for brass extrusion projects. Our integrated manufacturing approach ensures quality control at every stage of production.

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

Advanced CAD/CAM Design

Our engineering team utilizes sophisticated computer-aided design and manufacturing systems to develop optimal extrusion profiles. This technology allows us to identify potential issues early in the design process, saving time and resources while ensuring superior results.

Material Selection Expertise

MAIKONG’s metallurgists provide expert guidance on brass alloy selection, considering mechanical properties, machinability, heat treatment characteristics, and cost-effectiveness for each application. This ensures the optimal material for your specific requirements.

Precision Tooling Design

Our tooling specialists design and maintain extrusion dies that ensure initial quality and long-term consistency. Regular maintenance preserves die performance throughout production runs, delivering consistent quality across large orders.

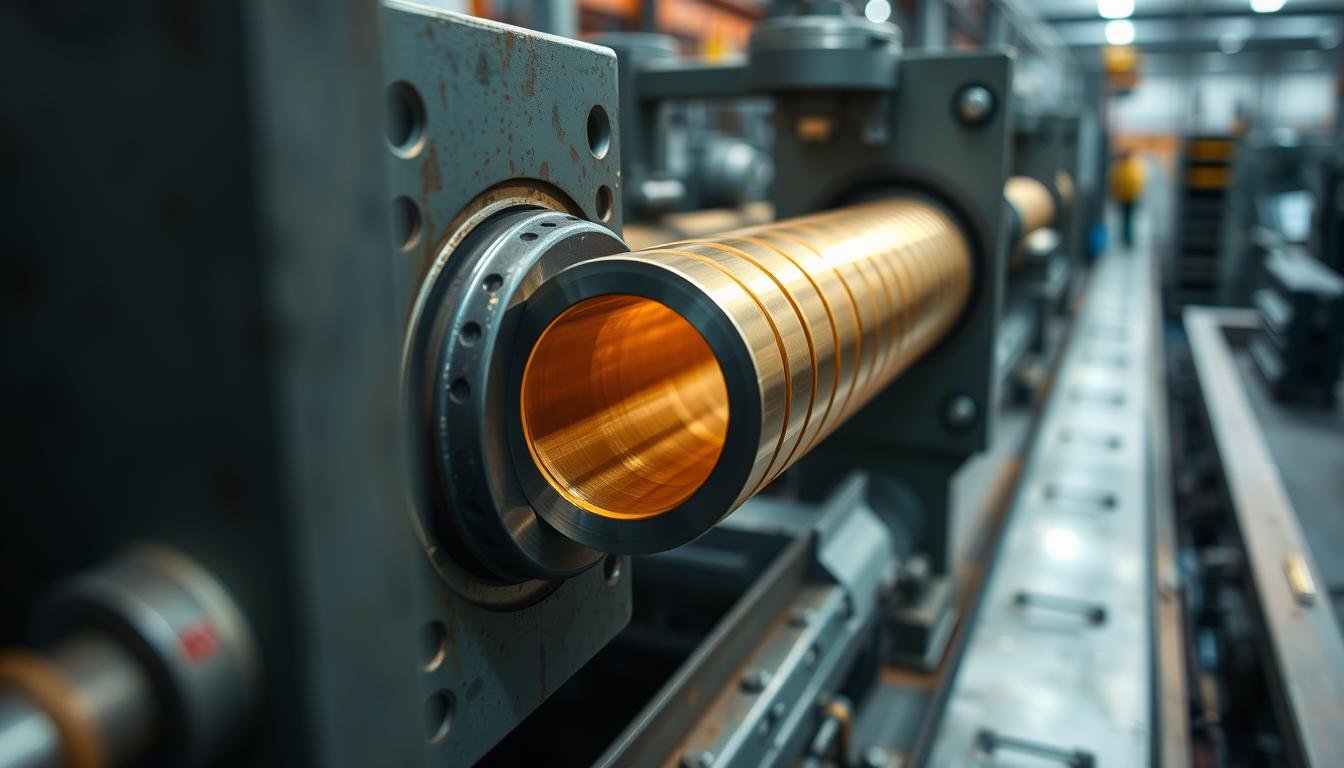

Advanced Extrusion Equipment

MAIKONG’s extrusion workshop features state-of-the-art hydraulic presses capable of handling diverse brass extrusion specifications. Our equipment combines power, precision, and efficiency to deliver superior results across a wide range of profile configurations.

Precision CNC Machining

For secondary operations, our CNC machining centers perform precise drilling, threading, and feature machining on extruded brass components. This integrated capability ensures dimensional accuracy and feature alignment for complex components.

Comprehensive Quality Control

MAIKONG’s quality assurance protocols include material verification, in-process monitoring, and final inspection using advanced measurement equipment. This multi-stage approach ensures every component meets or exceeds specified requirements.

Partner with MAIKONG for Your Brass Extrusion Projects

Experience the MAIKONG difference with our comprehensive brass manufacturing capabilities. We deliver precision components with competitive pricing and exceptional service.

Email: Lucy@maikongforge.us

Visit Our Website

Conclusion: Partnering with MAIKONG for Superior Brass Extrusions

The brass extrusion process offers remarkable versatility, efficiency, and value for producing precision components across diverse industries. From architectural elements to electrical components, extruded brass provides an optimal combination of mechanical properties, corrosion resistance, and aesthetic appeal.

MAIKONG brings decades of manufacturing expertise to every brass extrusion project. Our comprehensive capabilities—from material selection through final inspection—ensure consistent quality, competitive pricing, and reliable delivery. Whether you need standard profiles or custom extrusions for specialized applications, our engineering and production teams deliver solutions that meet your exact specifications.

MAIKONG delivers precision brass extrusions for applications worldwide

As a trusted partner to clients worldwide, MAIKONG combines technical excellence with responsive customer service. We’re currently expanding our presence in the United States and actively recruiting agents to represent our high-quality, competitively priced metal manufacturing services.